Patents

Literature

43results about How to "Low reaction temperature requirement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

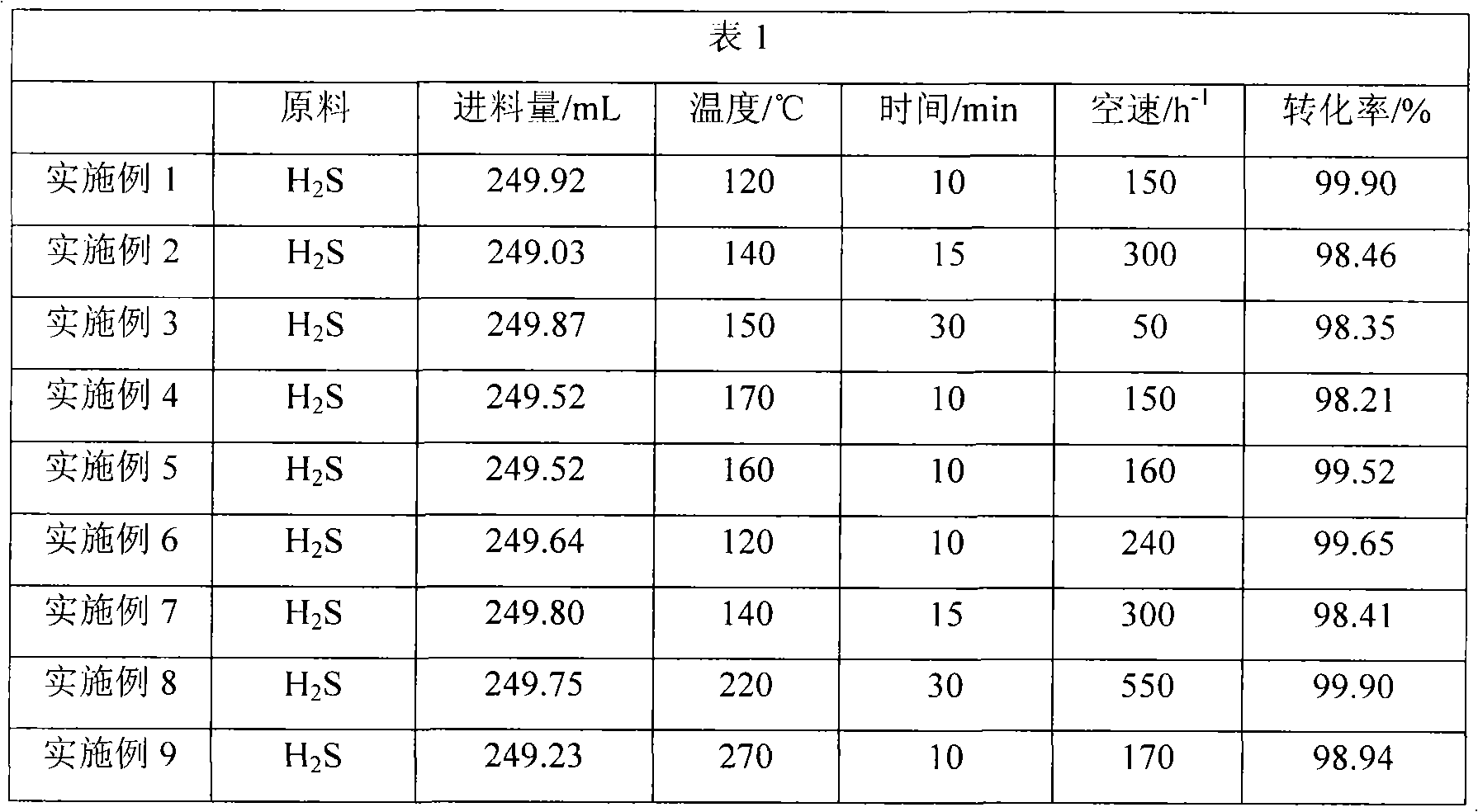

Catalyst for decomposing hydrogen sulfide by photocatalysis and preparation method of hydrogen and liquid sulfur by employing same

ActiveCN101590410ARealize comprehensive utilizationHigh activityDispersed particle separationSulfur preparation/purificationAlkaline earth metalVanadate

The invention relates to a catalyst for decomposing hydrogen sulfide by photocatalysis and a preparation method of hydrogen and liquid sulfur by employing same. The catalyst comprises a carrier, active component and assistant and has the characteristics that the carrier is one or more selected from vanadate, niobate and tantalate, the active component is one or more selected from alkali metal hydroxide, alkaline earth metal hydroxide, alkali metal nonmetal oxysalt, alkali metal nonoxysalt, alkaline earth metal nonmetal oxysalt and alkaline earth metal nonoxysalt and the assistant is lanthanide oxide or VIII group oxide. The catalyst of the invention can be used for preparing hydrogen and liquid sulfur so that the produced sulfur is easy to be separated from the catalyst, the catalyst can be recycled and the sulfur contained in hydrogen sulfide can be fully recycled, thus realizing the comprehensive utilization of hydrogen sulfide.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

