Patents

Literature

145results about How to "Does not change the structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Teaching system and teaching method of keyboard type musical instrument

The invention provides a teaching system and a teaching method of a keyboard type musical instrument. The teaching system is characterized by comprising an information collection unit, a signal processing unit and an information output unit; the teaching system has various working modes, and the various working modes comprise an optimal fingering prompting mode, a fingering correcting mode, an evaluating mode and a teaching mode; and the various working modes can be selected by a user and have the functions of fingering prompting, fingering correcting, evaluating, demonstrating and teaching. The teaching system provided by the invention is widely applied to various keyboard type musical instruments comprising a piano, an electronic organ, an accordion, a pipe organ and the like; and the teaching system has a strong teaching function, the using method is simple and flexible, and the teaching system has a very extensive application prospect.

Owner:ZHEJIANG UNIV

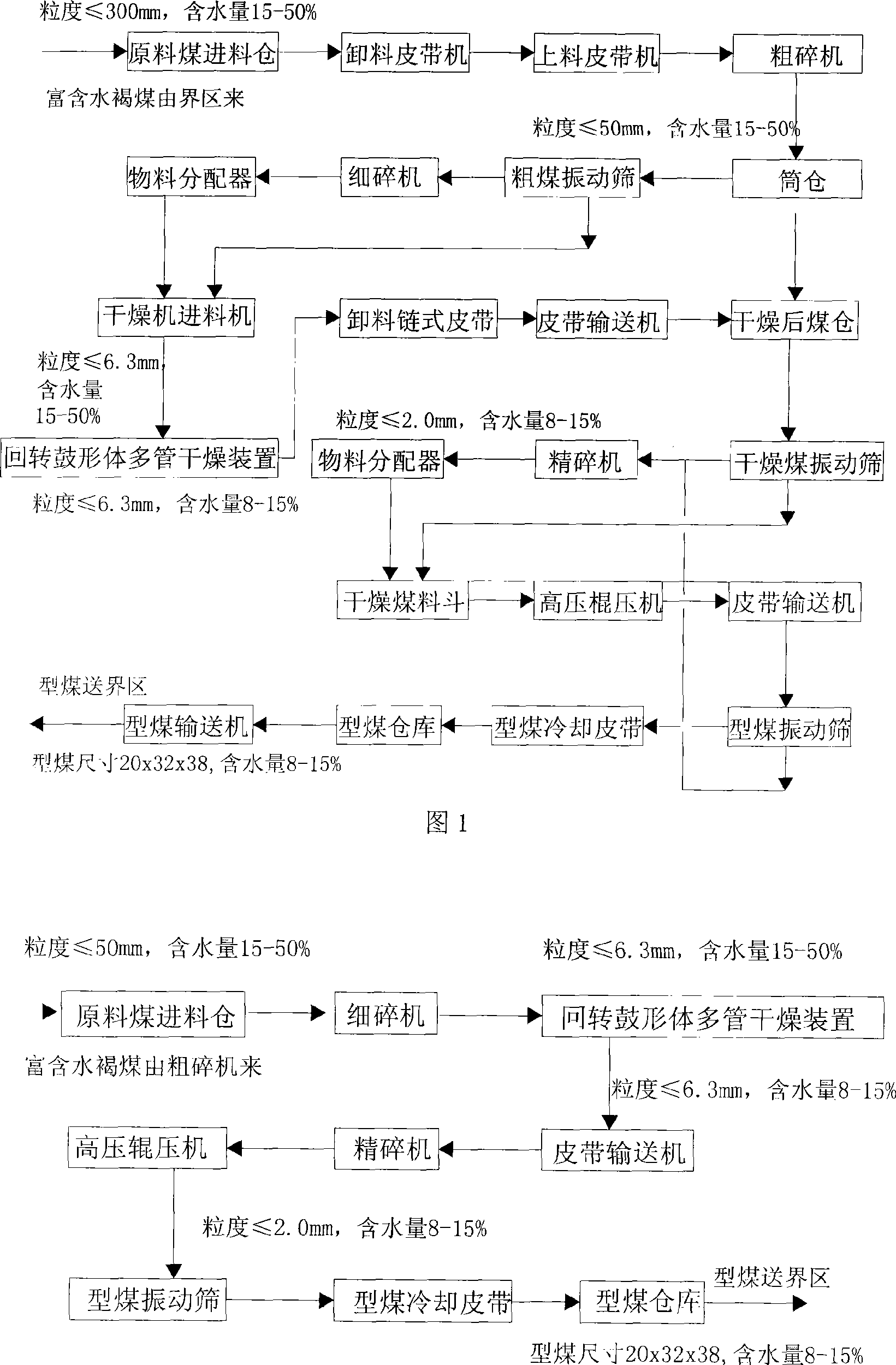

Process for dryness, formation and further processing of water-enriched lignite

ActiveCN101519614AIncrease contact areaImprove heat transfer coefficientSolid fuelsMaterial transferHot press

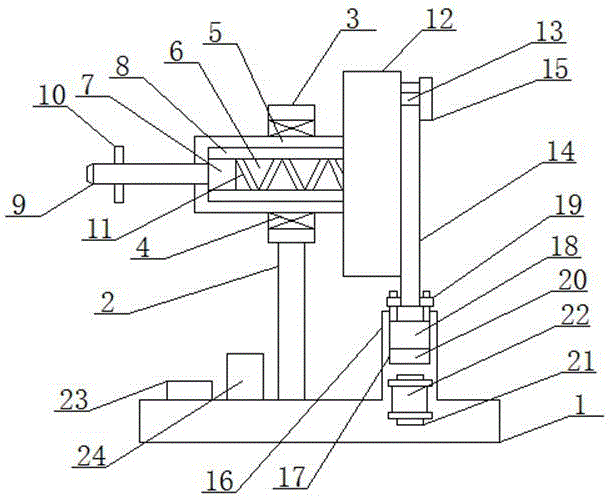

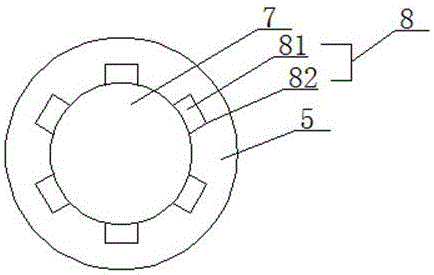

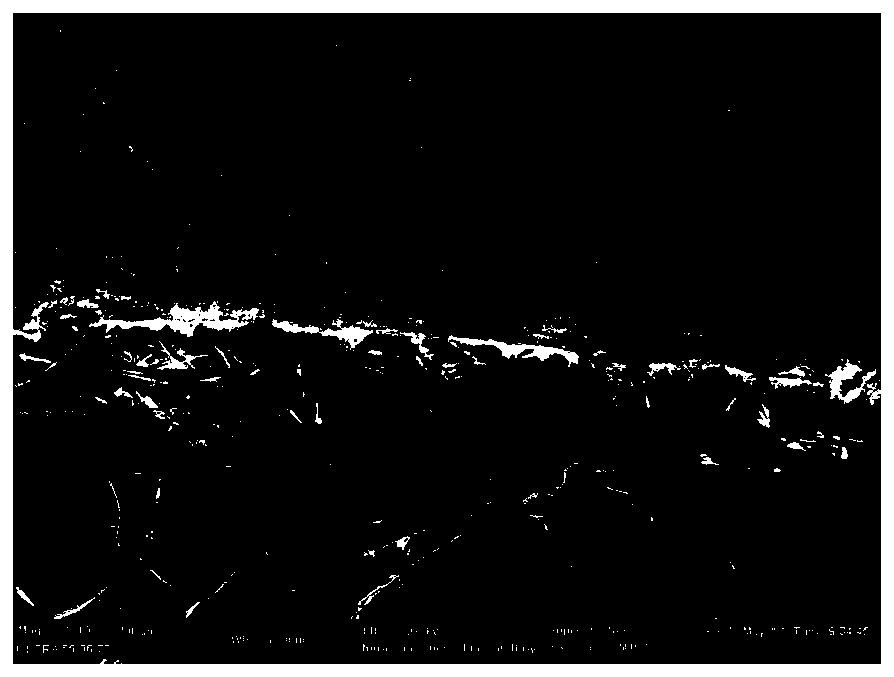

The invention provides a process for dryness, formation and further processing of water-enriched lignite. The process mainly comprises storage of the lignite, material transfer, crushing of lignite grains, rotary drum-shaped body multi-pipe drying, refined crushing, heating, hot pressing forming, screening and material return. The products can be used in process engineering in the fields of transportation, smelting, combustion, power generation or aerification. In the drying process, a rotary drum-shaped body multi-pipe drying device is used, and low-pressure vapor is indirectly used in the drying process, thereby avoiding the explosion due to the reaction of volatile compounds and oxygen, which is caused by too high temperature in the drying process; and in the forming process, little amount of internal water in capillary tubes of the lignite is used as a bonding agent, at certain temperature and grain size and under a certain pressure, gaps between lignite grains are filled by hot pressing so as to strengthen the contact between the lignite grains for forming. Because the hot pressing damages the structure of the capillary tubes of the lignite, the capillary tubes of the lignite are difficult to restore the original spongy property, thereby reducing the secondary adsorption water of the lignite grains. The process has the advantages of improving economic values of the lignite and causing little environmental pollution, along with safe drying and forming process.

Owner:CHINA NAT CHEM ENG GRP CORP LTD +1

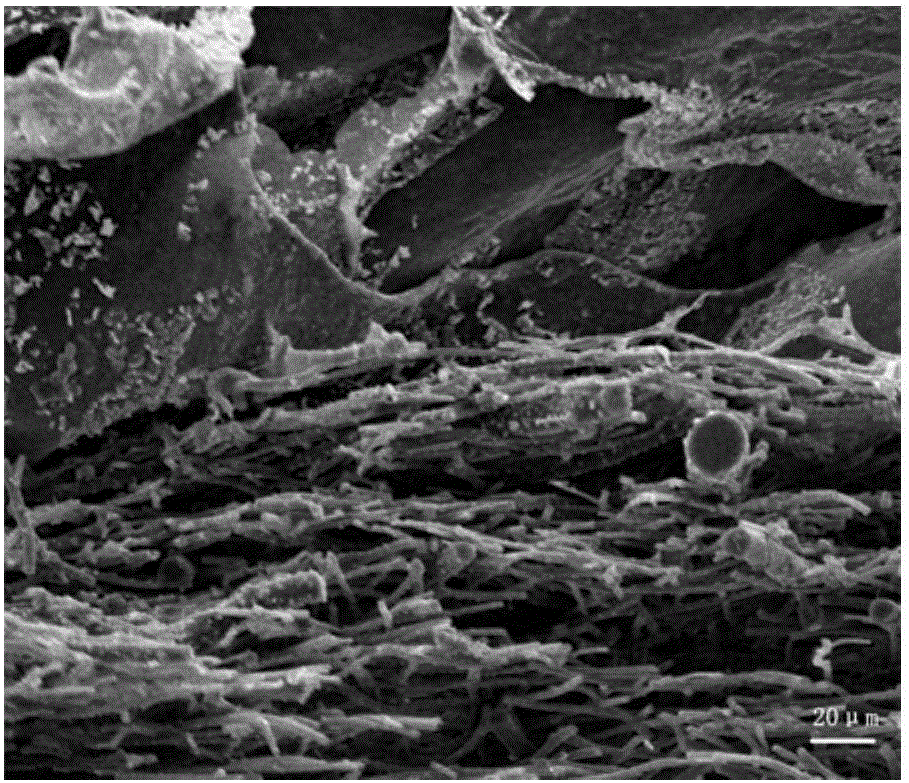

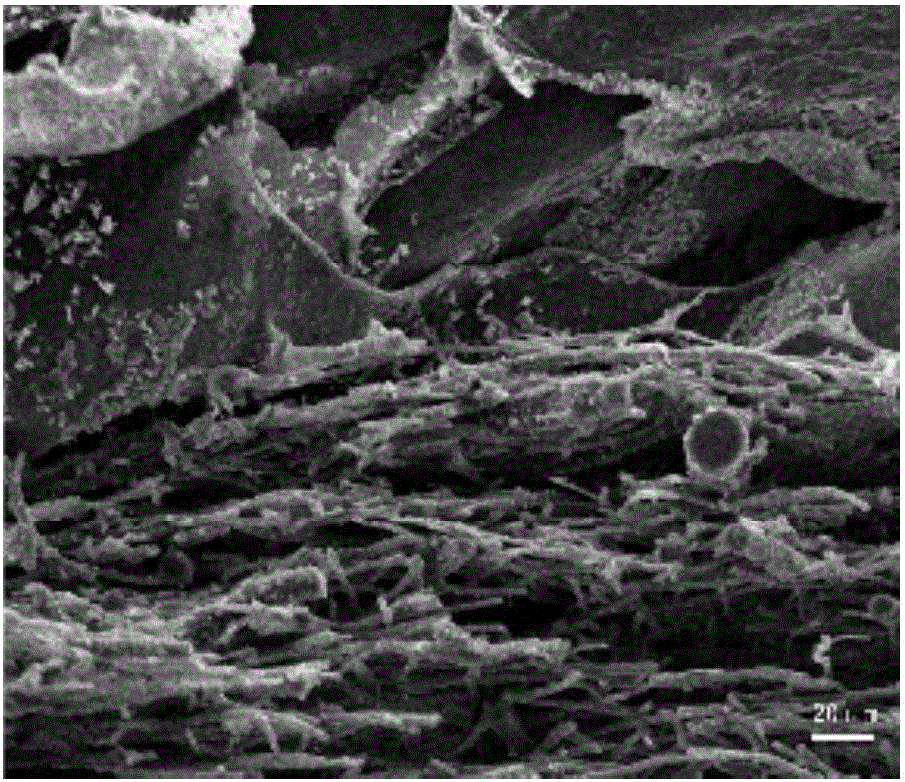

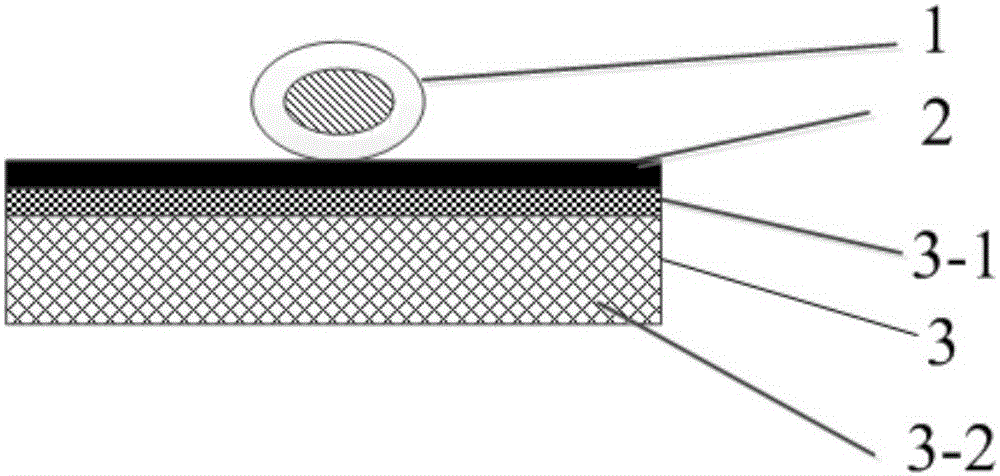

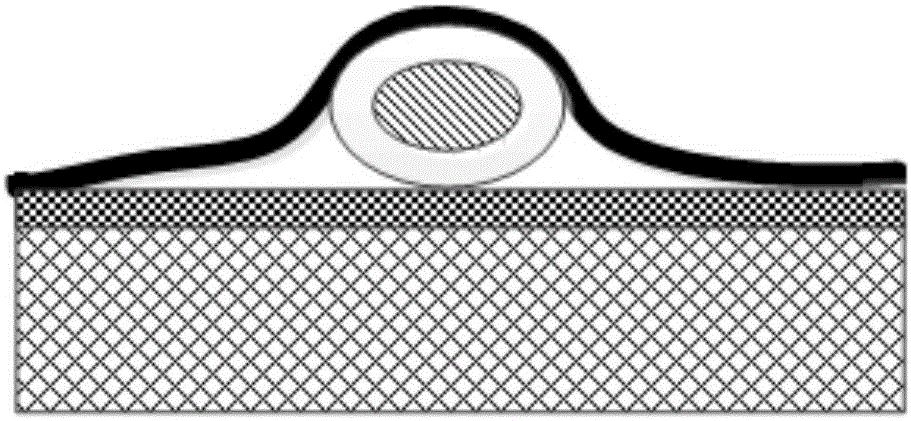

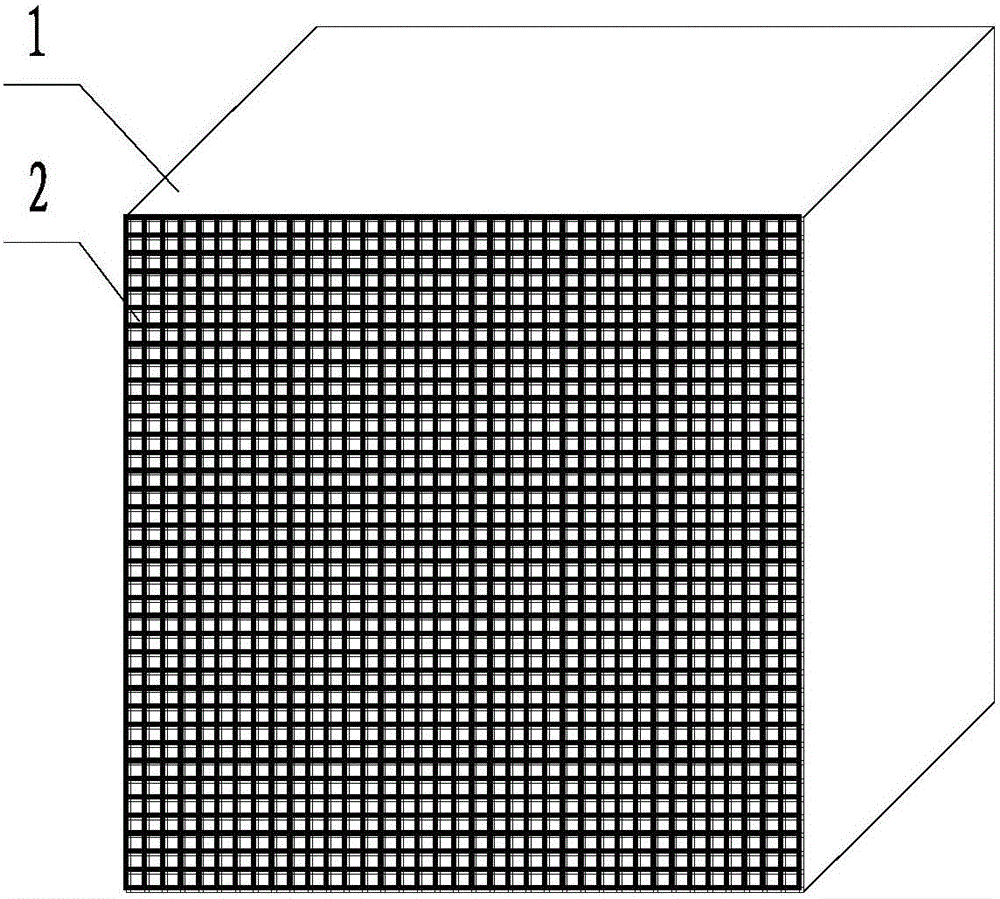

Composite hydrogel and preparation method thereof

The invention relates to composite hydrogel and a preparation method thereof. The composite hydrogel is hydrogel which takes a three-dimensional fiber network material as a skeleton, that is, the hydrogel comprises a three-dimensional fiber network material, wherein the three-dimensional fiber network material is a network structured material made of tingled fiber. As the three-dimensional fiber network material of the composite hydrogel is directly combined with the hydrogel, the purpose of strengthening the hydrogel can be achieved without changing the structure of the hydrogel self. Compared with a loosened and porous structure inside the hydrogel, the three-dimensional fiber network structure is dense, and medicines and active factors in the hydrogel can be densely coated, so that a slow-release effect can be achieved, the release velocities of the medicines can be reduced, and the utilization rates of the medicines can be increased.

