Epoxy resin composition as well as bonding sheet and copper-clad plate made from same

A technology of epoxy resin and composition, applied in the direction of online phenolic epoxy resin adhesive, epoxy resin glue, synthetic resin layered products, etc., can solve the problem of difficult to reduce production cost, difficult to reduce material cost, copper clad laminate Poor heat resistance and other problems, to achieve the effect of enhancing heat resistance polarity, improving heat resistance, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

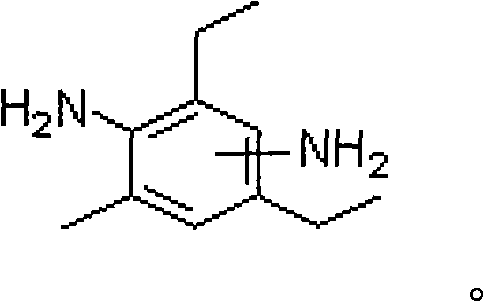

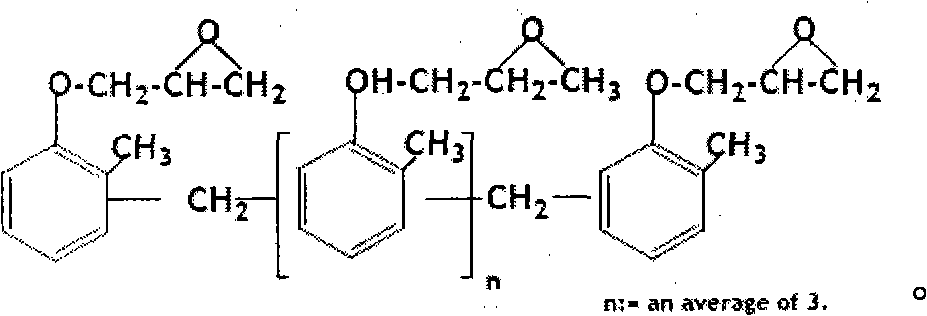

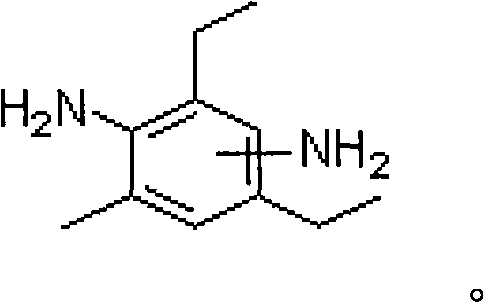

[0034] First, 1.86 parts of dicyandiamide (DICY) were dissolved in DMF, 20 parts of KEC-2180 o-cresol novolac epoxy resin were dissolved in DMF and butanone solvent, and 0.04 parts of 2-MI were dissolved in butanone. Then the above three solutions that have been dissolved are mixed with 73 parts of DER530A80 bromine flame-retardant epoxy resin, 3.5 parts of 1031 epoxy resin with UV light blocking function, and 1.6 parts of ETHACURE200 diethyltoluenediamine, supplemented with DMF and MEK Stir uniformly to form a glue solution; the solid resin content in the prepared glue solution is 55-70%, and the gelation time is 200s to 350s. Immerse the glass fiber cloth in the above resin composition glue, put the impregnated glass fiber cloth into the oven and bake. This step is applicable to the gluing mode of FR-4, and the baking temperature is required to be higher than that of FR-4. Bake in an oven at 155°C for 6 minutes, and make an adhesive sheet after semi-curing. Eight bonding sh...

Embodiment 2

[0036] First, 20 parts of EPON164 o-cresol novolac epoxy resin were dissolved in DMF and butanone solvent, and 0.004 parts of 2-MI were dissolved in butanone. Then the above two solutions that have been dissolved are mixed with 64 parts of DER530A80 bromine flame-retardant epoxy resin, 4 parts of 1031 epoxy resin with UV light blocking function, and 12 parts of ETHACURE200 diethyltoluenediamine, supplemented with DMF and MEK Stir uniformly to form a glue solution; the solid resin content in the prepared glue solution is 55-70%, and the gelation time is 200s to 350s. Immerse the glass fiber cloth in the above resin composition glue, put the impregnated glass fiber cloth into the oven and bake. This step is applicable to the gluing mode of FR-4, and the baking temperature is required to be higher than that of FR-4. Bake in an oven at 155°C for 6 minutes, and make an adhesive sheet after semi-curing. Eight bonding sheets prepared above were bonded and stacked together, and coppe...

Embodiment 3

[0038]First, dissolve 20 parts of KEC-2180 o-cresol novolac epoxy resin with butanone solvent, dissolve 0.03 parts of 2-MI with butanone, and dissolve 0.06 parts of boron trifluoride monoethylamine with butanone solvent . Then dissolve the above three solutions together with 43 parts of DER530A80 bromine flame retardant epoxy resin, 7 parts of 1031 epoxy resin with UV light blocking function, 2 parts of DDS, 3 parts of ETHACURE200 diethyltoluenediamine, 25 parts Parts of phenolic resin are mixed, supplemented with PM and MEK and stirred evenly to form a glue; the solid resin content in the prepared glue is 55-70%, and the gelation time is 200s to 350s. Immerse the glass fiber cloth in the above resin composition glue, put the impregnated glass fiber cloth into the oven and bake. This step is applicable to the gluing mode of FR-4, and the baking temperature is required to be higher than that of FR-4. Bake in an oven at 155°C for 6 minutes, and make an adhesive sheet after semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com