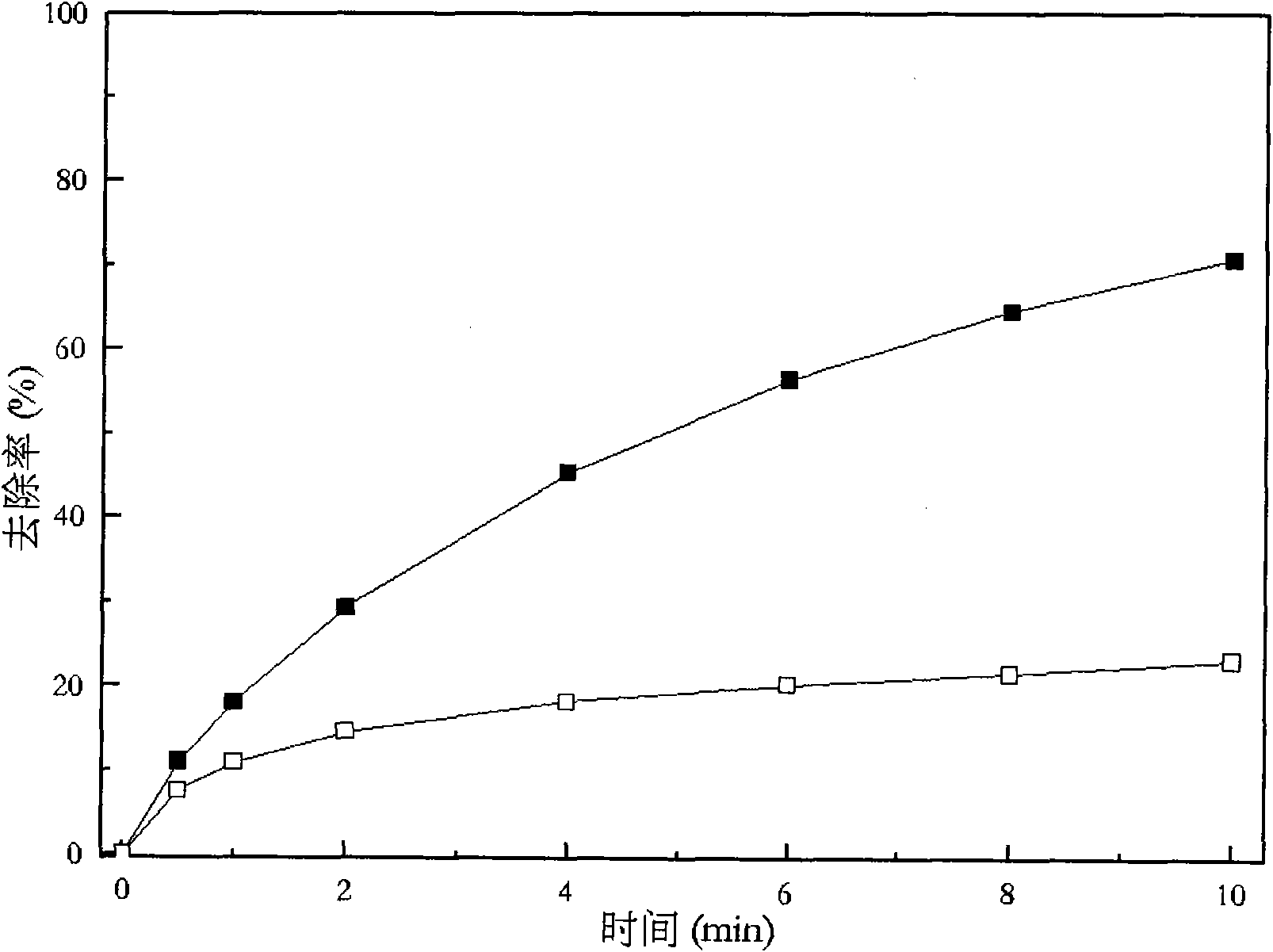

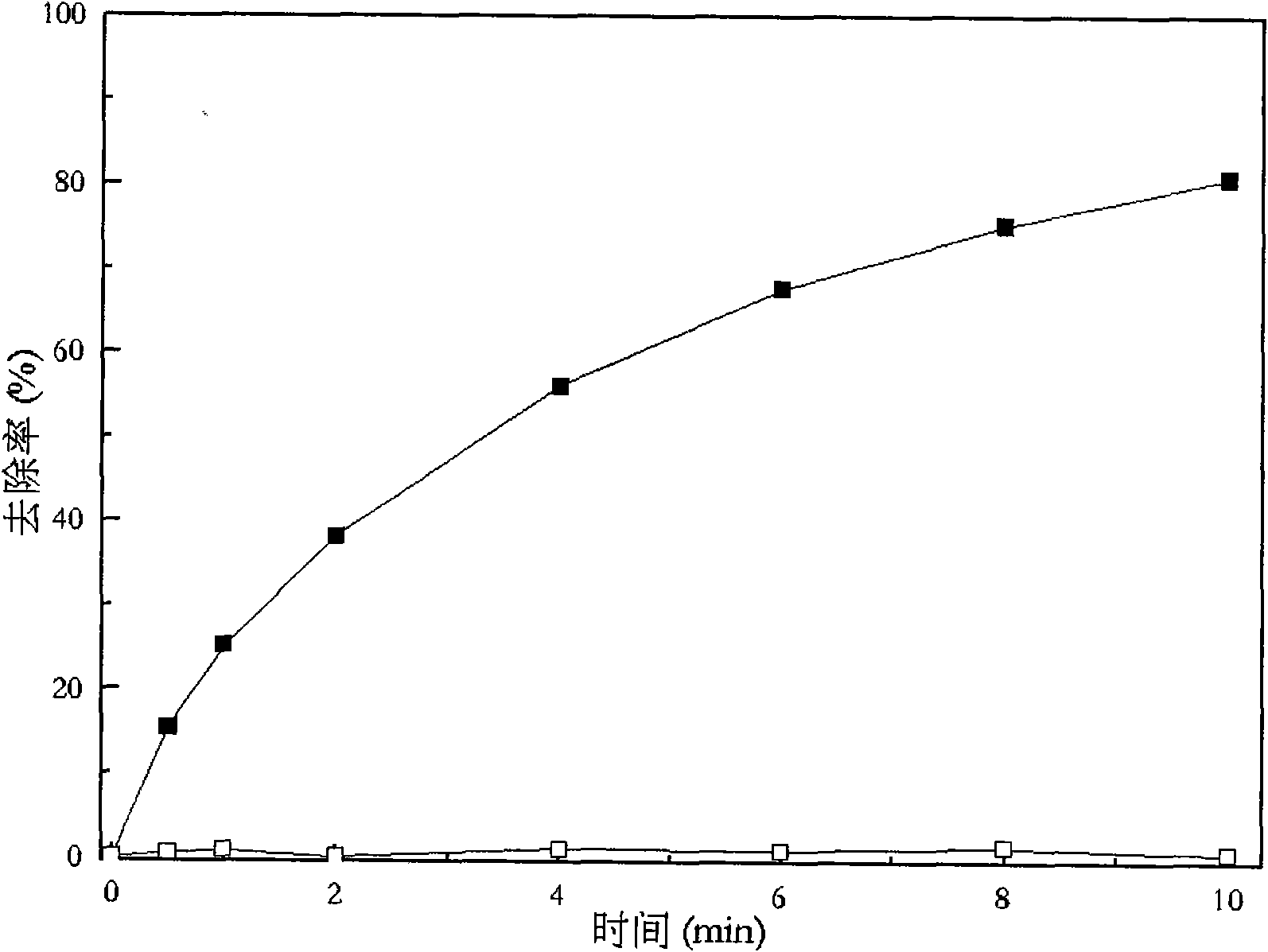

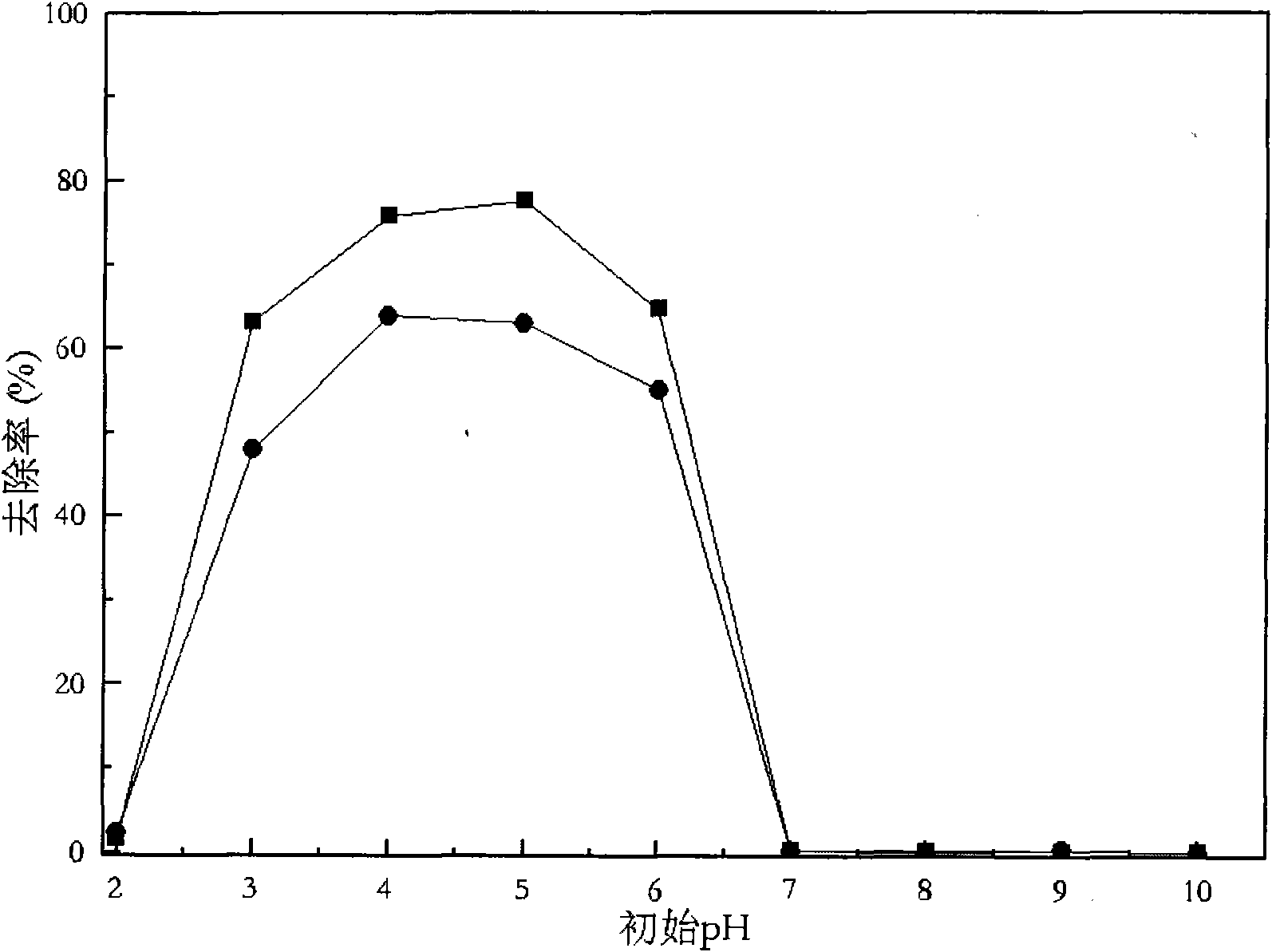

Fenton and Fenton-like system fortifier and using method thereof

ActiveCN101792205AReduce dosageEasy to useWater treatment parameter controlWater treatment compoundsSulfite saltHydrazine compound

The invention provides a Fenton and Fenton-like system fortifier and a using method thereof, which relate to a water treating fortifier and a using method thereof and overcomes the defects that the pH value of the Fenton and Fenton-like system reaction water body is limited, the adding amount of Fe<2+> is overhigh in the Fenton reaction, and the reaction speed is low in Fenton-like reaction. The fortifier is selected from ascorbic acid, sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine, hydroxyl-ammonium perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, carbohydrazide, ethanolamine, a hydroxylamine solution or N,N,N',N'-tetra substituted phenylenediamines. The using method has the following steps of: adding the Fenton and Fenton-like system fortifier, fortificated chemicals and peroxide into the treated water body; and then, uniformly stirring to react. The fortifier can accelerate the reaction of water treatment and decrease the using amount of the fortificated chemicals.

Owner:HARBIN INST OF TECH

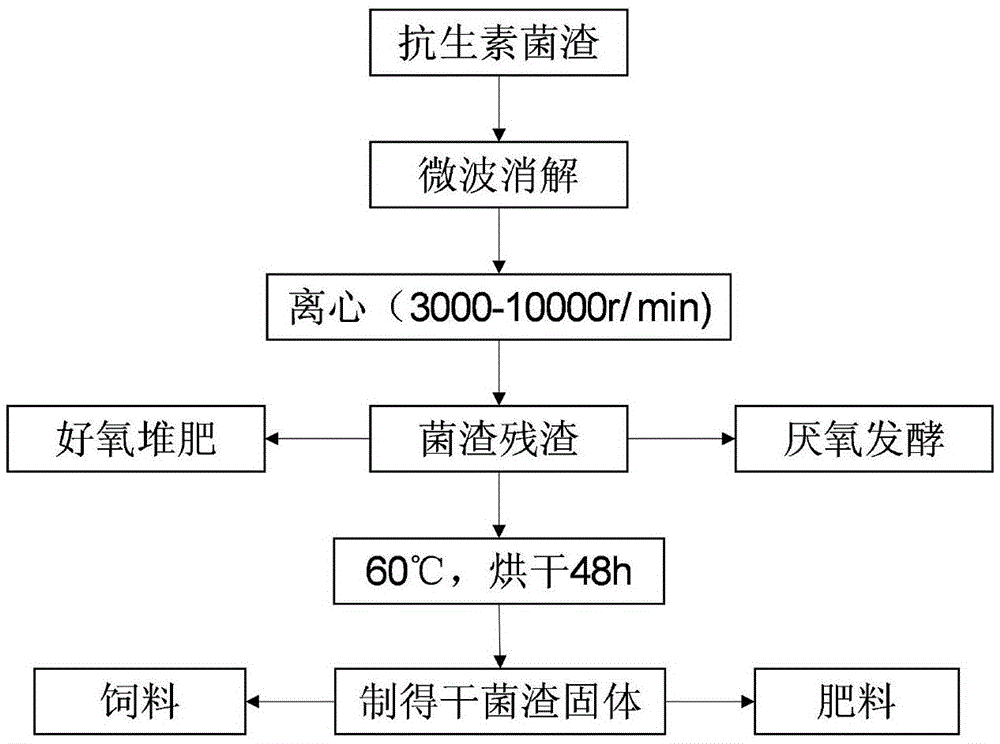

Treatment method and application of antibiotic bacterial residues

InactiveCN105537251ALow moisture content requirementRealize resourcesTransportation and packagingSolid waste disposalAfter treatmentAntibiotic Y

The invention relates to a treatment method and an application of antibiotic bacterial residues, and aims to solve problems that existing bacterial residue treatment methods are long in period, still have the environmental risk after treatment and the like. The method comprises steps as follows: 1) fresh bacterial residues are placed in a reaction tank, the moisture content is controlled between 85% and 95%, and the bacterial residues are evenly mixed; 2) the reaction tank containing the bacterial residues is placed in a microwave reactor, heated to 100 DEG C by a microwave generator with the microwave power of 100-900 W and kept for 10 min; 3) the antibiotic bacterial residues after the reaction are subjected to centrifugal separation, and obtained bacterial residues are precipitated and dried. With the adoption of the method, antibiotic residues in the bacterial residues can be removed quickly, and harmless treatment and recovery of the bacterial residues are realized.

Owner:HARBIN INST OF TECH

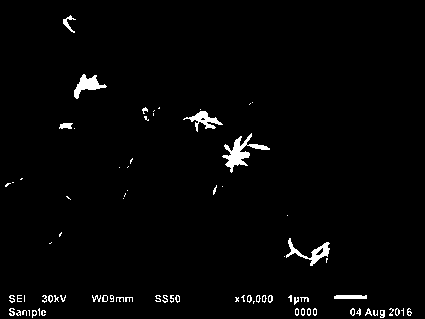

Preparation technology of hexagonal plate magnesium hydroxide

InactiveCN101544387AUniform particle sizeImprove flame retardant performanceMagnesium hydroxideLithium hydroxidePotassium hydroxide

The invention provides a preparation technology of hexagonal plate magnesium hydroxide. Magnesium hydroxide products are prepared into slurry mass concentration of which is 7.5 percent to 15 percent, the slurry is added into transforming agent solution to enable the total alkali concentration of the transforming agent solution to be 2-4mol / L; then all the mixture is mixed uniformly and placed in a high-pressure reaction kettle to react at 140-160 DEG C for 2-6h; and after being cooled, the reaction product is washed by water, dried and crashed to obtain the hexagonal plate magnesium hydroxide. The transforming agent is a composite transforming agent formed by mixing lithium hydroxide and sodium hydroxide or potassium hydroxide according to mol ratio of 1:1-1:4. Observed by a low vacuum laser scanning electron microscope, the magnesium hydroxide prepared in the invention is a hexagonal plate magnesium hydroxide with complete crystal formation and uniform granularity; the grain diameter of the magnesium hydroxide is correlative to raw materials; and the specific surface of the magnesium hydroxide is 3.0-20 m<2> / g. Due to the adoption of the new transforming agent, the invention has high transformation ratio, good product quality, stable crystal formation and low cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

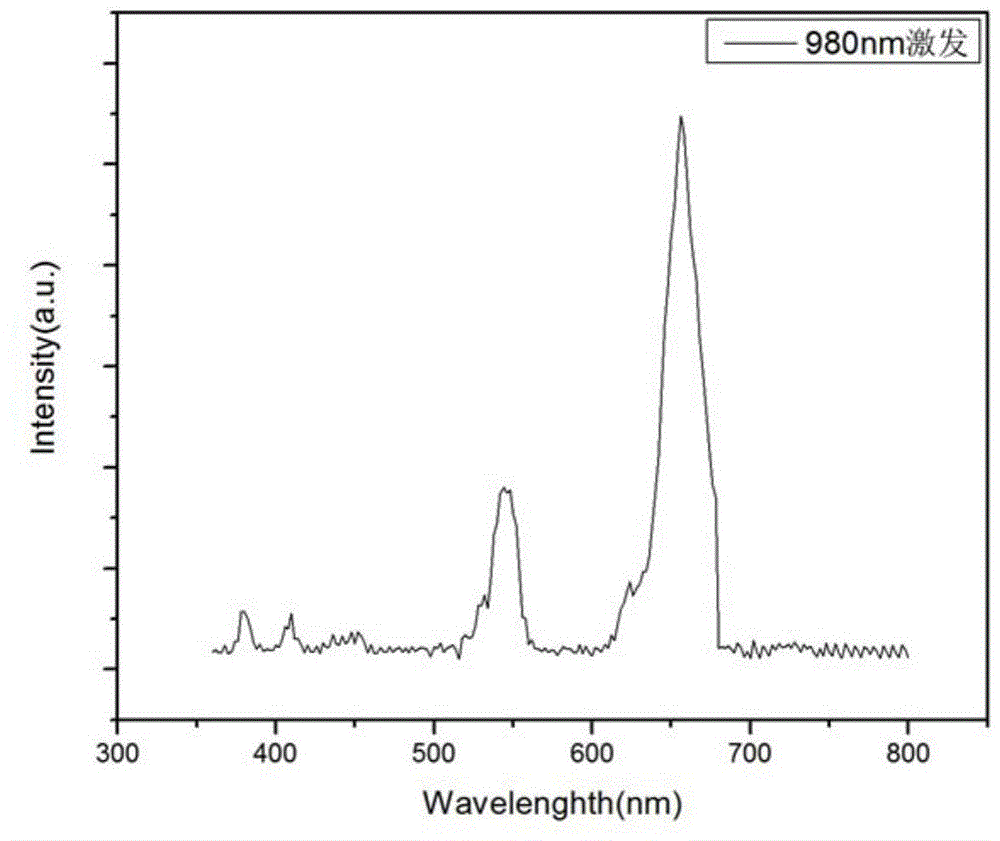

Method for preparing rare-earth fluorescent up-conversion material by use of waste fluorescent powder

