Silicon dioxide aerogel polyurea and preparation method thereof

A technology of silica and aerogel, which is applied in the field of preparation of silica airgel polyurea, can solve the problem of poor temperature resistance, poor ambient temperature, and poor weather resistance. and other issues to achieve the effects of enhancing weather resistance, expanding the working temperature range, and increasing the working temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

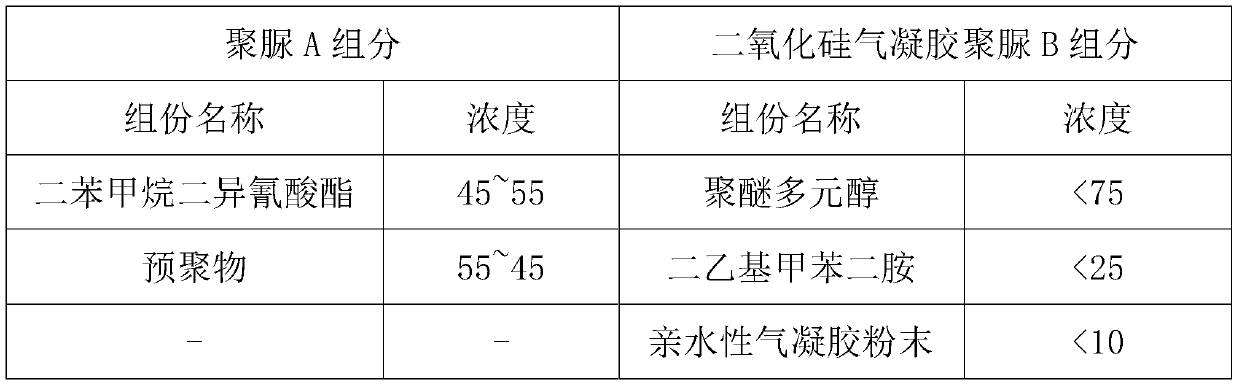

[0033] According to above-mentioned material description, a kind of preparation method of silica airgel polyurea is provided, and its steps are:

[0034] (1) After heating the polyurea component, pour it into the container of the disperser to fully stir;

[0035] (2) Divide the hydrophilic silicon dioxide powder into equal batches and add in the polyurea component successively for stirring;

[0036] (3) When mixing and stirring the hydrophilic silica powder and the polyurea component, keep the temperature of the polyurea component controlled at 50-60°C;

[0037] (4) When the volume ratio of the hydrophilic silica powder and the polyurea component after mixing is between 5% and 10%, and the viscosity is not higher than 1000mPa.s, component B is obtained;

[0038] (5) Mix component B and component A in proportion to obtain silica airgel polyurea.

[0039] In step (1), the heating temperature of the polyurea component is between 50-60° C., and the stirring speed of the polyurea...

Embodiment 1

[0044] By weighing 3g of hydrophilic silica airgel powder and 47g of polyurea component B, after fully and uniformly dispersing and mixing through a disperser, add 100g of traditional polyurea component A, and the ratio of A and B components is 2:1 (weight ratio) fully mixed and pressurized and heat-treated to obtain silica airgel polyurea;

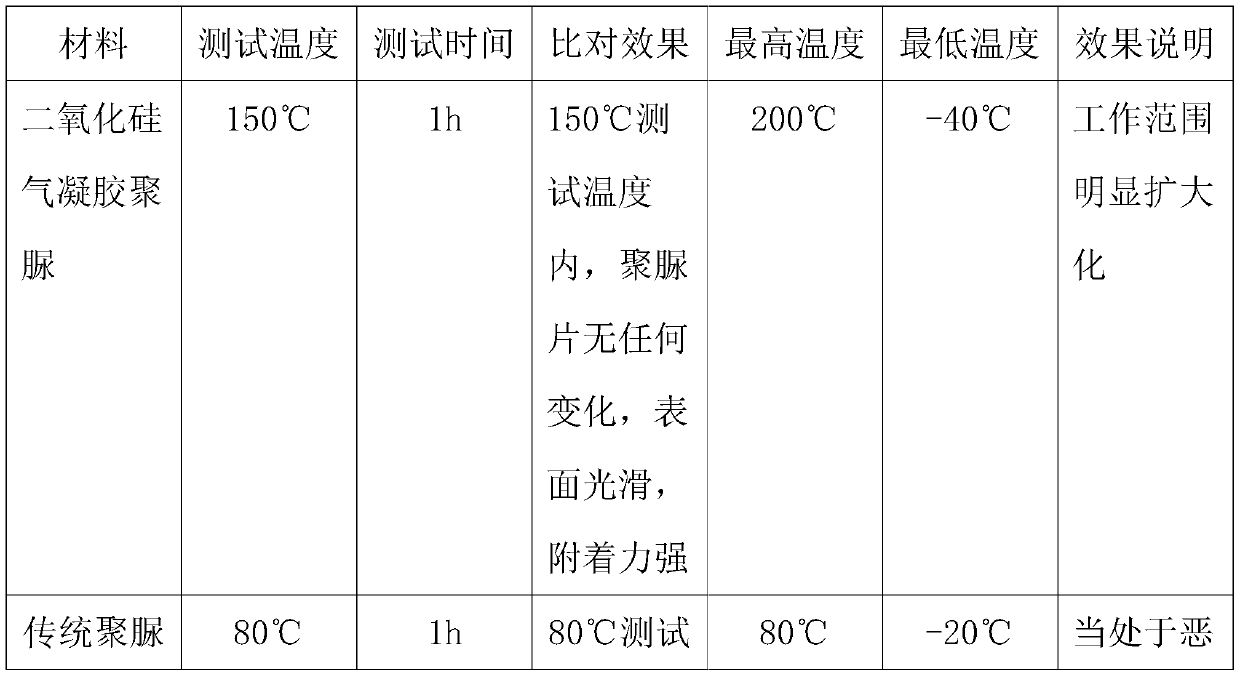

[0045] Subsequently, silica airgel polyurea and traditional polyurea were manually brushed on the upper surface of the stainless steel plate (size 150x150X10mm) substrate, the thickness was controlled within the range of 2mm±1mm, and the heating test was carried out after standing at room temperature for 24 hours. The performance measurement is as follows:

