Ethylene-chlorotrifluoroethylene copolymer for melt blowing and preparation method thereof

A technology of chlorotrifluoroethylene and copolymers, applied in the direction of single-component synthetic polymer rayon, fiber chemical characteristics, non-woven fabrics, etc., can solve the problem of reducing the yield of non-woven fabrics prepared by melt blown and the fluidity of resin melt To reduce the risk of copolymer degradation and equipment energy consumption, low melting temperature and good mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

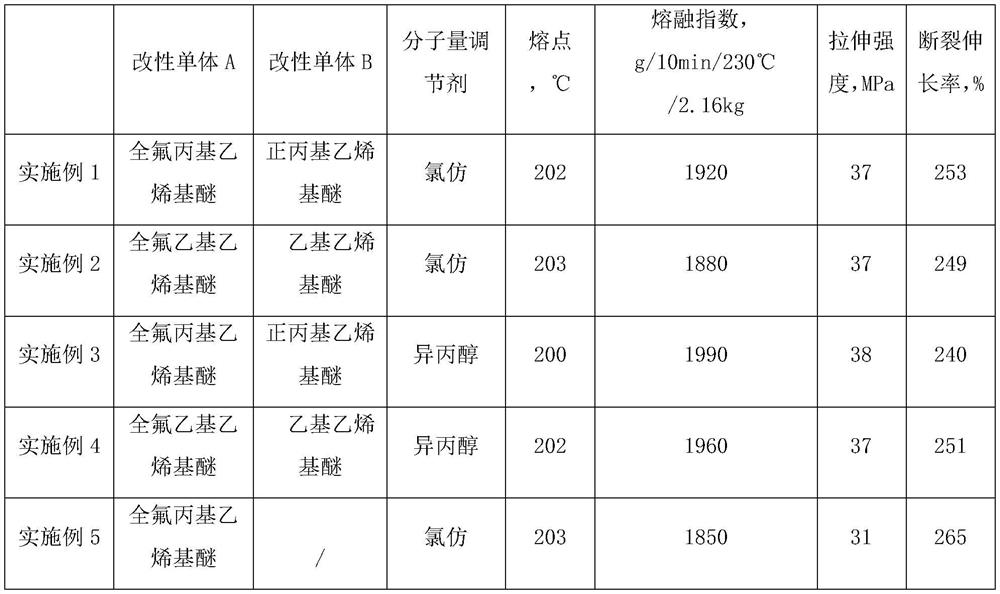

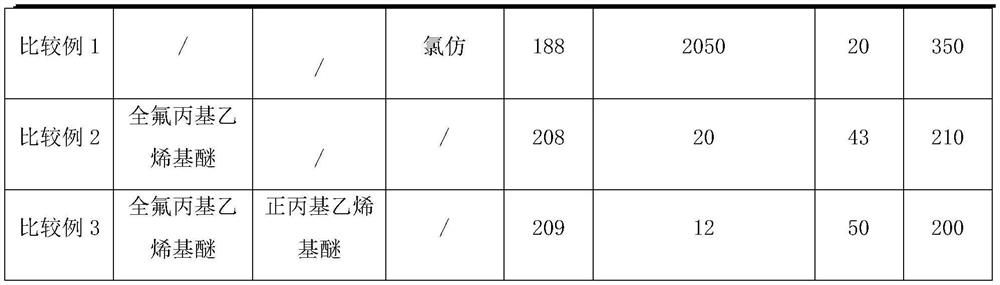

Examples

Embodiment 1

[0041] This embodiment provides a preparation method of ethylene-chlorotrifluoroethylene copolymer for melt blowing, the preparation method comprising the following steps:

[0042] (1) Dissolve 7g of hydroxypropyl methylcellulose completely in 1L of pure water first, add the dissolved cellulose aqueous solution and 2.5L of pure water into a 5L reactor, start stirring at 300r / min, and vacuum the reactor with nitrogen Replace until the oxygen content in the reactor is lower than 10ppm;

[0043] (2) Add 400g chlorotrifluoroethylene, 13g perfluoroethyl vinyl ether, 10g n-propyl vinyl ether, 10g trifluorotrichloroethane, 35g chloroform to the reactor, and feed ethylene to the reactor pressure is 2.5MPa. Increase the stirring speed of the reactor to 500r / min, the temperature inside the reactor is raised to 50°C, and 2g of diisopropyl peroxydicarbonate is added to start the polymerization reaction;

[0044] (3) By continuously adding ethylene monomer, the pressure in the reactor wa...

Embodiment 2

[0052] This embodiment provides a preparation method of ethylene-chlorotrifluoroethylene copolymer for melt blowing, the preparation method comprising the following steps:

[0053] (1) Dissolve 7g of hydroxypropyl methylcellulose completely in 1L of pure water first, add the dissolved cellulose aqueous solution and 2.5L of pure water into a 5L reactor, start stirring at 300r / min, and vacuum the reactor with nitrogen Replace until the oxygen content in the reactor is lower than 10ppm;

[0054] (2) add 400g chlorotrifluoroethylene, 12g perfluoroethyl vinyl ether, 10g ethyl vinyl ether, 10g trifluorotrichloroethane, 35g chloroform in reactor again, pass into ethylene until reactor pressure is 2.5 MPa. Increase the stirring speed of the reactor to 500r / min, the temperature inside the reactor is raised to 50°C, and 2g of diisopropyl peroxydicarbonate is added to start the polymerization reaction;

[0055] (3) By continuously adding ethylene monomer, the pressure in the reactor wa...

Embodiment 3

[0059] This embodiment provides a preparation method of ethylene-chlorotrifluoroethylene copolymer for melt blowing, the preparation method comprising the following steps:

[0060] (1) Dissolve 7g of hydroxypropyl methylcellulose completely in 1L of pure water first, add the dissolved cellulose aqueous solution and 2.5L of pure water into a 5L reactor, start stirring at 300r / min, and vacuum the reactor with nitrogen Replace until the oxygen content in the reactor is lower than 10ppm;

[0061] (2) Add 400g chlorotrifluoroethylene, 13g perfluoropropyl vinyl ether, 10g n-propyl vinyl ether, 10g trifluorotrichloroethane, 45g isopropanol to the reaction kettle, and feed ethylene to the reaction The kettle pressure is 2.5MPa. Increase the stirring speed of the reactor to 500r / min, the temperature inside the reactor is raised to 50°C, and 2g of diisopropyl peroxydicarbonate is added to start the polymerization reaction;

[0062] (3) By continuously adding ethylene monomer, the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com