Method for preparing embedding ion liquid and neutral phosphor (phosphine) extractant composite material and its use

An ionic liquid and composite material technology, which is applied in the field of preparation and application of composite materials embedding ionic liquid and neutral phosphorus (phosphine) type extractant, can solve the problems of slow performance, difficult phase separation, complex synthesis process, etc. To achieve the effect of easy reaction process, shortened gel time and uniform material composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

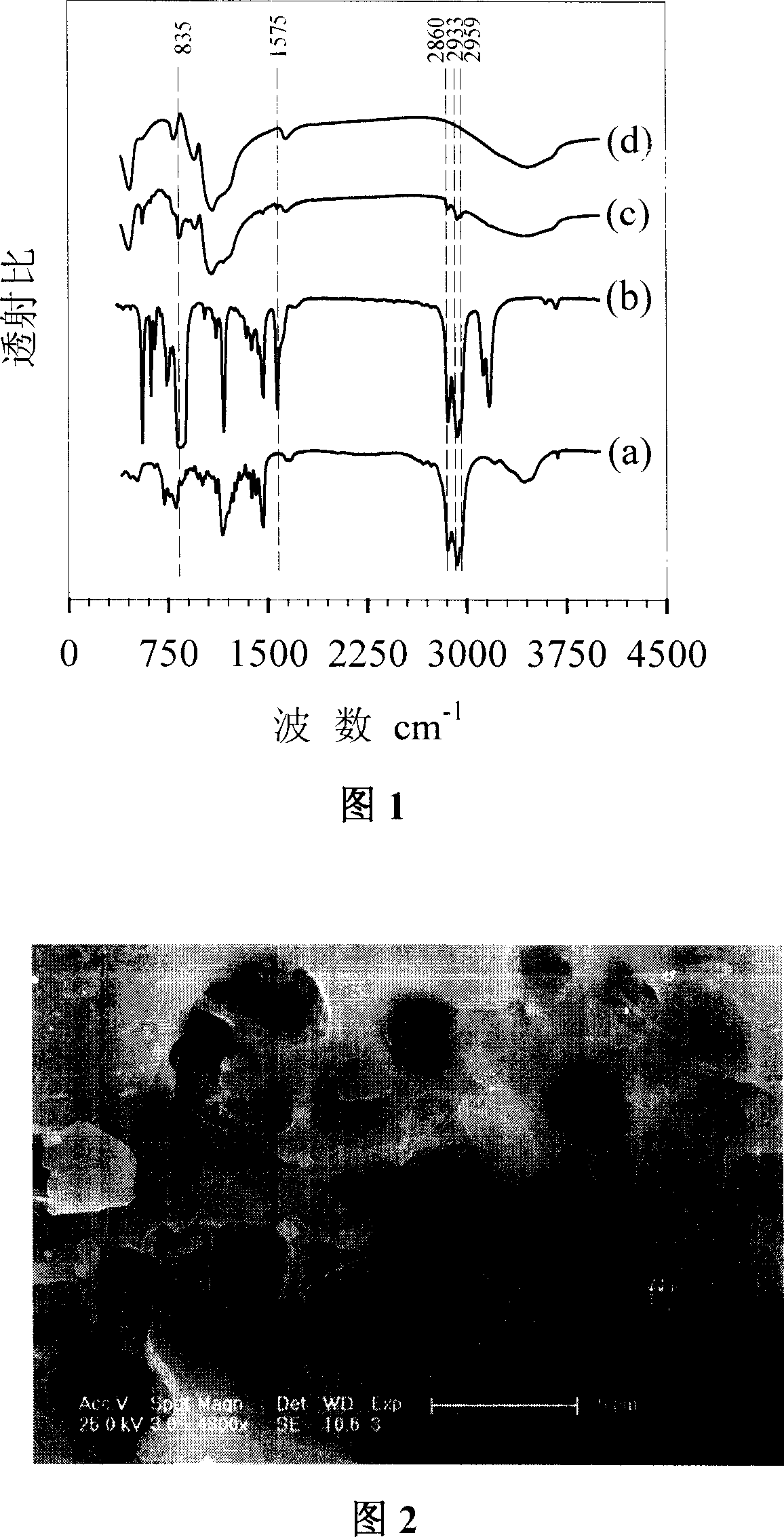

[0038] Embodiment 1: [C 8 mim][PF 6 ]Synthesis

[0039] [C 8 mim][PF 6 ], first synthesize [C 8 mim]Cl (1-octane-3-methylimidazolium chloride) compound. N-methylimidazole and chlorooctane were purified by distillation respectively, and then added to a three-necked container with a condenser in a molar ratio of 1:1, and heated at 70°C for 48-72 hours under stirring until Two phases are formed, and the upper phase is poured out, the lower phase is washed 3 times with ethyl acetate, and the remaining ethyl acetate is removed by distillation under reduced pressure to obtain [C 8 mim]Cl, >89% yield.

[0040] The mass percentage concentration is 60% HPF 6 aqueous solution and the newly synthesized [C 8 [C 8 mim][PF 6 ], washed with an equal volume of deionized water until the pH was nearly neutral, and the yield was 66%. [C 8 mim][PF 6 ] H NMR spectrum: δ0.86(t), 1.26(t), 2.06(m), 2.50(m), 3.00(s), 4.14(t), 7.69(t), 7.76(t), 9.09 (s). 13 CNMR spectrum: δ13.84, 22.12, ...

