Water foaming injection molding method for PP/LDPE ultra-extension product

A technology of injection molding and water foaming, applied in the direction of coating, etc., can solve the problems of high requirements, unconsidered, and difficulties in the control of process conditions, and achieve the effects of reducing equipment operating costs, improving dimensional accuracy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

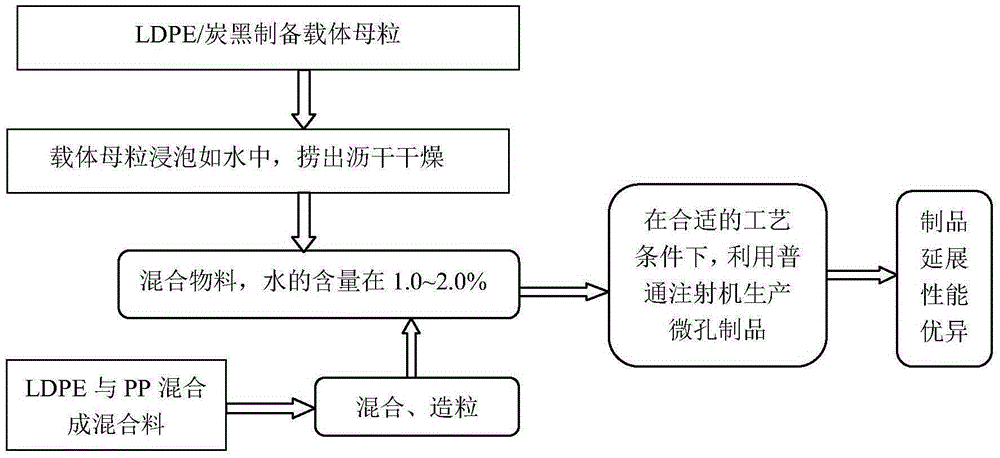

Method used

Image

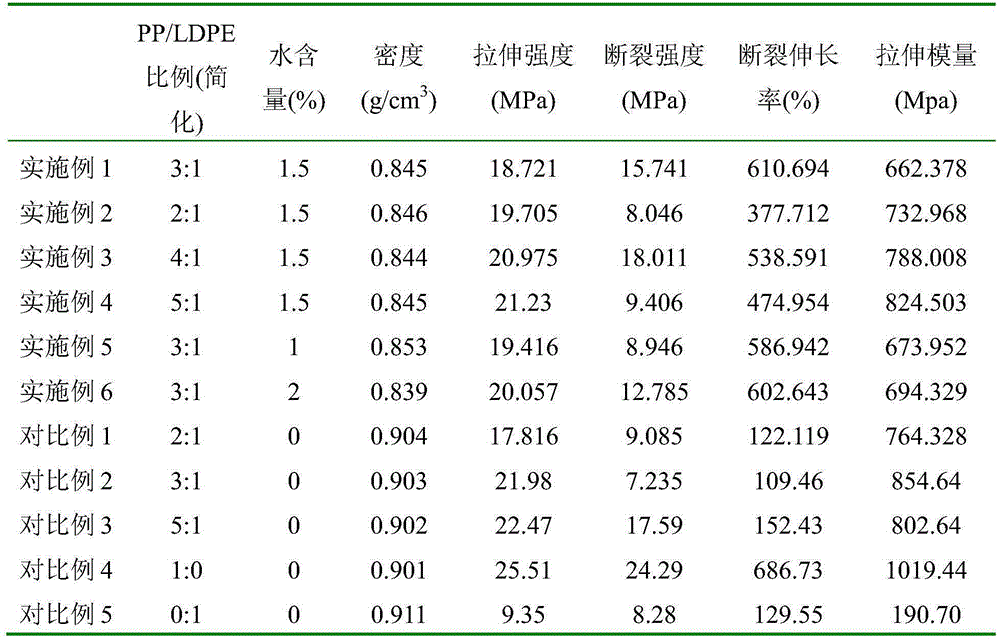

Examples

Embodiment 1

[0038] First, the carrier masterbatch is manufactured. Weigh raw materials according to the following weights: LDPE: 0.9kg, activated carbon: 0.1kg, and the mass ratio of activated carbon to LDPE is 1:9. After mixing activated carbon and LDPE raw materials, the carrier masterbatch is obtained through an ordinary plastic extruder, and the melt temperature is 165°C during the extrusion process;

[0039] Secondly, evenly disperse the above-mentioned carrier masterbatch and immerse it in water. After 6 hours, take it out and drain until there is no obvious water trace on the surface. Weigh its mass as 1175g, spread the masterbatch and blow it under the fan for about 20 minutes, and put Quality control is 1150g;

[0040] At the same time, weigh raw materials PP: 6.638KG, LDPE: 2.212KG, the mass ratio of LDPE to PP is 1:3, after mixing evenly, melt, extrude and pelletize through ordinary plastic extruder;

[0041] Afterwards, above-mentioned two kinds of materials are mixed homoge...

Embodiment 2

[0045] First, the carrier masterbatch is manufactured. Weigh the raw materials according to the following weights: LDPE: 0.5kg, activated carbon: 0.5kg, the mass ratio of activated carbon to LDPE is 1:1. After mixing activated carbon and LDPE raw materials, the carrier masterbatch is obtained through an ordinary plastic extruder, and the melt temperature is 165°C during the extrusion process;

[0046] Secondly, evenly disperse the above-mentioned carrier masterbatch and immerse it in water. After 6 hours, take it out and drain until there is no obvious water trace on the surface. Weigh its mass as 1175g, spread the masterbatch and blow it under the fan for about 20 minutes, and put Quality control is 1150g;

[0047] At the same time, weigh raw materials PP: 5.90KG, LDPE: 2.95KG, the mass ratio of LDPE to PP is 1:2, after mixing evenly, melt, extrude and pelletize through an ordinary plastic extruder;

[0048] Afterwards, above-mentioned two kinds of materials are mixed homog...

Embodiment 3

[0052] First, the carrier masterbatch is manufactured. Weigh raw materials according to the following weights: LDPE: 0.98kg, activated carbon: 0.02kg, and the mass ratio of activated carbon to LDPE is 1:49. After mixing activated carbon and LDPE raw materials, the carrier masterbatch is obtained through an ordinary plastic extruder, and the melt temperature is 165°C during the extrusion process;

[0053] Secondly, evenly disperse the above-mentioned carrier masterbatch and immerse it in water. After 6 hours, take it out and drain until there is no obvious water trace on the surface. Weigh its mass as 1175g, spread the masterbatch and blow it under the fan for about 20 minutes, and put Quality control is 1150g;

[0054] At the same time, weigh raw materials PP: 7.080KG, LDPE: 1.77KG, the mass ratio of LDPE to PP is 1:4, after mixing evenly, melt, extrude and pelletize through ordinary plastic extruder;

[0055] Afterwards, above-mentioned two kinds of materials are mixed homo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com