Technique for packing flue gas on surface of powder

A technology of wrapping and flue gas, which is applied to the device for coating liquid on the surface, special surface, powder suspension method granulation, etc. It can solve the problems that there is no flue gas wrapping powder surface technology, complex production process, etc., and it is not easy to achieve Volatility, strong hydrophobicity, effect of changing surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Using solid paraffin as a coating agent to wrap fertilizer powder

[0018] Test tube wrapping method: Add 10g of powder and measured paraffin into the test tube, keep it at a constant temperature of 90°C until all the paraffin is vaporized and evenly wrapped the powder, during which the paraffin must not be leaked. After cooling, samples were taken to measure the contact angle.

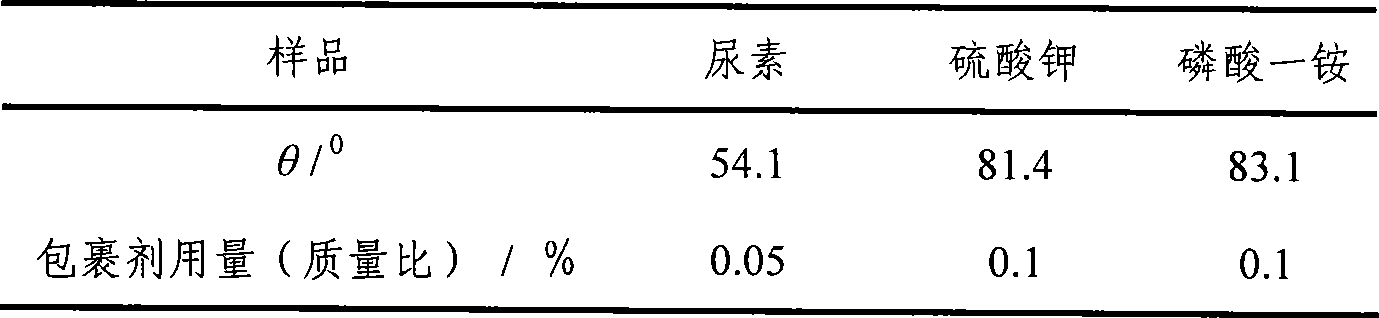

[0019] In the measurement of the contact angle of the Washburn dynamic method, the water is set to completely wet the surface of the uncoated powder, and the contact angle θ=0 0 , see Table 1 for the contact angles of the fertilizer product powders wrapped in liquid paraffin.

[0020] Table 1

[0021]

[0022] Under the conditions of enhanced caking test temperature of 24°C and relative humidity of 80%, the sample powder withstands about 710kg / m 2 Take out the sample after 24 hours; use a needle-shaped glass rod with a diameter of 2.16mm to measure the mass of the weight require...

Embodiment 2

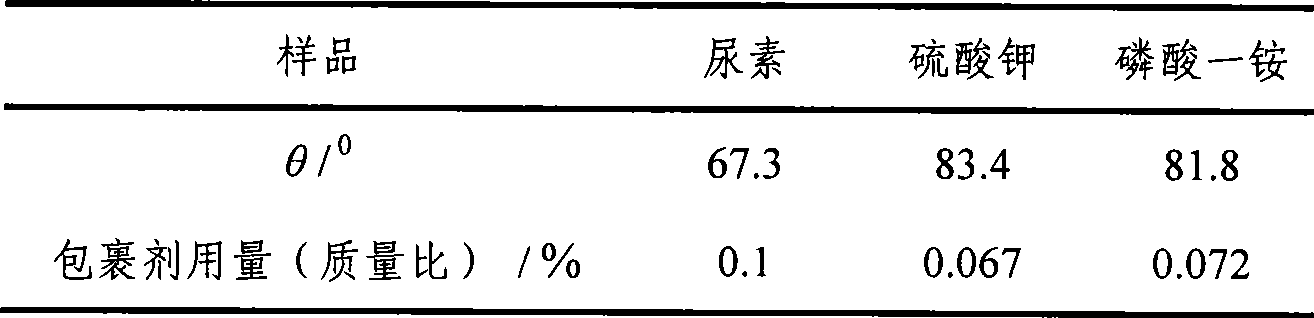

[0026] Example 2 Using Cetyl Alcohol as a Coating Agent to Coat Fertilizer Powder

[0027] The hot nitrogen gas brings out steam through the boiling cetyl alcohol, so that it evenly wraps the preheated sample powder. After cooling, samples are taken to measure the contact angle, and the amount of cetyl alcohol on the surface of the powder is determined by oxidation. The results are shown in Table 3.

[0028] table 3

[0029]

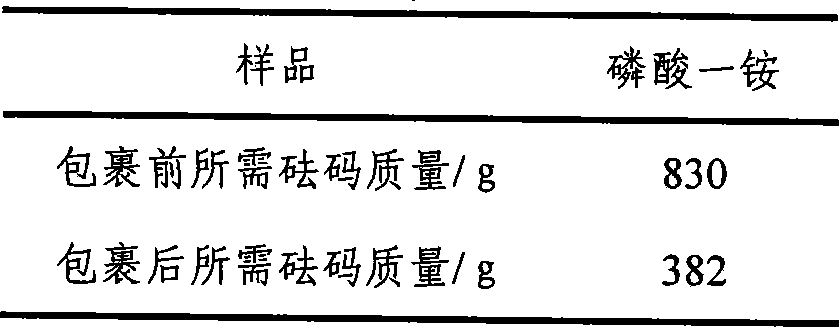

[0030] In the caking test, the results of the mass of the weight required to insert the sample block are shown in Table 4.

[0031] Table 4

[0032]

[0033] The test results show that the mass of weights required after wrapping is greatly reduced, indicating that the possibility of monoammonium phosphate powder agglomeration is greatly reduced.

Embodiment 3

[0034] Embodiment 3 adopts incomplete burning of turpentine, so that it produces carbon black soot and wraps heavy superphosphate product powder, and its contact angle~90 0 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com