Method for preparing high-purity platinum from platinum alloy waste

A platinum alloy and scrap technology, applied in the field of preparing high-purity platinum powder, can solve the problems of high equipment requirements, high smelting loss, and impracticability, and achieve the effects of improving purity, shortening the process, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

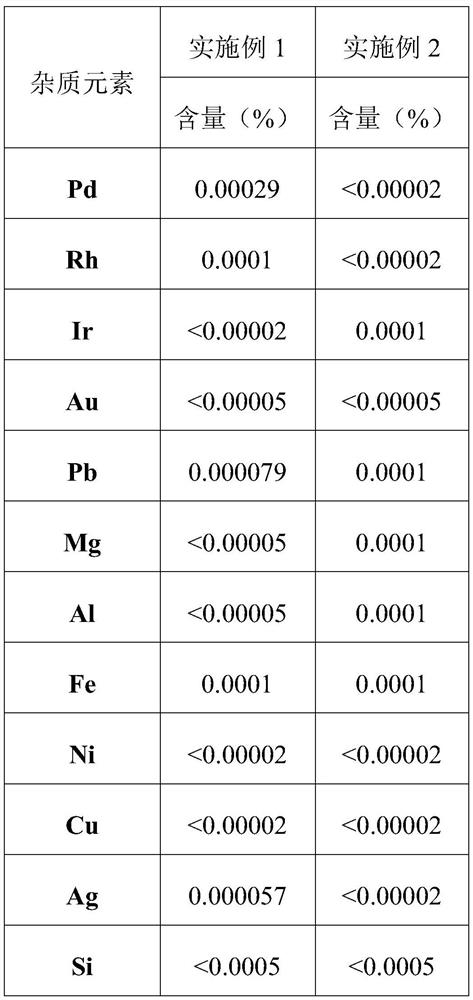

Examples

Embodiment 1

[0043] 1. Primary hydrolysis:

[0044] Weigh 100.05g of platinum-rhodium alloy waste with a rhodium content of 8%, cut it short with scissors to make a "Z" shape, place it in a 5000ml beaker, add 1500ml of dilute aqua regia to heat and dissolve, add 500ml of dilute aqua regia, and the alloy Dissolve completely, concentrate until crystal film appears on the liquid surface, add concentrated hydrochloric acid to catch up with nitrate until no reddish-brown gas is produced, add 60g of sodium chloride solid, evaporate to dryness, add water to dissolve, and obtain platinum-rhodium solution, boil, and use a mass concentration of 10% chlor-alkali is used to adjust the pH to 8, precipitate rhodium precipitation, stand still for about 20 hours, filter to obtain filtrate 1, precipitate and recover rhodium, and a small amount of platinum adsorbed on the precipitate to reduce the loss of precious metal platinum and rhodium;

[0045] 2. Secondary hydrolysis:

[0046] Concentrate the filtra...

Embodiment 2

[0061] 1. Primary hydrolysis:

[0062] Weigh 120.11g of platinum-iridium alloy waste with an Ir content of 5%, cut it short with scissors to make a "Z" shape, place it in a 5000ml beaker, add 1500ml of dilute aqua regia to dissolve, add 300ml of dilute aqua regia, and the alloy is completely Dissolve and concentrate until a crystal film appears on the liquid surface, add concentrated hydrochloric acid to catch the nitrate until no reddish-brown gas is produced, add 45g of sodium chloride solid, evaporate to dryness, add deionized water to dissolve, and obtain a platinum-iridium solution. The concentration is 20% chlor-alkali to adjust pH=10, precipitate iridium precipitate, stand for about 20 hours, filter to obtain filtrate 1, precipitate and recover rhodium, and a small amount of platinum adsorbed on the precipitate, reducing the loss of precious metal platinum iridium;

[0063] 2. Secondary hydrolysis:

[0064] Concentrate the filtrate 1 to about 200ml, add water 100ml con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com