PBAT composite film based on irradiation modification and preparation method thereof

A composite film and film product technology, applied in the field of irradiation modified fully biodegradable PBAT composite film and its preparation, can solve the problems of poor performance retention, weak anti-aging ability, high material cost, etc. Complementary properties, crack reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

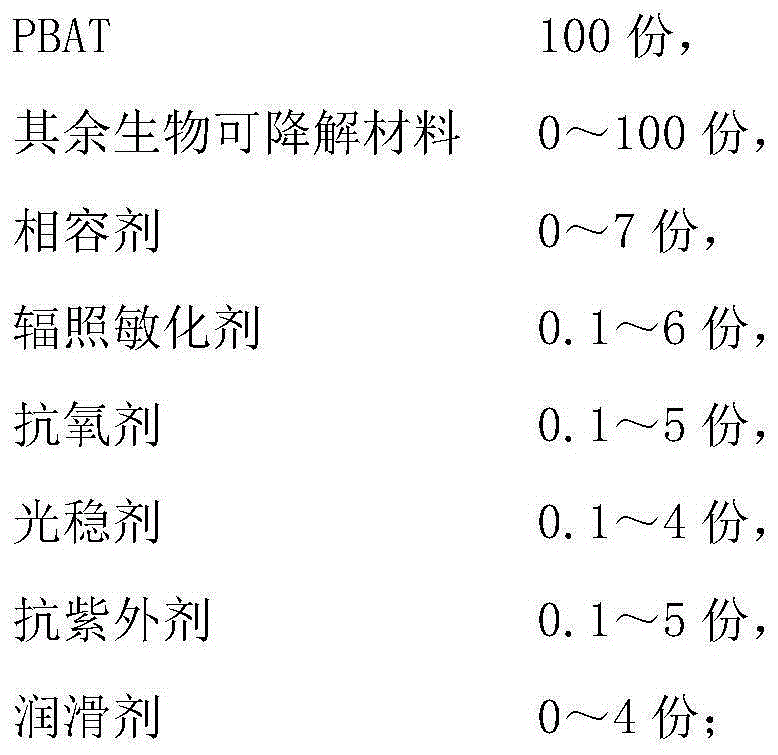

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a PBAT composite film based on radiation modification and a preparation method thereof, the components of the composite film are shown in Table 1; the preparation method of the composite film is as follows:

[0042] Raw material pretreatment: Take PBAT that was vacuum-dried at 30°C for 10 hours, mix the components and content ratios in Example 1 in Table 1, stir at 600 r / min at room temperature, and stir at high speed for 3 minutes;

[0043] Extrusion granulation: twin-screw extruder melt blending, extrusion granulation, extrusion temperature is 100-135 °C, die temperature of screw extruder is 120-200 °C, screw length-to-diameter ratio is 40:1 , speed 250r / min;

[0044] Processing and molding: vacuum drying at 30°C for 12 hours, blow molding at 110-130°C;

[0045] Irradiation treatment: The film was irradiated with 220 kGy electron beams to prepare a composite film (sample number 1).

Embodiment 2

[0047] This embodiment provides a PBAT composite film based on radiation modification and a preparation method thereof, the components of the composite film are shown in Table 1; the preparation method of the composite film is as follows:

[0048] Raw material pretreatment: Take PBAT and PLA that were vacuum-dried at 80°C for 2 hours, mix the components and content ratios shown in Example 2 in Table 1, and stir at a high speed of 800 r / min for 3 minutes at room temperature;

[0049] Extrusion granulation: twin-screw extruder melt blending, extrusion granulation, extrusion temperature is 110-180 °C, die temperature of screw extruder is 120-200 °C, screw length-to-diameter ratio is 40:1 , speed 150r / min;

[0050] Processing and molding: vacuum drying at 80°C for 4 hours, blow molding at 135-170°C;

[0051] Irradiation treatment: The film was irradiated with 160kGy electron beams to prepare a composite film (sample number 2).

Embodiment 3

[0053] This embodiment provides a PBAT composite film based on radiation modification and a preparation method thereof, the components of the composite film are shown in Table 1; the preparation method of the composite film is as follows:

[0054] Raw material pretreatment: Take PBAT and polyhydroxyalkanoate that were vacuum-dried at 60°C for 6 hours, mix the components and content ratios shown in Example 3 in Table 1, and stir at 1000r / min at a high speed for 3 minutes at room temperature;

[0055] Extrusion granulation: twin-screw extruder melt blending, extrusion granulation, extrusion temperature is 110-190 ℃, die temperature of screw extruder is 120-200 ℃, screw length-to-diameter ratio is 40:1 , speed 150r / min;

[0056] Processing and molding: vacuum drying at 80°C for 10 hours, blowing and casting at 160-190°C to form a film;

[0057] Irradiation treatment: The film was irradiated with 60 kGy electron beams to prepare a composite film (sample number 3).

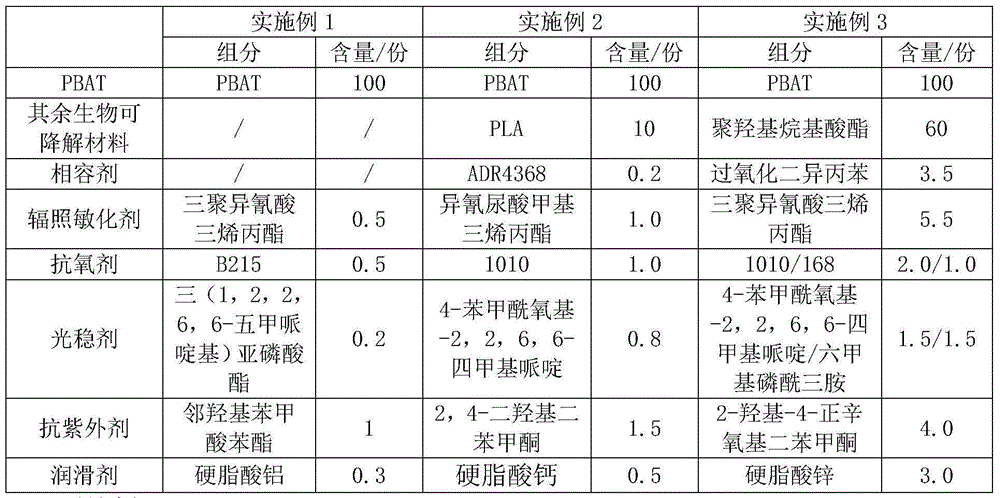

[0058] Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com