InactiveCN104388087ANo secondary pollutionRealize the comprehensive utilization of green high-value resourcesRecycling and recovery technologiesLuminescent compositionsRare-earth elementFiltration

The invention relates to a method for preparing a rare-earth fluorescent up-conversion material by use of waste fluorescent powder. The method comprises the following steps: weighing process waste fluorescent powder, and leaching the fluorescent powder in a sulfuric acid solution to obtain a solution; performing solid-liquid separation, regulating the pH by use of ammonia water, and then performing primary sedimentation, secondary sedimentation, third sedimentation, fourth sedimentation, aging and filtering to obtain filter residue; firing at a high temperature, cooling until the temperature drops to a room temperature, and then adding MOH solution and performing suction filtration to obtain white powder; adding a hydrochloric acid solution, and drying by distillation to obtain the mixture of anhydrous yttrium chloride and anhydrous europium chloride, MOH solid and MHF2 fine powder and RmF3 or RmCl3 solid, and homogenizing; adding a high boiling point solvent, heating and stirring; centrifuging, performing centrifugal washing on the obtained solid powder by use of normal hexane or acetone, drying and then washing by use of boiling water a plurality of times and drying, thereby obtaining the rare-earth fluorescent up-conversion material. The method for preparing the rare-earth fluorescent up-conversion material by use of the waste fluorescent powder has the advantage and the characteristic that green high-value recycling comprehensive utilization of rare earth elements in rare-earth trichromatic phosphor waste can be realized.

Owner:WUHAN UNIV OF TECH

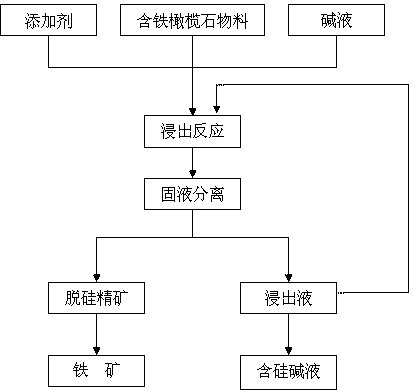

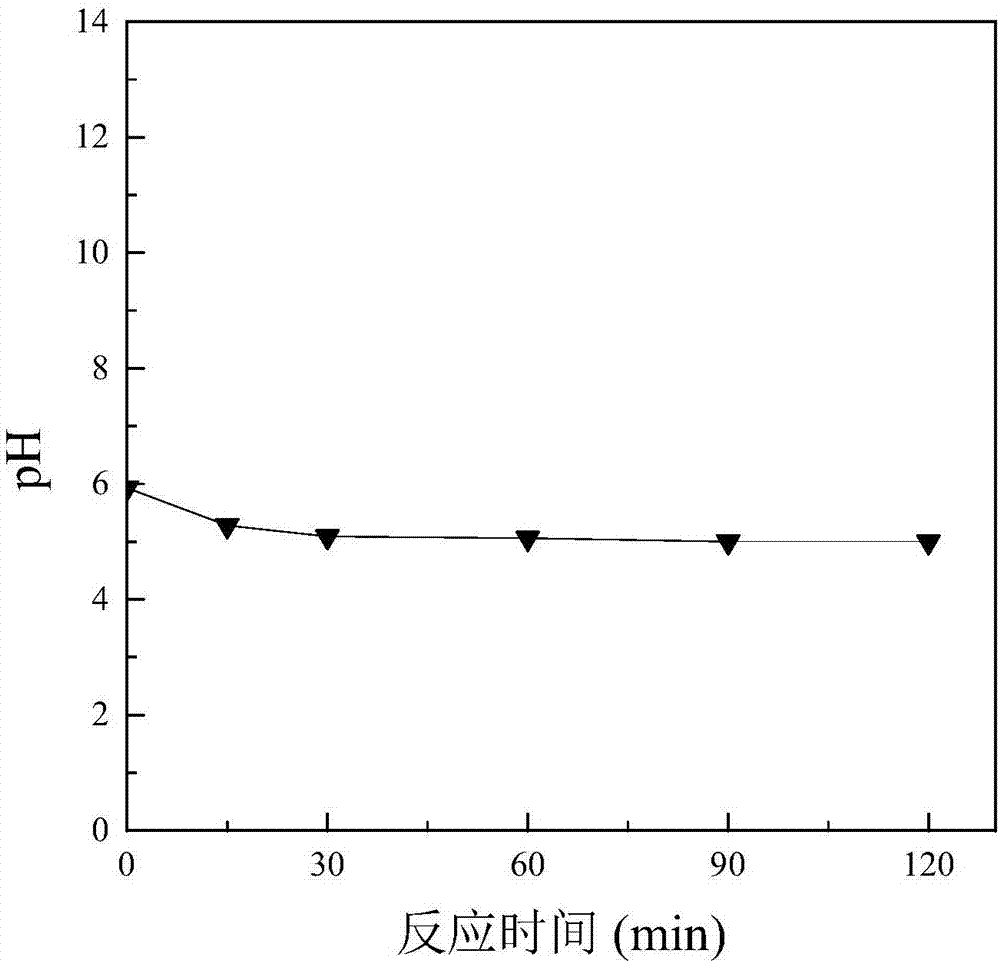

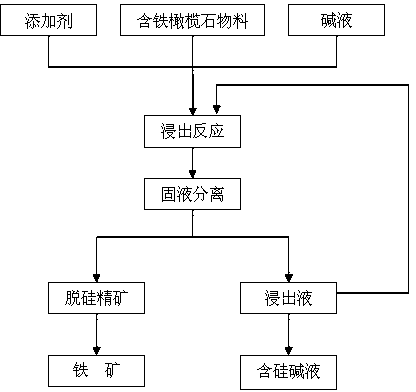

Comprehensive utilization method of ferriferous fayalite material

ActiveCN103343225AIncrease response rateEasy to separateProcess efficiency improvementFayaliteLiquid state

The invention discloses a comprehensive utilization method of a ferriferous fayalite material, relates to a processing method of the ferriferous fayalite material, and in particular relates to a method for separating and utilizing iron and silicon in fayalite. The method is characterized by comprising the following steps of: grinding the ferriferous fayalite material; mixing with alkaline liquor for leaching reaction; performing solid-liquid separation on obtained reaction slurry to obtain desilicated concentrate and silicon containing alkaline liquor; and oxidizing the desilicated concentrate in air to goethite. The method disclosed by the invention enriches, separates and extracts iron and silicon elements to form two products: goethite and silicon containing alkaline liquor through alkaline liquor leaching, wherein iron and silicon in ferriferous fayalite exist in solid and liquid states, so that the comprehensive utilization ratio of resources is high and the economic benefit is better.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

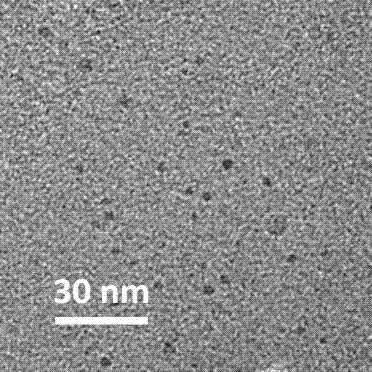

Preparation method for silver-doped graphene quantum dots

InactiveCN107572505AIncreased electronic transition levelsAchieve diversificationGrapheneNanotechnologySolubilityDoped graphene

The invention relates to a preparation method for metallic element-doped graphene quantum dots, specifically to a hydro-thermal preparation method for silver-doped graphene quantum dots, belonging tothe technical field of nano-materials. The hydro-thermal preparation method for the silver-doped graphene quantum dots is characterized in that sugar and silver acetate produce the water-soluble metalsilver-doped graphene quantum dots under hydrothermal reaction conditions. According to the invention, metal silver ions are introduced into graphene quantum dots, and the energy level structure of the graphene quantum dots is adjusted so as to all the graphene quantum dots to have more excellent photoelectric performance. The preparation method is simple in process, low in cost for raw materials, simple in equipment and beneficial for large-scale production of enterprises; and the prepared quantum dots have good water-solubility, substantial fluorescence properties, and important applicationvalue in fields like photocatalysis, photoelectrons, solar cells and chemical sensing.

Owner:YUNNAN NORMAL UNIV

Method for treating antibiotic fungi residues by percarbonate to prepare organic fertilizer

InactiveCN107686407AImprove the safety of useThe method is simpleOrganic fertilisersSolid/semi-solid fertilisersAfter treatmentThermal insulation

The invention discloses a method for treating antibiotic fungi residues by percarbonate to prepare an organic fertilizer, relates to a treating method and recycling for antibiotic fungi residues and aims at solving the problems that existing antibiotic fungi residue treatment cost is high, has environmental risk after treatment and the like. The method disclosed by the invention comprises the steps of adding percarbonate into antibiotic fungi residue liquid, putting in a reaction tank, heating to 60 to 80 DEG C, performing thermal-insulation reaction and centrifuging to collect precipitate toprepare the organic fertilizer, wherein the molar ratio of antibiotic to percarbonate is 1 to (300 to 500). By means of the method disclosed by the invention antibiotic residues can be degraded in high efficiency, and antibiotic drug resistance bacteria contained in the fungi residues are inactivated; furthermore, a pH need not be adjusted after treatment, and method procedures are simple. The method disclosed by the invention has the advantages of relatively moderate harmless treatment condition, lower reaction temperature requirement, ability in preventing protein denaturation, high safety,high efficiency and low cost. The fungi residue organic fertilizer does not contain the antibiotic drug resistance bacteria, cannot generate bacterium drug resistance in soil and has high use safety.

