Method for direct liquefaction and comprehensive utilization of ravens

A low-quality coal and direct technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, inorganic chemistry, etc., can solve problems such as high energy consumption, low efficiency, cumbersome process, etc., to reduce equipment requirements and energy consumption, The effect of improving resource utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

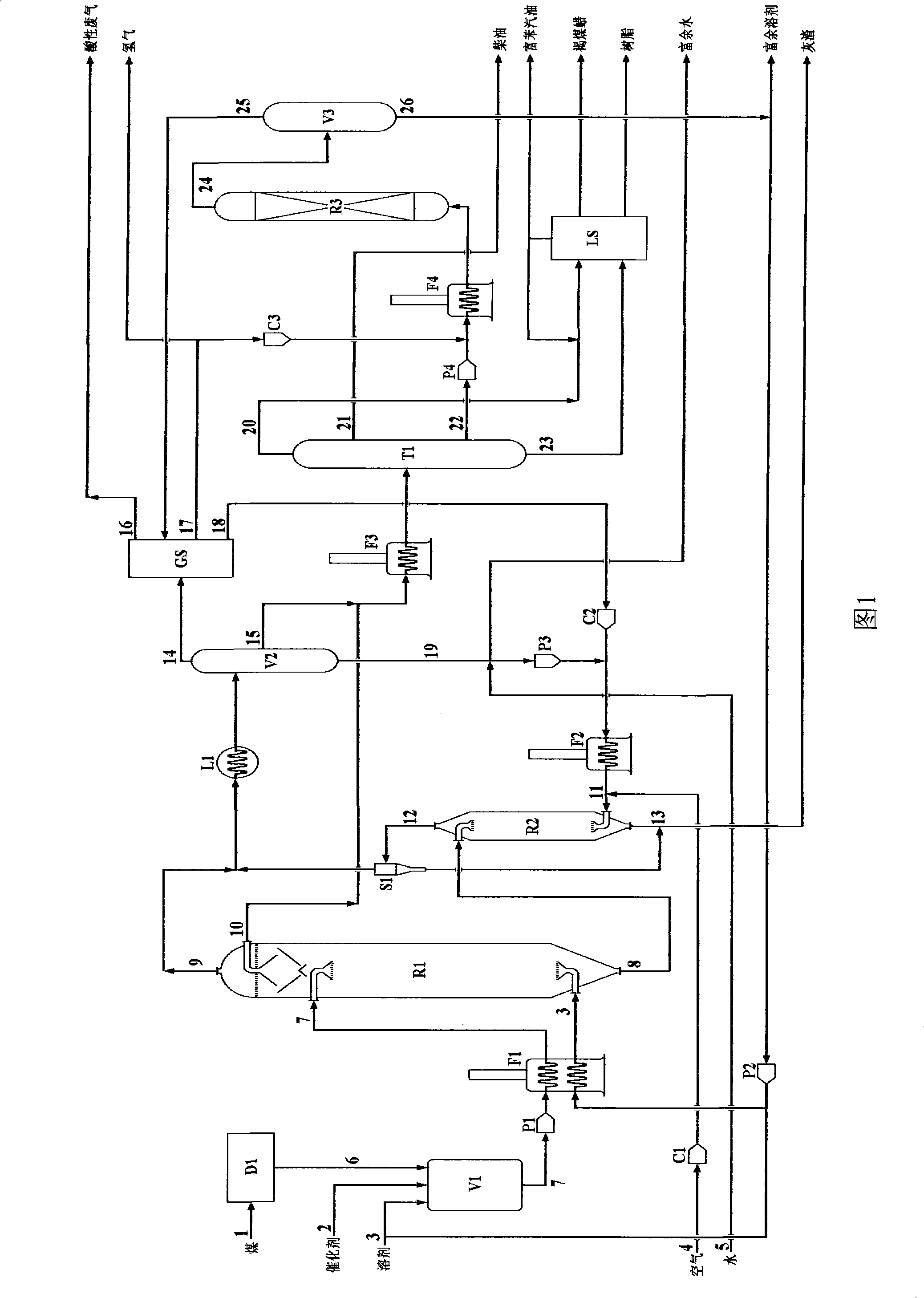

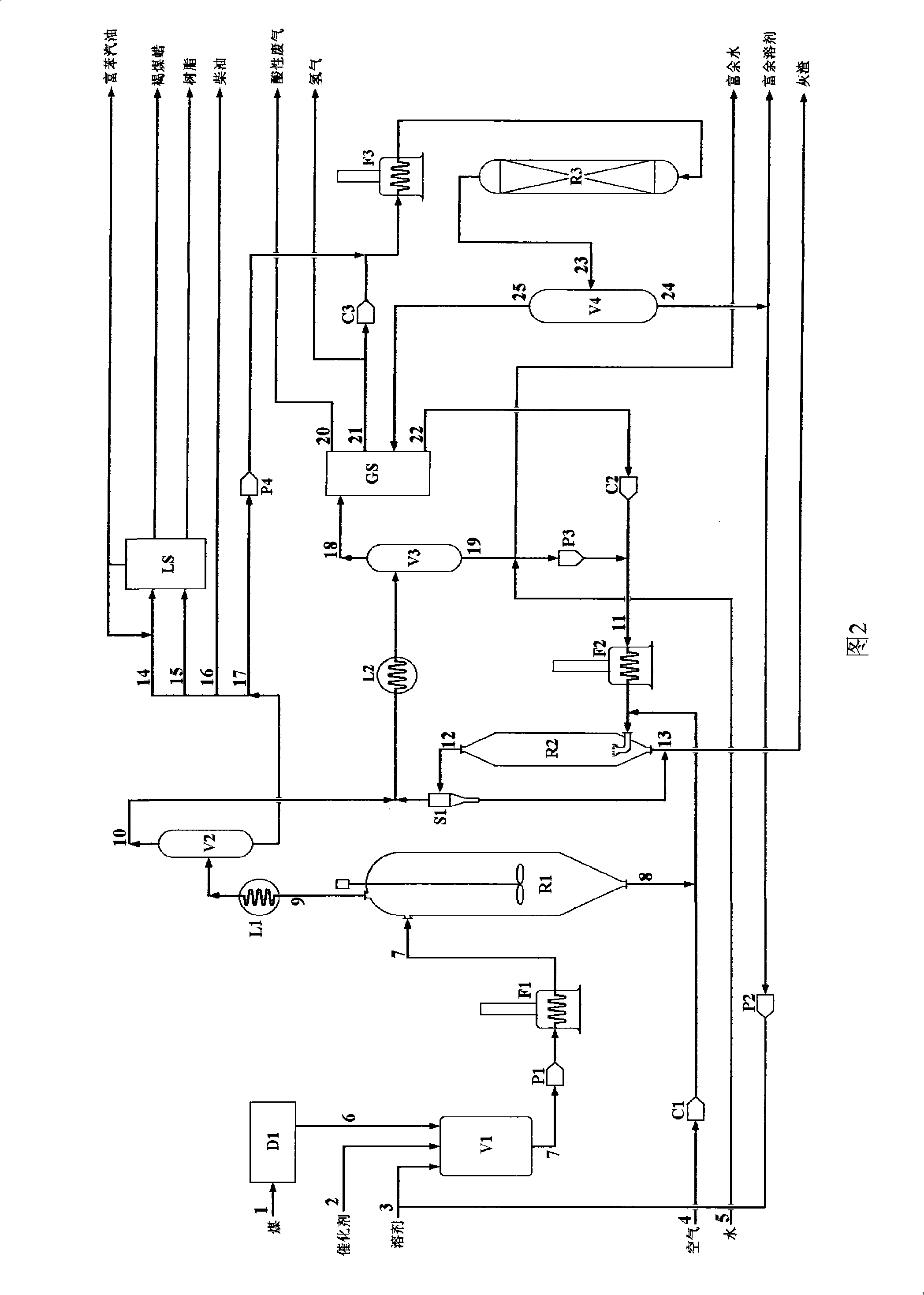

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Ammonium molybdate 7w%, nickel nitrate 10w%, ferrous sulfate 15w%, iron sulfate 8w%, polysorbate 4w%, polysorbate monooleate 6w%, alkyl polyglycoside 3w% , and the rest is distilled water.

Embodiment 2

[0059] Example 2: dimer acid urea complexed lanthanum 5w%, ethylenediaminetetraacetic acid complexed iron 12w%, isooctanoic acid urea complexed tungsten 15w%, isocaprylic acid urea complexed molybdenum 3w%, polysorbate 5w% , 5w% of shrinkable sorbitan monooleate, 4w% of polyoxyethylene sorbitan oleate, and the rest are petroleum distillates at 280-320°C.

Embodiment 3

[0060] Example 3: 10w% ammonium tungstate, 10w% cobalt nitrate, 15w% iron nitrate, 8w% iron sulfate, 5w% polysorbate, 6w% polysorbate monooleate, polyoxypropylene polyoxyethylene glycerin Ether 4w%, glycerin 10w%, and the rest is distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com