Thick warp-knitted spacer-fabric three-dimensional quilted mattress cover material and preparation method thereof

A warp knitting spacer fabric, imitation quilting technology, applied in warp knitting, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of low efficiency, high cost, long production cycle, etc., to reduce production costs, reduce Production process, the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

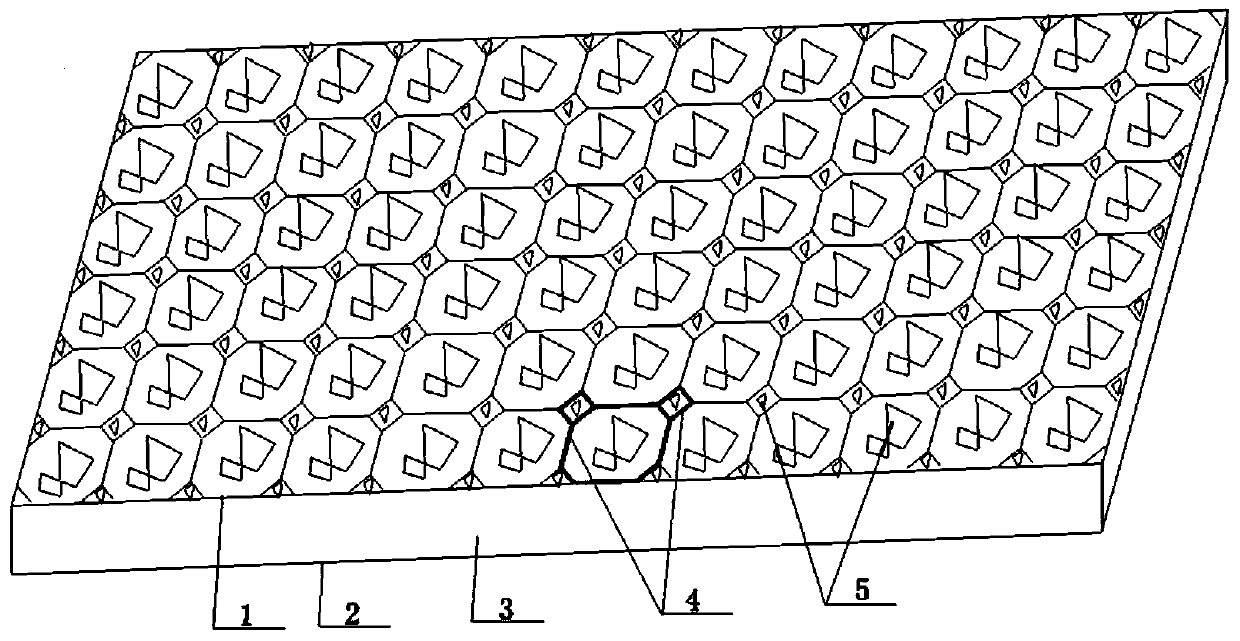

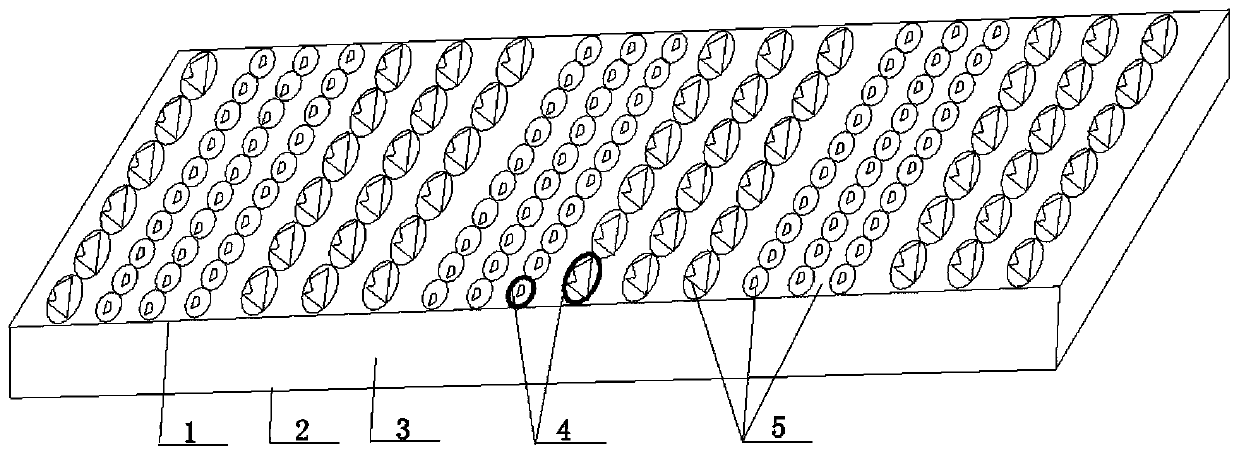

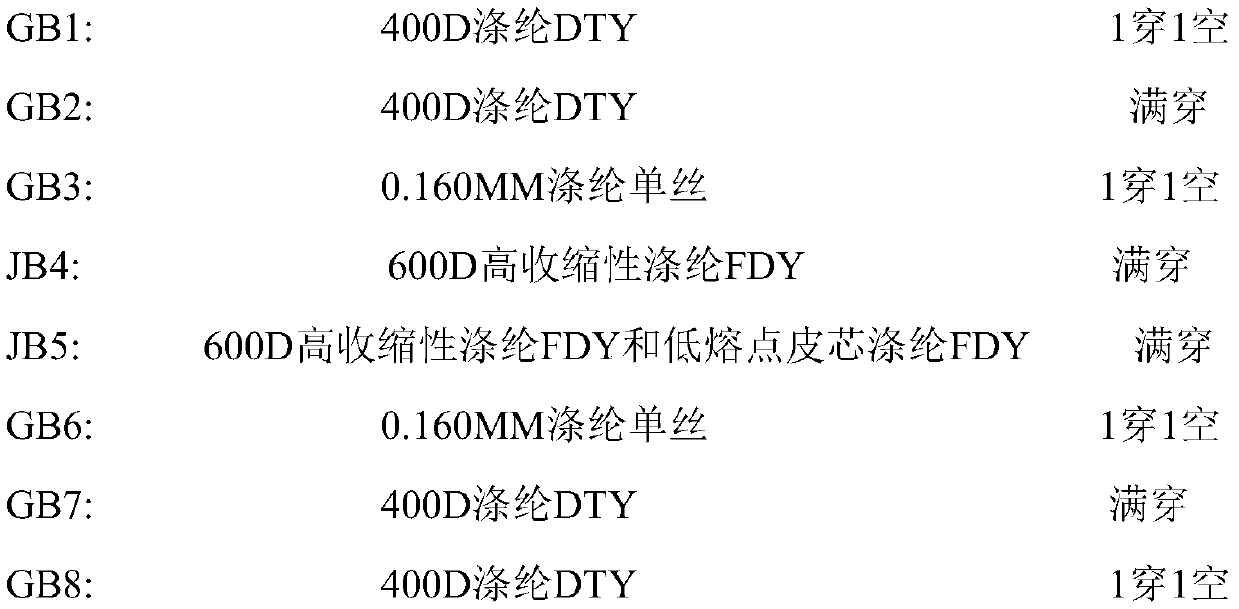

[0053] The preparation method of the thick-type warp-knitted spacer fabric three-dimensional imitation quilting mattress cover material comprises the following steps:

[0054] 1) The ground combs GB1 and GB2 are respectively full-threaded or empty-threaded with the yarns of the first system and the yarns of the second system according to the technical requirements, and the upper layer is knitted on the front needle bed according to the process design; the ground combs GB7 and GB8 are respectively According to the requirements of the process, the yarns of the seventh system and the eighth system are fully threaded or empty, and the lower layer is woven on the rear needle bed according to the process design;

[0055] 2) The ground combs GB3 and GB6 are respectively specified to be full or empty through the yarns of the third system and the yarns of the sixth system according to the process requirements, and are respectively placed on the front needle bed and the rear needle bed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com