Owner:HARBIN INST OF TECH

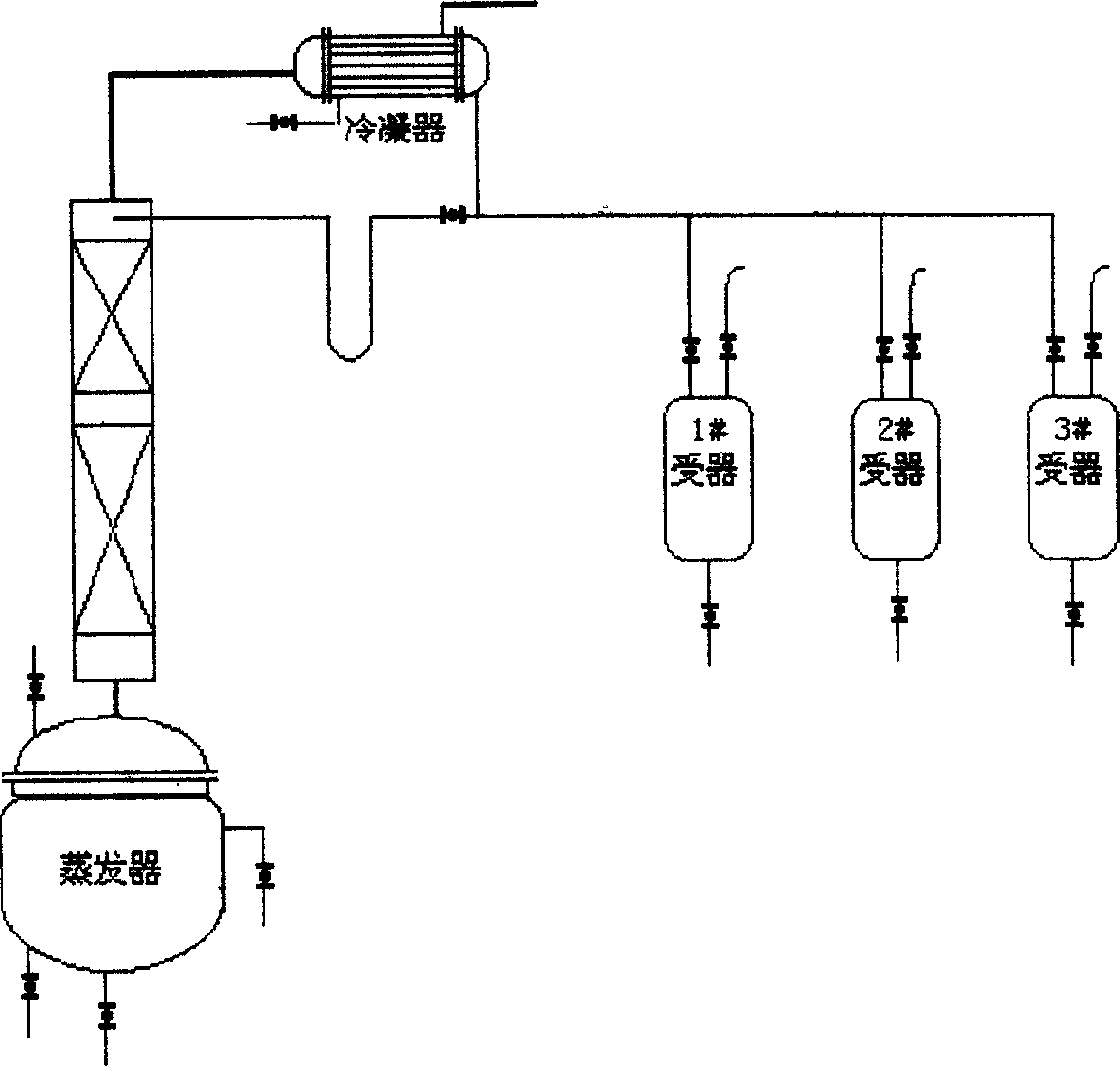

Method for preparing methanthiol

The invention discloses a method for preparing methanthiol. The method comprises the following steps: loading potassium tungstate into a carrier-Al2O3 in a conventional impregnation method; adding zinc chloride solution into the carrier to ensure that the quality content of the zinc chloride in the whole catalyst is 2-20 percent; impregnating and drying the mixture to reach a constant weight and roast for 1-6 hours; feeding hydrogen sulfide and liquid methanol according to a molar ratio of 1 to 10 in a mixed mode; pre-heating and vaporizing the mixed material at 260-300 DEG C; introducing the material into a reactor to fully contact the catalyst to react under the pressure of 0.5-1.0MPa at the regulation reaction temperature of 320-390 DEG C for 2-4 hours to obtain mixed gas; and performing separation treatment on the mixed gas to obtain a garget product of methanthiol. By adopting the method, the methanol conversion ratio is improved while the high selectivity of the methanthiol is maintained at the same time, the reaction condition is mild, and the production cost is reduced.