Owner:DONGHUA UNIV

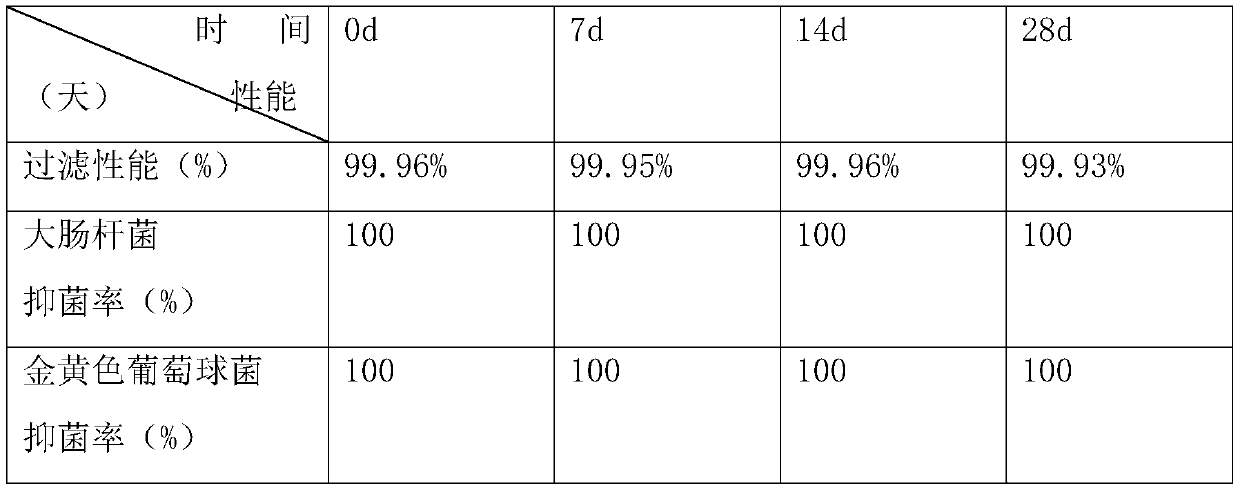

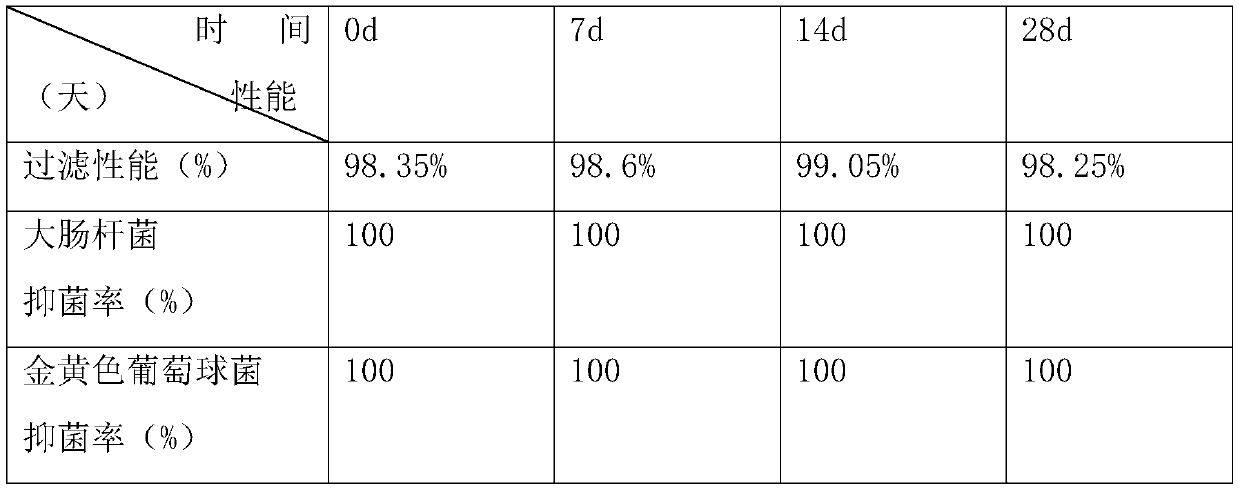

Method for preparing antimicrobial polysulfone ultrafiltration membrane

ActiveCN102698619AImprove pollutionImprove hydrophilicitySemi-permeable membranesEscherichia coliHydrophilic monomer

The invention relates to a method for preparing an antimicrobial polysulfone ultrafiltration membrane, which comprises the following steps: preparing a reaction solution containing an initiator, a capsaicin and a hydrophilic monomer, putting a pretreated polysulfone ultrafiltration membrane into the reaction solution for reaction of 0.32-8 hours, and modifying the surface of the pretreated polysulfone ultrafiltration membrane to obtain the antimicrobial polysulfone ultrafiltration membrane. The capsaicin is acrylamide with the derivative structures of capsaicin, the hydrophilic monomer is acrylamide, acrylic acid, methacrylic acid, hydroxyethyl acrylate or p-vinyl benzenesulfonic acid containing olefinic double bonds and hydrophilic groups, and the reaction solution is the mixture of an organic solvent and water. The flux of the ultrafiltration membrane prepared by adopting the method is more than 100L / (m<2>.h), and the ultrafiltration membrane can retain more than 93% of bovine serum albumin and can resist more than 85% of colon bacillus and more than 80% of staphylococcus aureus. The method is easy to operate, and the antibacterial and pollution-resisting properties of the ultrafiltration membrane are improved significantly. The prepared ultrafiltration membrane can be applied to the fields of industrial wastewater treatment, seawater desalination, etc.

Owner:OCEAN UNIV OF CHINA

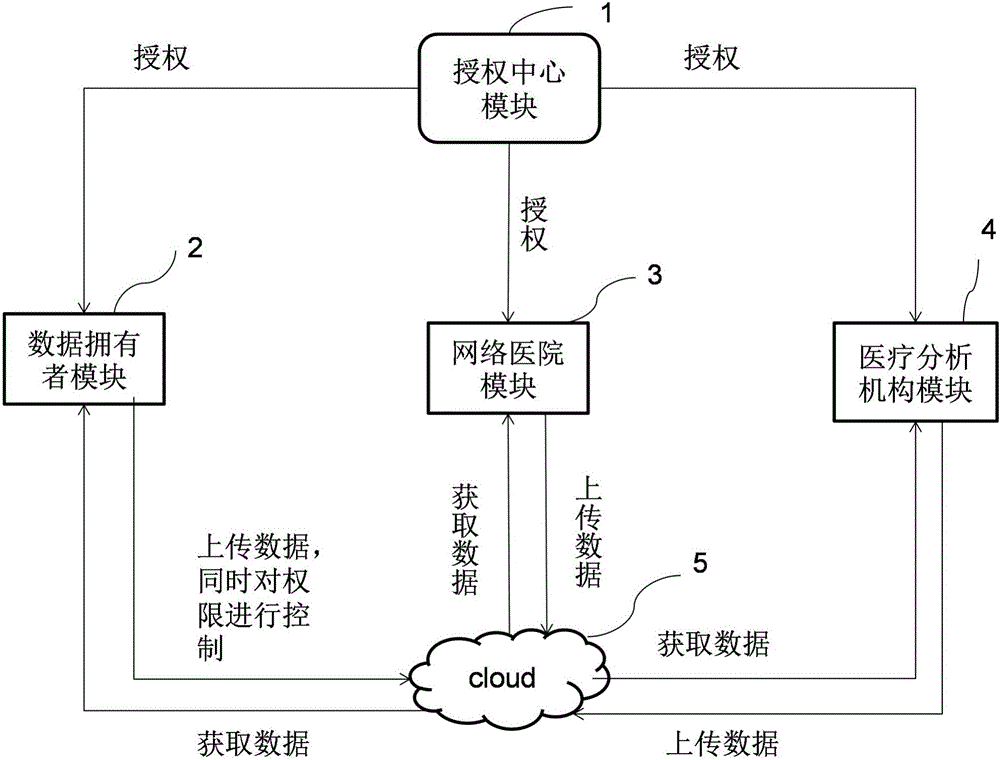

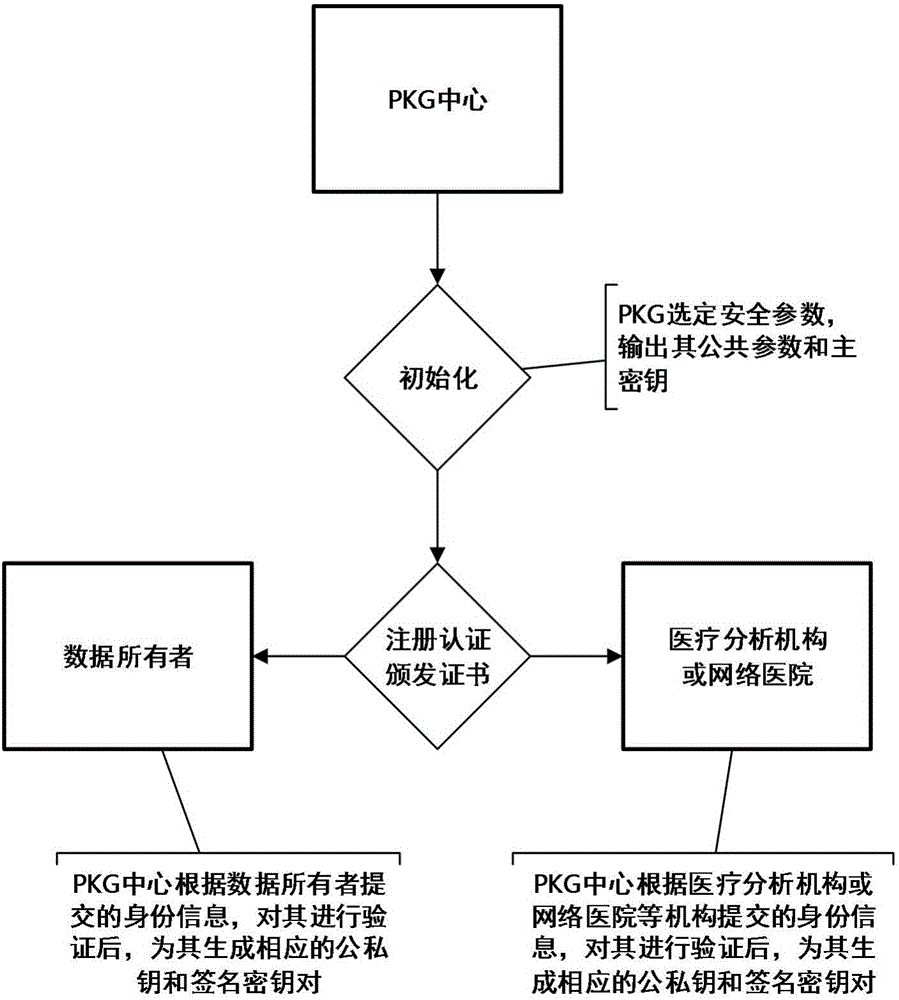

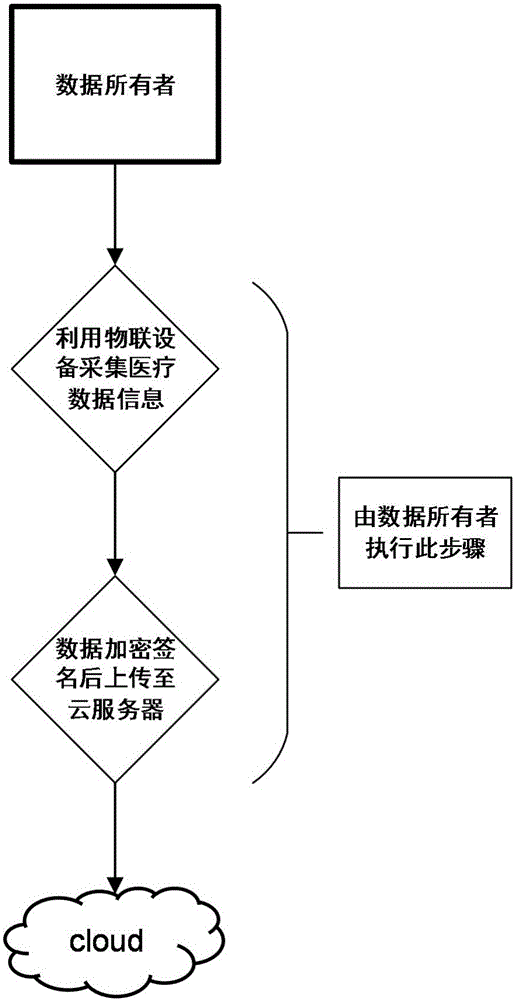

Intelligent medical service method based on undistinguishable confusion

ActiveCN105978854AFlexible Control AllocationAssignment Convenience ControlKey distribution for secure communicationData processing applicationsCiphertextData access

The invention discloses an intelligent medical service method based on undistinguishable confusion, which is characterized in that a data owner independently decides allocation for the medical data access authority through carrying out security symmetric encryption on medical information uploaded to a cloud server; a medical data analysis mechanism carries out confusion on a medical data analysis program by using an undistinguishable confusion technology, the confused program is deployed to the cloud server, and security analysis is carried out on the medical data by using a confusion program so as to acquire a correct medical analysis result; and the access authority of other related mechanisms for a ciphertext can be controlled conveniently without changing the ciphertext structure by using a key sharing scheme. According to the invention, the privacy of data is realized, interaction of keys is reduced, and storage and management of a great number of keys are avoided; the integrity and the effectiveness of data can be verified; and the access type of medical data is decided by the user, the overall structure of an algorithm is not change at the same time, and the expansibility of the scheme is enhanced.

Owner:XIDIAN UNIV

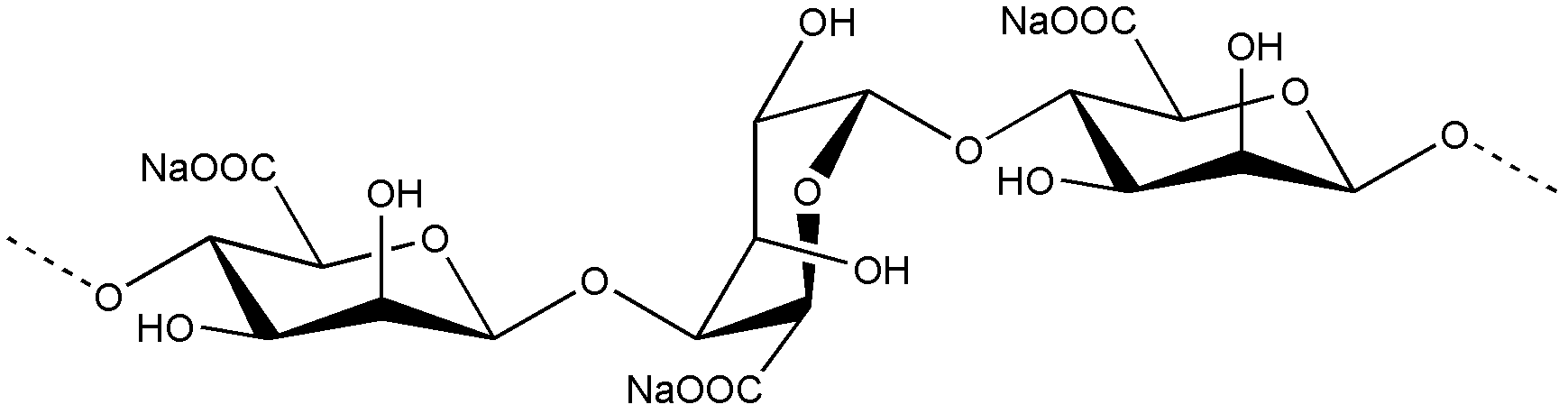

Enzymolysis-chemistry combined method for producing sodium alginate

ActiveCN102321191AThe production process is easy to controlChange the high energy consumption and high pollutionChemical industryCombined method

The invention relates to the field of seaweed chemical industry, and specifically provides an enzymolysis-chemistry combined method for producing sodium alginate. The method comprises steps of: mixing pretreated alga and compound enzyme at 45-60 DEG C and a pH of 4.5-6.5, reacting for 13-26 h, carrying out an enzymolysis, filtering and converting the filtrate to obtain sodium alginate; and addingalkali liquor in the precipitate after the enzymolysis, reacting for 2-4 h at 50-80 DEG C, calcifying a filtrate after filtering, and adding sodium carbonate into calcified precipitate to convert into sodium alginate. The method of the invention can fundamentally solve drawbacks of high energy consumption and high pollution of a traditional production technology. According to one ton of sodium alginate and iodine coproduct produced by the enzymolysis-chemistry combined method of the invention, fresh water for production is reduced by 38%, and coal is reduced by 23%, and soda acid waste water generated is reduced by 52% less; and the method can increase yield by 9-11% compared with a conventional chemical production technology.

Owner:SHANDONG JIEJING GROUP CORP

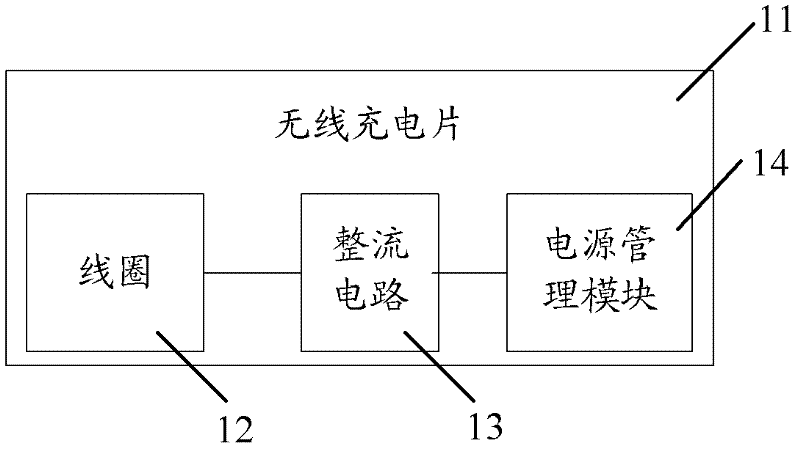

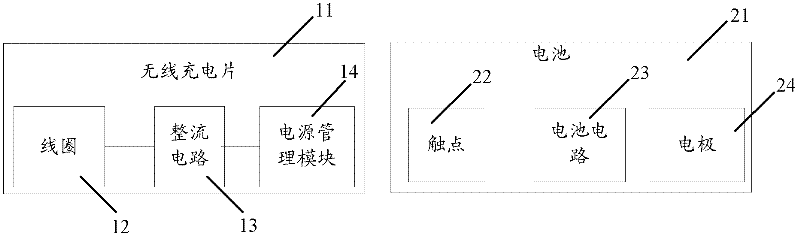

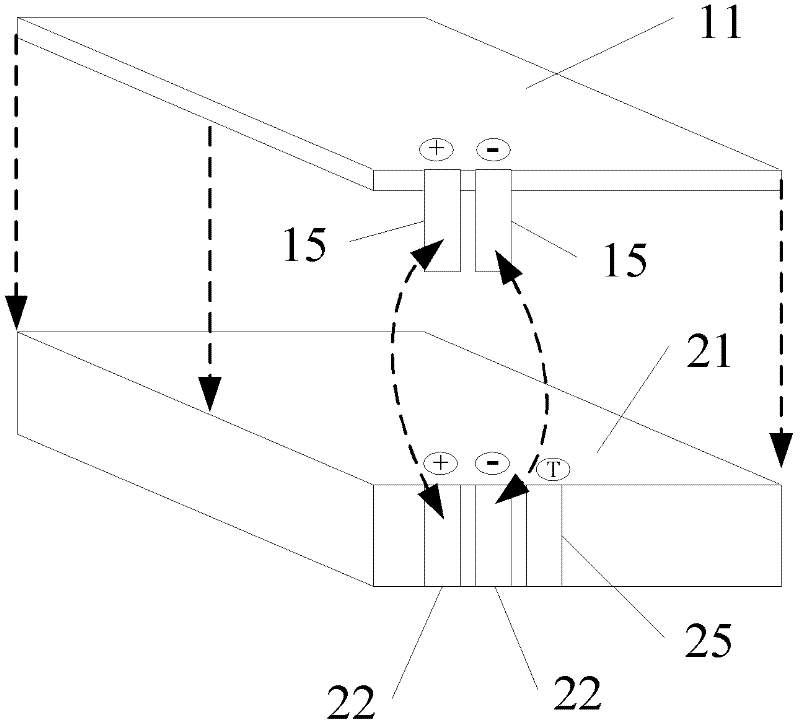

Realizing device for wireless charging

ActiveCN102315699AOverall small sizeDoes not change the structureBatteries circuit arrangementsElectromagnetic wave systemElectricityAlternating current

The invention discloses a realizing device for wireless charging, wherein the device comprises a wireless charging chip and a charging terminal; the wireless charging chip comprises a substrate and a shielding layer, the shielding layer is attached on the substrate, and the substrate is internally provided with a coil, a rectification circuit and a power source management module, wherein the coil, the rectification circuit and the power source management module are embedded in the substrate through an element integrating process for processing sheet materials, and the coil is used for generating alternating current under the action of a magnetic field; the rectification circuit is electrically connected with the coil and used for converting the alternating current generated by the coil into direct current and providing the direct current to the power source management module; and the power source management module is electrically connected with the charging terminal and used for providing direct current from the rectification circuit to the charging terminal.

