Antibacterial and antistatic TPU film material and preparation method thereof

A thin film material and antistatic technology, which is applied in the field of polymer material synthesis, can solve the problems of easy loss of silver, loss of antibacterial performance, poor compatibility, etc., and achieve the effect of improving dispersion, strong antistatic performance, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

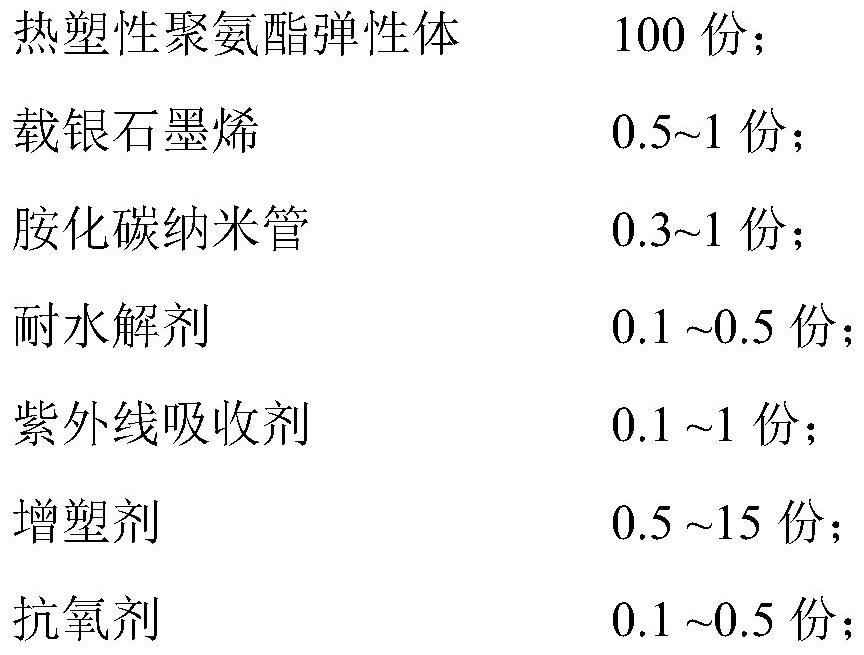

[0039] An antibacterial and antistatic TPU film material made of the following weights:

[0040]

[0041] Silver-loaded nano-graphene, the preparation method is as follows:

[0042] 1. Weigh graphene oxide, silane coupling agent KH-550, anhydrous ethanol and deionized water in turn, add them into the reaction flask and mix thoroughly, and disperse by ultrasonic; 2, the final product is processed to obtain silanized graphene oxide; wherein the feeding ratio of graphene oxide, silane coupling agent, absolute ethanol and deionized water is 3:0.48:42:14, the temperature of the silanization reaction is 62 ° C, and the reaction The time is 115min;

[0043] 2. AgNPs loaded on graphene surface: First, 500 mg of silanized modified graphene oxide was weighed and dispersed in 300 mL of stannous chloride solution with a concentration of 0.5 mmol / L for sensitization; then 80 mg of sensitized graphite oxide was taken. The alkene was ultrasonically dispersed in 1000 mL of absolute ethan...