Owner:GUIZHOU UNIV

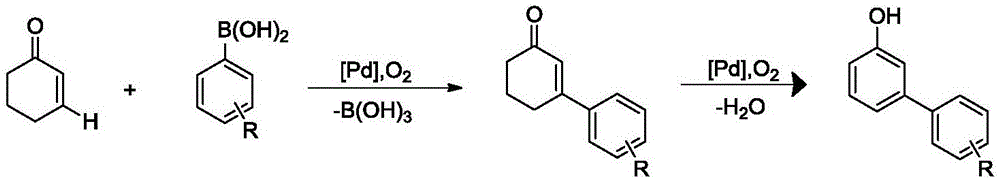

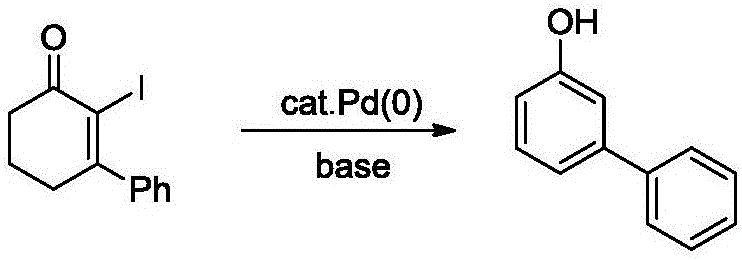

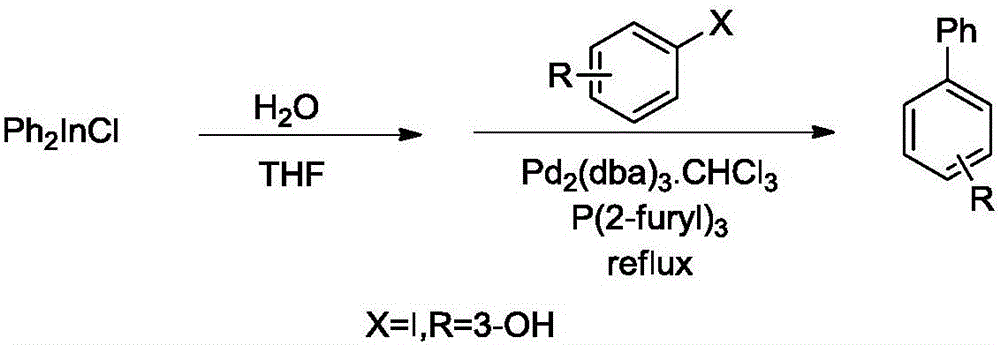

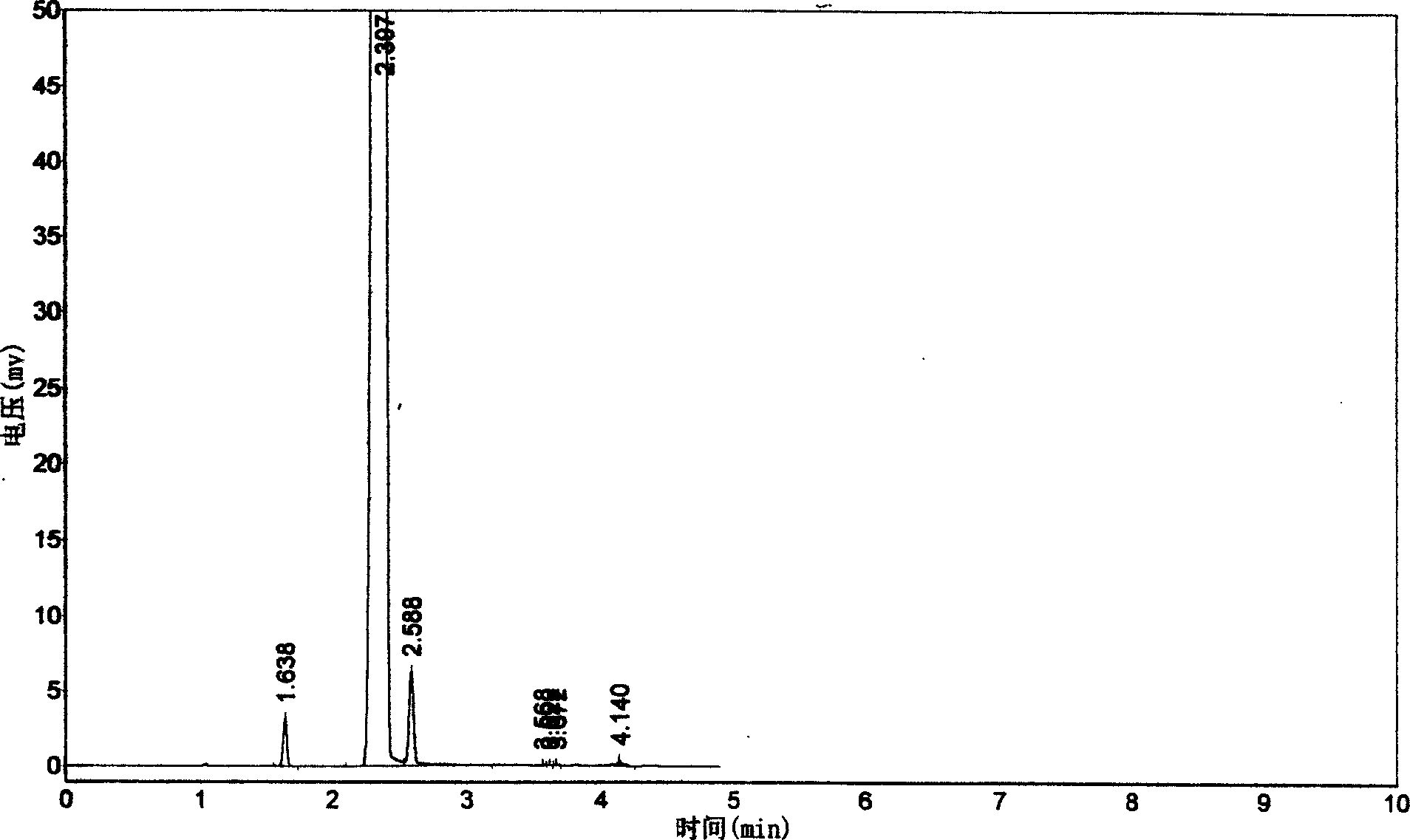

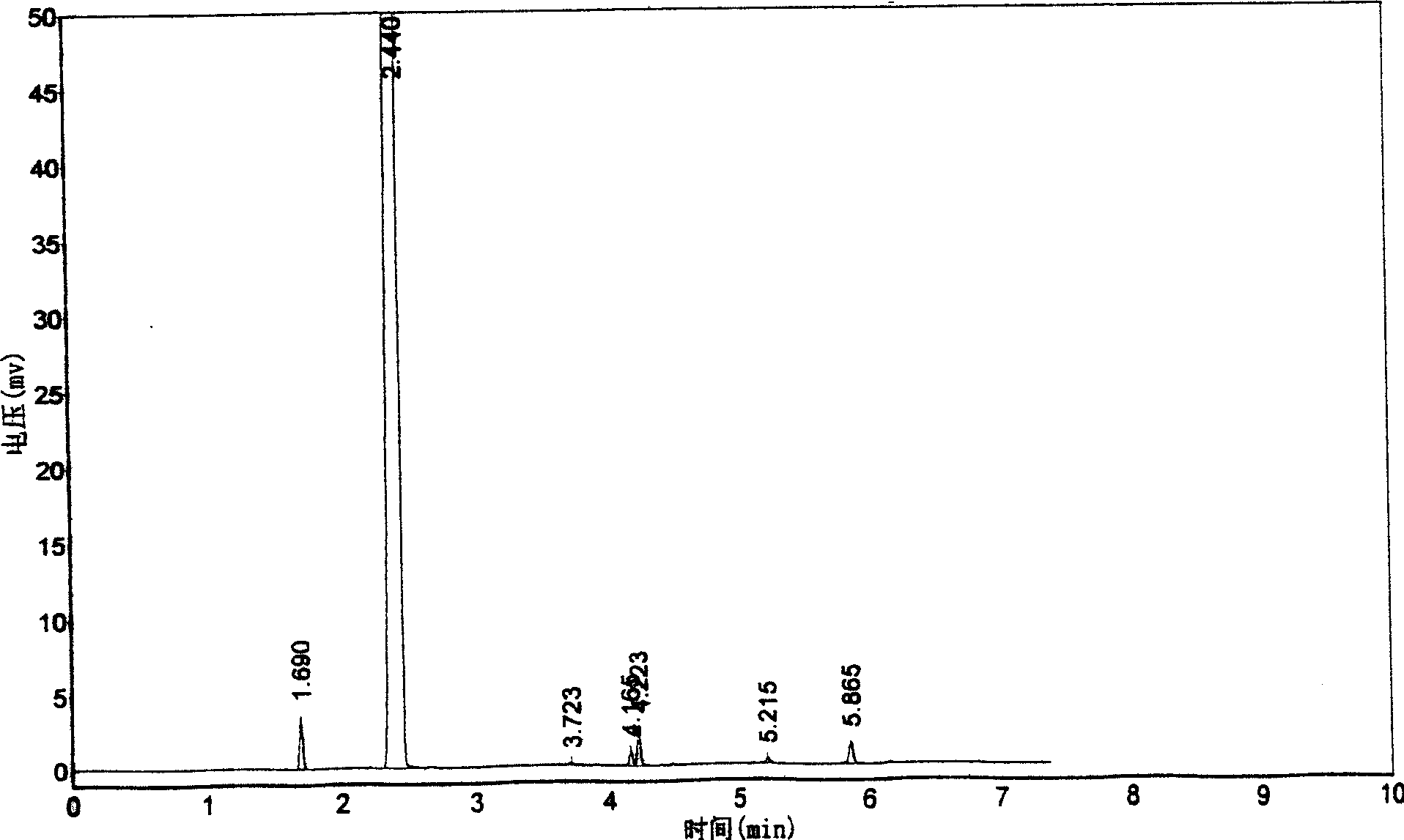

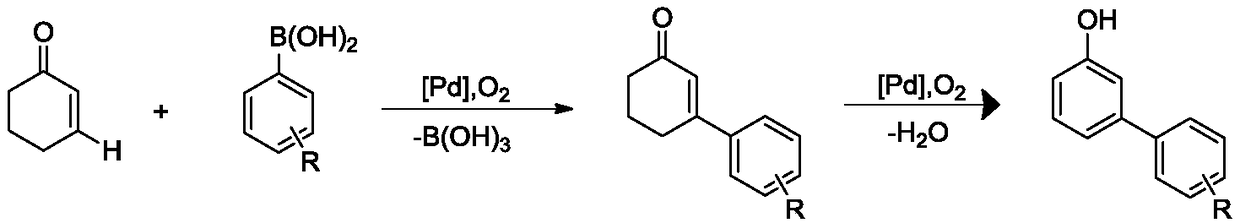

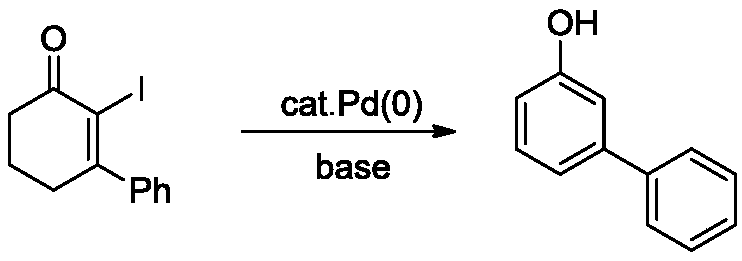

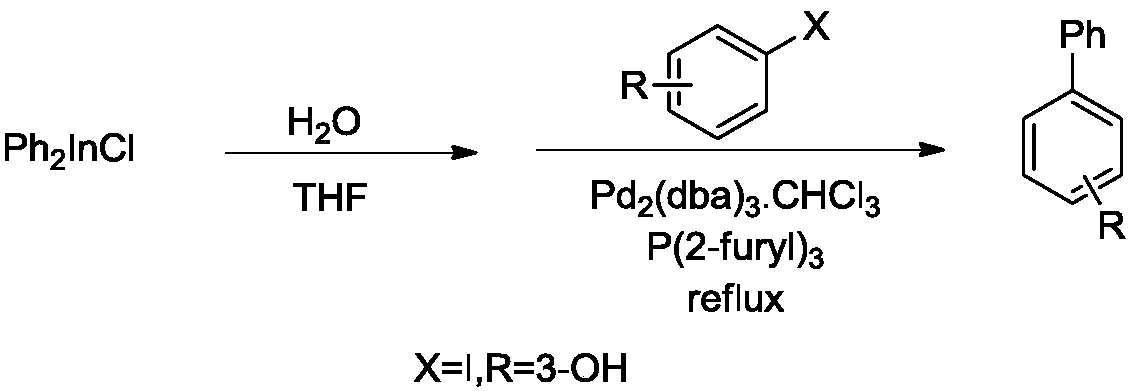

Poly-substituted 3-phenyl phenol derivatives and preparation method thereof

ActiveCN106748769AShort reaction timeLow reaction temperature requirementOrganic compound preparationCarboxylic acid esters preparationPhenol derivativePhenols

The invention provides poly-substituted 3-phenyl phenol derivatives and a preparation method thereof. Compared with the prior art, a series of novel poly-substituted 3-phenyl phenol derivatives is provided. Compared with common poly-substituted 3-phenyl phenol derivatives, the prepared poly-substituted 3-phenyl phenol derivatives have a multi-ring structure, the structure is more complicated, and thus the provided derivatives have a wide application in industries such as chemical engineering, clinical medicine, materials, and the like. Furthermore, the provided preparation method has the advantages of simpleness, high efficiency, and short reaction time.

Owner:陕西巴斯腾科技有限公司

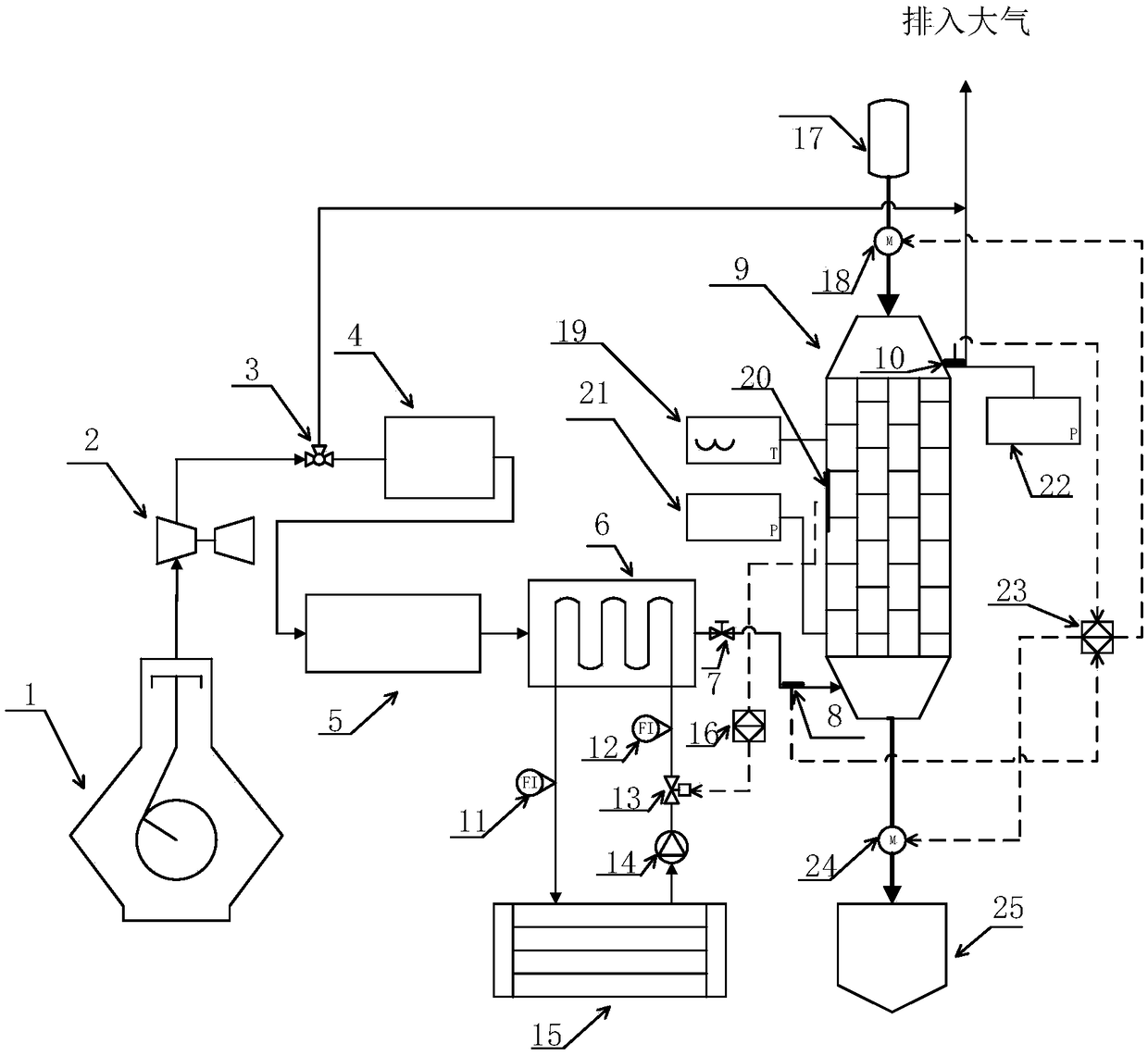

Activated carbon type exhaust gas denitration device and method of ship

ActiveCN108612577ASecondary pollution will not bringExcellent level of difficultyExhaust apparatusDispersed particle separationTurbochargerSorbent

The invention provides an activated carbon type exhaust gas denitration device of a ship. The device comprises a waste gas turbocharger 2, a smoke three-way valve 3, a PM removing device 4, a smoke cooler 5, an NO oxygenizer 5, a reactor 9, an activated carbon conveying control unit 23 and a temperature control unit 16. Compared with an existing ship denitration device, the device is simple in system composition; activated carbon is used as an adsorbent and a reducing agent; the activated carbon is high in adsorbing capacity and reducing capacity, so that the size of the reactor of a denitration system is far less than the size of a reactor of an existing urea based ship SCR (Selective Catalytic Reduction) denitration system; and the existing ship SCR denitration system basically adopts NH3, prepared through a urea water solution, as the reducing agent, the urea water solution easily forms urea crystals on the surfaces of a mixer and a catalyst to cause the reduction of working performances of the denitration system, while for the device, the consumed material is only the activated carbon, so that the advantages are obvious.

