High volume fraction silicon carbide particle reinforced aluminum matrix composite material and its preparation method

A technology of aluminum matrix composite material and silicon carbide particles, which is applied in the field of high volume fraction silicon carbide particle reinforced aluminum matrix composite material and its preparation, and the powder metallurgy preparation technology field of high volume fraction SiCp reinforced aluminum matrix composite material, which can solve the problem of difficult to achieve and other problems, to achieve the effect of low thermal conductivity, high elastic modulus, excellent mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

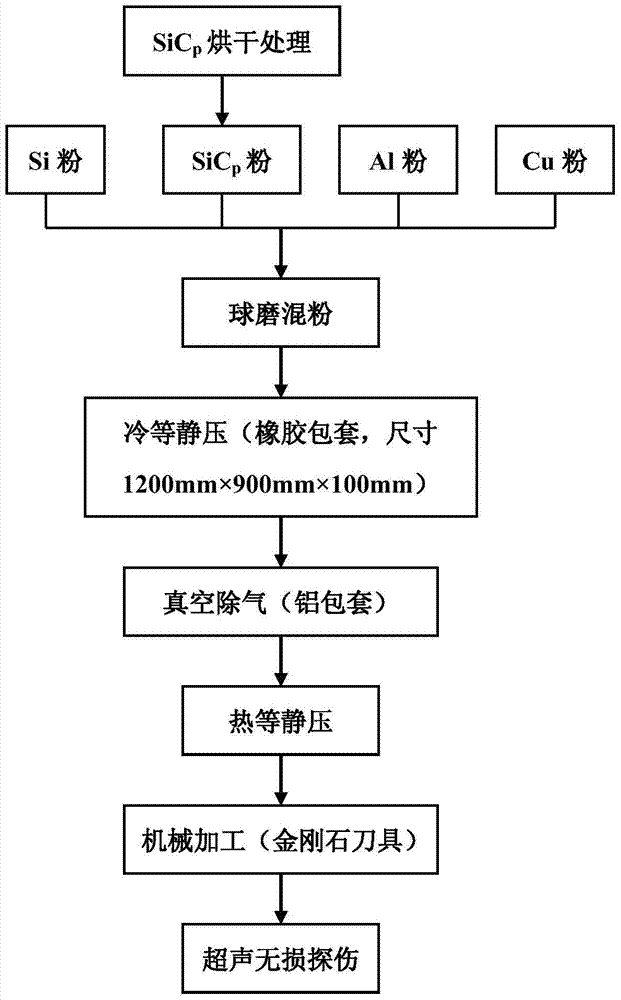

[0031] figure 1 For the preparation process roadmap of the present invention, SiC p Perform surface drying treatment, and then dry the SiC p Powder mixed with Si powder, Al powder and Cu powder by ball milling - cold isostatic pressing (rubber jacket, size 1200mm×900mm×100mm) - vacuum degassing (aluminum jacket) - hot isostatic pressing sintering - mechanical processing (such as diamond tools) - Ultrasonic non-destructive testing, and finally get a large size SiC p Reinforced Al-based composites.

[0032] In the following examples, the Al powder used may be gas-atomized aluminum powder, the Cu powder may be electrolytic copper powder, and the Si powder may be ordinary silicon powder. SiC p The drying process is carried out in a box-type incubator, the drying temperature is 120-180°C, and the holding time is 12-24 hours.