[0046]

[0047]

Embodiment 2

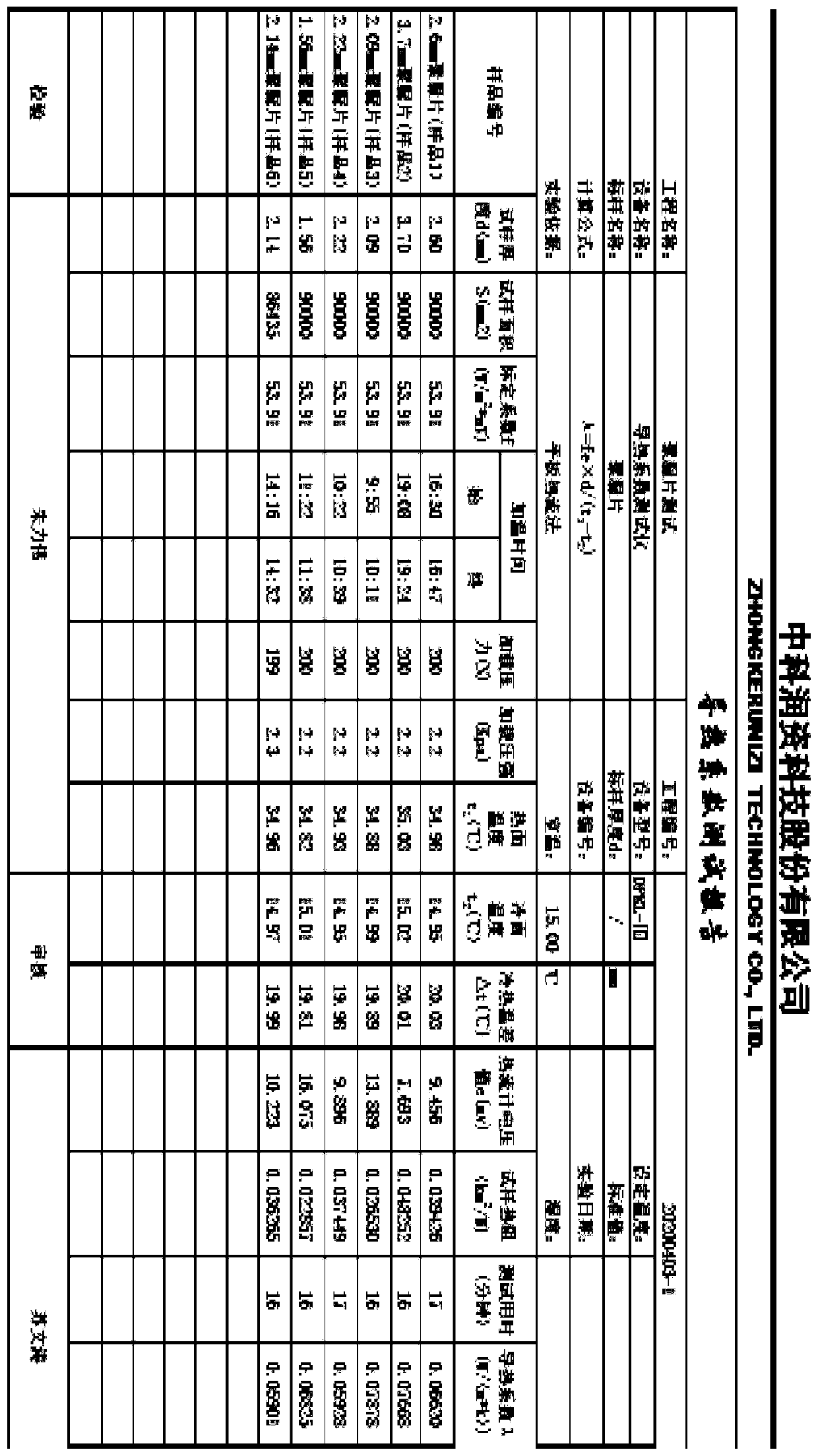

[0049] By weighing 4g of hydrophilic silica airgel powder and 46g of polyurea component B, after fully and uniformly dispersing and mixing through a disperser, add 50g of traditional polyurea component A, and the ratio of components A and B to 1:1 (weight ratio) fully mixed and pressurized and heated to obtain silica airgel polyurea; then sprayed evenly on the release plate with a high-pressure spray gun, the thickness is controlled within the range of 2mm ± 1mm, and then cut at room temperature for 24 hours Formed size: 300mmX300mm sheet, conduct thermal conductivity measurement, the measurement is shown in the following table:

[0050]

[0051]Traditional silica airgel is a solid powder, which neither dissolves nor melts in the temperature range of -196°C to 800°C. It cannot be added to the preparation process of polyurea. The invention provides a brand-new method for integrating silica airgel powder into the polyurea material preparation process, and further invents a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com