Embodiment 2

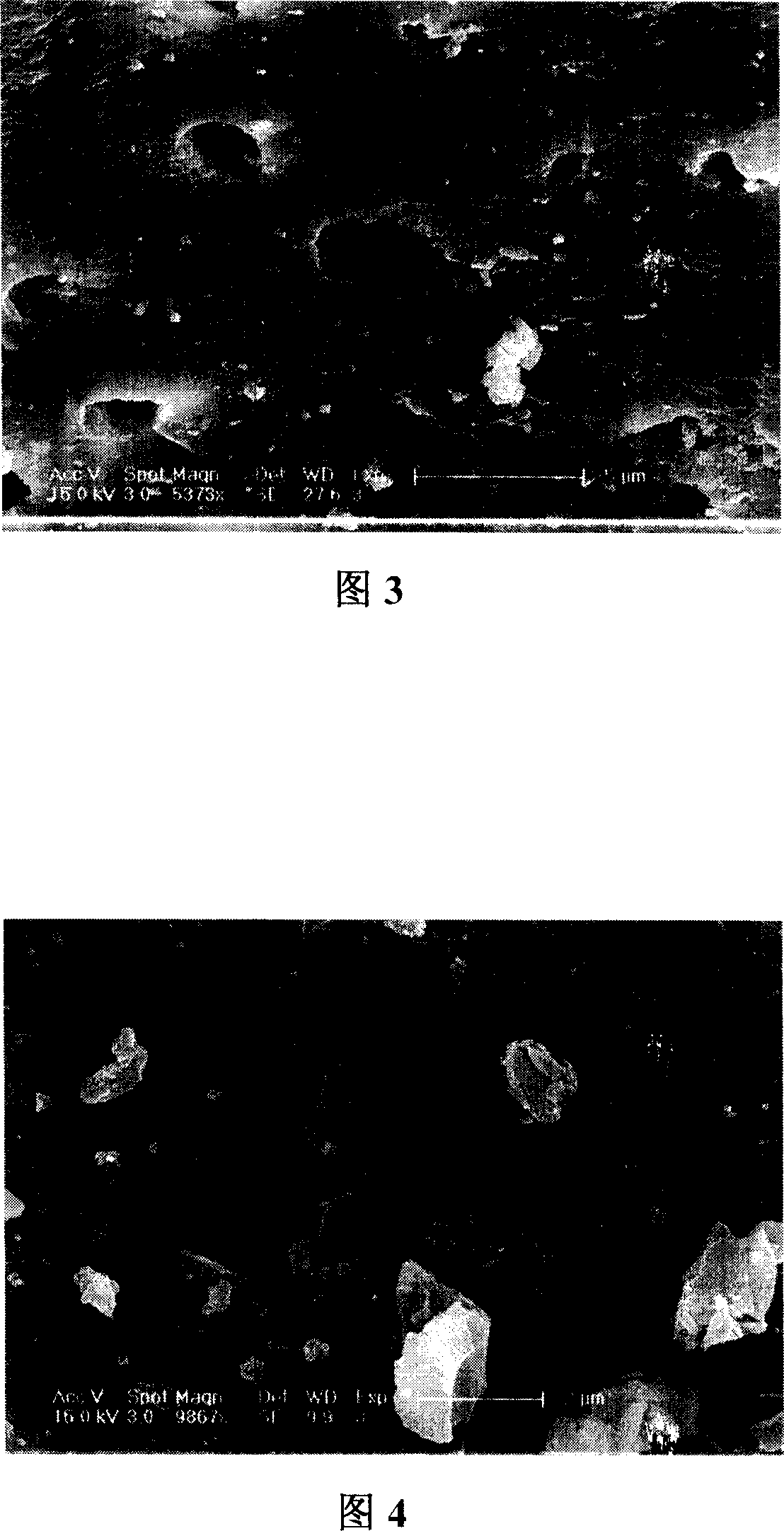

[0041] Embodiment 2: preparation does not contain the silica gel material of ionic liquid and neutral phosphorus (phosphine) class extraction agent

[0042] Mix 50ml tetraethyl orthosilicate, 15ml deionized water and 5ml 0.05mol l -1 Formic acid was mixed and magnetically stirred at 17°C for 20 hours. After drying, the dry gel was taken out, washed with distilled water until the pH value was 6.0, and vacuum-dried at 40° C. for 12 hours to obtain a silica gel material A free of ionic liquid and neutral phosphorus (phosphine) extractant.

Embodiment 3

[0043] Example 3: Preparation of a composite material embedding Cyanex923

[0044] Mix 25ml tetraethyl orthosilicate, 10ml deionized water and 2.5ml 0.05mol l -1 Formic acid was mixed and stirred magnetically at 22°C for 12 hours. Add 0.21ml of Cyanex923 into the system, and stir magnetically at 22°C until gelling. After drying, the xerogel was taken out, washed with distilled water until the pH value was 5.8, and dried under vacuum at 40°C for 12 hours to obtain composite material B embedded with Cyanex923.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com