Owner:青岛众海汇智能源科技有限责任公司 +2

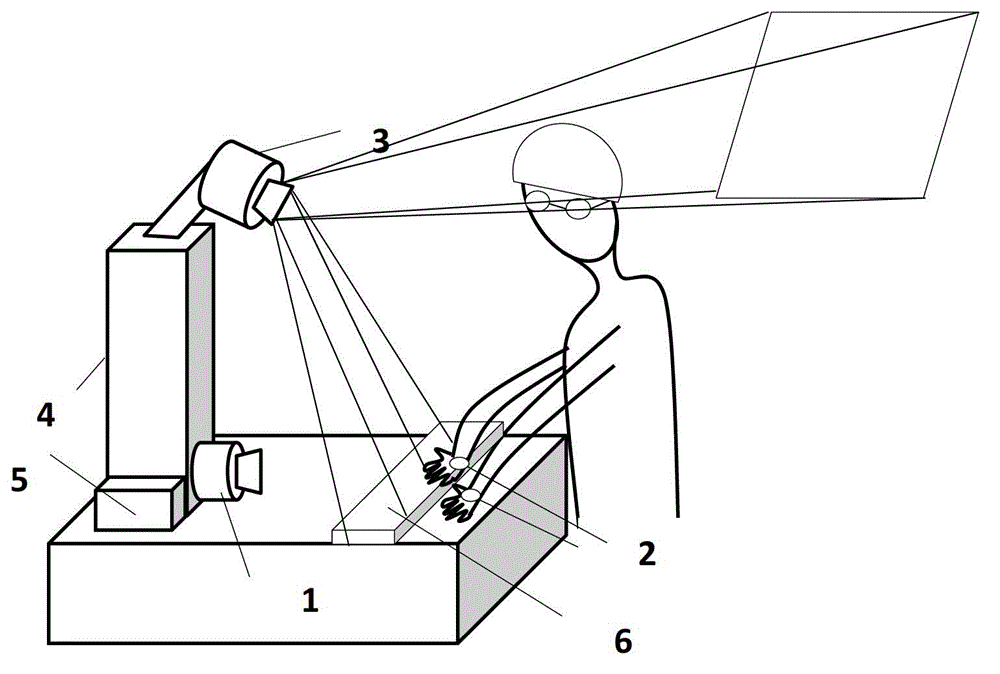

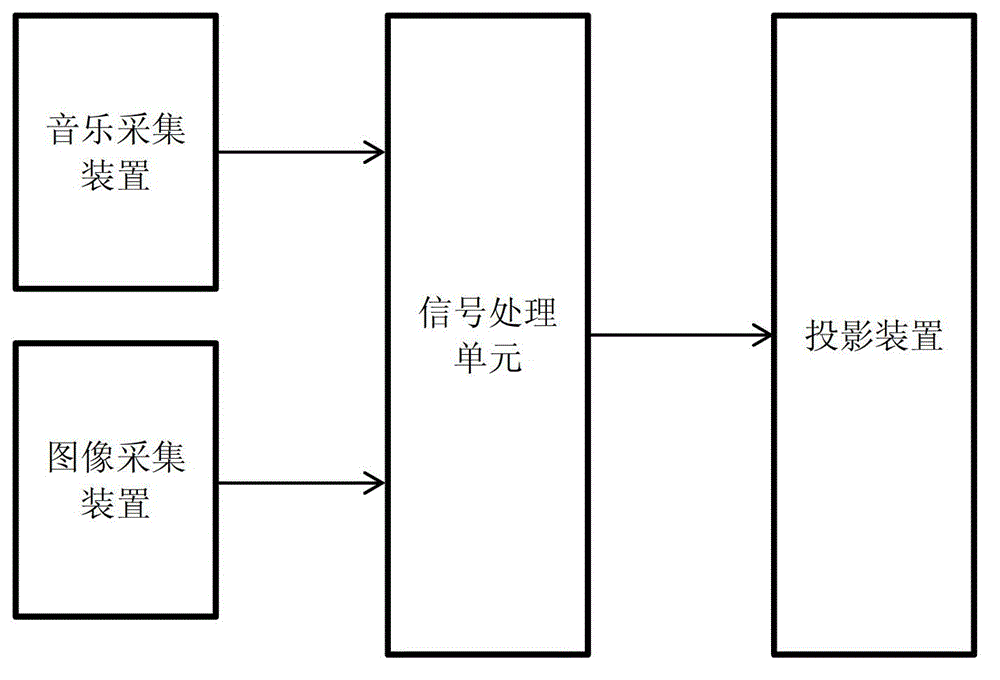

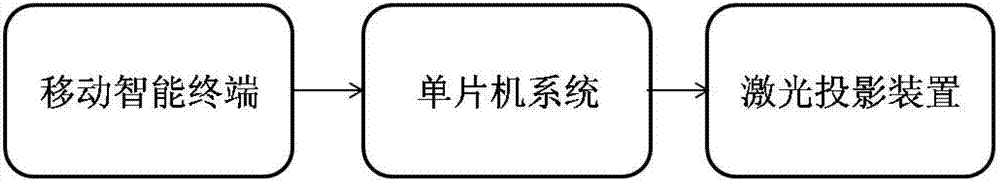

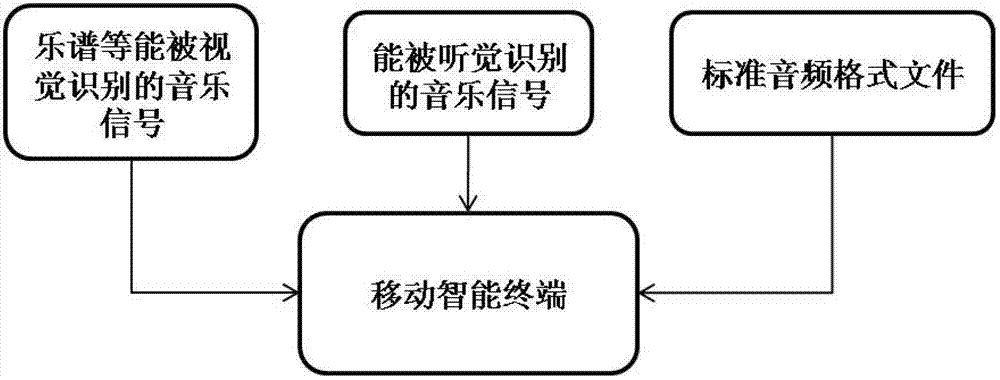

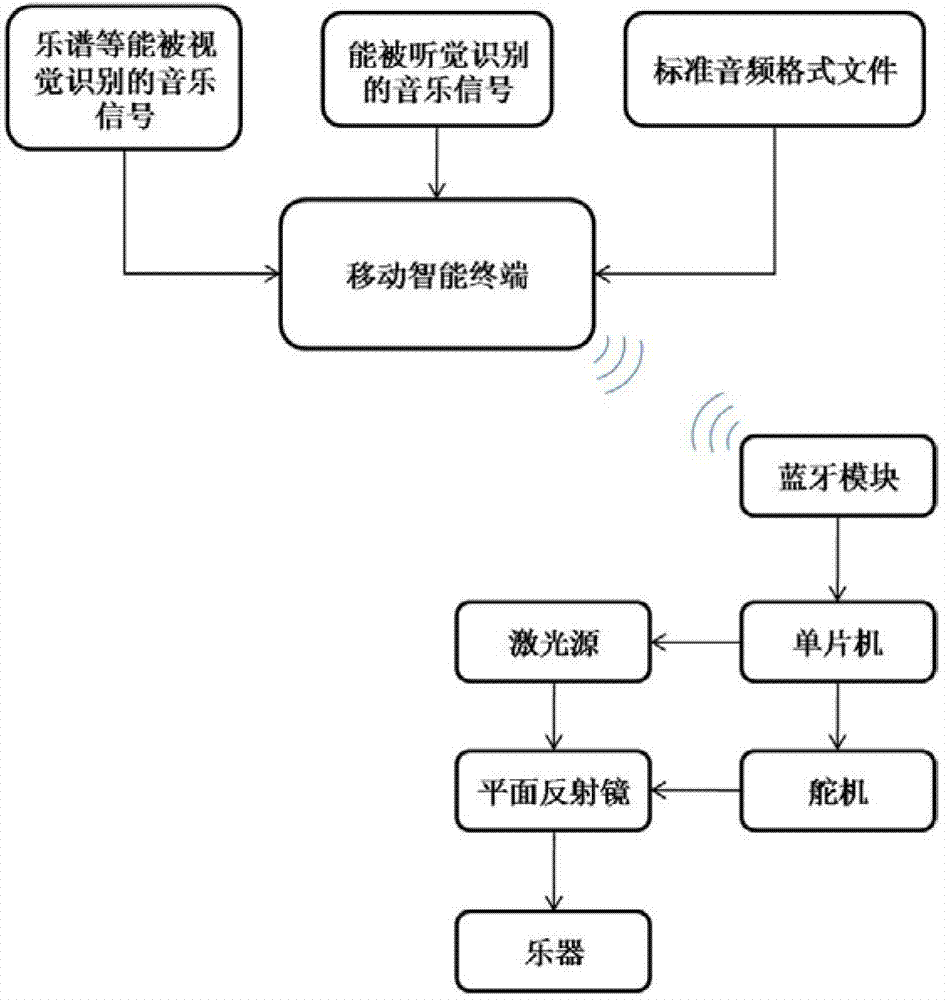

Teaching system and teaching method of laser identification keyboard music instrument

The invention relates to a teaching system and a teaching method of a laser identification keyboard music instrument. The teaching system comprises a mobile intelligent terminal, a singlechip system and a laser projection device, wherein the mobile intelligent terminal is used for acquiring and processing music signals and controlling the singlechip system to adjust the laser projection device through wireless communication, and then laser projection signals for indicating the play of the music instrument are generated in sequence; the teaching method comprises steps of initial positioning and correction of the keyboard music instrument, the acquisition and identification of music signals and the laser projecting teaching. The teaching system is various in teaching modes, needs not to be installed on the music instrument, is small in size and convenient to carry; a structure of the music instrument needs not to be changed; the teaching method is simple, easy to learn, strong in operability and is applicable to users of different ages and different music instrument playing levels, and is wide in application range.

Owner:ZHEJIANG UNIV

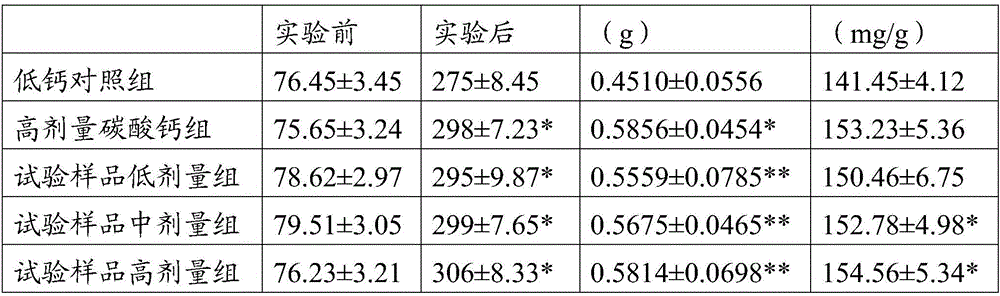

Composition used for improving skeletal system health, and applications thereof

InactiveCN106235311AStructural influencePromote mineralizationOrganic active ingredientsPeptide/protein ingredientsVitamin K2Joint arthralgia

The invention belongs to the field of health care food, and especially relates to a composition used for improving skeletal system health, and applications thereof. The composition comprises skimmed milk powder, fructo-oligosaccharide, yak bone, orange fruit powder, D-glucosamine hydrochloride, bone collagen, chondroitin sulfate, herba epimedii extract, rhizoma drynariae extract, mushroom powder, magnesium carbonate, casein phosphopeptide, and vitamin K2. The composition possesses excellent prevention effects on patients with osteoporosis and skeletal system disorders such as ankylosis, arthritis, osteoproliferation, arthralgia, and myospasm, and is capable of increasing bone mineral density, and improving skeletal system health. The composition can be used for preparing health care food capable of improving skeletal system health; application range is wide; and economic benefit and social benefit are both high.

Owner:GUANGZHOU KOHEALA BIOTECHNOLOGY CO LTD

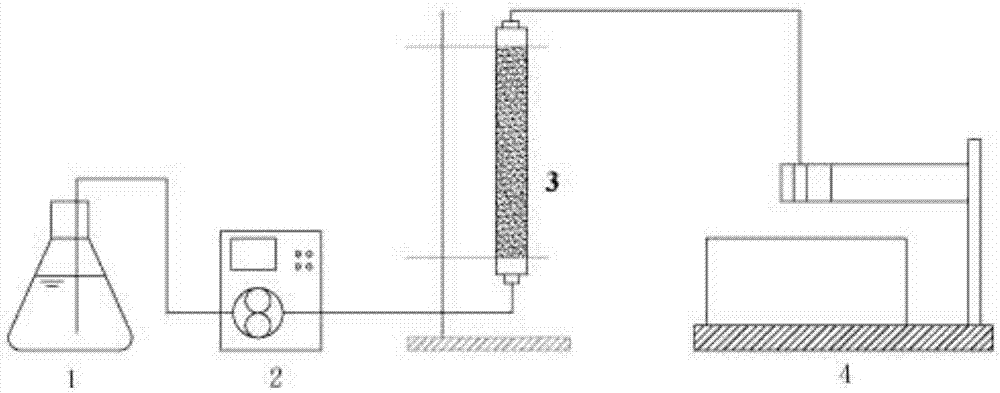

Method for repairing heavy metal contaminated soil by nanometer zero-valent iron

InactiveCN106984640AReduce leaching toxicityReduced effectivenessAgriculture tools and machinesContaminated soil reclamationDesorptionElution

The invention discloses a method for repairing heavy metal contaminated soil by nanometer zero-valent iron. The method comprises the following steps of: filling heavy metal contaminated soil in a fiberglass-reinforced column; introducing water until constant weight is obtained; and introducing nanometer zero-valent iron suspension liquid in the fiberglass-reinforced column to perform elution on the heavy metal contaminated soil. Through the adoption of the method disclosed by the invention, heavy metal with high toxicity in the soil can be eliminated or reduced once under the condition that the original ecological structure of the soil is not damaged, and secondary contamination of nanometer zero-valent iron and heavy metal desorption are avoided; and the method has the advantages of being simple in treating technology, low in cost and obvious in treatment effect.

Owner:HUNAN UNIV

Bionic tissue based on acellular matrix-cell-three-dimensional fiber network and preparation method of bionic tissue

ActiveCN105944143AGood biocompatibilityPromote degradationProsthesisAcellular matrixNetwork structure

The invention relates to bionic tissue based on an acellular matrix-cell-three-dimensional fiber network and a preparation method of the bionic tissue. The bionic tissue based on the acellular matrix-cell-three-dimensional fiber network at least comprises composite acellular matrix hydrogel and epithelial cells. The composite acellular matrix hydrogel adopts a three-dimensional fiber network material good in biocompatibility as a framework. The three-dimensional fiber network material good in biocompatibility is a network structure material formed by winding fibers good in biocompatibility. The bionic tissue based on the acellular matrix-cell-three-dimensional fiber network can carry out simulation according to the tissue and organ structures, has good application prospects in tissue engineering, and can be widely applied to the field of biomedicine.

Owner:DONGHUA UNIV

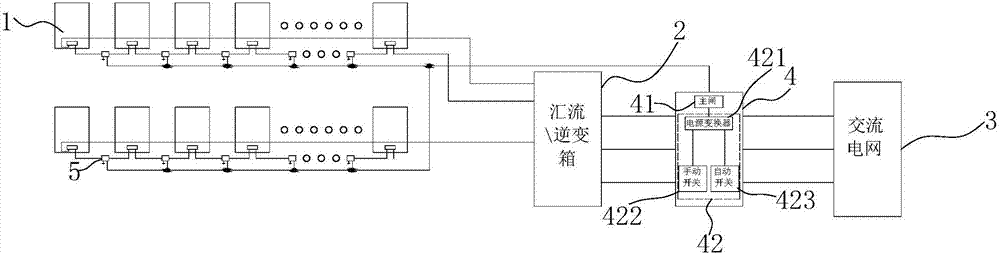

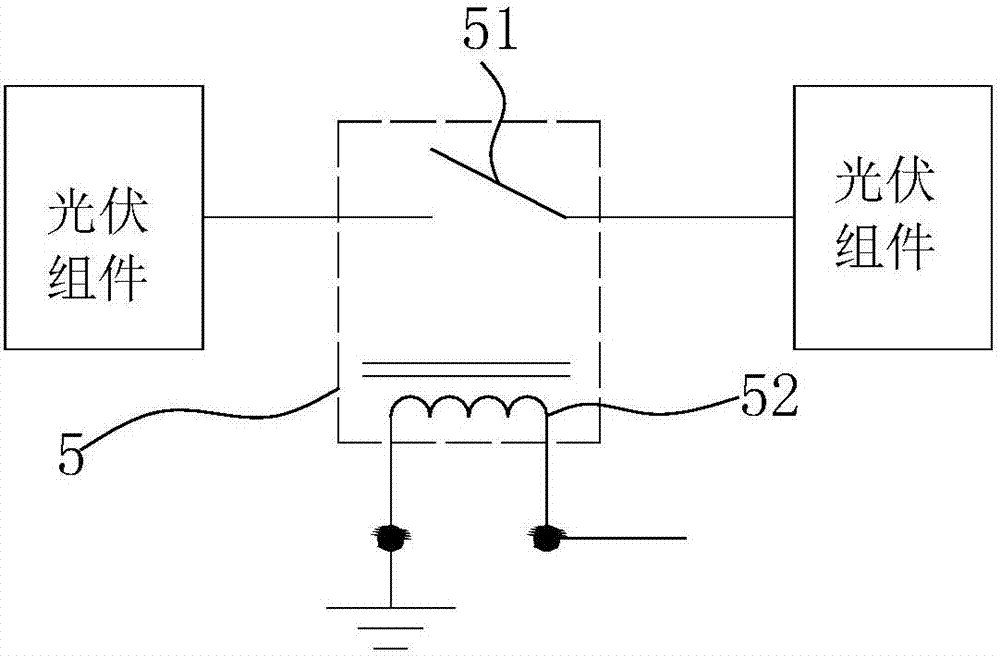

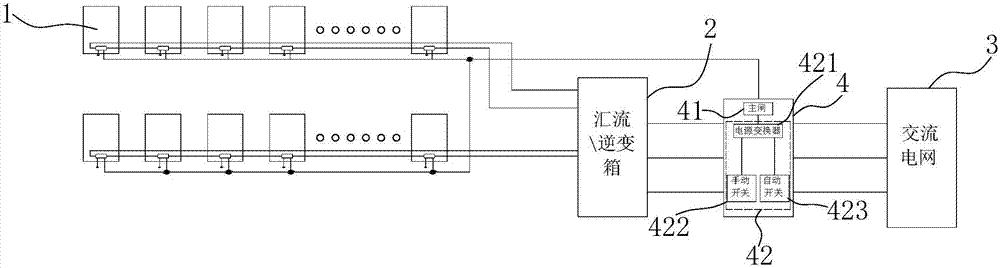

Rapid switch-off system applied to photovoltaic generation

InactiveCN107425808ADoes not change the structureEasy to transformPhotovoltaicsSingle network parallel feeding arrangementsPower gridDistribution system

The invention provides a rapid switch-off system applied to photovoltaic generation, relates to the field of photovoltaic generation, and specifically relates to a rapid switch-off system with high security and reliability and applied to photovoltaic generation. The rapid switch-off system is connected to a photovoltaic module array in series and comprises rapid switch-off photovoltaic junction boxes, the photovoltaic module array comprises a plurality of photovoltaic modules, the plurality of photovoltaic modules are connected in series and conveyed to an alternating current power grid through a combiner / inversion box, an alternating current distribution system is arranged between the alternating current power gird and the combiner / inversion box, the rapid switch-off photovoltaic junction boxes are connected in series between the adjacent photovoltaic modules and used for switching off the photovoltaic modules, the alternating current distribution system comprises a main switch and a slave switch, the main switch is arranged between the alternating current power grid and the combiner / inversion box, the slave switch comprises a power supply converter, a manual switch and an automatic switch, the automatic switch and the manual switch are separately connected with the power supply converter, and the power supply converter is connected with the rapid switch-on photovoltaic junction boxes. The system is advantaged by high security and good stability.

