Production technique of bone peptide calcium

A production process and bone protein technology, applied in the field of production technology of bone protein peptide calcium, can solve the problems of low absorption rate, poor solubility, low content of small molecular peptides, etc., and achieve rich nutrition, easy absorption, and reasonable calcium to phosphorus ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A production process of bone protein peptide calcium powder is completed according to the following steps: ① take fresh beef and sheep bones; ② precook and remove oil; mm), colloid milling (≤0.05mm); ⑤ make bone mince; ⑥ adjust the pH value of bone mince to 6.0; ⑦ carry out hydrolysis (add enzyme amount 0.5%, temperature 55 ℃, time about 3 hours); ⑧Inactivate the enzyme by heating (95°C, 10min); ⑨Get the hydrolyzate; ⑩Filtrate the hydrolyzate, dissolve the filter residue with acid, filter, and dry the filtrate to obtain bone calcium phosphate powder; filter the filtrate through the membrane After the obtained serum is spray-dried, bone protein peptide powder is obtained; finally, bone protein calcium phosphate powder and bone protein peptide powder are mixed to obtain bone protein peptide calcium powder.

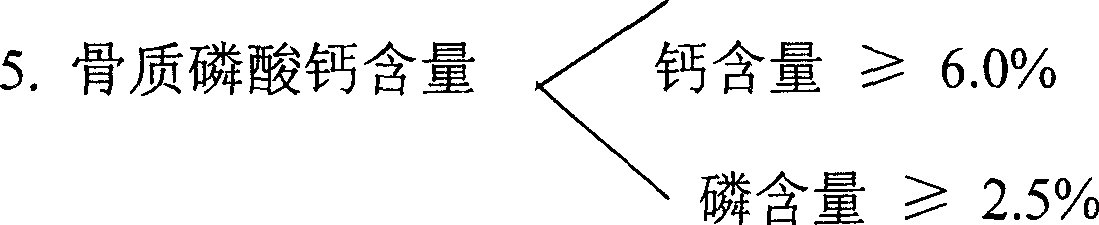

[0014] The quality index of the bone protein peptide calcium powder that the present invention produces is as follows:

[0015] 1. Total protein ≥ 10.0%

[0016] 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com