Antistatic melt-sprayed composite antibacterial nanofiber non-woven fabric and preparation method thereof

A non-woven fabric, composite antibacterial technology, applied in the field of non-woven materials, can solve the problems of increasing production process, generating energy consumption, reducing the filtration and air permeability of composite filter materials, and achieving the effect of saving energy consumption and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

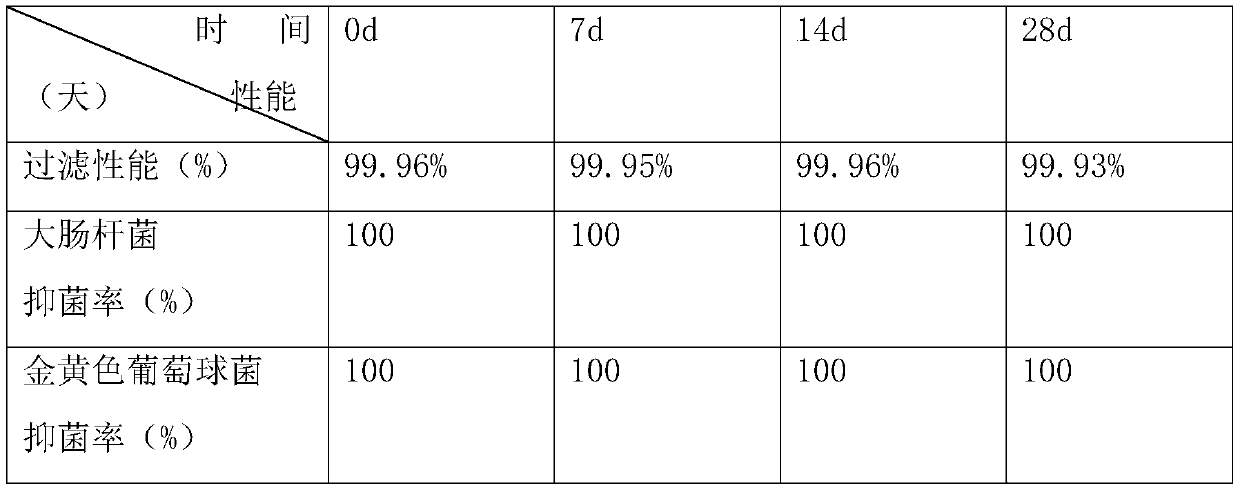

Embodiment 1

[0025] Embodiment 1, a kind of preparation method of antistatic melt-blown composite antibacterial nanofiber nonwoven fabric, carries out melt mixing, melt-blown spinning, solution mixing, electrospinning successively, promptly carries out following steps successively:

[0026] a) According to the mixing characteristics between nanoparticles and polypropylene, and the weak conductivity required by the electrospinning substrate, adding titanium dioxide particles with a mass fraction of 0.2% and 20nm to the polypropylene slice;

[0027] b) Process the meltblown fiber layer in the following order: drying→melt mixing→extrusion→air stretching→cooling and solidification→meltblown fiber layer;

[0028] c) adding silver particles with a mass fraction of 0.5% and 10nm in the polyvinylidene fluoride solution system;

[0029] d) using the meltblown fiber layer as the nanofiber receiving substrate in the electrospinning process;

[0030] e) Process the nanofiber layer as follows: solutio...

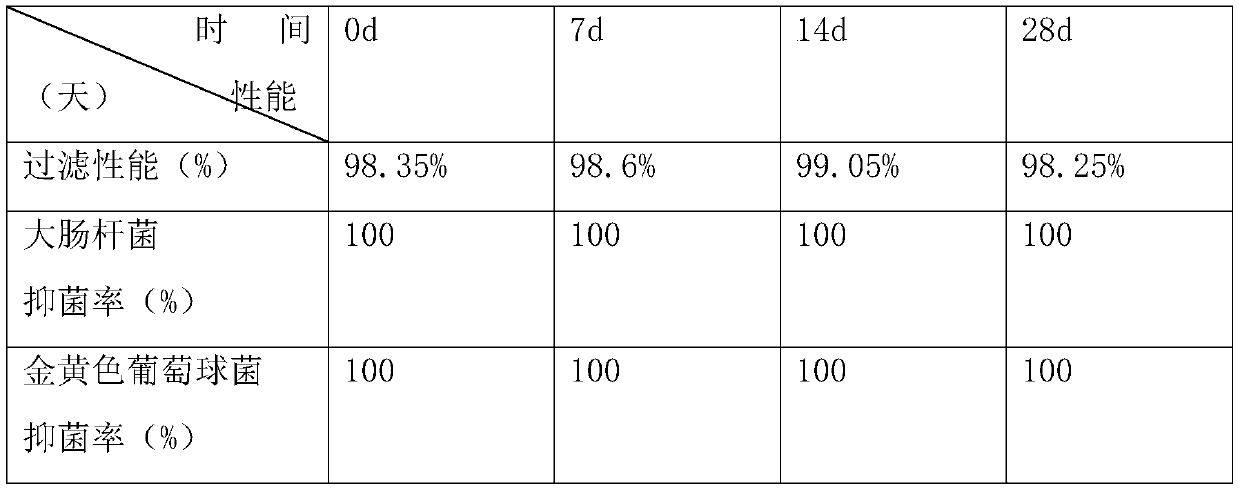

Embodiment 2

[0038] Embodiment 2, a kind of preparation method of antistatic melt-blown composite antibacterial nanofiber nonwoven fabric, carry out melt mixing, melt-blown spinning, solution mixing, electrospinning successively, promptly carry out the following steps successively:

[0039] a) According to the mixing characteristics between the nanoparticles and the polypropylene, and the weak electrical conductivity required by the electrospinning substrate, adding nano silver particles with a mass fraction of 0.2% and 20nm to the polypropylene slice;

[0040] b) Process the meltblown fiber layer in the following order: drying→melt mixing→extrusion→air stretching→cooling and solidification→meltblown fiber layer;

[0041] c) adding silver particles with a mass fraction of 0.5% and 10nm in the polyvinylidene fluoride solution system;

[0042] d) using the meltblown fiber layer as the nanofiber receiving substrate in the electrospinning process;

[0043] e) Process the nanofiber layer as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com