Owner:JIANGSU TONGLIN ELECTRIC

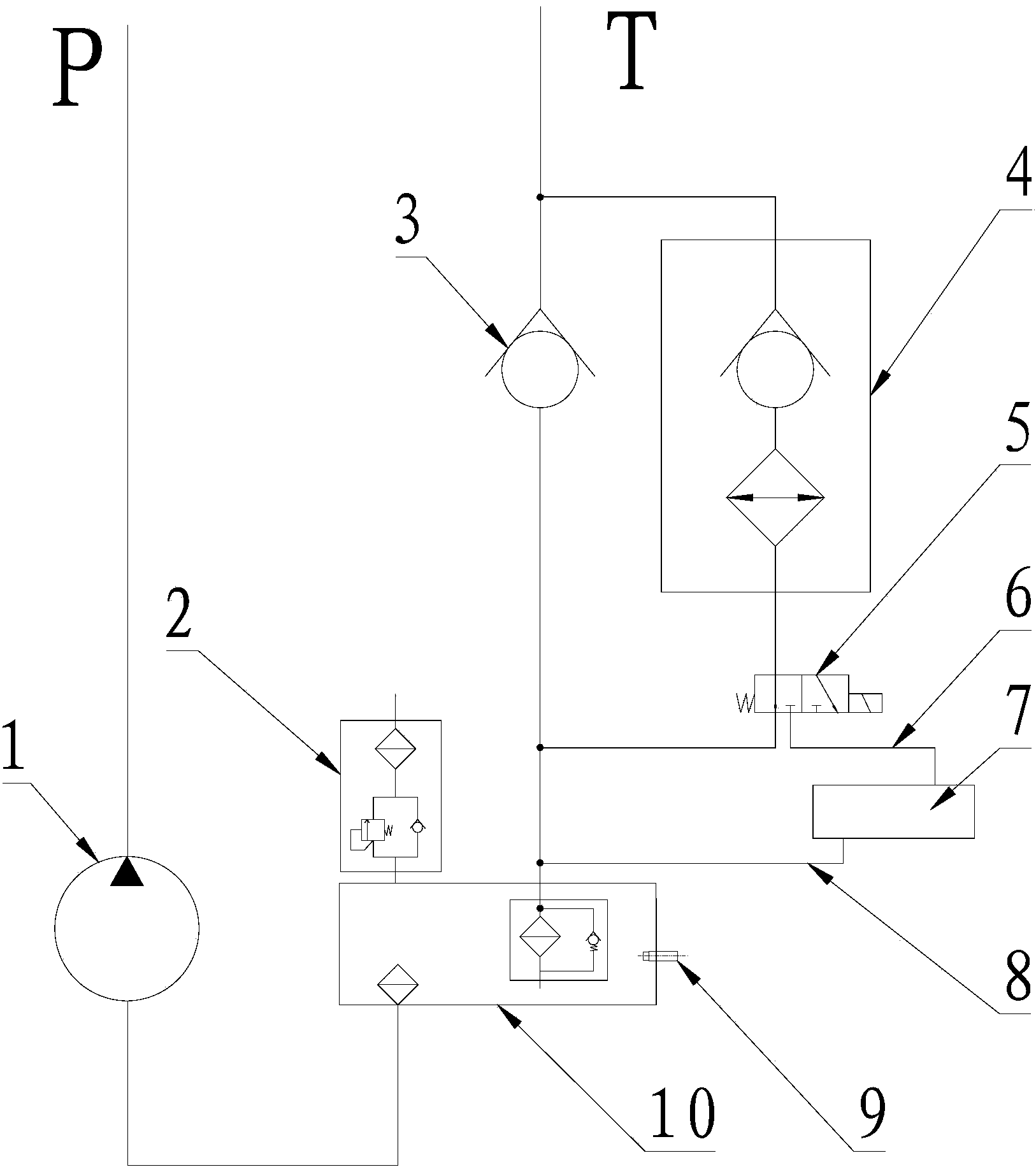

Hydraulic oil temperature control system and engineering machinery

InactiveCN103912540AExtend cycle timeExtended cooldownFluid-pressure actuator componentsControl systemFuel tank

The invention provides a hydraulic oil temperature control system and engineering machinery. The hydraulic oil temperature control system comprises a pump, a main oil tank, an oil return circuit, a radiator, an auxiliary oil tank, a reverse valve, a temperature sensor and a controller. When the hydraulic oil temperature in the main oil tank is higher than a preset value, the controller controls the reverse valve to cut off the oil circuit between the radiator and the main oil tank and communicates with another oil circuit between the radiator and the auxiliary oil tank; when the hydraulic oil temperature in the main oil tank is lower than the preset value, the controller controls the reverse valve to cut off the oil circuit between the radiator and the auxiliary oil tank and communicates with the oil circuit between the radiator and the main oil tank. By the arrangement, the auxiliary oil tank can be selectively connected or disconnected according to the hydraulic oil temperature in the main oil tank, so that the hydraulic oil temperature can be sustained within the best temperature range, leakage of hydraulic oil can be further reduced, and operation efficiency of the hydraulic system can be improved while the service life of the same can be prolonged.

Owner:SANY HEAVY MACHINERY

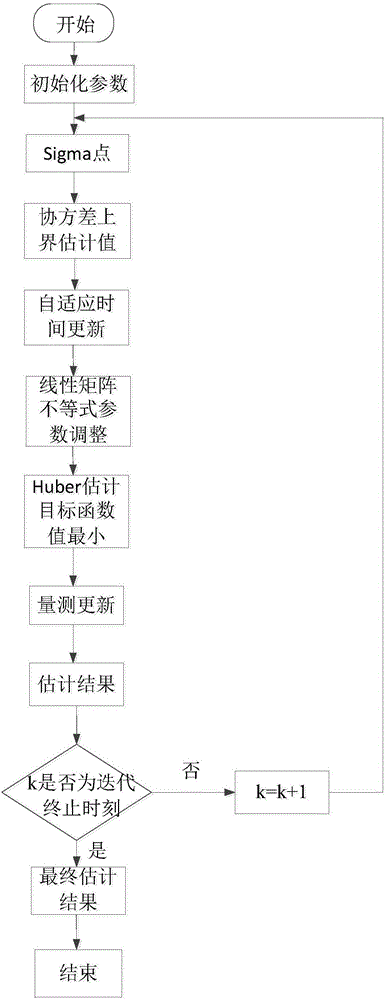

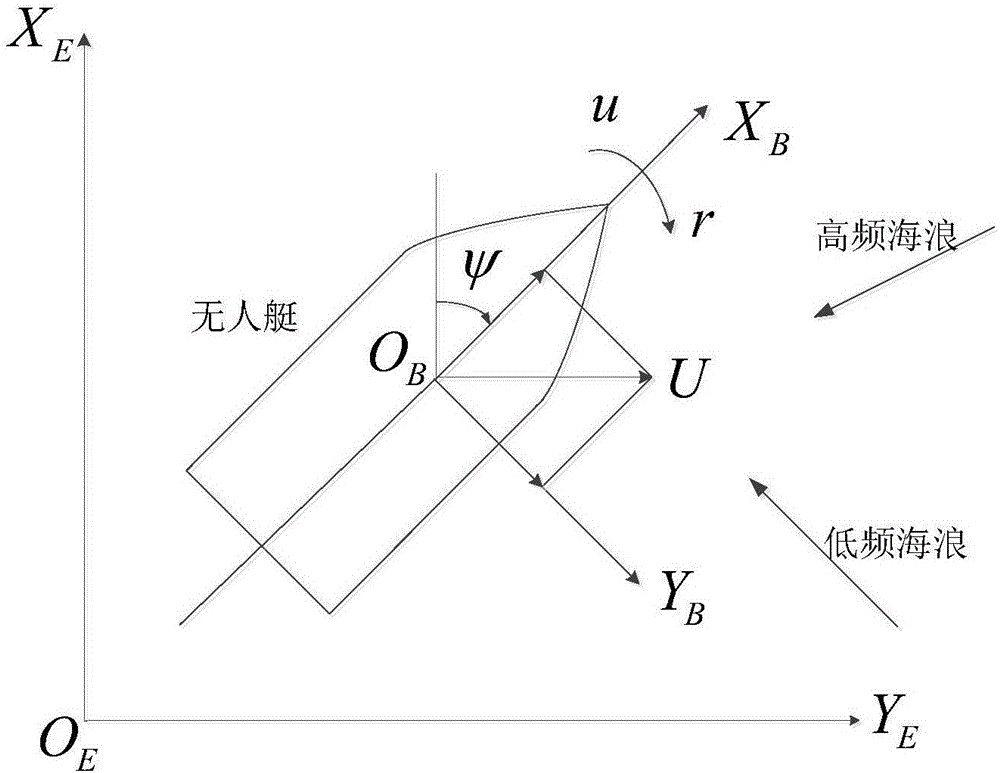

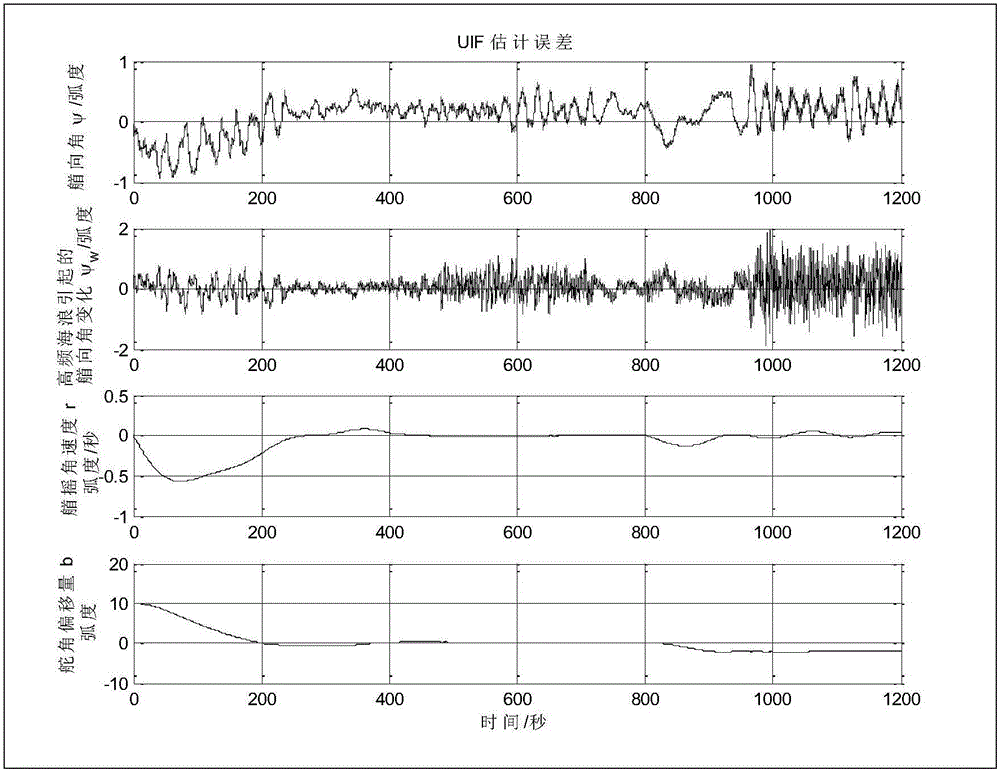

Robust adaptive filtering and state estimation method based on Huber estimation

ActiveCN107179693AEasy extension for multi-source fusionImprove scalabilityComplex mathematical operationsAdaptive controlPattern recognitionEstimation methods

The present invention provides a robust adaptive filtering and state estimation method based on Huber estimation. Firstly, an estimation value is calculated through estimating an upper bound of a covariance matrix of a one-step prediction dual-uncertainty system in an online way, only a time updating process is modified, at the same time a method of a linear matrix inequality is used to carry out adaptive parameter adjustment, and an adaptive traceless information filter for an uncertainty model is obtained. Then the matrix inversion theorem is applied and a Huber estimation method is used to modify a measurement update process, and a final estimation value is obtained. The precision of filtering and state estimation is high, and the stability is good. According to the robust adaptive filtering and state estimation method, a filtering and state estimation problem of a dual-uncertainty unmanned ship is solved, the advantages of an information filter structure are retained, the precision and stability of filtering and state estimation are improved, and the calculation is simple and the application is convenient.

Owner:HARBIN ENG UNIV

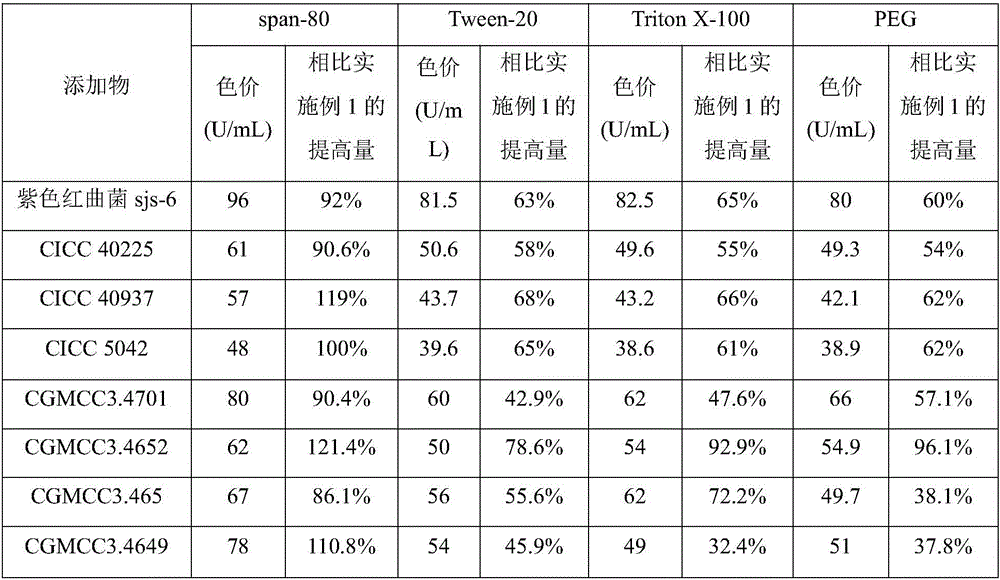

Method for producing monascus yellow pigment by promoting liquid-state fermentation of monascus

ActiveCN106636249AImprove permeabilityEasy to operateMicroorganism based processesFermentationMonascusChemistry

The invention discloses a method for producing a monascus yellow pigment by promoting liquid-state fermentation of monascus and belongs to the technical field of microorganism fermentation. The method comprises the following steps: after inoculating a monascus strain culture solution into a liquid-state culture medium, fermenting at 30 DEG C for 6d to 8d; adding a surfactant into a fermentation culture solution within 72h after fermentation is started, so as to promote the synthesis of an active substance, namely the monascus yellow pigment, in a growth process of the monascus. According to the method disclosed by the invention, a biosynthesis capability of the monascus yellow pigment by liquid-state fermentation of the monascus can be improved through effective regulation; the concentration of a target product with a high additional value, which is synthesized by the fermentation, can be improved through relatively low additional investment; the method is convenient and practical and has great economic benefits.

Owner:JIANGNAN UNIV

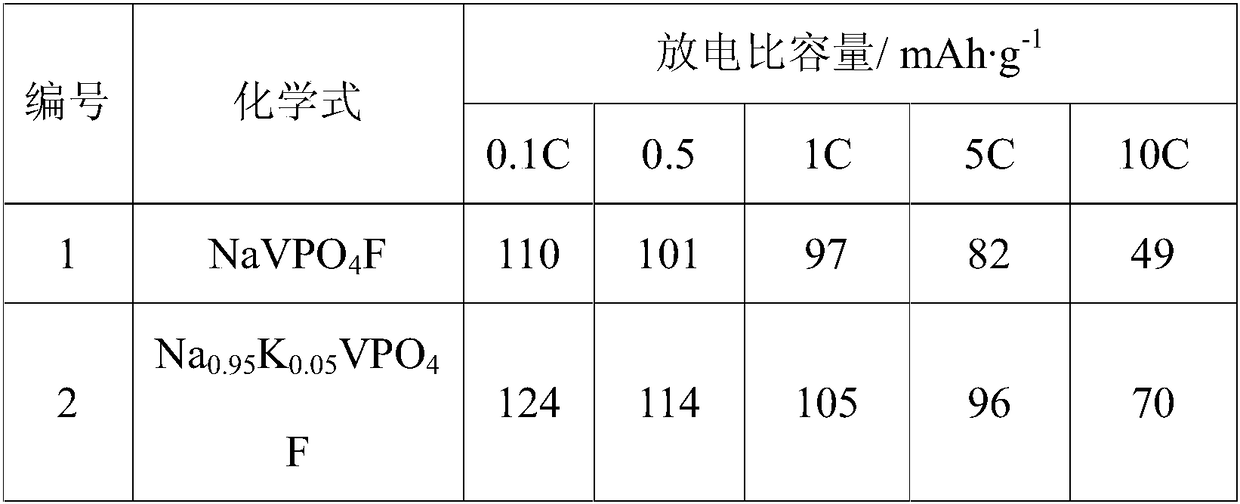

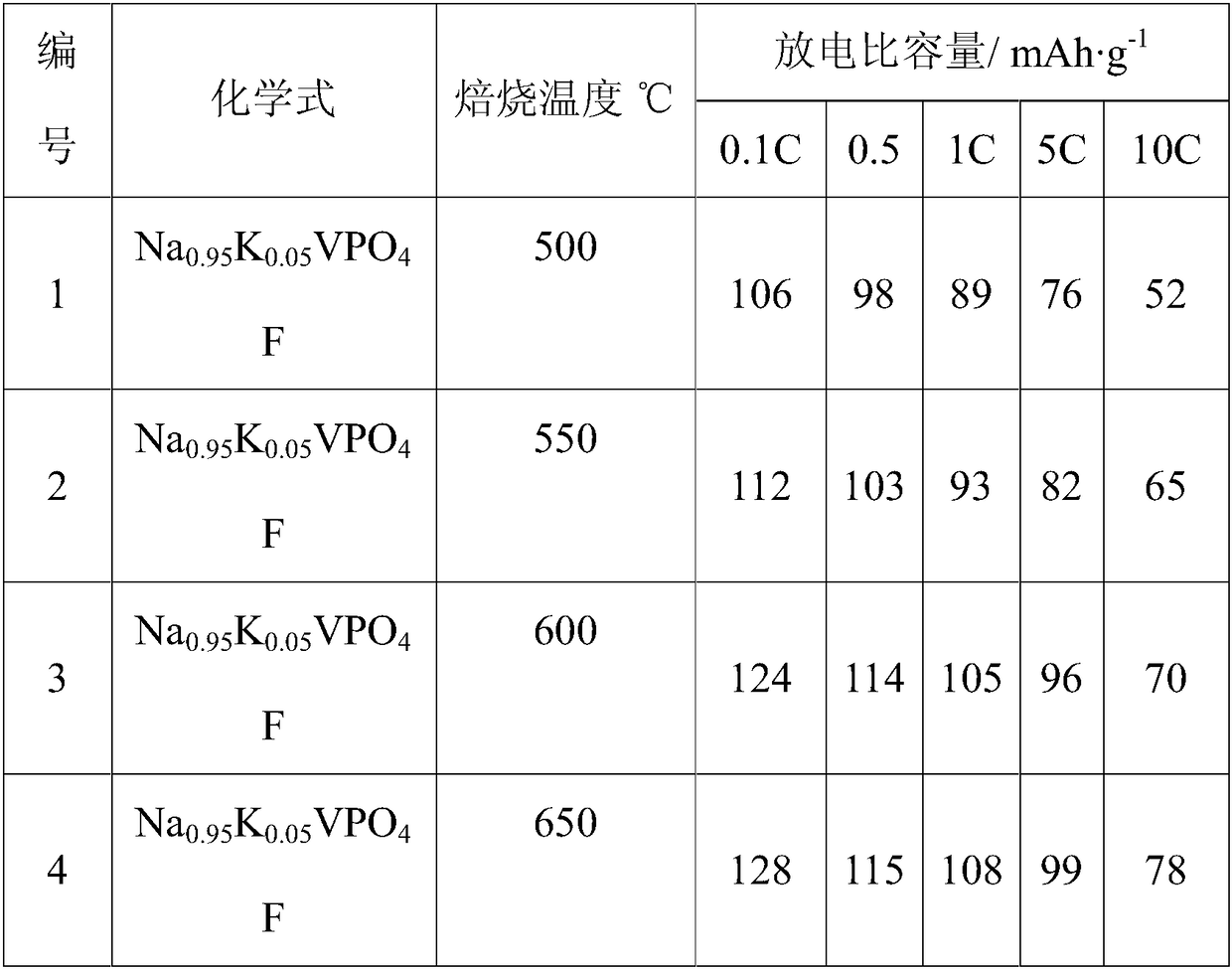

Doping modified sodium vanadium fluorophosphates positive electrode material and preparation method thereof

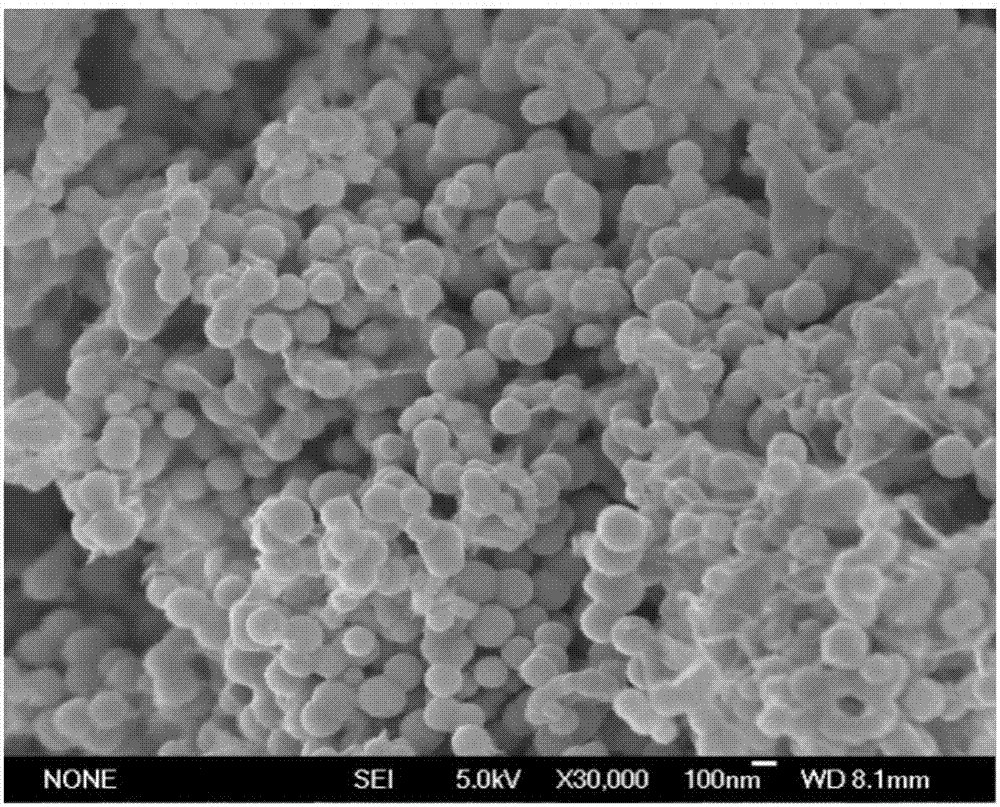

InactiveCN108899505AHigh purityImprove charge and discharge performanceCell electrodesSecondary cellsFreeze-dryingPotassium

The invention provides a doping modified sodium vanadium fluorophosphates positive electrode material and a preparation method thereof. The positive electrode material is represented by a general formula of Na(1-x)KxVPO4F, wherein x is more than or equal to 0 and less than or equal to 0.15. The preparation method disclosed by the invention comprises the following steps: mixing and dissolving various raw materials into deionized water to realize uniform mixing on a molecular level; freezing, and performing freeze-drying treatment to prepare a powdered material having the characteristics of excellent dispersion property, light particle aggregation and the like; and calcining twice at a medium temperature and a high temperature, thereby obtaining the doping modified sodium vanadium fluorophosphates positive electrode material with the advantages of being loose and porous, fine and uniformly distributed in particle system, high in purity and excellent in charge and discharge performance.