Embodiment 2

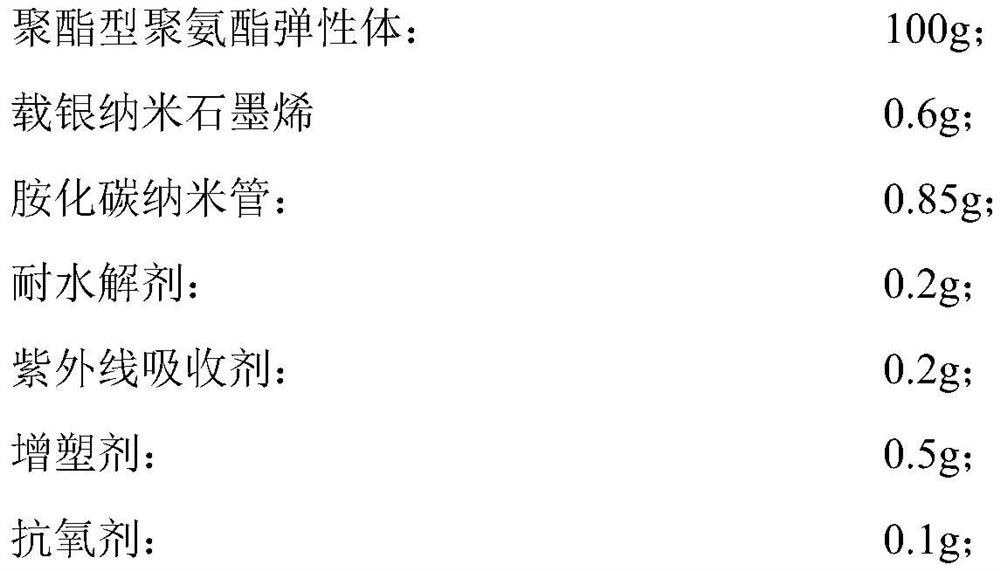

[0050] The preparation of an antibacterial and antistatic TPU film material is made of the following weights:

[0051]

[0052] The silver-loaded nano-graphene is prepared as follows:

[0053] 1. Weigh graphene oxide, silane coupling agent KH-570, absolute ethanol and deionized water in turn, add them into the reaction flask and mix thoroughly, and disperse by ultrasonic; 2 , the final product is processed to obtain silanized graphene oxide; wherein the feeding ratio of graphene oxide, silane coupling agent, absolute ethanol and deionized water is 3:0.5:44:15, the temperature of silanization reaction is 65 ℃, and the reaction The time is 120min;

[0054] 2. AgNPs supported on graphene surface: First, 500 mg of silanized modified graphene oxide was weighed and ultrasonically dispersed in 300 mL of stannous chloride solution for sensitization at a concentration of 0.5 mmol / L; then 80 mg of sensitized graphite oxide was taken. The alkene was ultrasonically dispersed in 1000 ...

Embodiment 3

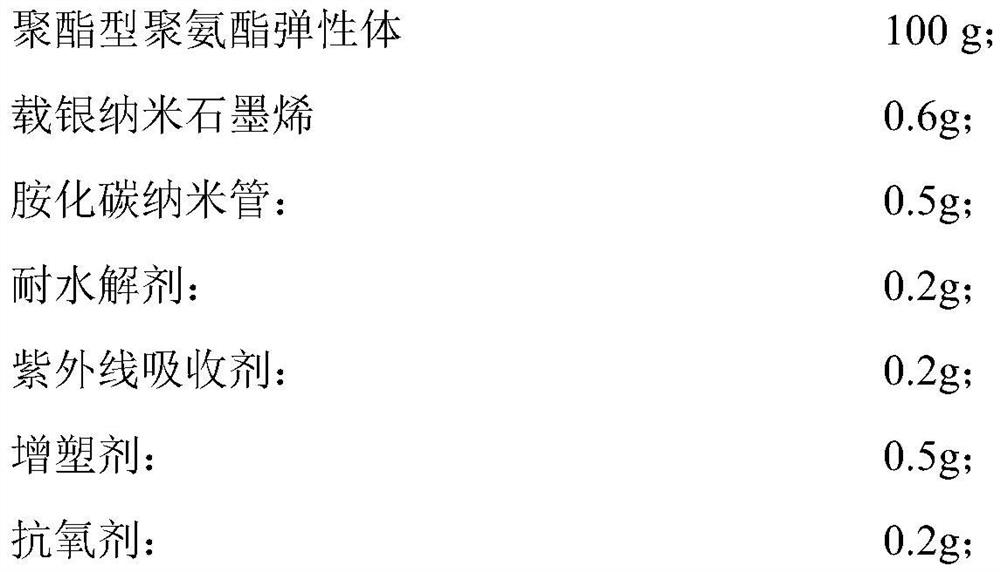

[0061] The preparation of an antibacterial and antistatic TPU film material is composed of the following weights:

[0062]

[0063]

[0064] Silver-loaded nano-graphene, the preparation method is as follows:

[0065] 1. Weigh graphene oxide, silane coupling agent KH-550, anhydrous ethanol and deionized water in turn, add them into the reaction flask and mix thoroughly, and disperse by ultrasonic; 2 , the final product is processed to obtain silanized graphene oxide; wherein the feeding ratio of graphene oxide, silane coupling agent, absolute ethanol and deionized water is 3:0.52:48:16, the temperature of silanization reaction is 68 ℃, and the reaction The time is 125min;

[0066] 2. AgNPs supported on graphene surface: First, 500 mg of silanized modified graphene oxide was weighed and ultrasonically dispersed in 300 mL of stannous chloride solution for sensitization at a concentration of 0.5 mmol / L; then 80 mg of sensitized graphite oxide was taken. The alkene was ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com