Synthesis method of diethyltoluenediamine

A technology of diethyltoluenediamine and toluenediamine, which is applied in the chemical field, can solve problems such as low catalytic activity, strong toxicity, and high price, and achieve the effects of overcoming easy coking, easy control, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

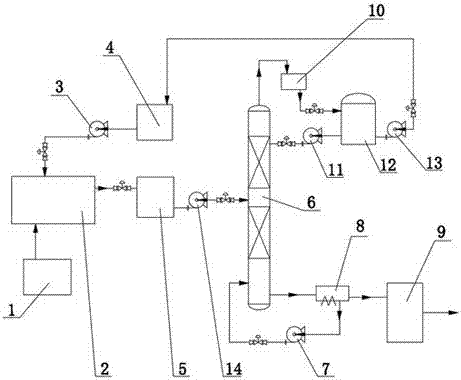

[0026] 1. Control cabinet, 2. High-pressure reaction kettle, 3. Toluenediamine feeding pump, 4. Toluenediamine storage tank, 5. Transfer tank, 6. Distillation tower, 7. Bottom reflux pump, 8. Boiler, 9. Tower bottom product storage tank, 10. Tower top total condenser, 11. Tower top reflux pump, 12. Tower top storage tank, 13. Toluenediamine circulation pump, 14. Rectification feed pump

[0027] combine Figure 1~2 , a kind of catalytic synthesis diethyltoluenediamine process of the present invention, under the condition of 80 ℃ constant temperature water bath, prepare the aqueous solution of copper nitrate, zinc nitrate, aluminum nitrate, cerium nitrate, according to molar ratio n (硝酸铜) :n (硝酸锌) :n (硝酸铝) :n (硝酸铈) =1:1:2:0.06, that is, the molar ratio of copper nitrate, zinc nitrate, aluminum nitrate, and cerium nitrate is 1:1:2:0.06, the solution is blue, fully stirred for 0.5 h, and then according to the molar ratio n (柠檬酸) :n (硝酸铜+硝酸锌+硝酸铝+硝酸铈) =1.2:1, that is, the mola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com