Owner:CENT SOUTH UNIV

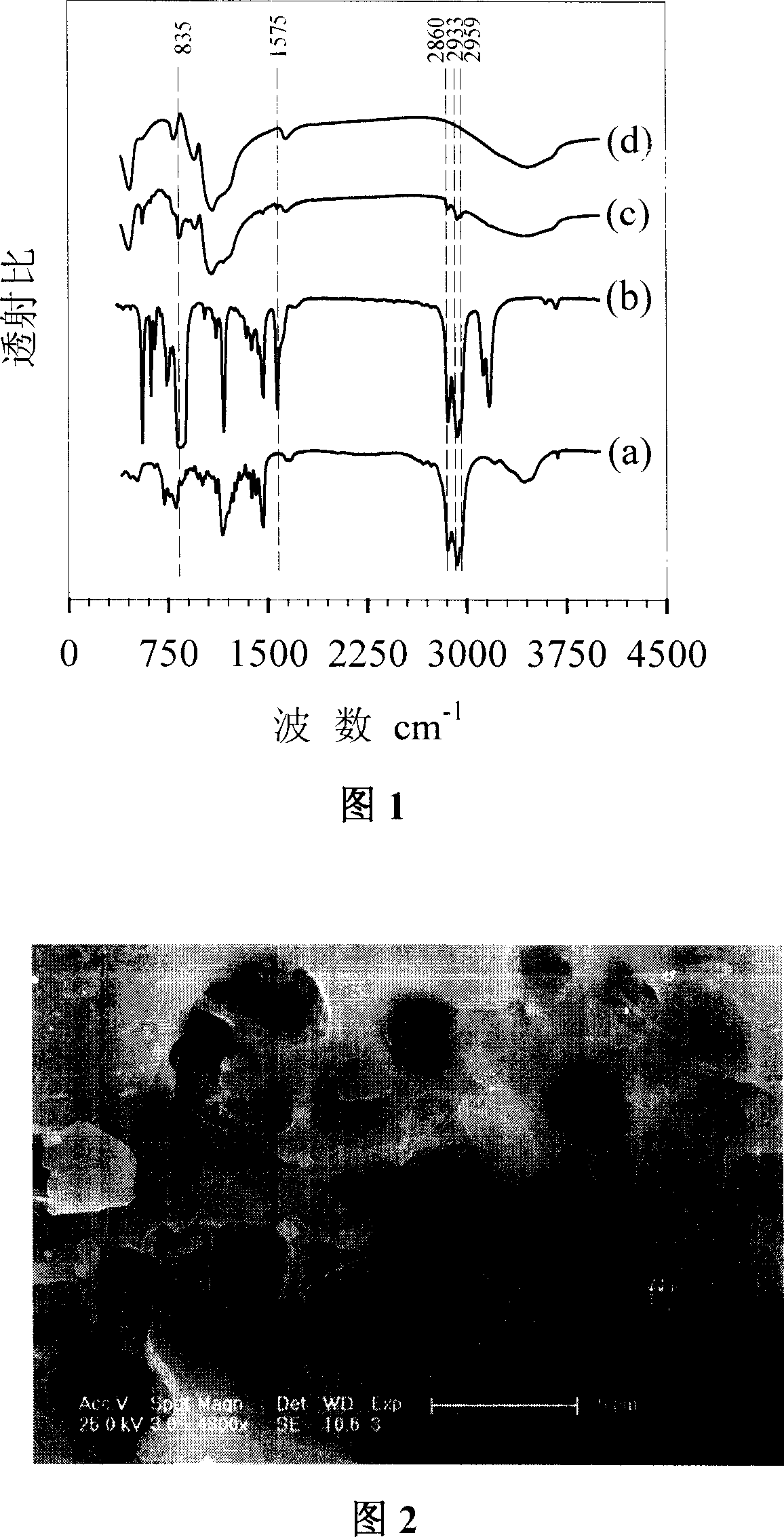

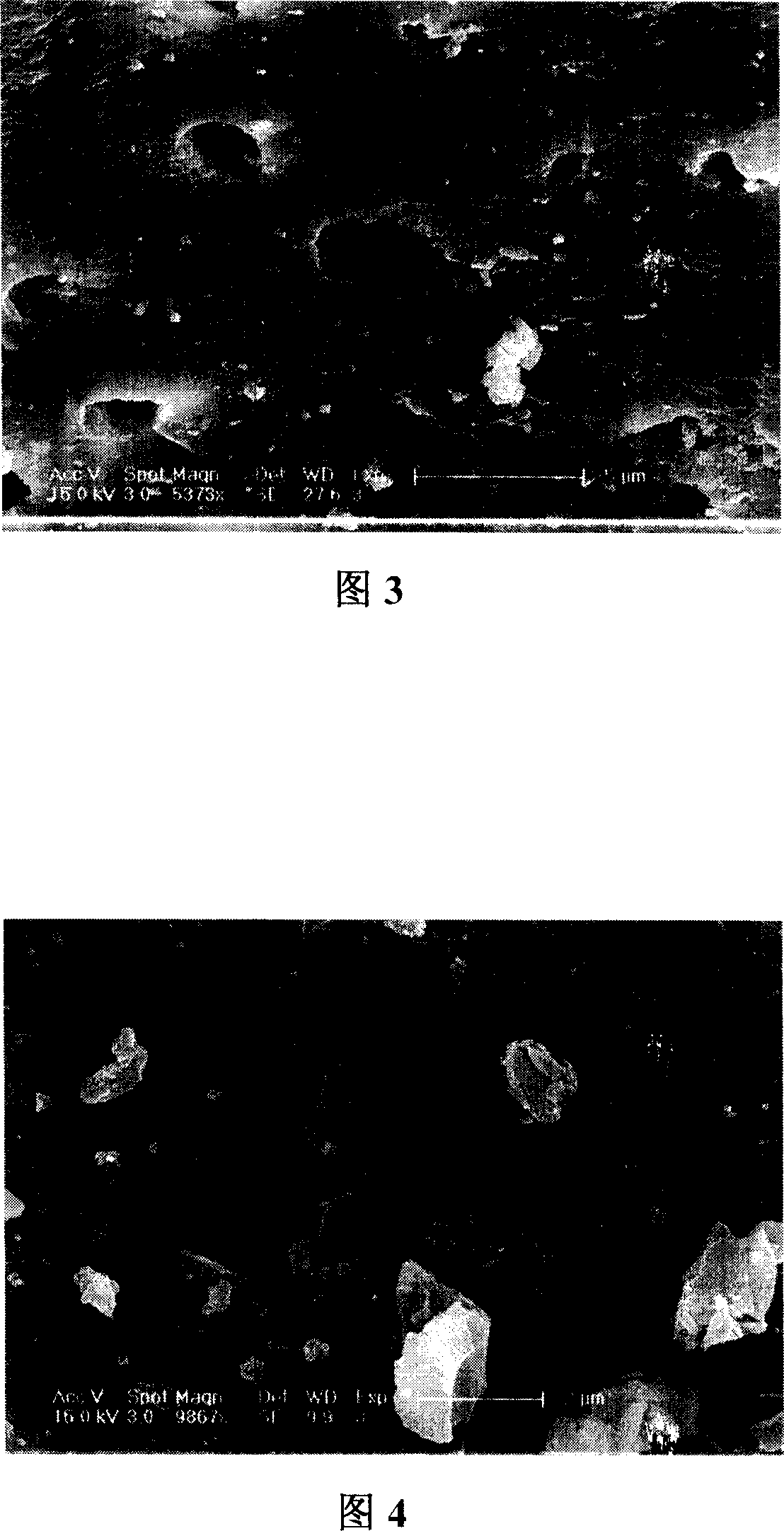

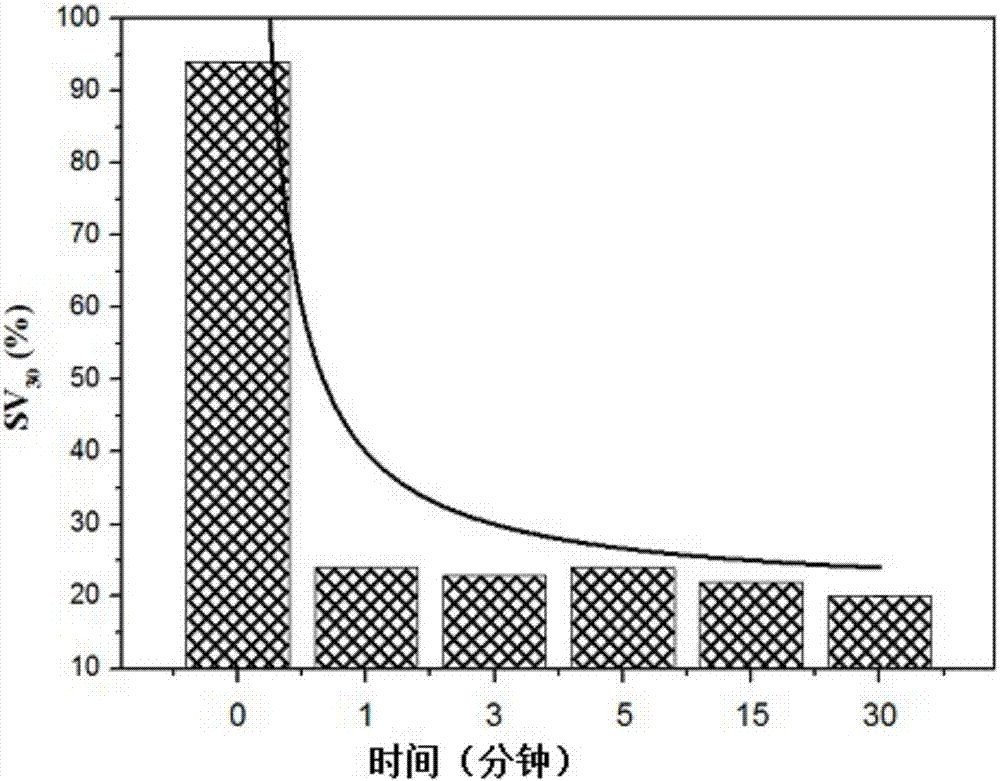

Method for preparing embedding ion liquid and neutral phosphor (phosphine) extractant composite material and its use

InactiveCN1936034ADoes not change the structureStay chemically activeSolvent extractionProcess efficiency improvementPhosphorRare earth

The invention relates to making method for compound material of entrapment iron liquid and neutrality phosphor extraction agent. The compound material is made up from fixing iron liquid and neutrality phosphor extraction agent into silicons, titania or alumna inorganic network to form a new type organic-inorganic hybridization material. And the iron liquid is 1, 3-dialkyl imidazole salt that the anion section is fluoboric acid radical and fluorophosphoric acid radical. The neutrality phosphor extraction agent is the compound that the three hydroxyls in orthophosphoric acid molecule are fully be replaced or esterified. The method could shorten reaction time. It could be used to effectively separate yttrium and heavy rare earths, and could be recycled.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

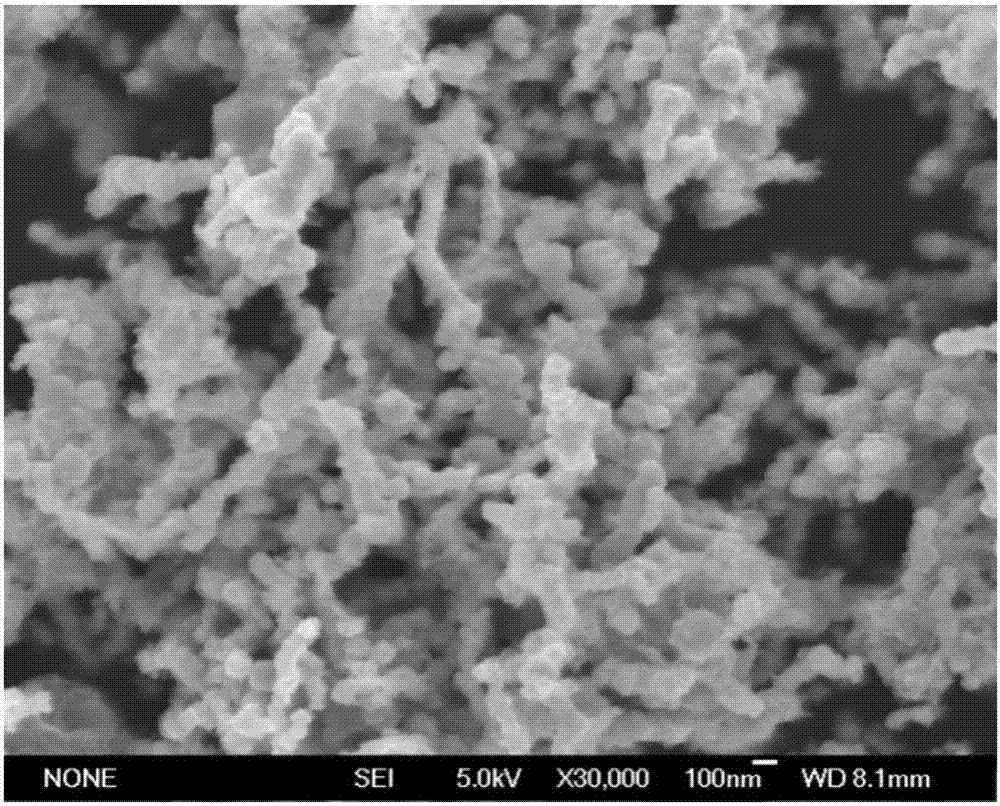

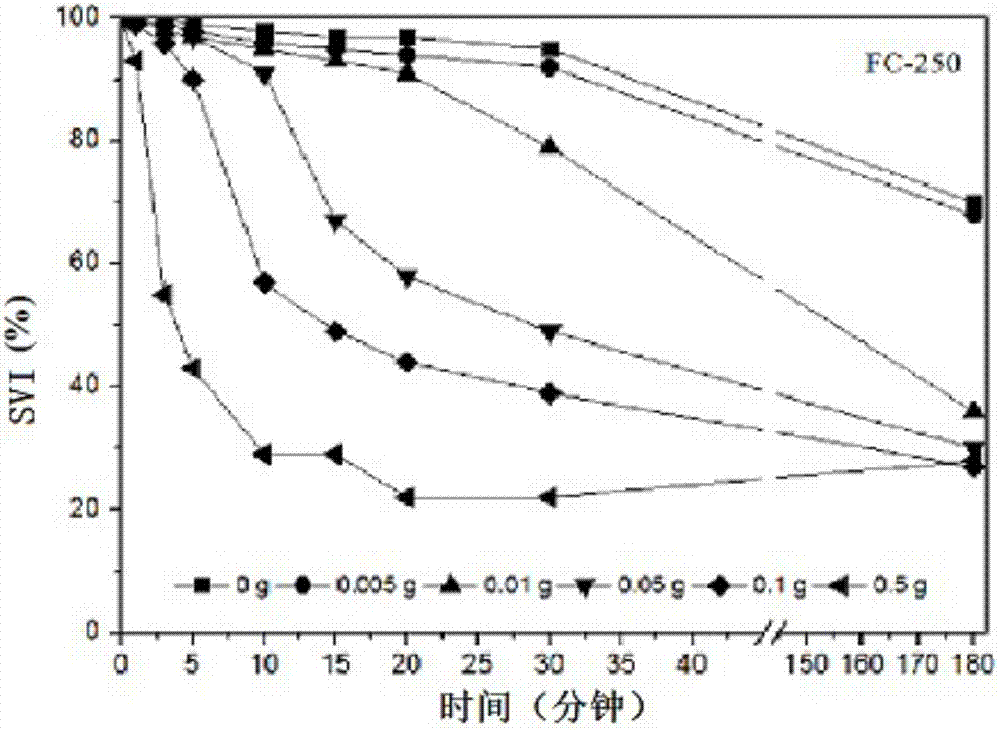

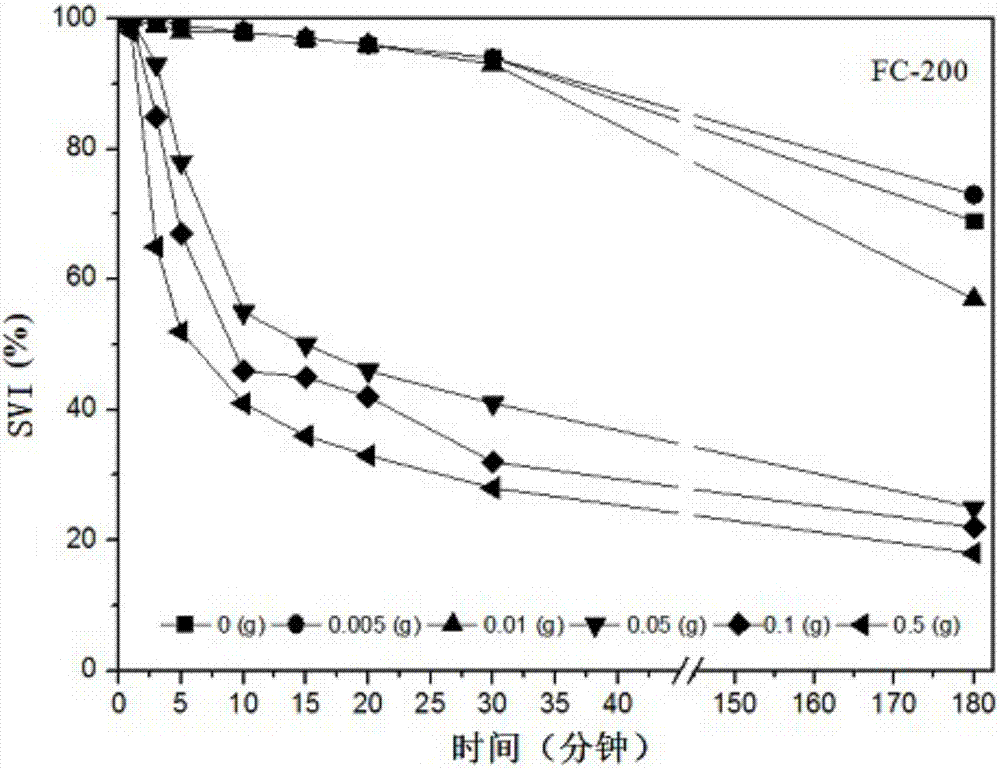

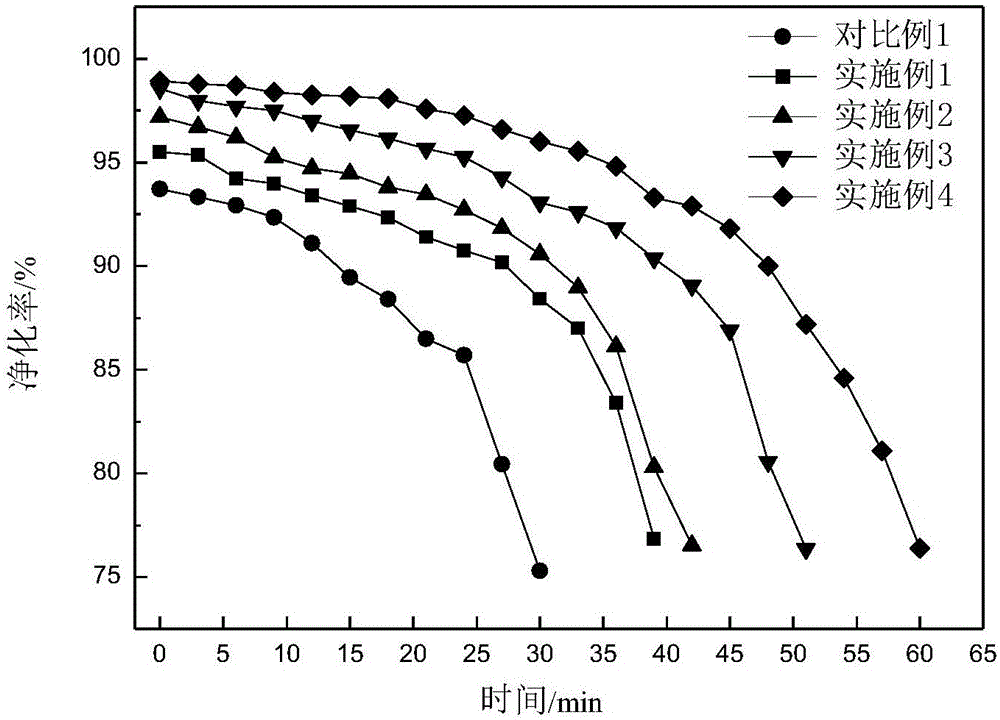

Broad-spectrum biochemical sludge bulking control chemical and preparation method

ActiveCN107176701AQuick resultsNo secondary pollutionSludge treatmentBiological water/sewage treatmentBiocompatibility TestingElectron

The invention discloses a broad-spectrum biochemical sludge bulking control chemical and a preparation method and belongs to the technical field of biochemical sewage treatment. The chemical is prepared from an iron ion salt solution, activated carbon and graphene which are reacted with an alkali solution, and a final component includes a mixture of iron oxide, activated carbon and graphene. The chemical smartly combines an efficient graphene electron conduction function, biocompatibility of activated carbon, electron neutralization of iron ions and a flocculation function; and in addition, the chemical takes the advantages of functions such as magnetic attraction and self gravity compression of the iron oxide, multiple functions are applied to sewage bulking control, and thus the chemical has the advantages of being rapid in effect taking, free of secondary pollution, long-lasting in inhibition function, good in broad-spectrum property and the like.

