Organic silicon resin modified epoxide resin composition

A technology of epoxy resin and novolac epoxy resin, which is applied in the field of compositions containing silicone resin flame retardant modified epoxy resin, can solve the problems of reducing the elongation at break and toughness of the resin internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

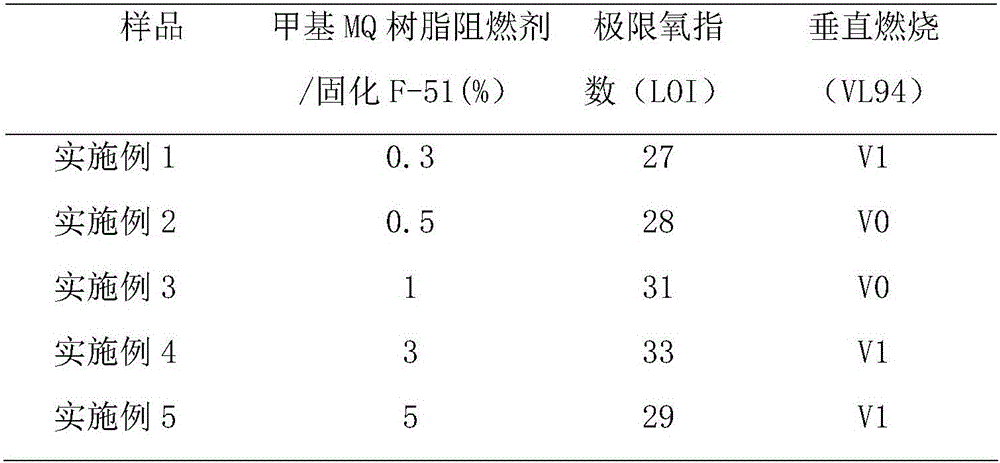

Embodiment 1

[0015] Preparation of epoxy resin composition: Heat 100 parts of novolac epoxy resin (epoxy value 0.51mol / 100g, Shanghai Resin Co., Ltd. F-51) to 80°C, add 10 parts of silicone resin solubilizer, and stir slowly for 0.5 hours , add 0.3 parts of methyl MQ silicone resin (industrial grade Zhonglan Chenguang Chemical Research Institute) with a double-layer compact spherical structure, and 19.58 parts of diethyltoluenediamine. After stirring evenly, pour it into a preheated mold ( To prevent the silicone from curing, this step must be done within 15 minutes). Then heat and cure in a blast drying oven at a suitable temperature, the temperature is 130°C / 2.5 hours, 160°C / 2.5 hours. After curing, the flame-retardant epoxy resin cured product is obtained.

[0016] Preparation of silicone resin solubilizer: Put 23.6g of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH560) and 18g of dimethyldimethoxysilane (DEMS) and appropriate amount of absolute ethanol into Put into the 250ml round-bo...

Embodiment 2

[0018] Epoxy resin composition: heat 100 parts of novolak epoxy resin (epoxy value 0.51mol / 100g, Shanghai Resin Co., Ltd. F-51) to 80°C, add 10 parts of silicone resin solubilizer (same as Example 1) , stirred at a slow speed for 0.5 hours, added 0.5 parts of methyl MQ silicone resin with a double-layer compact spherical structure, 19.58 parts of diethyltoluenediamine, and poured it into a preheated mold after stirring evenly (to prevent silicon The resin is cured, this step must be completed within 15 minutes). Then heat and cure in a blast drying oven at a suitable temperature, the temperature is 130°C / 2.5 hours, 160°C / 2.5 hours. After curing, the flame-retardant epoxy resin cured product is obtained.

Embodiment 3

[0020] Epoxy resin composition: Heat 100 parts of novolak epoxy resin (epoxy value 0.51mol / 100g, F-51 of Shanghai Resin Co., Ltd.) to 80°C, add 10 parts of silicone resin solubilizer (HPSi) developed in the laboratory, Stir at a slow speed for 0.5 hours, add 1 part of methyl MQ silicone resin with a double-layer compact spherical structure, and 19.58 parts of diethyltoluenediamine. After stirring evenly, pour it into a preheated mold (to prevent the silicone resin from Curing, this step must be completed within 15 minutes). Then heat and cure in a blast drying oven at a suitable temperature, the temperature is 130°C / 2.5 hours, 160°C / 2.5 hours. After curing, the flame-retardant epoxy resin cured product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com