Embodiment 1

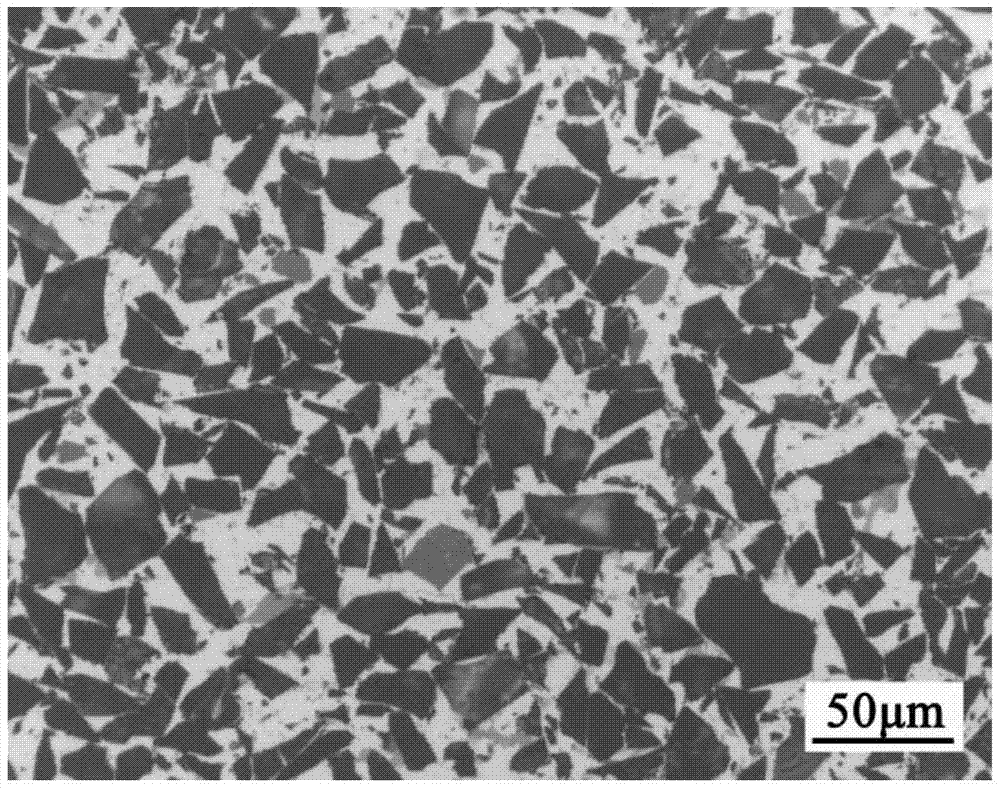

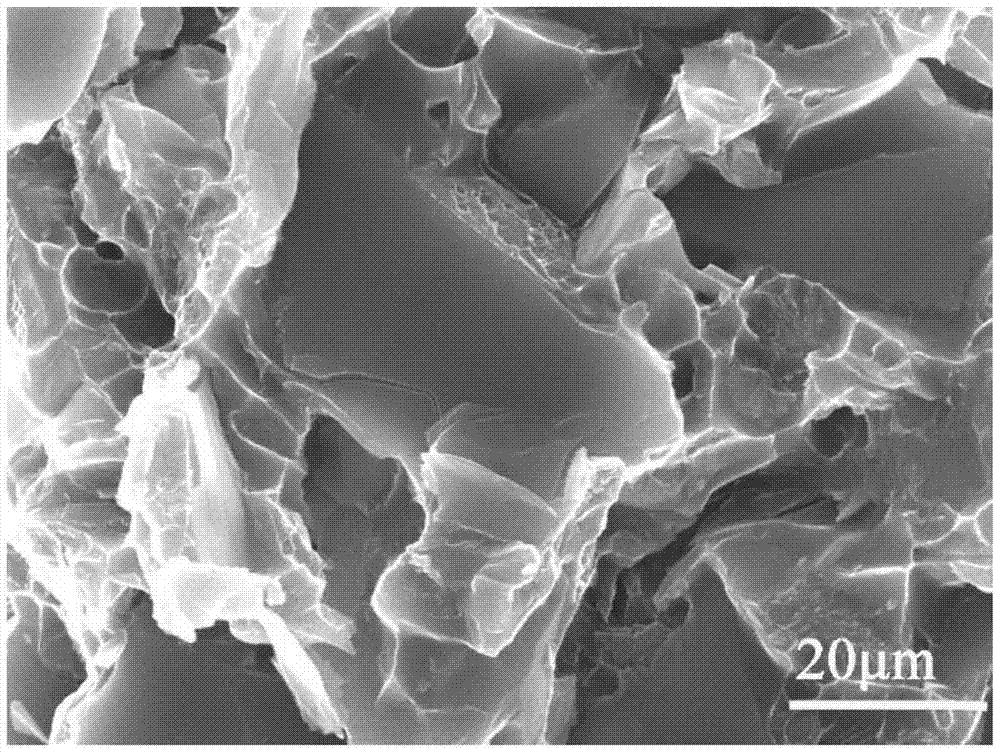

[0034] The volume fraction of the composite material is: SiC p The reinforcing phase content is 55vol.%, and the Al-Cu-Si matrix content is 45vol.%. SiC p The particle size is 20-40 μm, the particle size of Al powder is 15-20 μm, the particle size of Cu powder is 5-10 μm, and the particle size of Si powder is 5-10 μm. SiC p The reinforcement is dried, and the matrix powder with the nominal composition of Al-3.5Cu-5Si (wt%) is configured, and then 140Kg of 55vol.% SiC p Mix powder with 45vol.% Al-3.5Cu-5Si for ball milling, ball mill speed 150 rpm, ball milling time 16h, ball-to-material ratio 5:1, dry blend; sieve the mixed powder and put it into cold water Static pressure rubber sheath (the sheath size is 1200mm×900mm×100mm), the metal rod is used to guide the powder and then the cold isostatic pressing is formed, the cold isostatic pressing pressure is 200MPa, and the pressing time is 30min; Vacuum degassing isostatically pressed ingot, and the vacuum degree is required ...

Embodiment 2

[0038] The volume fraction of the composite material is: SiC p The reinforcing phase content is 55vol.%, and the Al-Cu-Si matrix content is 45vol.%. SiC p The particle size of Al powder is 20-40 μm, the particle size of Al powder is 15-20 μm, the particle size of Cu powder is 5-10 μm, and the particle size of Si powder is 5-10 μm. First dry the SiC p Reinforcement body, and configure the matrix powder whose nominal composition is Al-4.5Cu-5Si, and then add 140Kg of 55vol.% SiC p Mix with 45vol.% Al-4.5Cu-5Si powder by ball milling, the speed of the ball mill is 150 rpm, the ball milling time is 16h, the ball-to-material ratio is 5:1, and dry-mix; Statically press the rubber sheath (the sheath size is 1200mm×900mm×100mm), and then carry out cold isostatic pressing molding, the cold isostatic pressing pressure is 200MPa, and the pressing time is 30min; Vacuum degassing, the vacuum degree is required to be less than 10 at the end of vacuum degassing -3 Pa; the vacuum degasse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com