Owner:NANJING UNIV YANCHENG ENVIRONMENTAL PROTECTION TECH & ENG RES INST +1

Novel adsorbent used for purifying volatile organic waste gas

ActiveCN106552580AImprove adsorption capacityAdjustable dosageGas treatmentOther chemical processesMolecular sieveSorbent

The invention belongs to the technical field of environmental protection, and particularly relates to a novel adsorbent-modified sepiolite base molecular sieve used for purifying volatile organic waste gas and a preparation method and application thereof. Modified sepiolite serves as the base material of the adsorbent and can be used for purifying industrial organic waste gas. The preparation method of the novel volatile organic compound adsorbent provided by the invention includes the steps that the sepiolite is ground into powder particles and then is acid-activated; and an inorganic binder solution is added to be evenly stirred so that a mixture can be obtained, the mixture is aged to be squeezed to be of a granular or honeycomb structure, and the novel volatile organic compound adsorbent can be prepared by means of solidifying and roasting. The novel volatile organic compound adsorbent prepared through the method is used for purifying the industrial organic waste gas, the method for solving the VOCs pollution problem is provided, and meanwhile the rich sepiolite resources in China can be efficiently utilized.

Owner:SHANGHAI LANBAO ENVIRONMENTAL PROTECTION TECH CO LTD

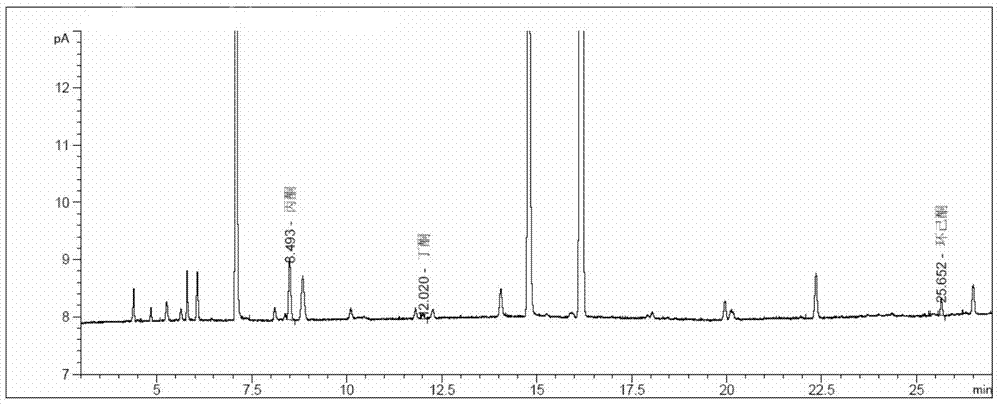

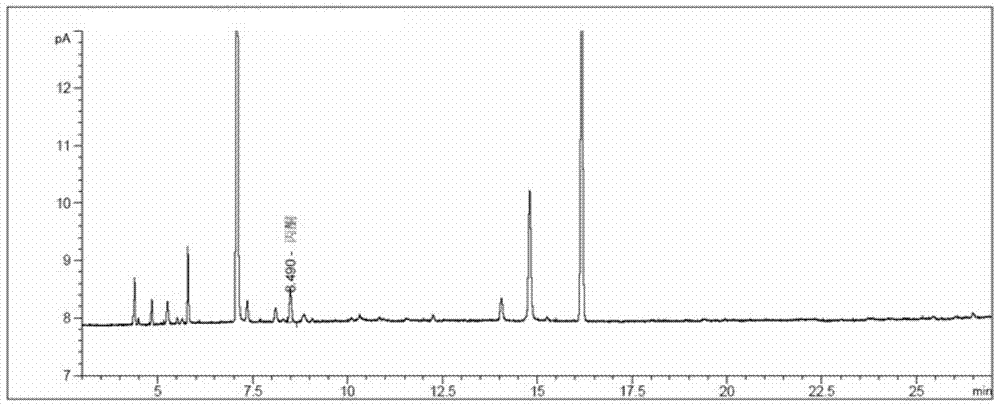

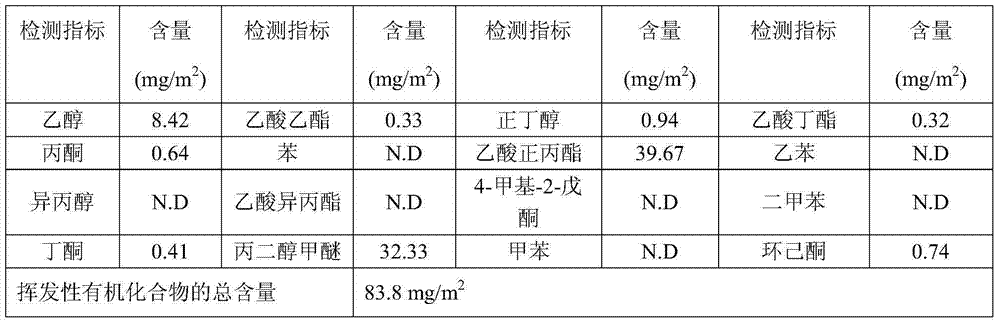

Ketone-removing additive for removing ketone substances from packaging card paper and application of additive

ActiveCN103882766AEasy to removeExcellent selective elimination effectDefoamers additionNon-macromolecular organic additionPropanoic acidPtru catalyst

The invention discloses a ketone-removing additive for removing ketone substances from packaging card paper, and application of the additive. The ketone-removing additive comprises organic amine and a catalyst, wherein the organic amine is one or more of ethanediamine, propane diamine, butanediamine, ethanolamine, guanidine and dimethyl biguanide; the catalyst is one or more of acetic acid, propionic acid, citric acid and malic acid; the mass ratio of the organic amine to the catalyst is 1.5: 1 to 2.5: 1. The ketone-removing additive is added into a water dispersible coating solution containing acrylic resin at room temperature to obtain a water-based coating solution, wherein the mass percent of the ketone-removing additive in the coating solution is 0.5%-5.0%. The water-based coating solution is used for removing the ketone substances from the packaging card paper. An experiment shows that the water-based coating solution can be used for effectively removing the ketone substances from the packaging card paper. The water-based coating solution is low in production cost, cannot change the structure and the characteristics of the paper in a ketone removing process, and cannot influence the subsequent processing process of the packaging card paper.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

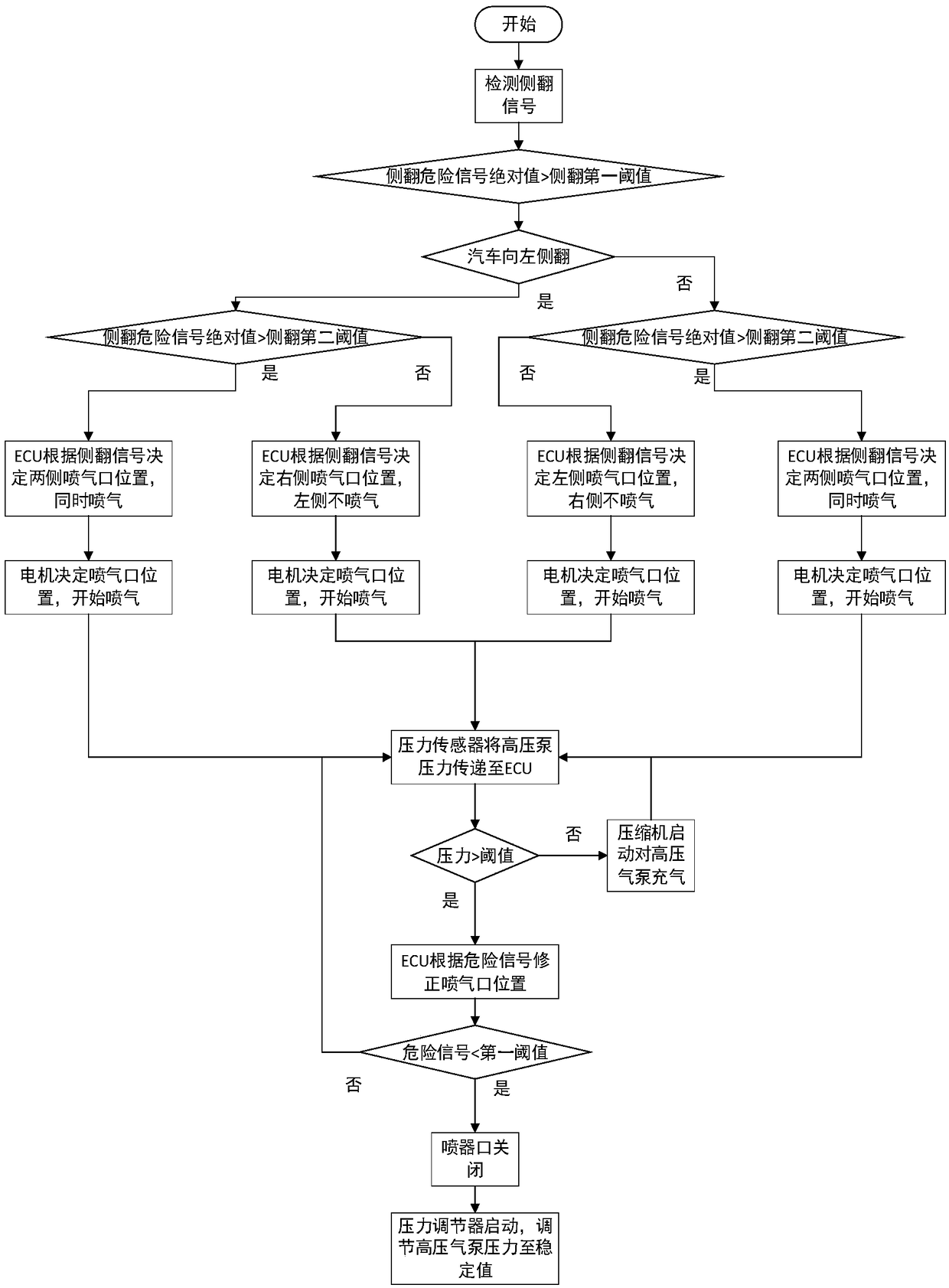

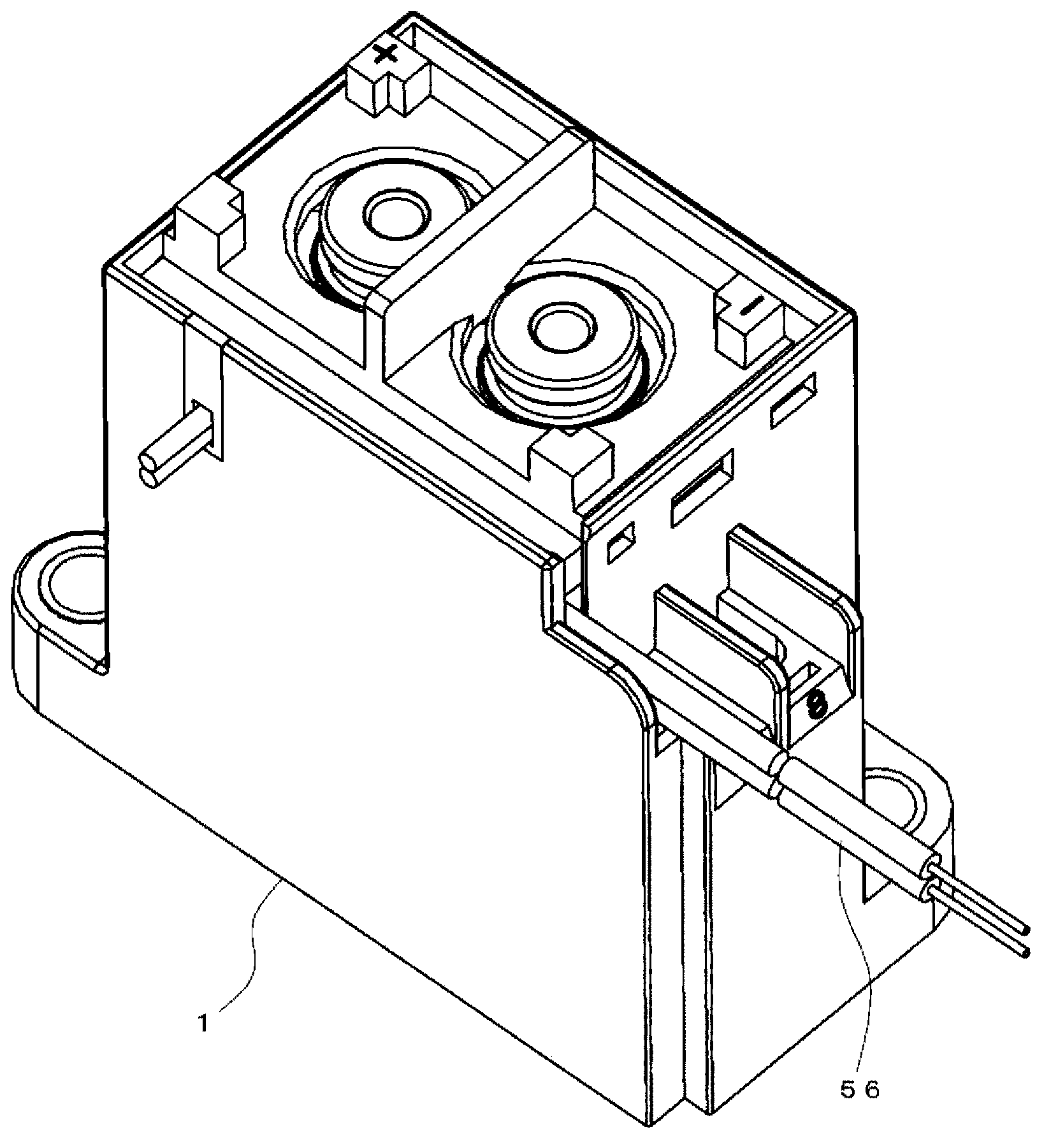

Angle-adjustable air-spray anti-rollover device and method

PendingCN108891492ASimple structureEasy to installVehicle body stabilisationPedestrian/occupant safety arrangementRolloverActive safety

The invention discloses an angle-adjustable air-spray anti-rollover device and a method and belongs to the technical field of vehicle active safety. The device comprises a compressor, a left air sprayport, a right air spray port, a left universal ball joint, a right universal ball joint, a left vertical guide rail, a right vertical guide rail, a left high pressure air pump, a right high pressureair pump, a left control motor and a right control motor. According to the device, the air spray ports can achieve multi-angle air spray at different positions of the guide rails according to a rollover danger signal, anti-rollover torque is formed, the device can work under different modes according to the rollover danger degree, and the anti-rollover effect is achieved. The invention further discloses the adjustment method of the device. The device and method are suitable for vehicles of different types, the device is simple in structure, the air spray effect can be adjusted in real time when the rollover danger occurs, the danger of rollover of the vehicles is reduced, the safety of the vehicles can be improved, and the driving stability of the vehicles is guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

