High-toughness epoxy resin composition applied to RTM (resin transfer molding) process and preparation method thereof

An epoxy resin and high-toughness technology, applied in the field of high-toughness epoxy resin composition and its preparation, can solve the problem of limited toughness improvement, low strength, modulus and glass transition temperature, low strength, modulus and glass transition temperature Reduce the temperature and other problems, to achieve the effect of low viscosity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Stir 19 parts of diethyltoluenediamine and 10 parts of polyetheramine D-230 at room temperature, and mix uniformly to form a component B liquid curing agent containing polyetheramine D-230 with a mass fraction of 34%;

[0023] Then at 40°C, remove the air bubbles with the A-component 830 epoxy resin and the B-component liquid curing agent in a vacuum;

[0024] Use an RTM injection machine to mix evenly according to the mass ratio of component A: component B = 100:29, then inject it into an RTM mold with a mold temperature of 35°C, and cure at 80°C / 1h+100°C / 2h+130°C / 2h , to obtain cured epoxy resin.

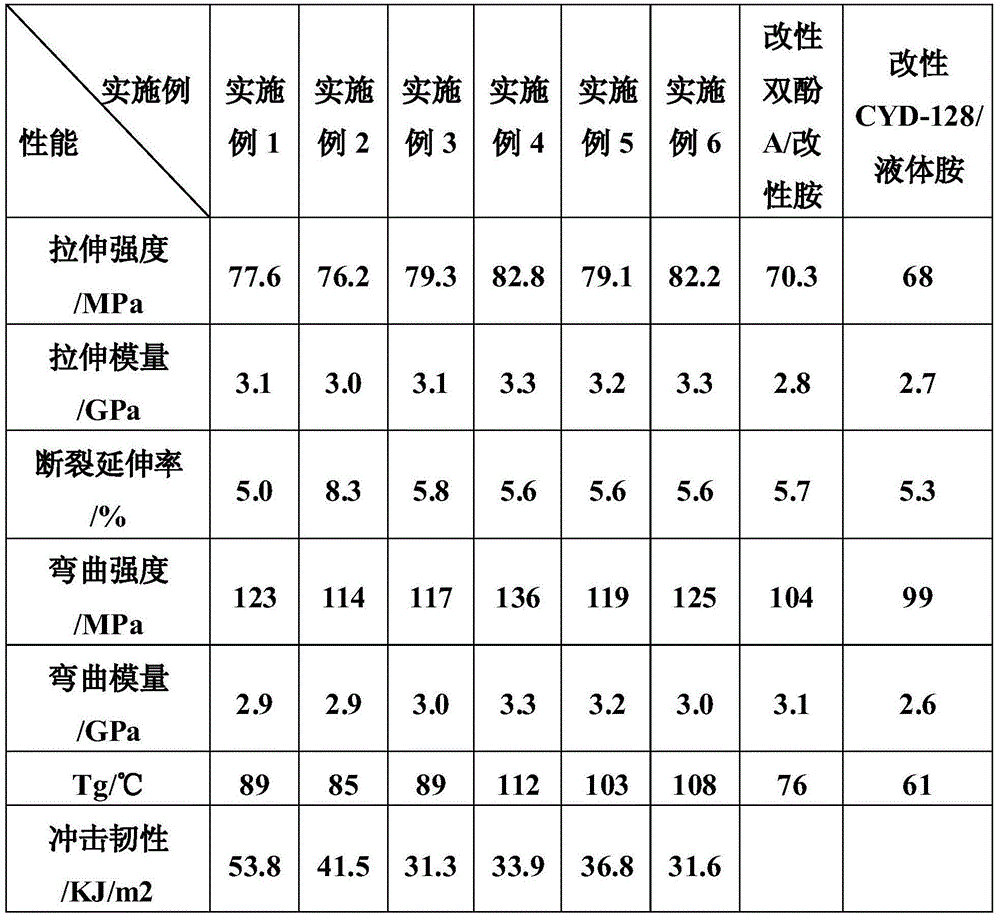

[0025] The RTM operating process window of the epoxy resin composition at 35° C. is 148 min (viscosity2 , while its tensile strength is 77.6MPa, tensile modulus is 3.1GPa, glass ring transition temperature Tg is 89 ℃. See Table 1 for other performance data.

Embodiment 2

[0027] Stir 15 parts of diethyltoluenediamine and 15 parts of polyetheramine D-230 evenly at room temperature, and mix them into a component B liquid curing agent containing D-230 with a mass fraction of 50%;

[0028] Then, at 35°C, remove the air bubbles with the A-component 830 epoxy resin and the B-component liquid curing agent in a vacuum;

[0029] Use an RTM injection machine to mix evenly according to the mass ratio of component A: component B = 100:30, then inject it into the RTM mold with a mold temperature of 38°C, and cure at 80°C / 1h+100°C / 2h+130°C / 2h , to obtain cured epoxy resin.

[0030] The RTM operating process window of the epoxy resin composition at 35° C. is 140 min (viscosity2 , while the tensile strength is 76.2MPa, the tensile modulus is 3.0GPa, and the glass ring transition temperature Tg is 85°C. See Table 1 for other performance data.

Embodiment 3

[0032] Stir 11 parts of diethyltoluenediamine and 20.5 parts of polyetheramine D-230 evenly at room temperature, and mix them into a component B liquid curing agent containing D-230 with a mass fraction of 65%;

[0033] Then, at 30°C, remove the air bubbles with the A-component 830 epoxy resin and the B-component liquid curing agent in a vacuum;

[0034] Use an RTM injection machine to mix evenly according to the mass ratio of component A: component B = 100:31.5, then inject it into an RTM mold with a mold temperature of 35°C, and cure at 80°C / 1h+100°C / 2h+130°C / 2h , to obtain cured epoxy resin.

[0035]The RTM operating process window of the epoxy resin composition at 35° C. is 139 min (viscosity2 , while the tensile strength is 79.3MPa, the tensile modulus is 3.1GPa, and the glass ring transition temperature Tg is 89°C. See Table 1 for other performance data.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com