Roll groove forming die used for stretching panel

A forming die and rolling groove technology, which is applied in the field of forming dies, can solve the problems of large loss of forging panel materials, environmental pollution, and large energy consumption, and achieve the effects of reducing labor intensity, easy process control, and low energy consumption of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

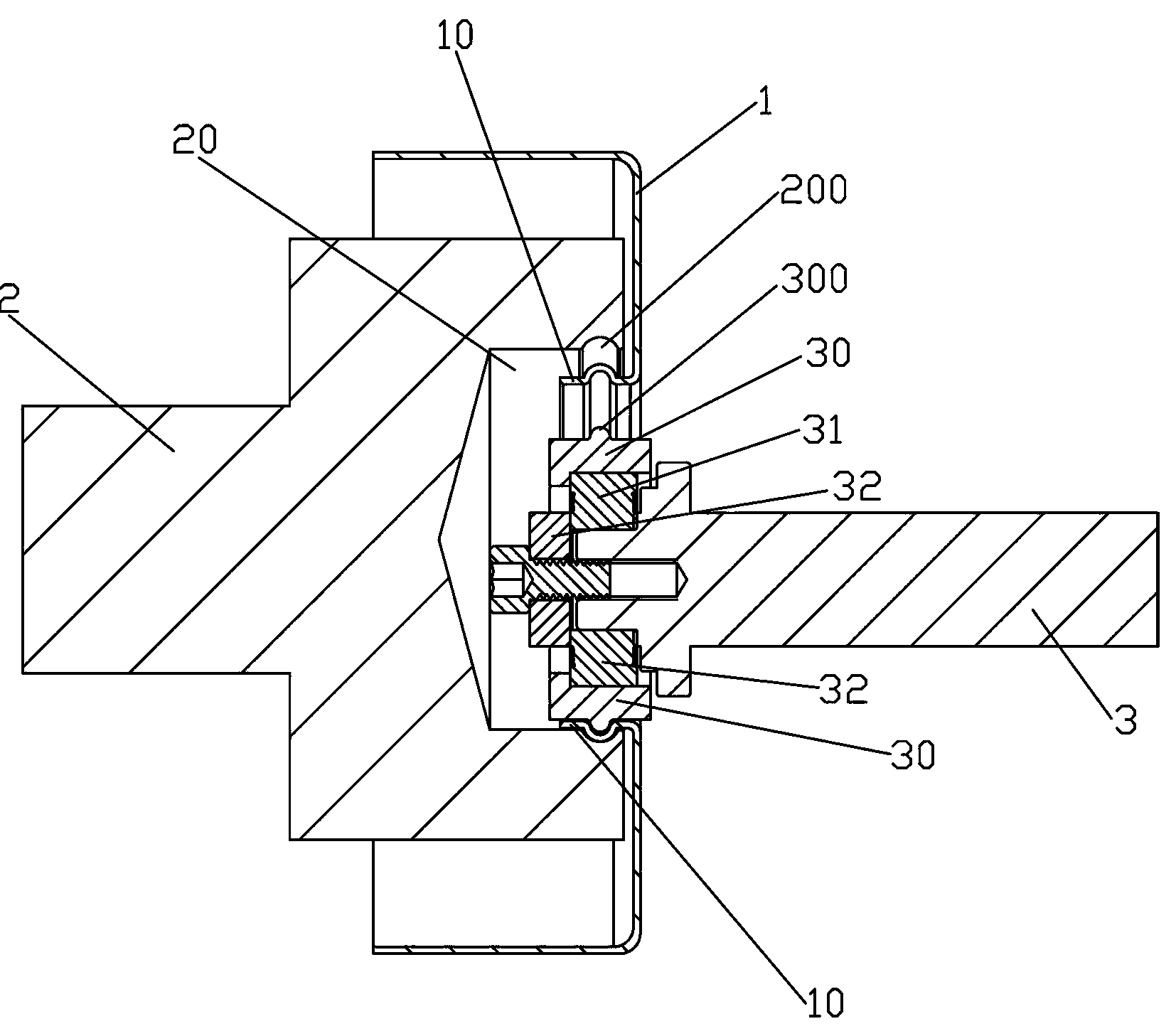

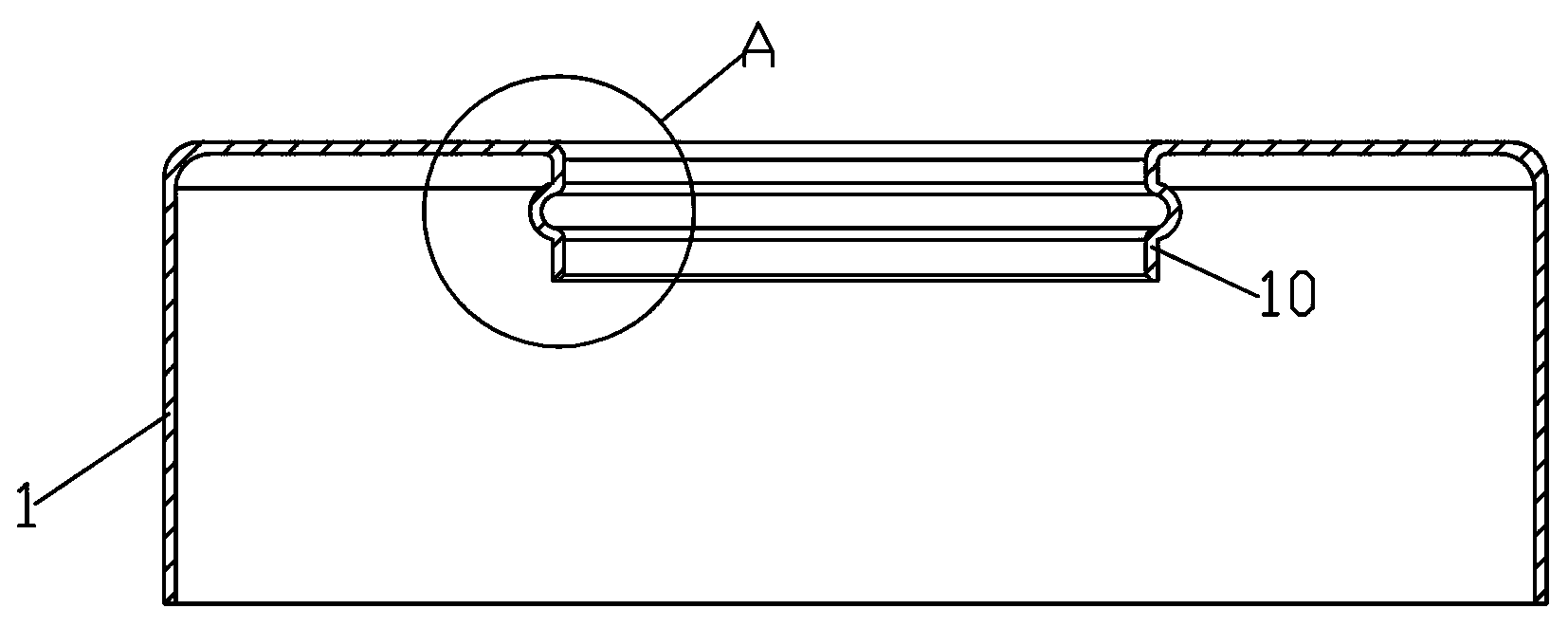

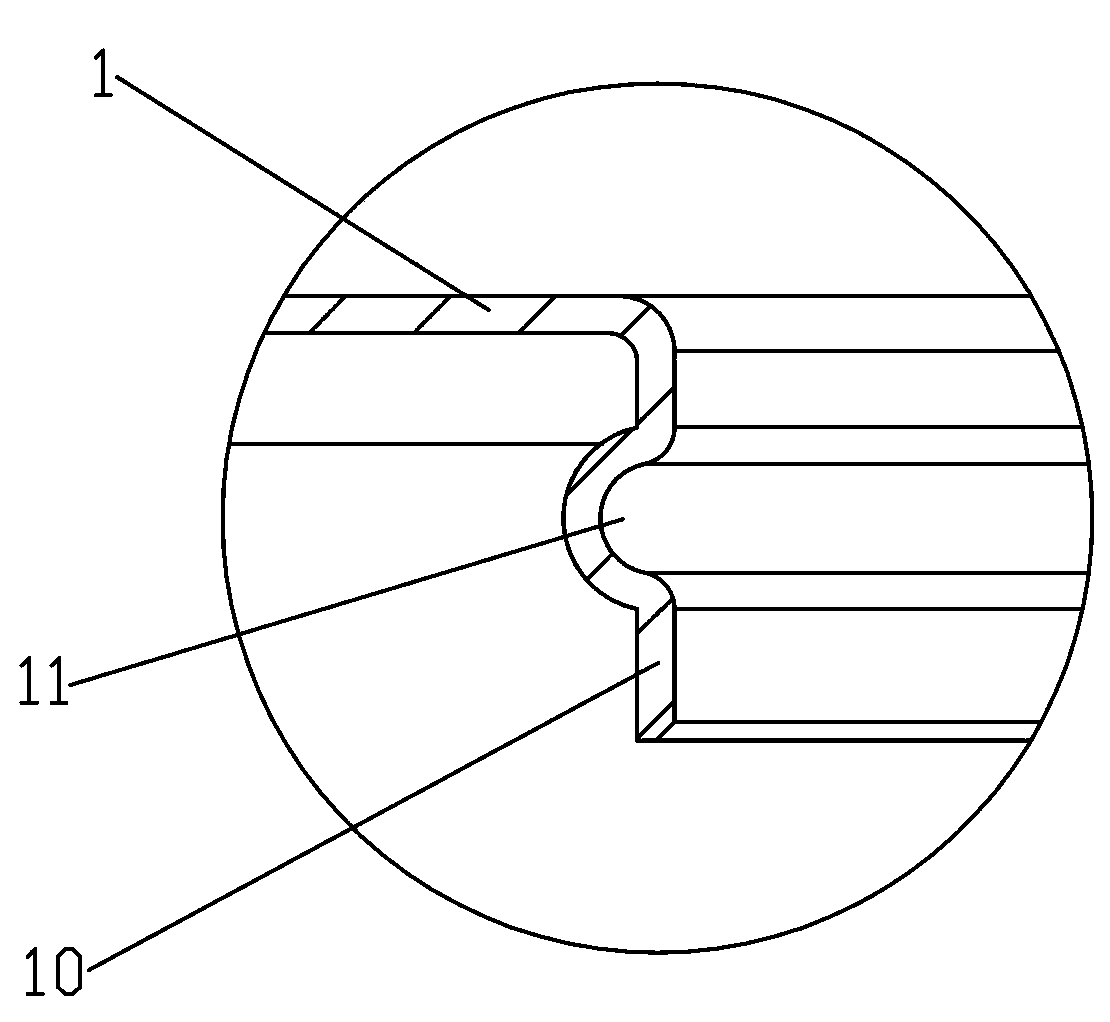

[0013] refer to figure 1 As shown in FIG. 3 , a rolling groove forming mold for stretching panels includes a rolling groove fixing seat 2 for fixedly installing the stretching panel 1 , and one end side wall of the rolling groove fixing seat 2 is opened to allow stretching. The concave extension 10 of the panel 1 is embedded into the installation groove 20 inside and abuts against its inner side wall. A forming rolling groove 200 is opened on the side wall of the installation groove 20. One side of the installation groove 20 It is also provided with a forming tool bar 3 that can extend into its inside, and the end of the forming tool bar 3 extending into the installation groove 20 is provided with a forming roller 30 that matches the forming rolling groove 200, the forming roller 30 is provided with a circular arc protrusion 300 that can be pressed into the forming roll groove 200. When the concave extension 10 of the stretch panel 1 is located between the forming roll groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com