Organic silicon monomer hydrolysis device

A hydrolysis device and organosilicon technology, which is applied in the direction of feeding device, chemical/physical/physicochemical fixed reactor, chemical/physical/physicochemical process, etc., can solve the problem of low efficiency of organosilicon hydrolysis and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

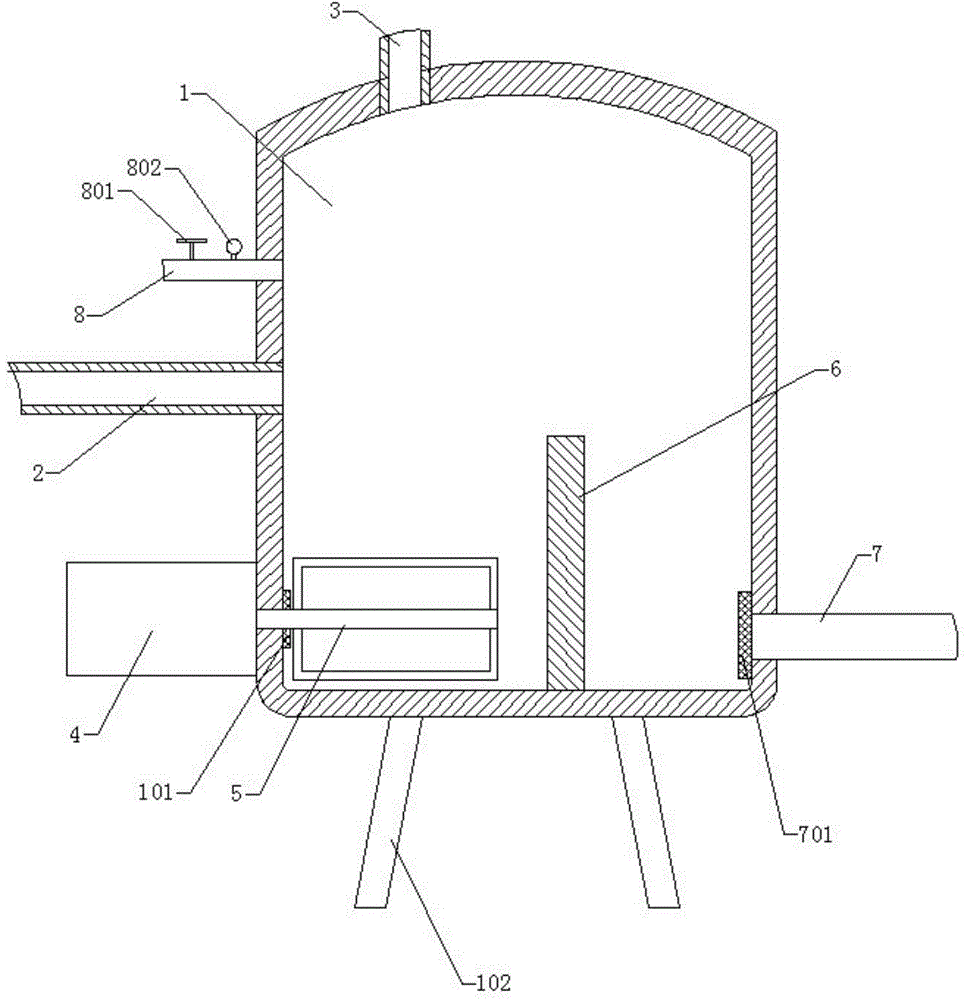

[0021] Such as figure 1 As shown, it includes a hydrolysis tank 1, a water inlet pipe 2, an organic silicon monomer pipe 3, a motor 4, an agitator 5, a partition 6, a drain pipe 7, and a hydrochloric acid inlet pipe 8, and the water inlet pipe 2 is located at the center of the left end of the hydrolysis tank 1 place, the two are connected by welding, the organosilicon single tube 3 is located on the left side of the top center of the hydrolysis tank 1, and the two are connected by welding, and the motor 4 is located at the lower end of the center of the water inlet pipe 2, and it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com