A kind of antistatic polyurethane elastomer and preparation method thereof

A polyurethane elastomer and antistatic technology, applied in the field of polyurethane, can solve the problems of poor antistatic performance of polyurethane elastomer, and achieve the effects of superior antistatic performance, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A kind of preparation method of antistatic polyurethane elastomer, it comprises following preparation steps:

[0078]Step 1. 70 kg of polyether polyol with a functionality of 2 and a number average molecular weight of 1000, 28 kg of toluene dicyanate, and an antioxidant (bis[β(3-tert-butyl-5-methyl-4- Hydroxyphenyl) propionate] triethylene glycol ester) 2kg were added to the container in turn, and reacted in the container at 67°C for 3 hours to obtain component A with a mass content of isocyanide of 5.2%;

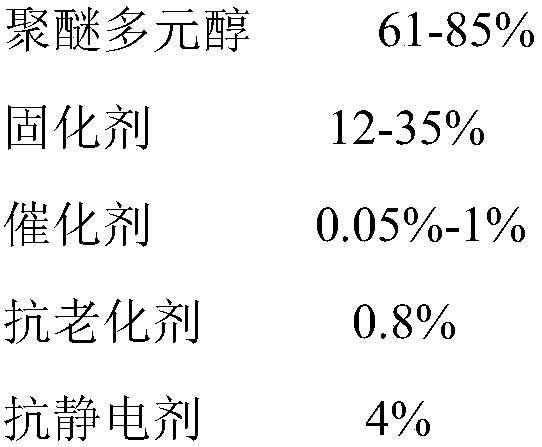

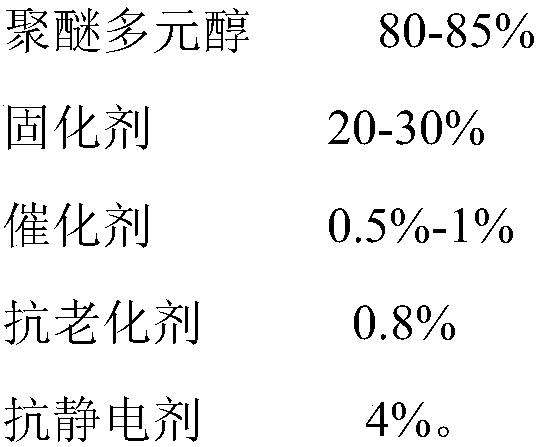

[0079] Step 2. Add 61 kg of polyether polyol with a functionality of 3 and a number average molecular weight of more than 5000, 33 kg of curing agent diethyltoluenediamine, catalyst N,N-bis[3-(dimethylamino)propyl ]-N',N'-dimethyl-1,3-propylenediamine 1㎏, anti-aging agent {2-(2'-hydroxy-3',5'-di[1,1-dimethylbenzene Base]) – benzotriazole)-5-chlorinated benzotriazole} 1㎏, antistatic agent octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate 4 kg are added to t...

Embodiment 2

[0082] A kind of preparation method of antistatic polyurethane elastomer, it comprises following preparation steps:

[0083] Step 1. 65 kg of polyether polyol with a functionality of 2 and a number average molecular weight of 1500, 33 kg of toluene dicyanate, antioxidant (bis[β(3-tert-butyl-5-methyl-4- Hydroxyphenyl) propionate] triethylene glycol ester) 2kg were added to the container in turn, and reacted in the container at 70°C for 2 hours to obtain component A with a mass content of isocyanide of 7.2%;

[0084] Step 2. Add 70 kg of polyether polyol with a functionality of 3 and a number average molecular weight of more than 5000, 25 kg of curing agent diethyltoluenediamine, catalyst N,N-bis[3-(dimethylamino)propyl ]-N',N'-Dimethyl-1,3-propylenediamine 0.05kg, anti-aging agent {2-(2'-hydroxy-3',5'-bis[1,1-dimethylbenzene base]) – benzotriazole)-5-chlorinated benzotriazole} 0.95kg, antistatic agent octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate 4kg were added t...

Embodiment 3

[0087] A kind of preparation method of antistatic polyurethane elastomer, it comprises following preparation steps:

[0088] Step 1. Add 64 kg of polyether polyol with a functionality of 2 and a number average molecular weight of 3000, 35 kg of toluene dicyanate, antioxidant (bis[β(3-tert-butyl-5-methyl-4- Hydroxyphenyl) propionate] triethylene glycol ester) 1kg was sequentially added to the container, and reacted in the container at 70°C for 3 hours to obtain component A with a mass content of isocyanide of 7.0%;

[0089] Step 2. Add 82kg of polyether polyol with a functionality of 3 and a number average molecular weight of more than 5000, 12kg of curing agent diethyltoluenediamine, catalyst N,N-bis[3-(dimethylamino)propyl ]-N',N'-Dimethyl-1,3-propylenediamine 0.5kg, anti-aging agent {2-(2'-hydroxy-3',5'-di[1,1-dimethylbenzene Base]) – benzotriazole)-5-chlorinated benzotriazole} 1.5kg, antistatic agent octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate 4kg were adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com