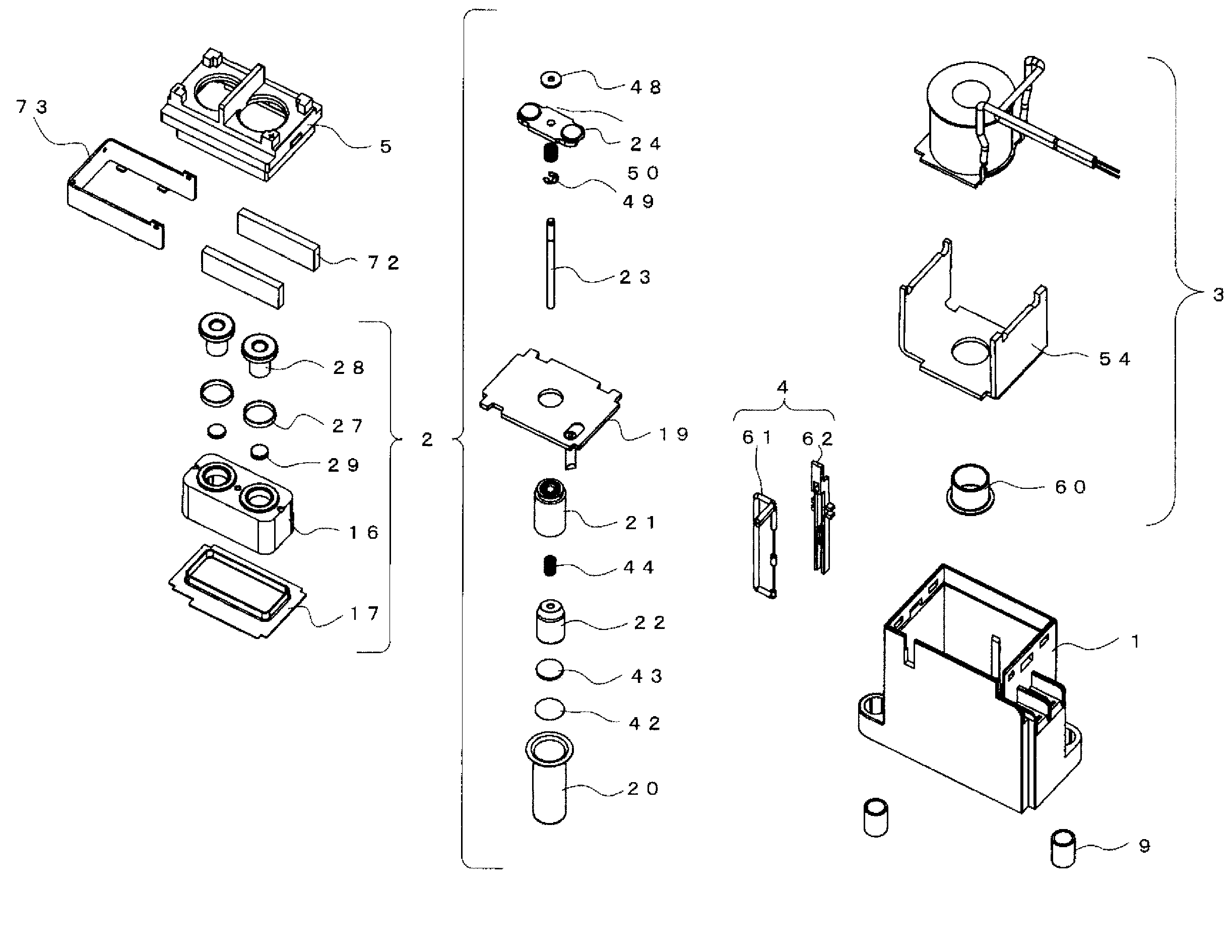

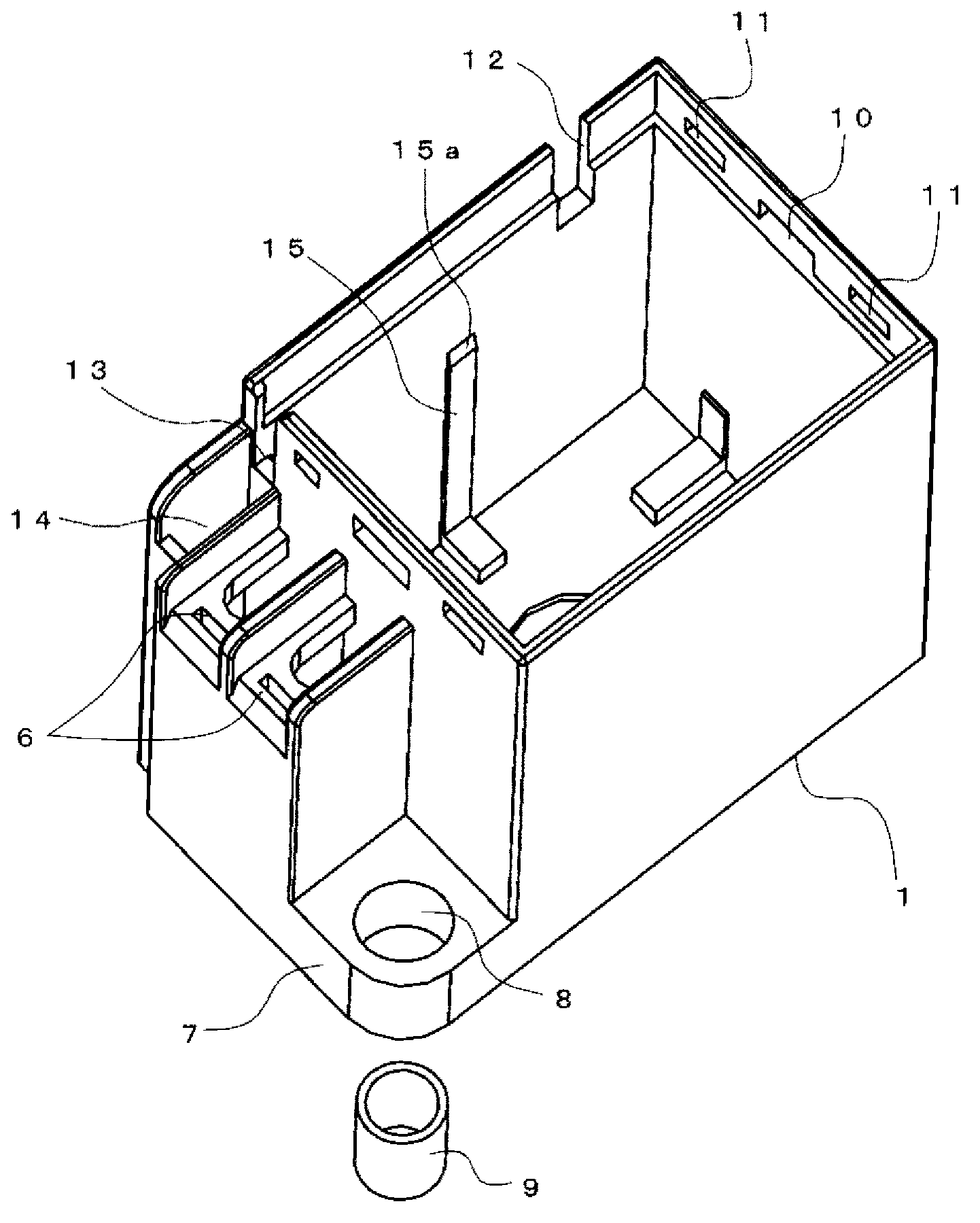

Electromagnetic relay and reed switch attachment structure

ActiveCN103282994AEfficient use ofDoes not change the structurePermanent magnet reed switchesElectromagnetic relay detailsEngineeringMechanical engineering

In a box shaped case (1) having an opening part on one surface is housed an electromagnet unit (3) wherein a coil (53) is wound on the outer periphery of a spool (52) having a cylindrical shaped body section (52c) and a yoke is connected to one end part of a stationary iron core (21) disposed on the inner periphery thereof. Part of a magnetic circuit is formed by the stationary iron core (21) and the yoke by applying voltage to the coil (53). A reed switch (61) is disposed along the winding part of the coil (53) parallel to the axial direction of the electromagnet unit (3).

Owner:ORMON CORP

Preparation process of blood-sugar-reducing and lipid-lowering potentilla discolor medicinal granules

InactiveCN103054971AEasy to operateReduce extraction timeMetabolism disorderAntinoxious agentsDrugWater soluble

The invention discloses a preparation process of blood-sugar-reducing and lipid-lowering potentilla discolor medicinal granules, which belongs to the field of processing of Chinese herbal medicine dietary therapy health-care products. The process comprises the steps of preparation of medicinal material extracts and the medicinal granules. The process is simple, easy to operate and low in cost, and can ensure that medicinal ingredients can be effectively maintained without being lost. The potentilla discolor extractant prepared by the method is high in water solubility and tasty and refreshing to drink, and as a new source food and a health-care product, the health-care medicinal granules without any additive and with effects of natural herbal medicines has high application and development values and wide market prospect.

Owner:HENAN UNIV OF SCI & TECH

Mechanical type starting device for agricultural machinery

ActiveCN106677950AReduce labor intensityAvoid injuryPower operated startersMachines/enginesAgricultural engineeringUltimate tensile strength

The invention discloses a mechanical type starting device for agricultural machinery. The mechanical type starting device comprises a base plate, a controller and an accumulator, wherein the controller and the accumulator are fixed to the upper surface of the base plate. A supporting rod is fixed to the upper surface of the base plate. A circular ring shell body is fixed to the top of the supporting rod. The interior of the circular ring shell body is connected with a connection sleeve through bearing. The connection sleeve is in a hollow structure. A plurality of limiting structures are arranged in the interior, located at the hollow structure, of the connection sleeve. A baffle is fixed in the interior, located at the hollow structure, of the connection sleeve through the limiting structures. The electromagnetic principle and the connecting rod principle are combined, less electric power is utilized to conduct a starting effect on an engine of the agricultural machinery, and an agricultural machinery head is started in a full-automatic mode, so that the labor intensity of labor personnel is reduced; and furthermore, after the agricultural machinery head is started, a contact part with the agricultural machinery can be led out automatically, so that occurring of a people hurting incident is prevented, and the mechanical type starting device does not change the structure of the agricultural machinery.

Owner:南京游有方智能科技有限公司

Antistatic melt-sprayed composite antibacterial nanofiber non-woven fabric and preparation method thereof

InactiveCN110960925AHas antibacterial and antistatic propertiesAchieving weak electrical conductivityDispersed particle filtrationMembrane filtersSpinningElectrospinning

The invention discloses a preparation method of an antistatic melt-sprayed composite antibacterial nanofiber non-woven fabric. A composite non-woven fabric layer with the gradient fiber diameter is prepared by adopting a method of combining electrostatic spinning and melt-sprayed spinning. Meanwhile, an antistatic agent and an antibacterial agent are added into a melt-sprayed material, and an antibacterial agent is added into an electrostatic spinning solution. By controlling the thickness of the melt-sprayed non-woven fabric and the thickness of the electrostatic spinning fiber layer, the composite melt-sprayed non-woven air filtering material which is antibacterial, antistatic and efficient in filtering is prepared. The technology is simple and easy to implement, the filtering performance of the polypropylene melt-sprayed non-woven fabric is improved, and meanwhile, the filtering material is endowed with antibacterial and antistatic performance.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

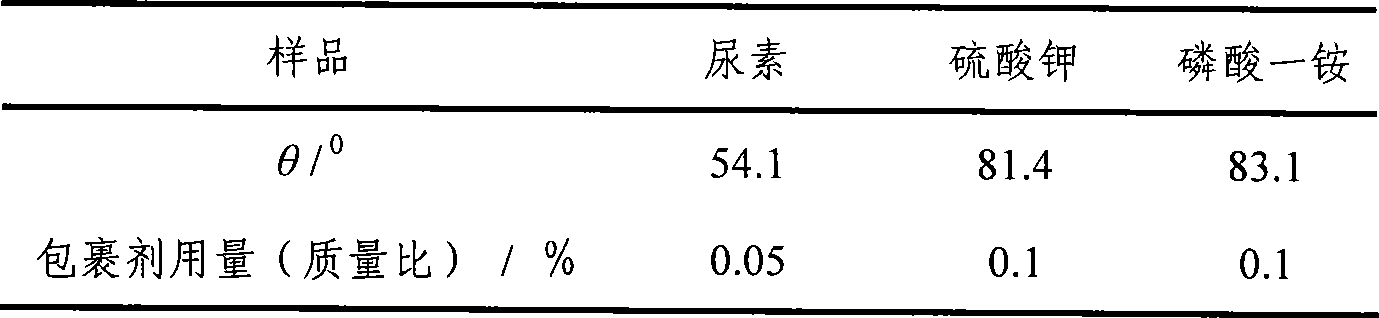

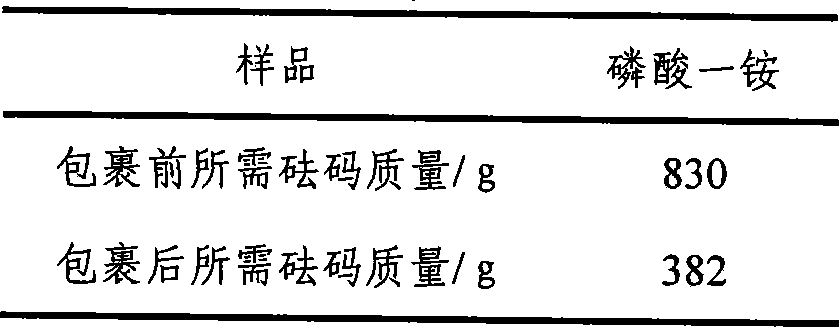

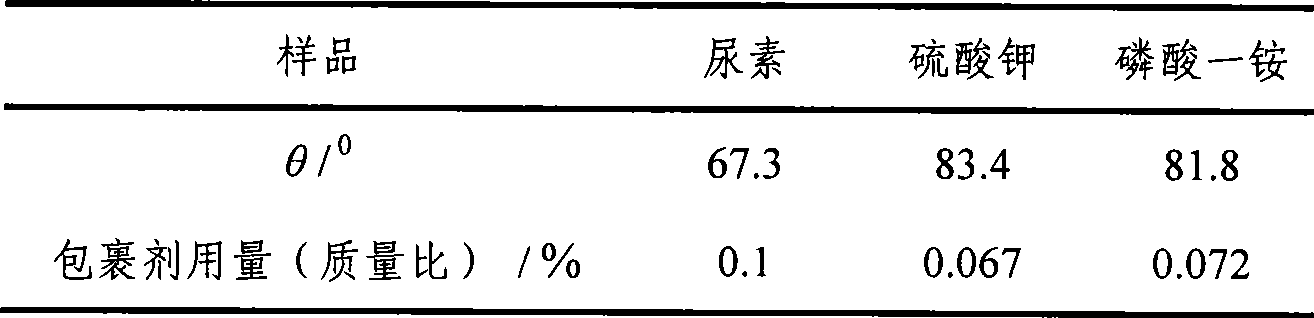

Technique for packing flue gas on surface of powder

InactiveCN101485967AEasy to wrapReduce dosageGranulation by powder suspensionCoatingsCombustionBoiling point

The invention discloses technology for coating fume on the powder surface. The technology comprises that: oil compounds, or oil gas without complete combustion, or organic compounds or solution with high boiling point are heated for boiling or fuming, the generated vapor or fume is made to fumigate the solid powder, so that a coating membrane at the molecular level is formed on the surface of the solid powder; or the oil is incompletely combusted, the generated carbon black and fume coats the surface of the powder material. The organic compounds used for heating to generate the vapor or the fume are compounds with the boiling point of between 150 and 350 DEG C such as multi-carbon ethanol, multi-carbon carboxylic acid, multi-carbon amine, multi-carbon hydrocarbon or halogenated hydrocarbon or compound of the multi-carbon ethanol, multi-carbon carboxylic acid, multi-carbon amine, multi-carbon hydrocarbon or halogenated hydrocarbon. The use level of the coating agent is less than 0.1 percent. The method has the advantages of conveniently carrying out coating operation of the powder, and effectively achieving the aim of changing surface properties and making the powder not agglomerated without changing the composition and property of the powder; moreover, the method can carry out the coating operation of any powder in principle, particularly suitable for prevention of agglomeration of fertilizer powder products.

Owner:GUIZHOU UNIV

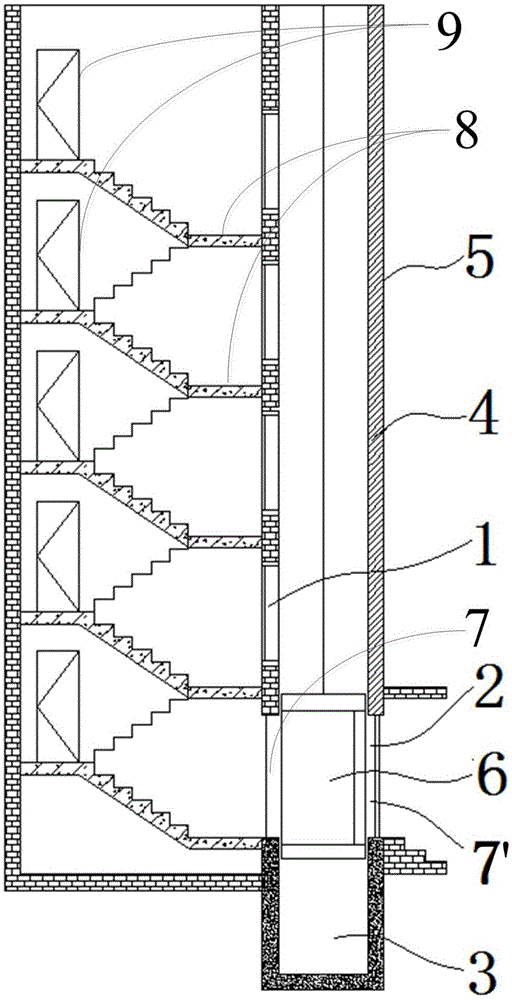

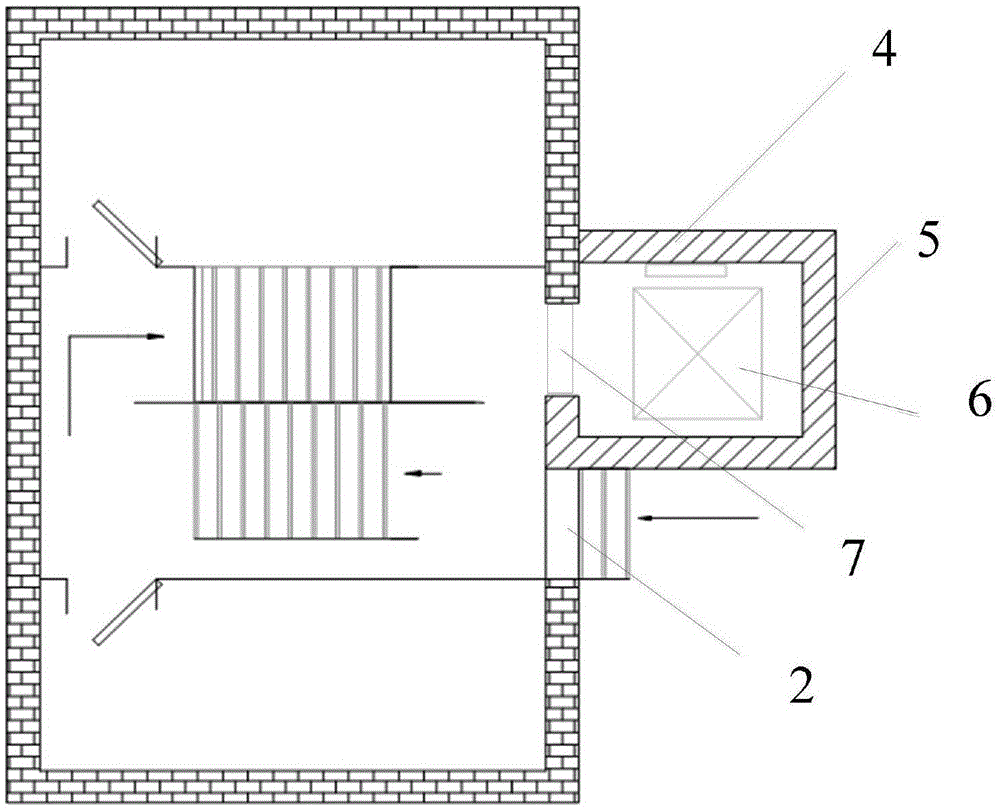

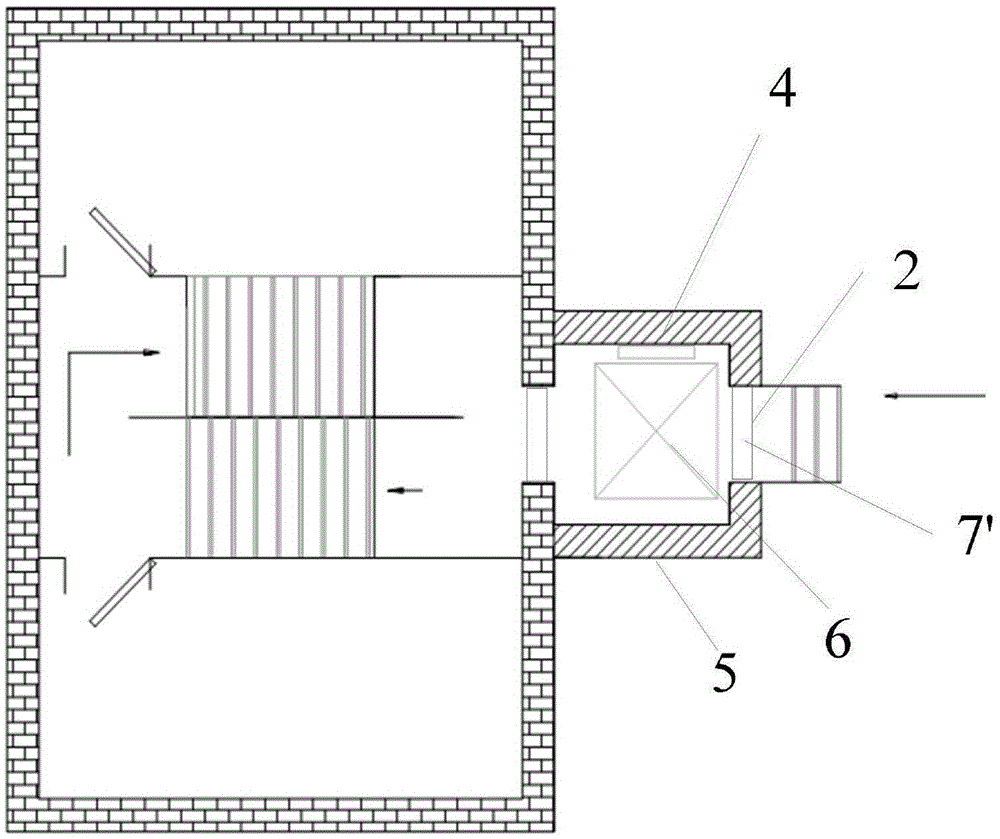

Method for adding elevator in existing building

InactiveCN105525762AMode of operation is reasonableConvenient travelBuilding repairsAgricultural engineeringSteel frame

The embodiment of the invention provides a method for adding an elevator in the existing building. The method comprises the following steps: selecting an outer building wall at the scissors stair platform of the existing building as an elevator shaft mounting position, mounting an elevator shaft base at the bottom of the mounting position, erecting a steel frame structure above the elevator shaft base, and mounting an elevator car in the steel frame structure. The method does not affect the normal life of existing residents and can also realize the transportation function of the elevator.

