Method for producing long-glass-fiber-reinforced polypropylene foaming injection product by using water as foaming agent

A polypropylene and long glass fiber technology, which is applied in the field of processing and manufacturing of polymer materials, can solve the problems of unclear applicability of long glass fiber reinforced polypropylene materials, and achieve the effects of avoiding adverse effects, facilitating addition and reducing weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

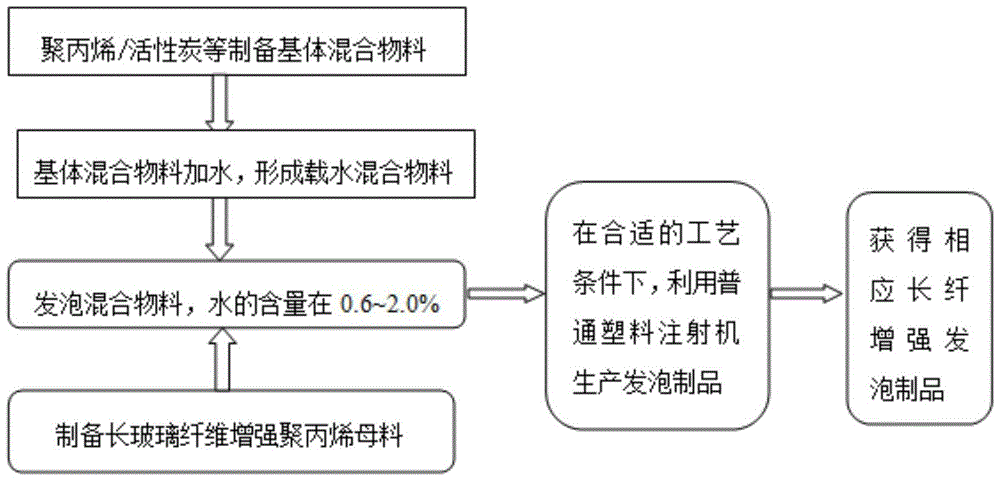

Method used

Image

Examples

Embodiment 1

[0047] First, a long glass fiber reinforced polypropylene masterbatch is prepared. Weigh 2750g of dried polypropylene 1 (PP1), 50g of antioxidant, 50g of lubricant and 150g of compatibilizer, mix them evenly and add them into the hopper of the plastic extruder, set the temperature of each section of the extruder to 150- 200°C, adjust the speed of the main engine to 60rpm, and at the same time, 2000g of glass fiber bundles are continuously drawn into the impregnation head, and the speed is adjusted to about 1.2m / s, and the composite material of glass fiber and polypropylene resin after impregnation is extruded. After the machine head is cooled, cut the material, and the cut length is 10mm, and the cross-sectional area is about 3.3mm 2 The long glass fiber reinforced polypropylene masterbatch is weighed, and its total mass is 5kg, so the glass fiber content in the long glass fiber reinforced polypropylene masterbatch is 40wt%.

[0048] Next, prepare the matrix mixture material....

Embodiment 2

[0062] First, a long glass fiber reinforced polypropylene masterbatch is prepared. Weigh 2250g of dried polypropylene 1 (PP1), 50g of antioxidant, 50g of lubricant and 150g of compatibilizer, mix them evenly and add them into the hopper of the extruder, set the temperature of each section of the extruder to 150-200 ℃, adjust the speed of the host machine to 60rpm, and at the same time, 2500g of glass fiber bundles are continuously drawn into the impregnation head, and the speed is adjusted to about 1.5m / s, and the impregnated glass fiber and polypropylene resin composite material extruder After the head is cooled, it is cut to a length of 8mm and a cross-sectional area of about 3.1mm 2 The long glass fiber reinforced polypropylene masterbatch is weighed, and its total mass is 5kg, so the long glass fiber content in the long glass fiber reinforced polypropylene masterbatch is 50wt%.

[0063] Next, prepare the matrix mixture material. Weigh the dried polypropylene 2 (PP2), c...

Embodiment 3

[0075] First, a long glass fiber reinforced polypropylene masterbatch is prepared. Weigh 3250g of dried polypropylene 1 (PP1), 50g of antioxidant, 50g of lubricant and 150g of compatibilizer, mix them evenly and add them into the hopper of the extruder, set the temperature of each section of the extruder to 150-200 ℃, adjust the speed of the main machine to 100rpm, and at the same time, 1500g of glass fiber bundles are drawn into the impregnation head continuously, and the speed is adjusted to about 1.2m / s, and the impregnated glass fiber and polypropylene resin composite material extruder After the head is cooled, it is cut to a length of 15mm and a cross-sectional area of about 3.5mm 2 The long glass fiber reinforced polypropylene masterbatch is weighed, and its total mass is 5kg, so the glass fiber content in the masterbatch is 30wt%.

[0076] Next, prepare the matrix mixture material. Weigh the dried polypropylene 2, compatibilizer, nucleating agent, activated carbon, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com