Composite hydrogel and preparation method thereof

A composite hydrogel and hydrogel technology, applied in the field of hydrogel preparation, can solve the problems of insufficient structural strength, fast migration speed of effectively added components, etc., and achieve the effects of improving utilization rate, compact structure and reducing release speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

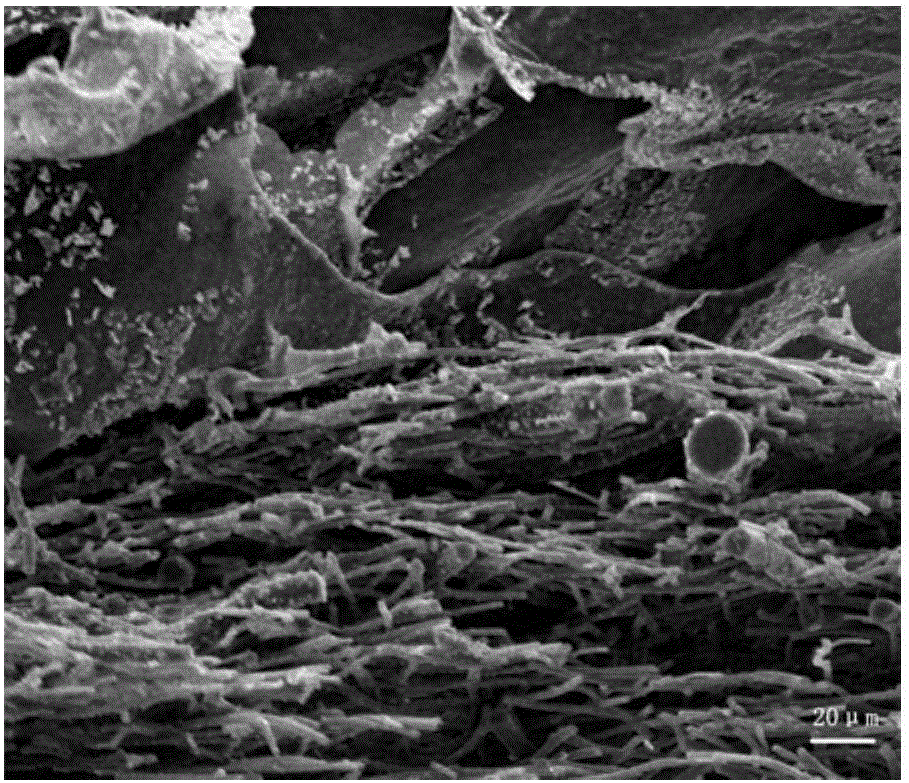

[0066] A method for preparing a composite hydrogel. First, the bladder acellular matrix is frozen and ground into powder, digested and dissolved with pepsin to form an aqueous solution with a concentration of 40 wt%, and at the same time, 0.025 wt% of vascular endothelial growth factor is added to obtain the hydrogel precursor body solution; before the gel is formed, the silk fibroin fiber prepared by electrospinning is soaked in the said Precursor solution; form a composite hydrogel through chemical gelation, and finally store the prepared composite hydrogel at 4°C.

[0067] Tests show that the main component of the hydrogel is water, the porosity is 50%, and the pore size is 50 μm-100 μm; the vascular endothelial growth factor is dispersed and wrapped in the hydrogel; the whole hydrogel contains silk fibroin fibers, and the composite hydrogel The hydrogel and silk fibroin fibers are in a mutual inclusion structure, the pores of the silk fibroin fibers contain hydrogel cons...

Embodiment 2

[0069] A method for preparing a composite hydrogel. Firstly, starch is heated and dissolved into an aqueous solution with a concentration of 30wt%, and at the same time, 0.05wt% insulin is added to obtain a hydrogel precursor solution; before the gel is formed, three-dimensional weaving will be used The polyvinyl alcohol fiber with a fiber diameter of 3 μm, a pore size of 8.0 μm-9.0 μm, a porosity of 90% and uniform micropore distribution prepared by the method is soaked in the precursor solution; a composite hydrogel is formed through physical gelation, Finally, the prepared composite hydrogel was stored at 40°C.

[0070] Tests show that the main component of the hydrogel is water, the porosity is 90%, and the pore size is 40 μm-100 μm; insulin is dispersed and wrapped in the hydrogel; the whole hydrogel contains polyvinyl alcohol fibers, and the hydrogel in the composite hydrogel The glue and the polyvinyl alcohol fiber are in a mutual inclusion structure, the pores of the p...

Embodiment 3

[0072] A method for preparing a composite hydrogel, firstly directly dissolving poly-L-glutamic acid to make an aqueous solution with a concentration of 40wt%, and adding 2wt% aspirin at the same time to obtain a hydrogel precursor solution; before the gel is formed, Soak nano-carbon fiber composite β-calcium phosphate with a fiber diameter of 900nm, a pore size of 3.0 μm-4.0 μm, a porosity of 80% and uniform micropore distribution prepared by electrospinning in the precursor solution; The gel forms a composite hydrogel, and finally the prepared composite hydrogel is stored at 10°C.

[0073] Tests show that the main component of the hydrogel is water, the porosity is 60%, and the pore size is 10 μm-30 μm; aspirin is dispersed and wrapped in the hydrogel; the whole hydrogel contains nano-carbon fiber composite β-calcium phosphate, and the composite hydrogel The hydrogel and the nano-carbon fiber composite β-calcium phosphate are mutually contained structures, the pores of the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com