Owner:BEIJING ANTAI HONGYUAN ELEVATOR DESIGN

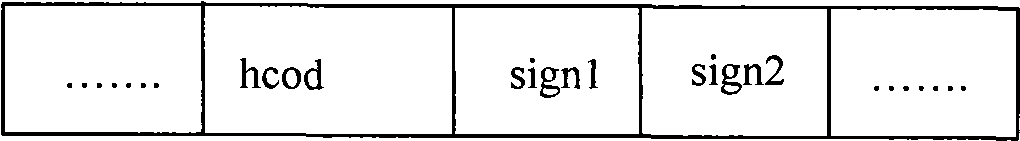

VFTO protection device and method for transformer in GIS substation

InactiveCN104158163AWide range of applicationsSteep dropEmergency protective arrangements for limiting excess voltage/currentLightning arresterTransformer

The invention provides a VFTO protection device and method for a transformer in a GIS substation. The protection device comprises a lightning arrester, a capacitor, a discharging coil, a switch and a fuse, a series connection branch circuit composed of the fuse and the capacitor is connected to the two ends of the lightning arrester in parallel, and the fuse is located between the capacitor and the circuit; a discharging branch circuit composed of the discharging coil and the switch in a series connection mode is connected to the two ends of the capacitor C in parallel. According to the protection method, parameters of the capacitor C are obtained through calculation of the principle of the circuit wave process. Through the VFTO protection device and method for the transformer in the GIS substation, the substation having been put into operation does not need to change too much, the VFTO amplitude and steepness can be effectively suppressed, longitudinal insulation of the transformer is protected, and the VFTO protection device is convenient to install and high in working reliability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

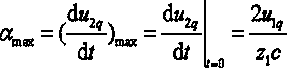

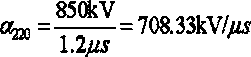

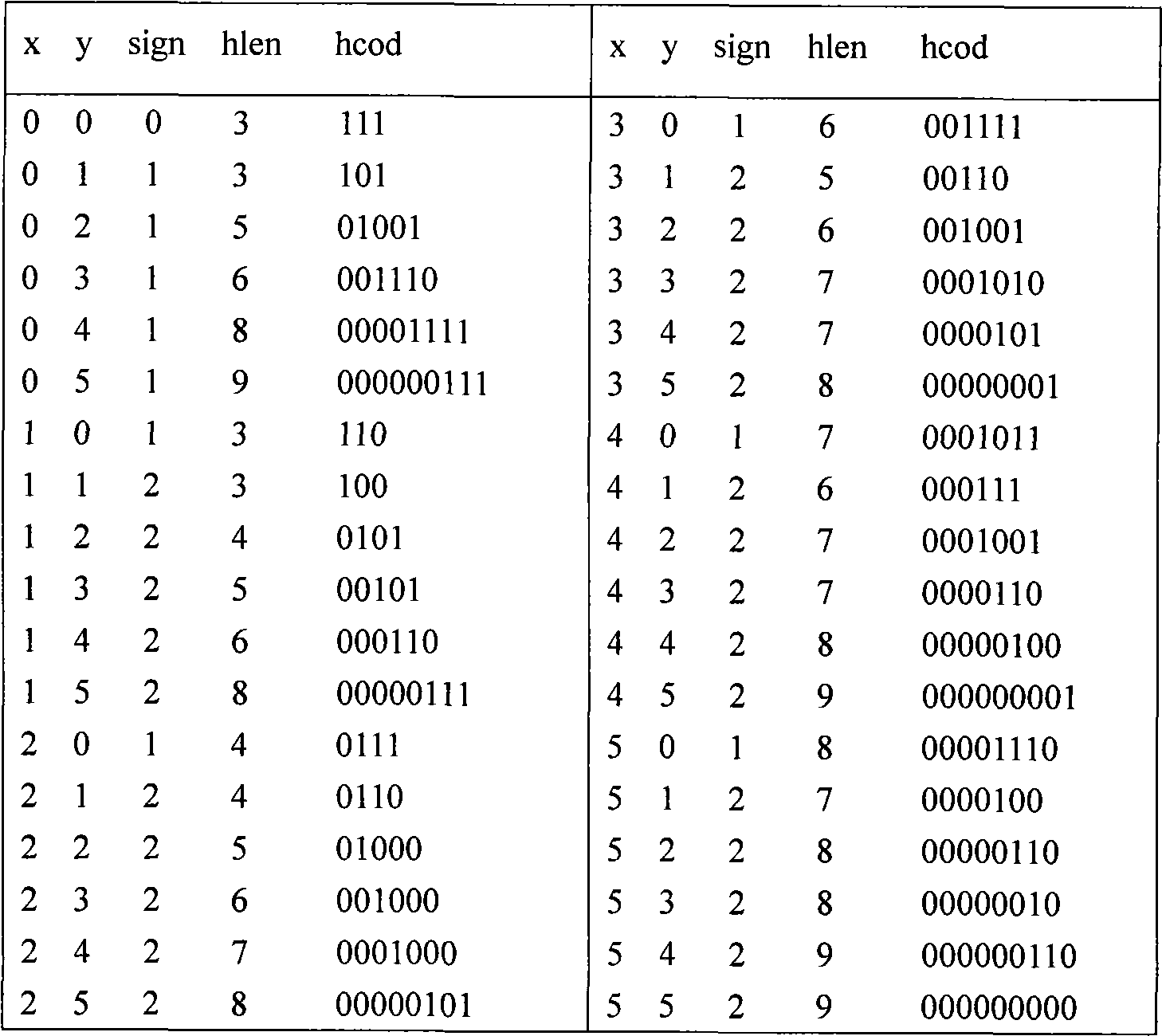

Method for secretly writing and extracting secret information of compressed digital audio

InactiveCN101546559ALarge steganography capacityMultiple steganography capacitySpeech analysisComputer hardwareSign bit

The invention discloses a method for secretly writing and extracting secret information of compressed digital audio, which is characterized by classifying all code words in each Huffman code table layer upon layer, then determining the base of all effective code words, and secretly writing data according to the base of the effective code words, wherein the base is larger, the amount of secretly written information is more, thus the secret writing capacity of the method is far larger than that of the prior binary mode secret writing method of which the base is 2; and selecting variable long code words of main data as objects for secretly writing the secret information, and achieving the modification of the variable long code words by replacing attributes corresponding to the long code words so that the code word length and the sign bits of the variable long code words after the modification can be kept unchanged with that of original variable long code words, thus the structure of an original audio code stream is not changed after secretly writing the secret information so as to avoid the problems of increasing the coding bit rate and changing the file length of the whole digital audio caused by secret writing operations, and effectively ensure the security for secretly writing the secret information.

Owner:NINGBO UNIV

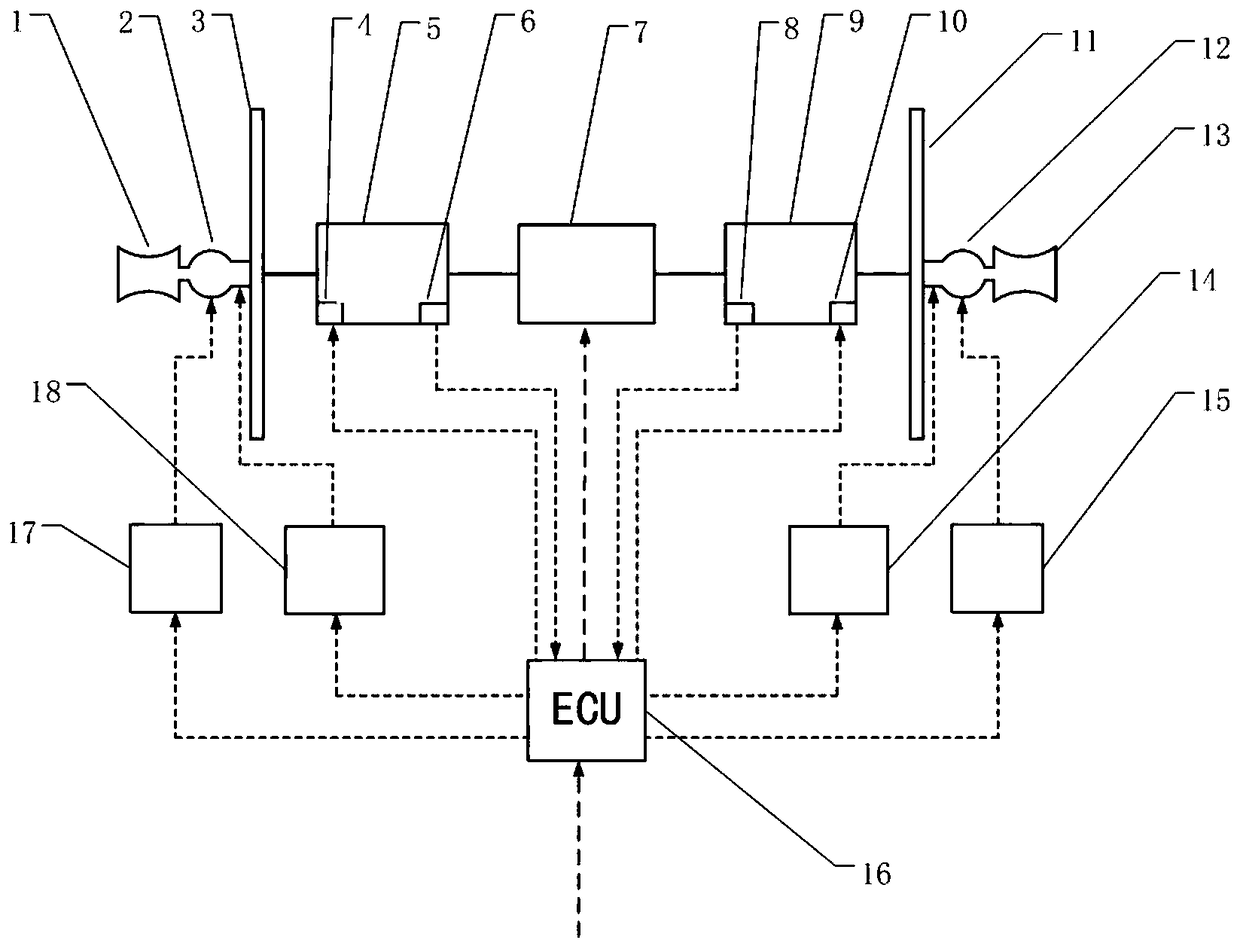

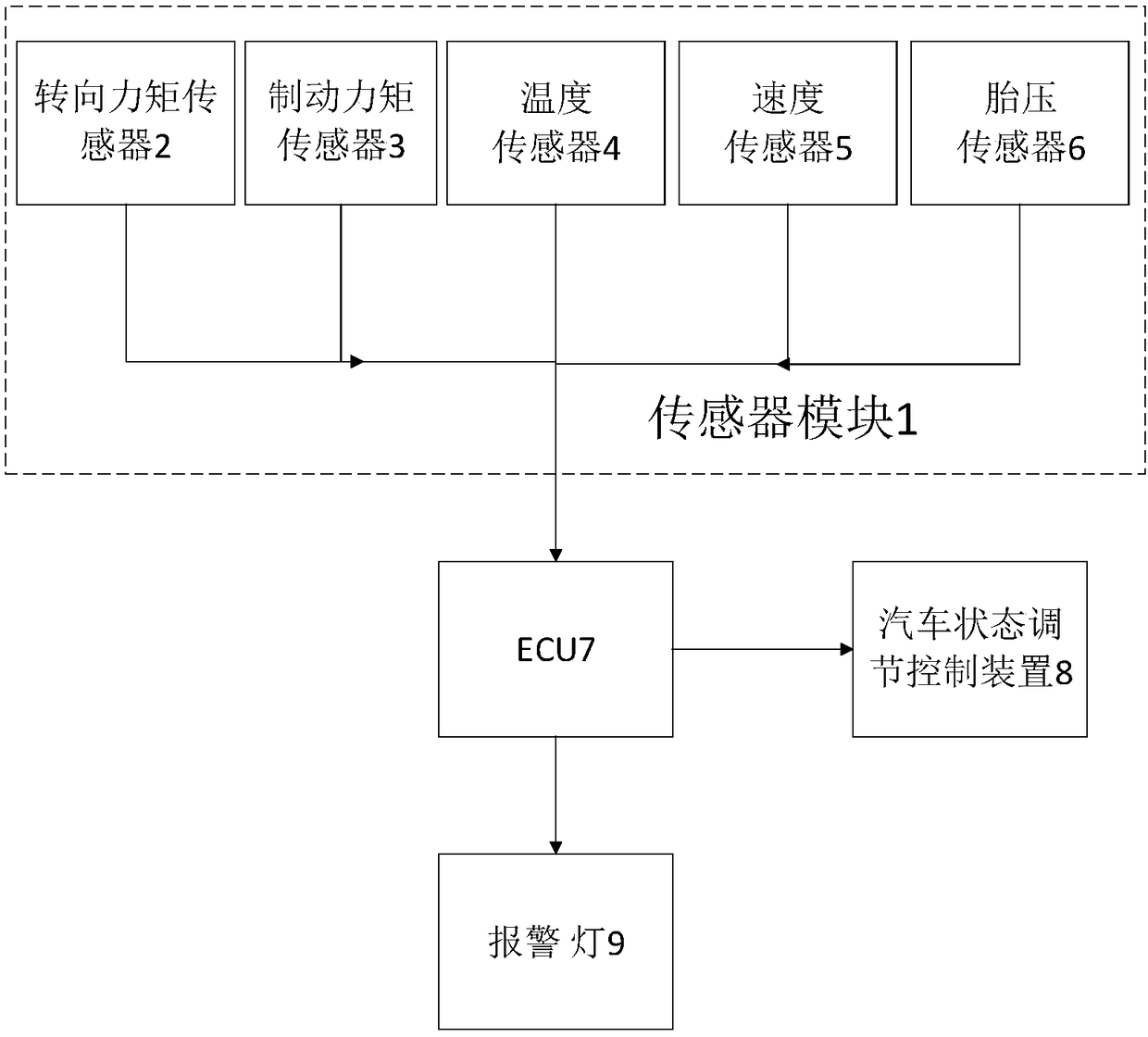

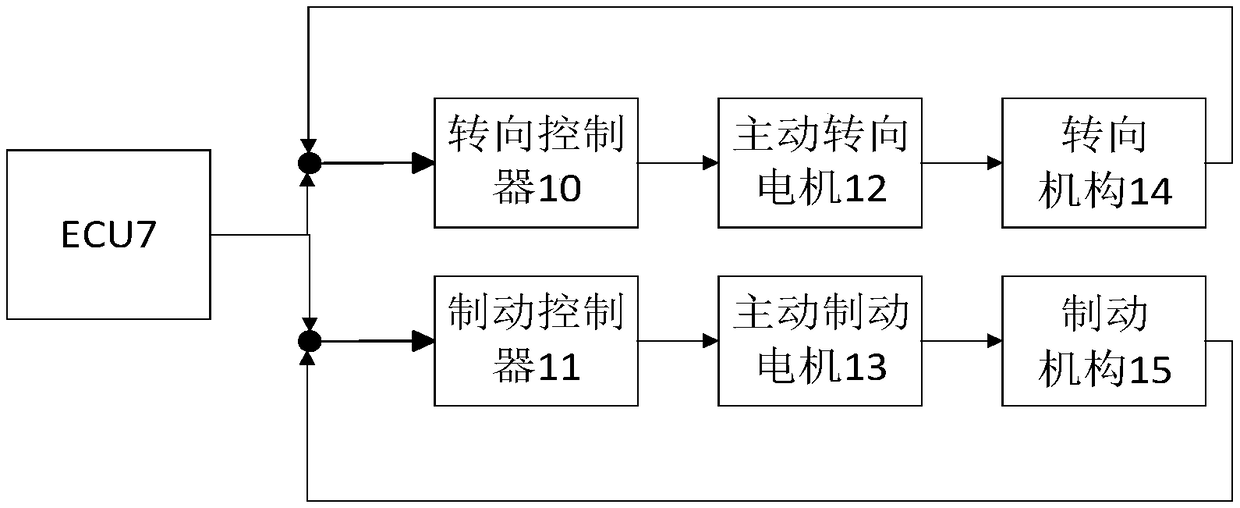

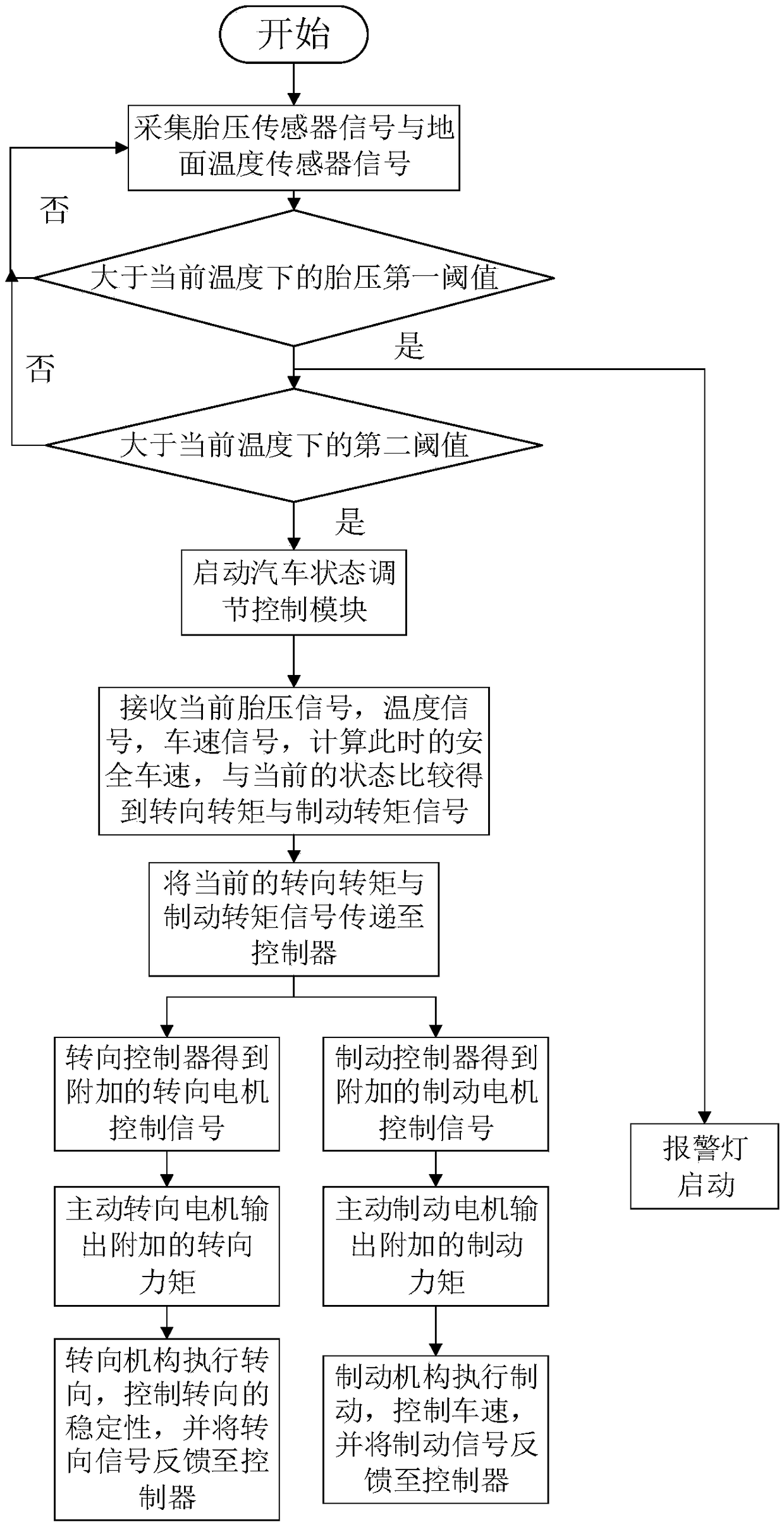

Adjusting device and method for preventing automobile instability due to high-temperature tire bursting

PendingCN108638763ATo achieve the adjustment effectPrevent tire blowoutAnchor handling/lashingTyre measurementsElectricityElectronic control system

The invention discloses an adjusting device and method for preventing automobile instability due to high-temperature tire bursting and belongs to the field of electronic control systems of automobilesafety. The adjusting device comprises a sensor module, an electronic control unit, an automobile state adjusting device and an alarm lamp. Through information exchanging of electric signals between devices, quick response is conducted to change the automobile traveling state so as to change the air pressure of a tire. The original steering action of a driver can be kept, the automobile speed is decreased, the situation that due to the overlarge tire pressure, the driver conducts operating mistakenly and thus stability is lost is avoided, meanwhile the change amplitude of the automobile speedis small, and the traveling safety is guaranteed. The invention further discloses the adjusting method. According to the adjusting method, the tire pressure can be monitored in real time when an automobile travels at the high temperature, and according to the traveling environment, the traveling posture of the automobile is changed to control the tire pressure of the automobile so as to prevent the automobile instability due to tire bursting.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com