Equipment for producing biochar from rice straw and technology for producing biochar

A technology of rice straw and production equipment, applied in the field of biochar production equipment and technology, can solve the problems of high process energy consumption, long production cycle, short production cycle, etc., and achieve simple production process, large apparent specificity, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

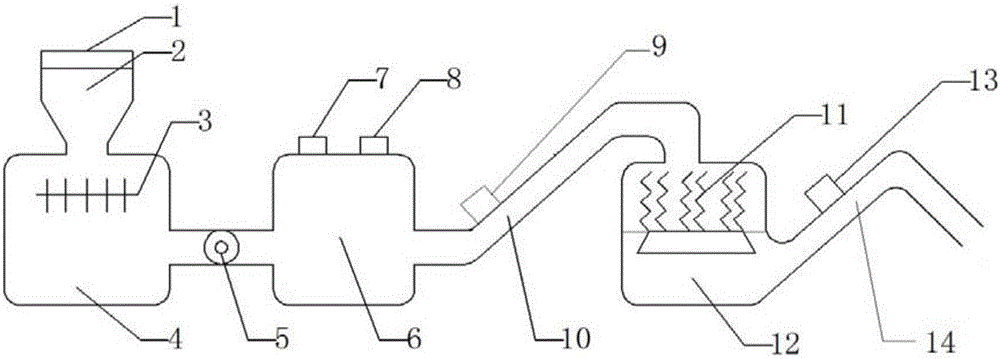

[0034] figure 1 The first embodiment of the present invention is given as figure 1 As shown, a rice straw biochar production equipment includes a feed box 2, a pulverizer 4, a reaction vessel 6, a discharge conveying pipe 10, a cracking box 11, a furnace 12, a first cooler 9, and a second cooler 13 , the feed box 2 is located above the pulverizer 4, the feed box 2 is provided with a feed port 1, the pulverizer 4 is provided with a pulverizing blade 3, the pulverizer 4 and the reaction vessel 6 The room is connected by a discharge valve 5, the reaction vessel 6 is provided with a heater 8 and a pressurizing device, the discharge delivery pipe 10 is connected between the reaction vessel 6 and the furnace 12, and the first cooler 9 is provided with At the outlet connection of the reaction vessel 6, the cracking box 11 is located above the stove 12, and the side wall of the stove 12 is also provided with a discharge pipe 14, and the second cooler 13 is located on the discharge pi...

Embodiment 2

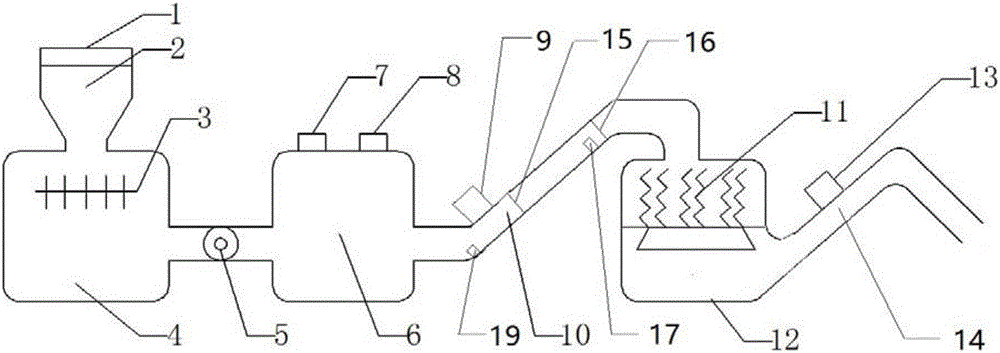

[0038] figure 2 Provided the 2nd embodiment of the present invention, as figure 2 , Figure 4As shown, the difference between embodiment 2 and embodiment 1 is that one end of the discharge conveying pipe 10 close to the reaction vessel 6 is also provided with a lower gate 15, and the other end is provided with an upper gate 16, and in the discharge conveying pipe 10 Near the position of the upper gate 16, a feed amount detection sensor 17 is provided, and the feed amount detection sensor 17 is used to detect the feed amount of the cracking box 11, and is connected with the lower gate 15, the upper gate 16 and the feed amount. The detection sensor 17 is connected with an MCU18, and a display screen is connected with the MCU18. The MCU18 is pre-stored with cracking box 11 feed amount preset data, and the MCU18 is controlled according to the feed amount data collected by the feed amount detection sensor 17. The opening and closing of the lower gate 15 and the upper gate 16. ...

Embodiment 3

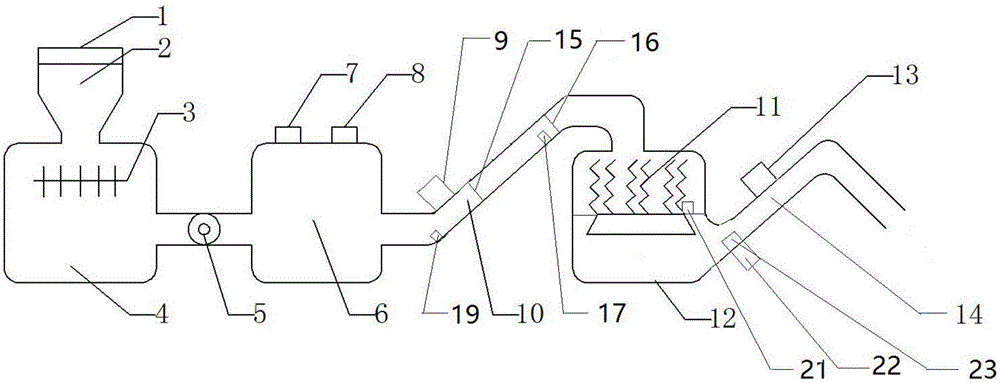

[0043] image 3 Provided the 3rd embodiment of the present invention, as image 3 As shown, the difference between embodiment 3 and embodiment 2 is that the bottom of the cracking box 11 is also provided with a tar catalyst chamber 21, and a tar catalyst is arranged in the tar catalyst chamber 21.

[0044] The outlet of the furnace 12 is also provided with a tar separator 23, and a tar cracking chamber 22 is connected with the tar separator 23, and a tar waste gas exhaust pipe is connected with the tar cracking chamber 22.

[0045] Embodiment 3 all the other are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com