Bottle flake recycled polyester elastic wig filaments

A technology of recycled polyester and bottle flakes, applied in the field of textile fibers, can solve the problems of inability to imitate texture and texture, poor heat resistance, wig burning, etc., and achieve the effects of stable shrinkage, stable chemical properties, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

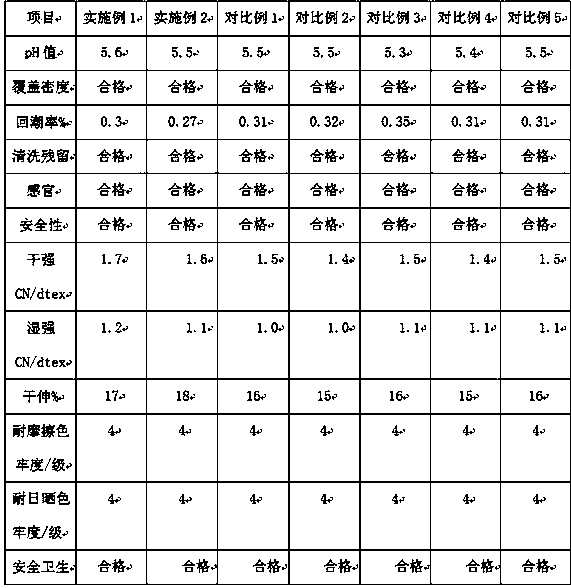

Examples

Embodiment 1

[0022] A bottle flake regenerated polyester elastic wig filament, mainly made from the following raw materials: 100 parts of waste PET bottle flakes, 3 parts of neopentyl glycol, 2.4 parts of diethylaminoethanol, 1.5 parts of 1,4-butanediol, ethanol 0.1 part of diol, 0.5 part of heat stabilizer, 1 part of toughening agent, 3 parts of terpene resin, 0.5 part of diethyltoluenediamine, 0.5 part of antioxidant, and 11 parts of filler.

[0023] A bottle flake regenerated polyester elastic wig filament, its preparation method comprises the steps:

[0024] (1) Washing and drying: Cut and crush the waste PET bottle flakes into bottle flakes with a diameter of 8~20mm, and then heat wash and dehydrate with clean water. Continuously rolling and stirring, heated by the heating mantle to 140°C~180°C for crystallization for 1 hour, and then dried at this temperature for 4~6 hours. The compression pressure is 0.8~0.95MPa, and the moisture contained in the raw material is extracted to reduce...

Embodiment 2

[0031] A bottle flake regenerated polyester elastic wig filament, which is mainly prepared from the following raw materials: 130 parts of waste PET bottle flakes, 5 parts of neopentyl glycol, 2.7 parts of diethylaminoethanol, 2.1 parts of 1,4-butanediol, ethanol 0.2 parts of diol, 0.5 parts of heat stabilizer, 1 part of toughening agent, 5 parts of terpene resin, 3 parts of diethyltoluenediamine, 1 part of antioxidant, and 14 parts of filler.

[0032] A bottle flake regenerated polyester elastic wig filament, its preparation method comprises the steps:

[0033] (1) Washing and drying: Cut and crush the waste PET bottle flakes into bottle flakes with a diameter of 8~20mm, and then heat wash and dehydrate with clean water. Continuously rolling and stirring, heated by heating mantle to 140℃~180℃ for crystallization for 1 hour, and then dried at this temperature for 4 hours. During this period, vacuum was continuously pumped by vacuum pump to generate negative pressure in the vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com