Owner:HARBIN ENG UNIV

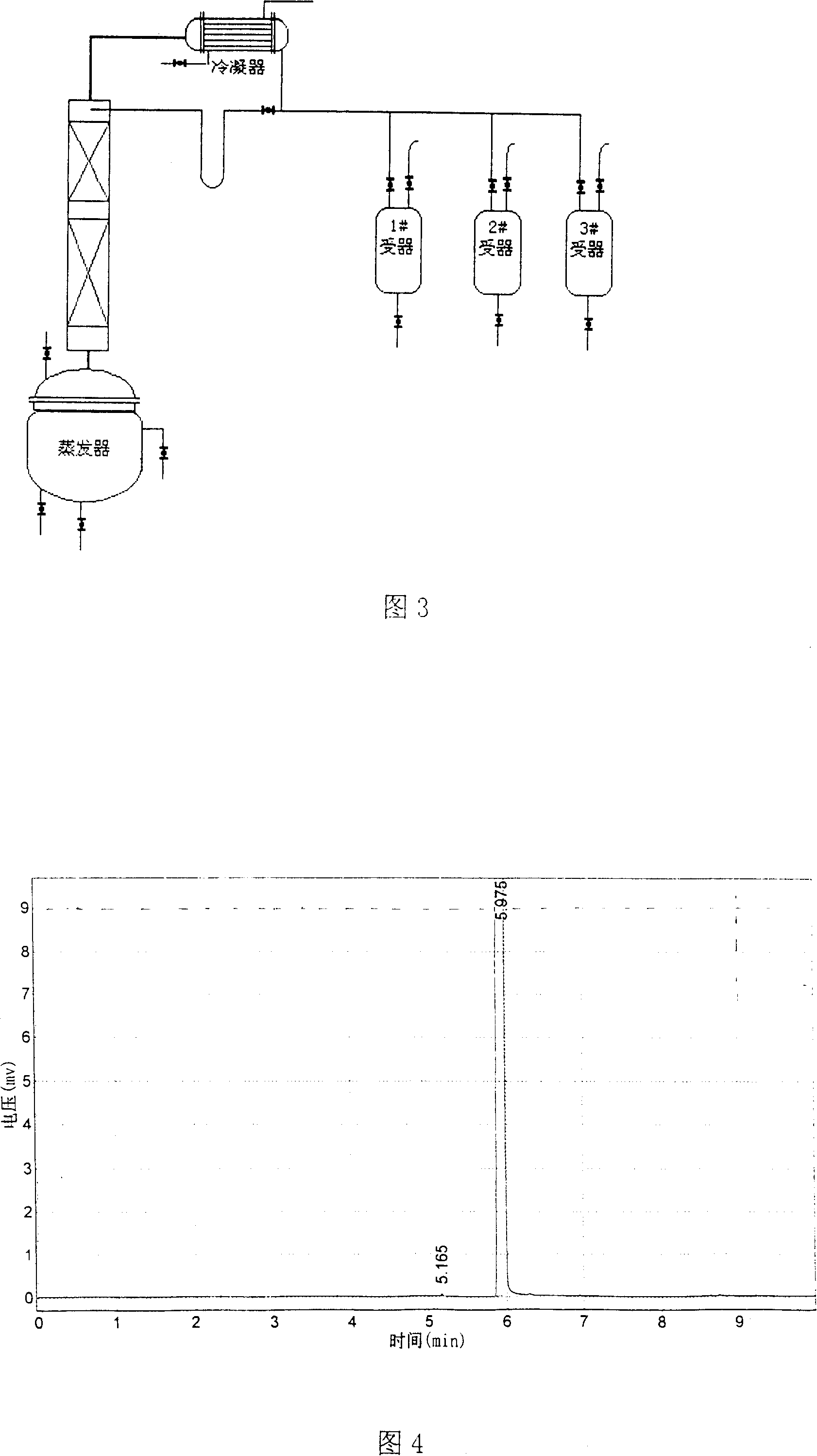

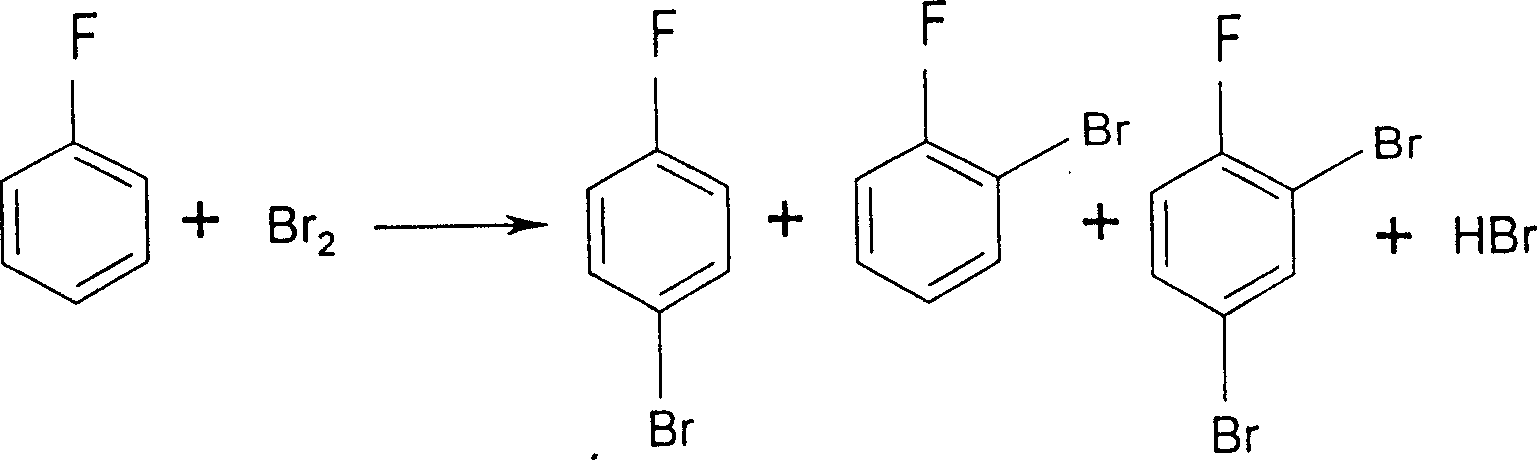

Prepn process of p-bromofluoro benzene

ActiveCN1810745AEfficient removalSimple operation processHalogenated hydrocarbon preparationHydrogen chlorideFluorobenzene

The present invention discloses preparation process of p-bromofluoro benzene. Liquid fluoro benzene and elementary substance bromine as reactants are made to produce bromination in the presence of catalyst to produce p-bromofluoro benzene and hydrogen bromide. The preparation process features that chlorine gas is introduced into the reaction system for oxidation reaction with hydrogen bromide to produce oxide of hydrogen chloride and hydrogen bromide, and the oxide of hydrogen bromide further reacts with fluoro benzene to produce p-bromofluoro benzene. After the bromination, the product is used as final product or post-treated to eliminate at least one of produced hydrogen chloride, p-chlorofluoro benzene and m-bromofluoro benzene for raised purity of p-bromofluoro benzene product. The process has the advantages of low liquid bromine consumption and low cost.

Owner:宗铿

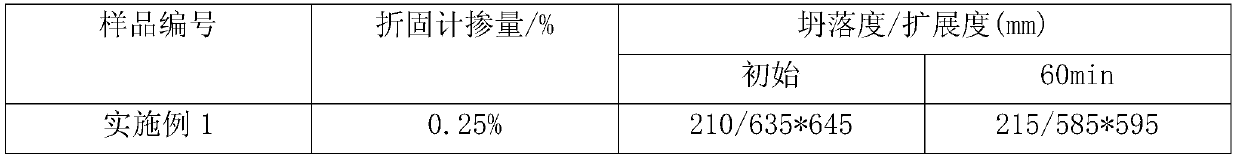

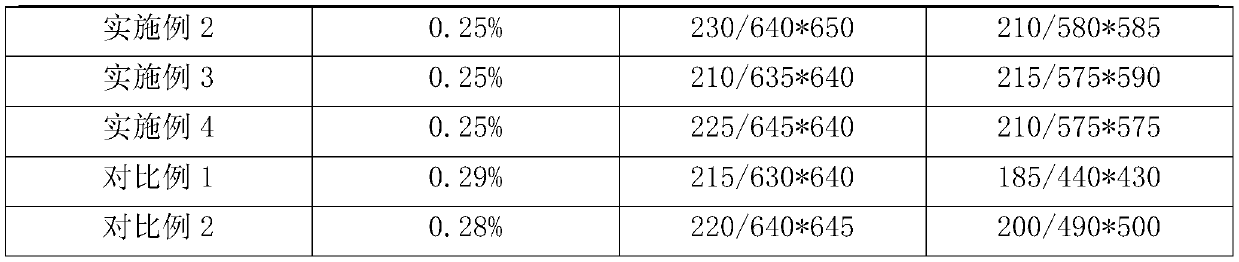

Novel anti-mud polyether type polycarboxylate superplasticizer and normal-temperature synthesis process thereof

The invention discloses ananti-mud type polycarboxylate superplasticizer and a normal-temperature synthesis process thereof. The anti-mud type polycarboxylate superplasticizer is prepared from0.4-1.6parts of a reducing agent, 0.9-3.8 parts of a chain transfer agent, 29-35 parts of a functional monomer, 240 parts of an unsaturated polyoxyethylene ether VPEG, 230-240 parts of softened water and 2-3parts of an oxidant. The anti-mud type polycarboxylate superplasticizer is prepared from the unsaturated polyoxyethylene ether VPEG, an unsaturated monobasic acid and a derivative monomer thereof, unsaturated sulfonate and a derivative thereof, an amide group-containing functional monomer and a derivative thereof, a phosphate type functional monomer and a derivative thereof, the oxidant and the reducing agent through polymerization. The invention confirms the normal-temperature synthesis process of the anti-mud type polycarboxylate superplasticizer. On one hand, the production cycle is greatly shortened, continuous periodic production is achieved, the economic cost is lowered, the energy consumption is reduced, and on the other hand, the polycarboxylate superplasticizer has good dispersibility and anti-mud properties.

