Enzymolysis-chemistry combined method for producing sodium alginate

A technology of sodium alginate and combined method, applied in the field of seaweed chemical industry, can solve the problems of environmental pollution, difficult treatment, high cost, etc., achieve the effects of reducing acid-base wastewater, easy control of production process, and reducing coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

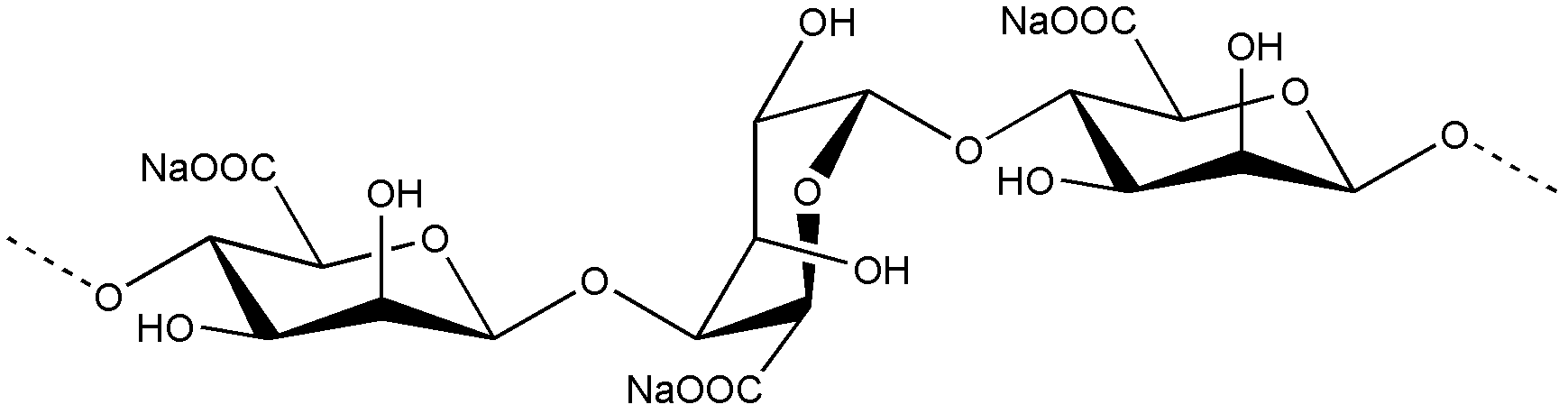

Image

Examples

Embodiment 1

[0032] Weigh 10 kg of brown algae such as light dried kelp, Ascophyllum nodosum, blackened Leisong algae or bark algae, add 50 liters of tap water to soak for 1 hour, and remove the sediment. Then add 50 liters of tap water to soak for 3 hours, and filter. Cut the brown algae into 20 cm long pieces with a shredder, transfer to a 50 L beater and add 20 liters of tap water to stir and beat for 0.5 h. Transfer the slurry to a 50L enzymolysis tank with heat preservation and heating functions, and transfer the compound enzyme that has been prepared according to the ratio to the enzymolysis tank. .5, heat preservation enzymolysis under the condition that the action time is 13h. After enzymatic hydrolysis, the temperature was raised to 90°C and kept for 0.5h to inactivate the enzyme. The enzymatic solution was separated by filtration, and the filter residue was kept for later use. Add 100 meshes and 1.0 kg of chemically pure anhydrous sodium carbonate to the enzymolysis filtrate, ...

Embodiment 2

[0035]Weigh 10 kilograms of dried brown algae such as Ascophyllum nodosum, blackened Leisongella, barkweed or lightly dried kelp, add 50 liters of tap water to soak for 1.5 hours, and remove the sediment. Then add 50 liters of tap water to soak for 3.5 hours, and filter. Cut the brown algae into 15cm long pieces with a shredder, transfer to a 50L beater and add 20 liters of tap water to stir and beat for 1.5h. Transfer the slurry to a 50L enzymolysis tank with heat preservation and heating functions, add the compound enzyme that has been prepared according to the ratio into the enzymolysis tank, the enzyme addition is about 300u / g, at a temperature of 55 ° C, pH .0, heat preservation enzymolysis under the condition that the action time is 25h. After enzymatic hydrolysis, the temperature was raised to 85°C and kept for 45 minutes to inactivate the enzyme. The enzymatic solution was separated by filtration, and the filter residue was retained. Add 100 meshes of 0.8 kg chemica...

Embodiment 3

[0039] The difference from Example 1 is:

[0040] The compound enzyme consists of 6ml of liquid cellulase (270,000 u / ml imported from the United States, C11840 type), 4.5 g of refined solid pectinase (P-3028, 500,000 u / ml from Sigma, USA) and hydrolyzed plant protease (F-3925, American Sigma company, 100,000 u / g) 1.5g composition. 4.02 million u

[0041] Weigh 10 kilograms of dried brown algae such as Ascophyllum nodosum, blackened lysophylla, bark algae or lightly dried kelp, add 50 liters of tap water to soak for 2.0 hours, and remove the sediment. Then add 50 liters of tap water to soak for 4.0 hours, and filter. Cut the brown algae into 15cm long pieces with a chopper, transfer to a 50L beater and add 20 liters of tap water to stir and beat for 1.8h. Transfer the slurry to a 50L enzymolysis tank with heat preservation and heating functions, and add the compound enzyme that has been prepared according to the ratio into the enzymolysis tank. .0, heat preservation enzymol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com