Method for extracting lignin from wood fiber cell walls

A technology of lignocellulose and lignin, which is applied in the fields of biomass basic chemistry and renewable resource utilization, can solve the problems of low yield, lignin quality loss, complicated process operation, etc., and achieves low boiling point, improved efficiency, and operational safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

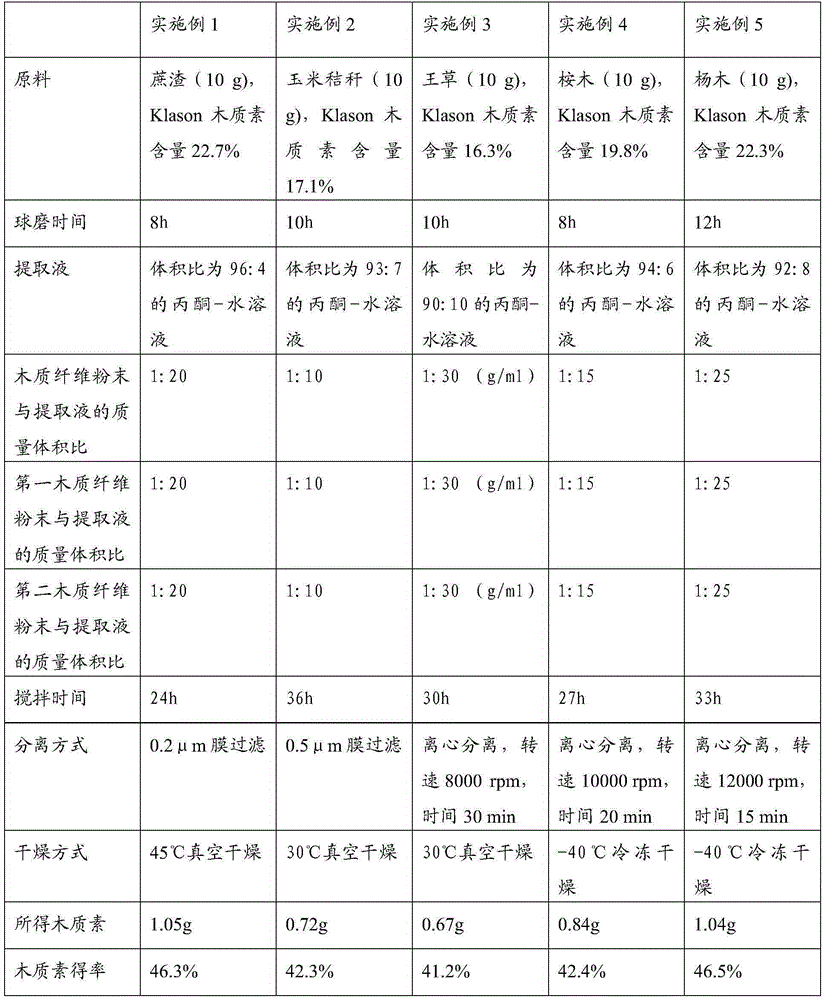

[0036] The present invention will be further described in detail below in conjunction with the examples.

[0037] Get the air-dried lignocellulosic raw material in Table 1, pulverize, and get the lignocellulosic powder that has passed through a 40-mesh sieve.

[0038] The lignocellulosic powder is extracted with a benzene-ethanol solution with a volume ratio of 2:1, and the extract is dissolved in the benzene-ethanol solution. After the extraction is completed, the benzene-ethanol solution and the extract dissolved therein are discarded. A lignocellulosic powder without extractables is obtained.

[0039]Use a ball mill to mill the obtained wood fiber powder without extractables, and the milling time is shown in Table 1. Then, 10 g of lignocellulosic powder was dispersed in the extracting solution shown in Table 1 to obtain a suspension of lignocellulosic powder. The mass-volume ratio of lignocellulosic powder and extract is shown in Table 1.

[0040] Stir in a closed contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com