Owner:GUIZHOU DR SHI TECH

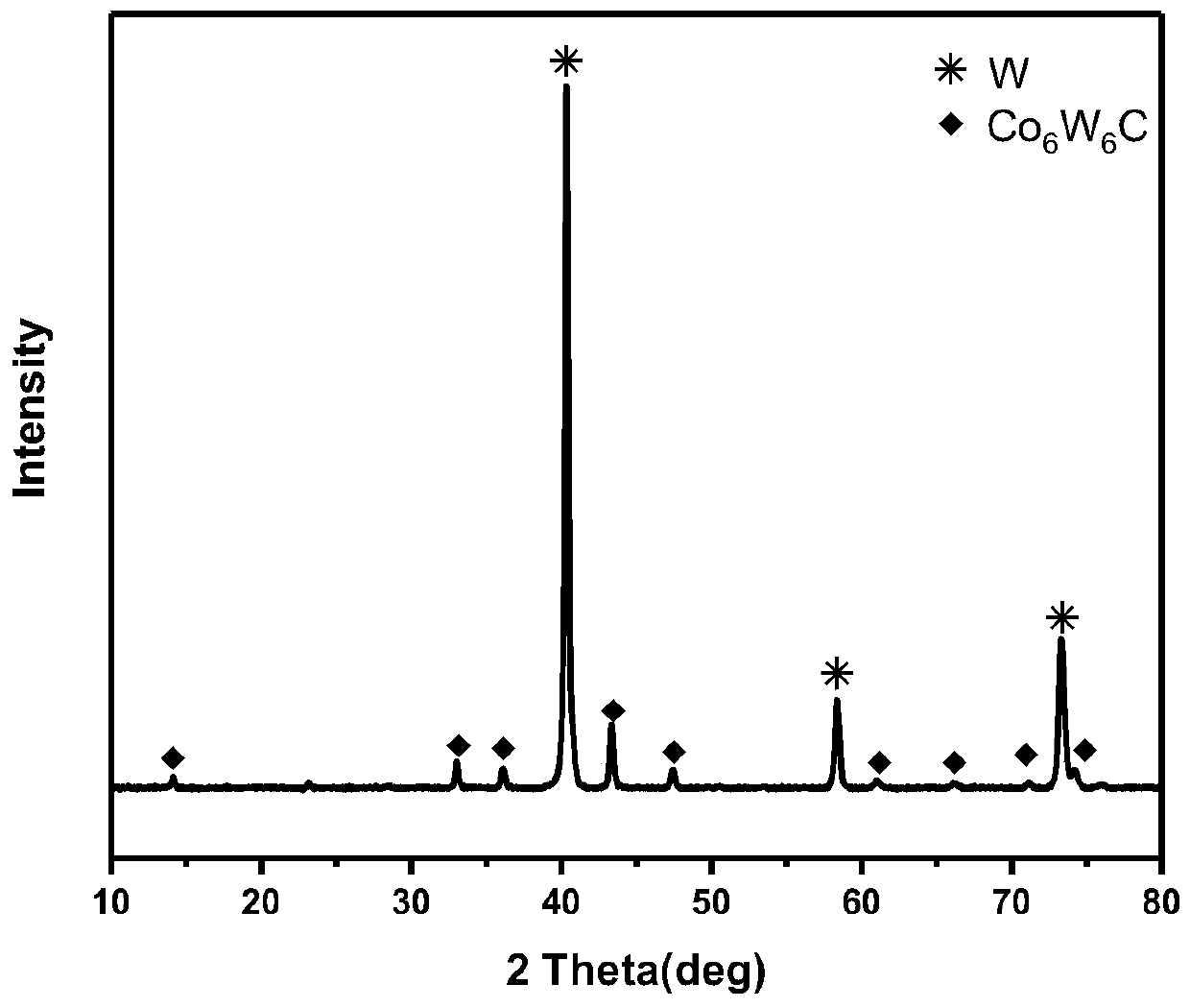

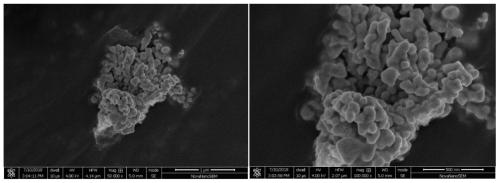

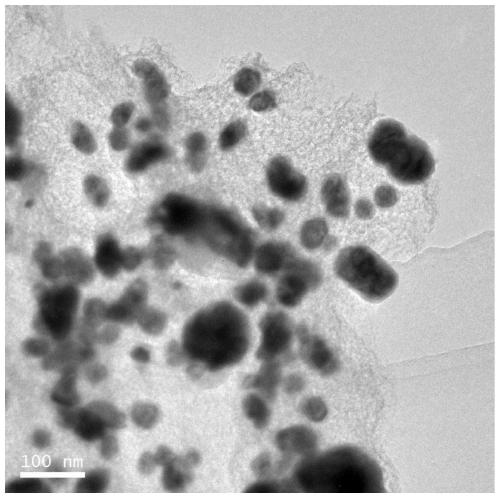

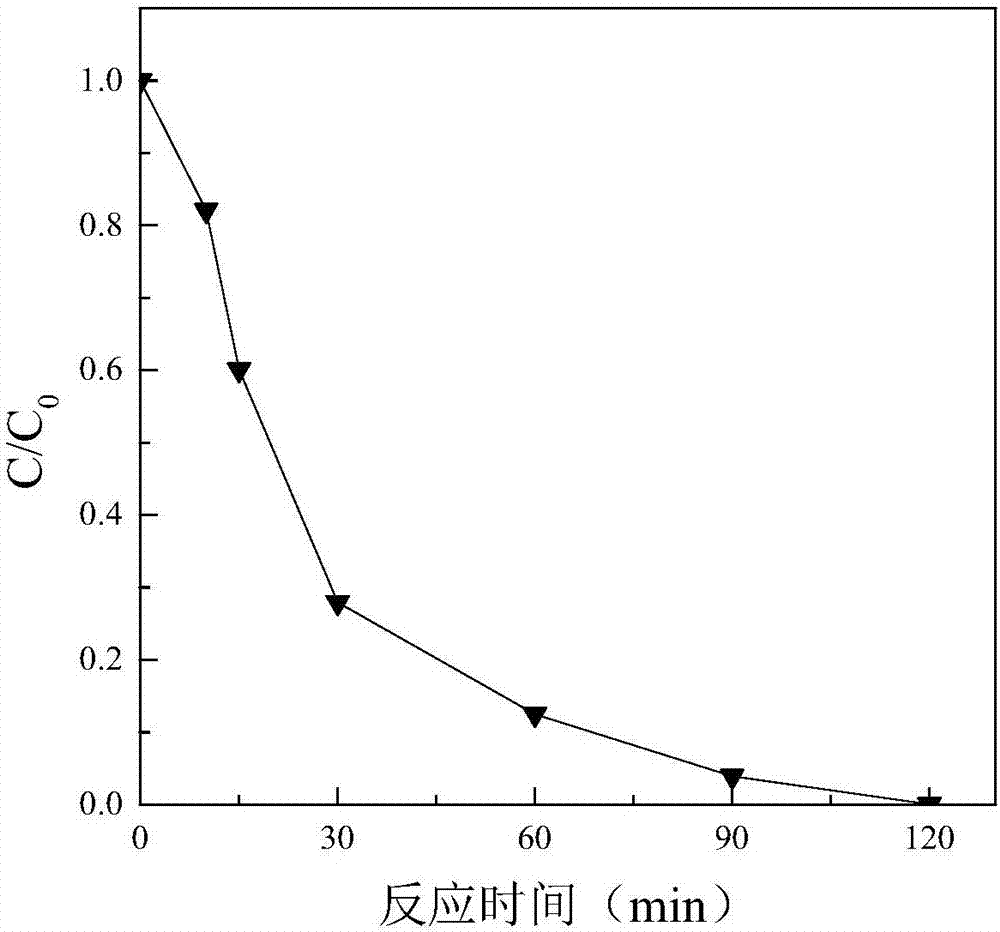

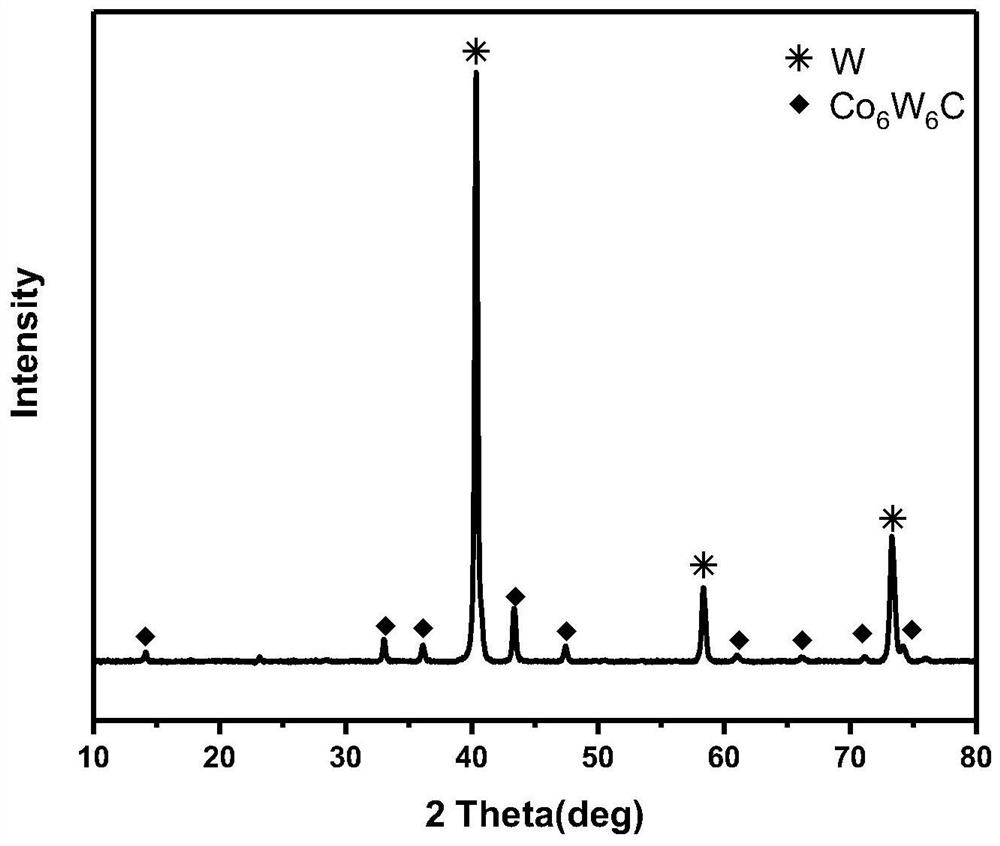

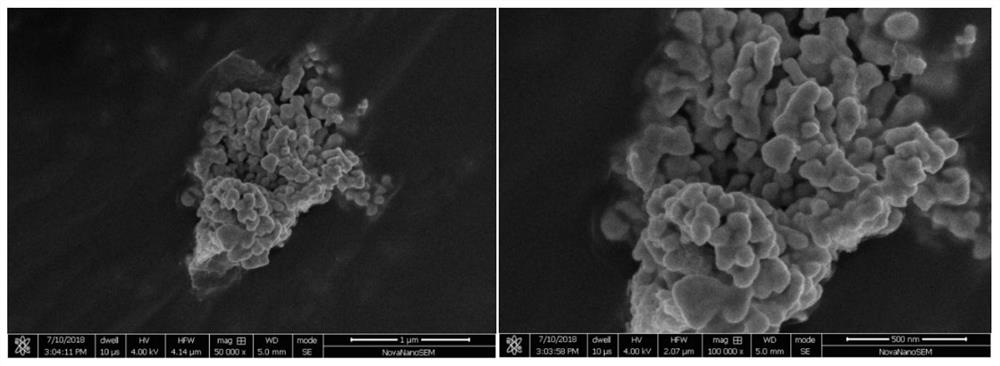

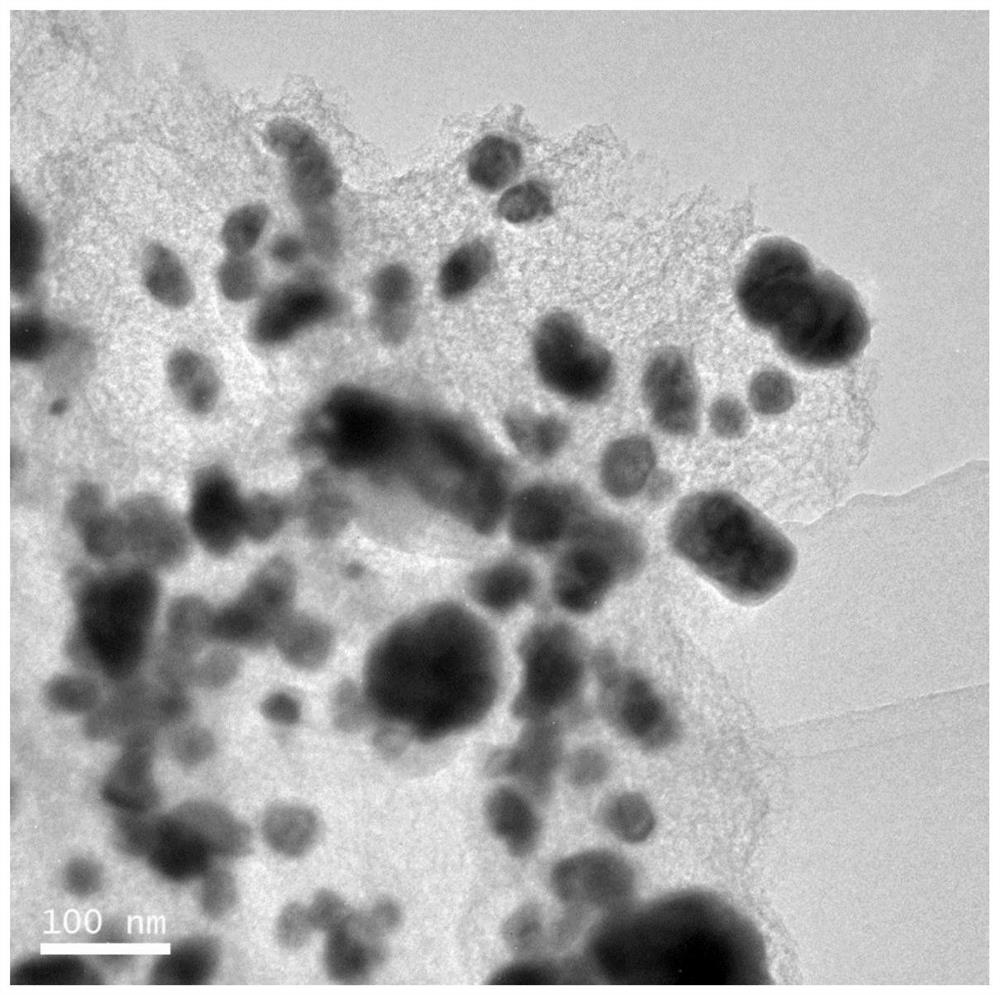

Method for preparing bimetallic carbide composite material through thermolysis approach

ActiveCN110104649AUniform sizeAvoid corrosionMaterial nanotechnologyOxy/sulfo carbidesHydrogenElectrolysis

The invention relates to a method for preparing a bimetallic carbide composite material. The method comprises the steps of dripping a hetero-tungstic acid solution Na10[Co4(H2O)2(PW9O34)2] 27H2O intoan organic amine solution during stirring, continuing stirring for 1 hour after dripping, performing centrifuging, conducting washing with deionized water, performing drying to obtain precursor solidpowder, and calcining the precursor solid powder to obtain the bimetallic carbide composite material. According to the method for preparing the bimetallic carbide for efficient electrolyzation of water for hydrogen evolution, prepared bimetallic carbide nanoparticles are uniform in size and high in dispersibility, wherein the molar ratio of Co6W6C is controlled within a range from 50% to 60%, andthe nanoparticles are coated with carbon in the thickness of 3-5 nm so that a corrosion effect of an electrolyte on a catalyst in a hydrogen evolution process can be effectively prevented. The methodhas the advantages of simple preparation process, convenient operation, lower requirement for reaction temperature and high efficiency and achieves a broad application prospect in the aspect of industrial application.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing organic fertilizer by utilizing erythrocin dregs

InactiveCN107324905AImprove the safety of useSimple methodBioloigcal waste fertilisersAmmonium salt fertilisersAntibiotic resistancePh regulation

The invention relates to a method for preparing an organic fertilizer by utilizing erythrocin dregs and relates to a processing method and recycling of the erythrocin dregs. The invention aims to solve the problems, such as, high processing cost and environmental risk after the processing of the present erythrocin dregs. The method comprises the following steps: respectively adding peroxysulphate and less potassium permanganate into the erythrocin dreg solution, placing into a reaction tank for heating, reacting under heat-insulating condition, centrifuging and then collecting sediment, thereby acquiring the organic fertilizer. In the invention, the erythrocin residue can be efficiently degraded, the antibiotic resistance bacteria contained in the dregs are inactivated, the pH regulation is not required after the processing and the method is simple in process. In the invention, the innocent treatment condition for assisting in oxidization by potassium permanganate and activating peroxysulphate by manganese ions is relatively mild, the requirement for reaction temperature is lower and the protein denaturation is prevented; the safety is high, the efficiency is high and the cost is low; the removal rate of erythrocin is 99.95%; and the organic fertilizer made from erythrocin dregs contains no antibiotic resistance bacteria, the antimicrobial resistance is not caused in soil and the use safety is high.

Owner:HARBIN INST OF TECH

Comprehensive utilization method of ferriferous fayalite material

ActiveCN103343225BIncrease response rateEasy to separateProcess efficiency improvementFayaliteLiquid state

The invention discloses a comprehensive utilization method of a ferriferous fayalite material, relates to a processing method of the ferriferous fayalite material, and in particular relates to a method for separating and utilizing iron and silicon in fayalite. The method is characterized by comprising the following steps of: grinding the ferriferous fayalite material; mixing with alkaline liquor for leaching reaction; performing solid-liquid separation on obtained reaction slurry to obtain desilicated concentrate and silicon containing alkaline liquor; and oxidizing the desilicated concentrate in air to goethite. The method disclosed by the invention enriches, separates and extracts iron and silicon elements to form two products: goethite and silicon containing alkaline liquor through alkaline liquor leaching, wherein iron and silicon in ferriferous fayalite exist in solid and liquid states, so that the comprehensive utilization ratio of resources is high and the economic benefit is better.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

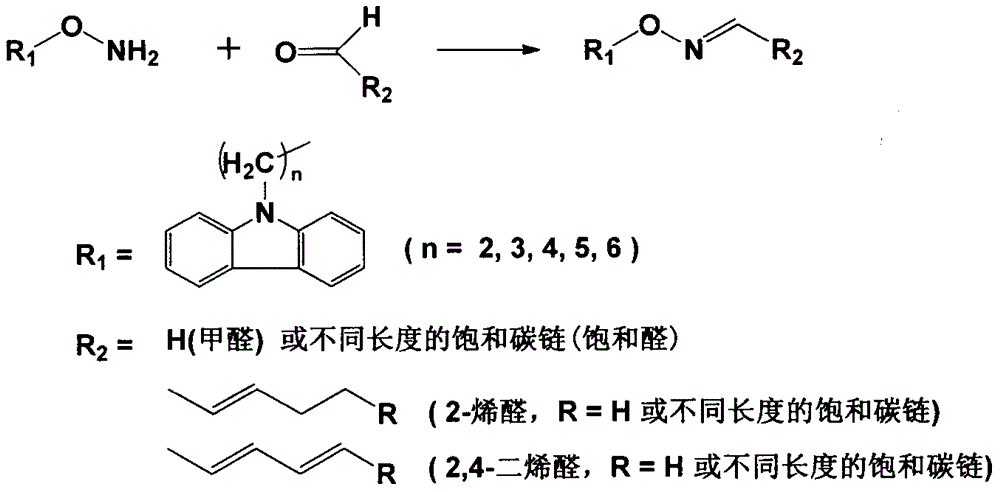

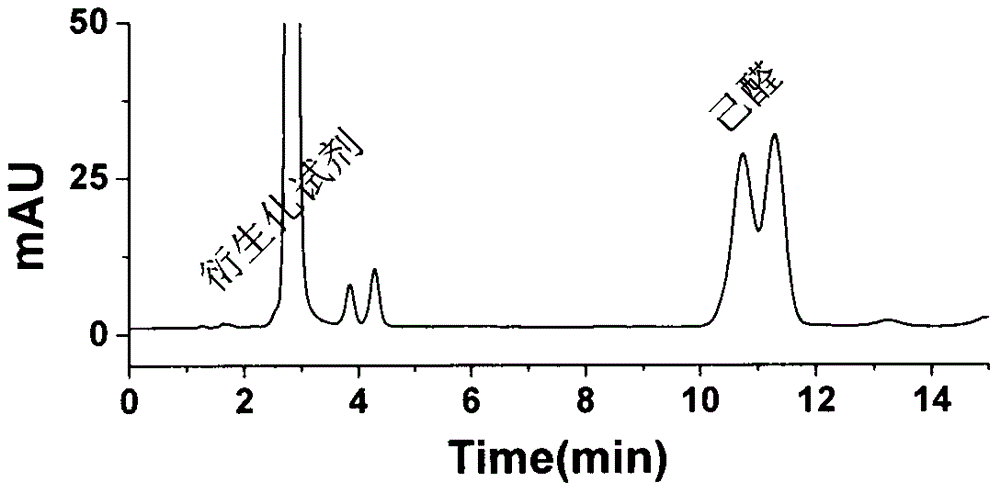

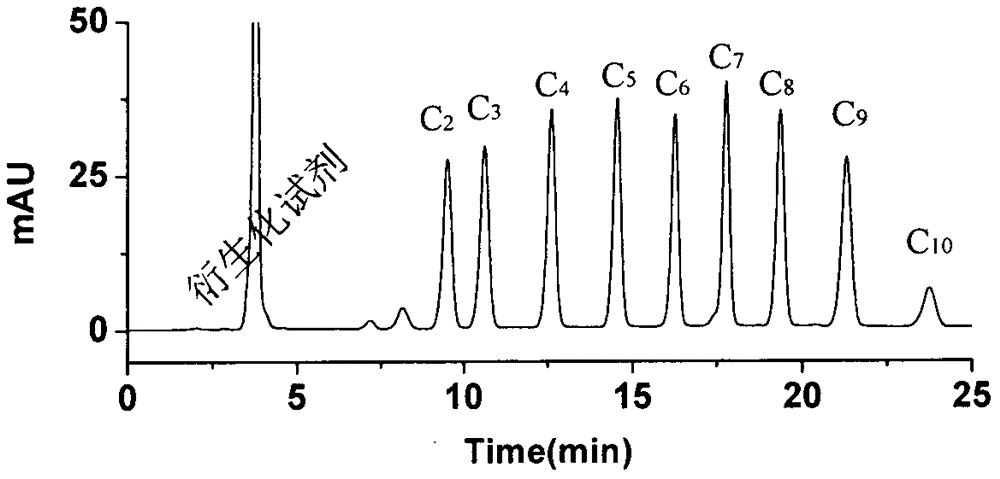

A preparing and purifying method for O-substituted hydroxylamine fluorescence derivatization reagents

InactiveCN106397302AHigh fluorescence intensityHigh reactivityOrganic chemistryComponent separationHydroxylamineFluorescence

The invention relates to a preparing and purifying method for O-substituted hydroxylamine fluorescence derivatization reagents. Tetra-n-butylammonium bromide and potassium hydroxide are adopted as catalysts. The method includes reacting carbazole and alpha,omega-dihaloalkane to obtain an intermediate I that is 9-(omega-chloroalkyl)-9H-carbazole or 9-(omega-bromoalkyl)-9H-carbazole, reacting the intermediate I with N-hydroxy-5-norbornene-2,3-dicarboximide in dimethylformamide under catalysis of potassium carbonate to obtain an intermediate II that is (3aR,4R,7S,7aS)-2-((9H-carbazole-9-yl)alkoxy)-3a,4,7,7a-tetrahydro-1H-4,7-methanoisoindole-1,3(2H)-dione, purifying the intermediate II through column chromatography, reacting the intermediate II with hydrazine hydrate to obtain a target product that is O-(omega-(9H-carbazole-9-yl)alkyl) hydroxylamine. The purifying method includes suspending the target product into water, adjusting the mixture to be acidic, extracting with an organic solvent to remove impurities, adjusting a water layer to be alkaline, extracting with an organic solvent, and recovering the organic solvent until the product is dry. The prepared product can be used for pre-column derivatization-liquid chromatography measurement of aldehydes or fluorescence labeling of aldehyde group containing compounds.

Owner:CHINA PHARM UNIV

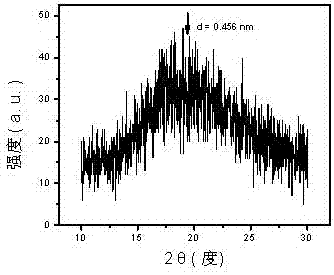

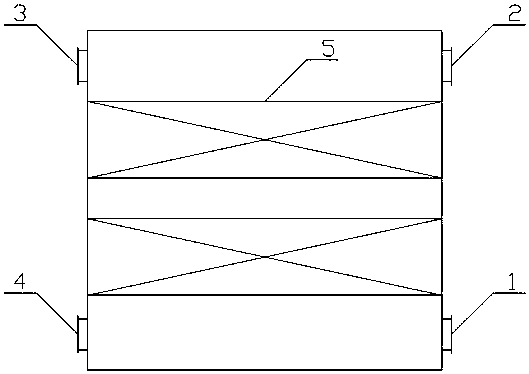

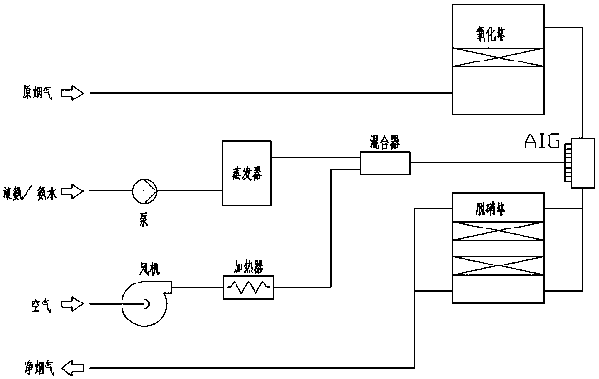

Novel catalytic denitration apparatus and technology aiming at coke oven flue gas

InactiveCN109701384ALow reaction temperature requirementLong chemical lifetimeDispersed particle separationMetal catalystFlue gas

A novel catalytic denitration apparatus and technology aiming at coke oven flue gas, relating to the field of coke oven flue gas purification. By means of the denitration principle of NH3-SCR, a nanomulti-metal catalyst is used as a denitration catalyst with assistance of an ammonia removal catalyst, thus achieving integration of denitration and ammonia removal. The key of the technology is the catalyst, which is a real low-temperature catalyst, reaction temperature zone being 80-140 DEG C. The catalyst is free of a heating furnace and a flue gas heat exchanger, thus greatly reducing investment and operation cost.

Owner:XIAN MEIZHILV INFORMATION TECH CO LTD

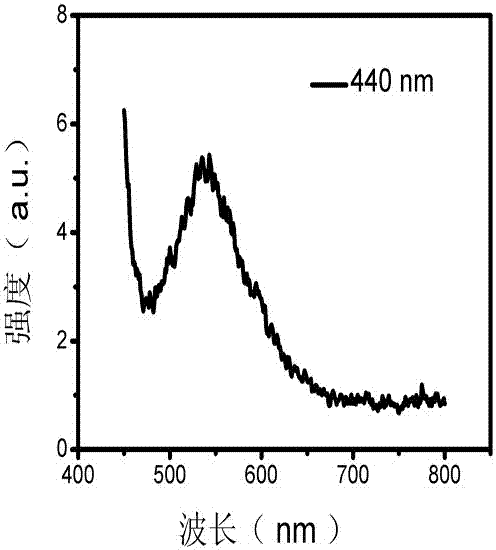

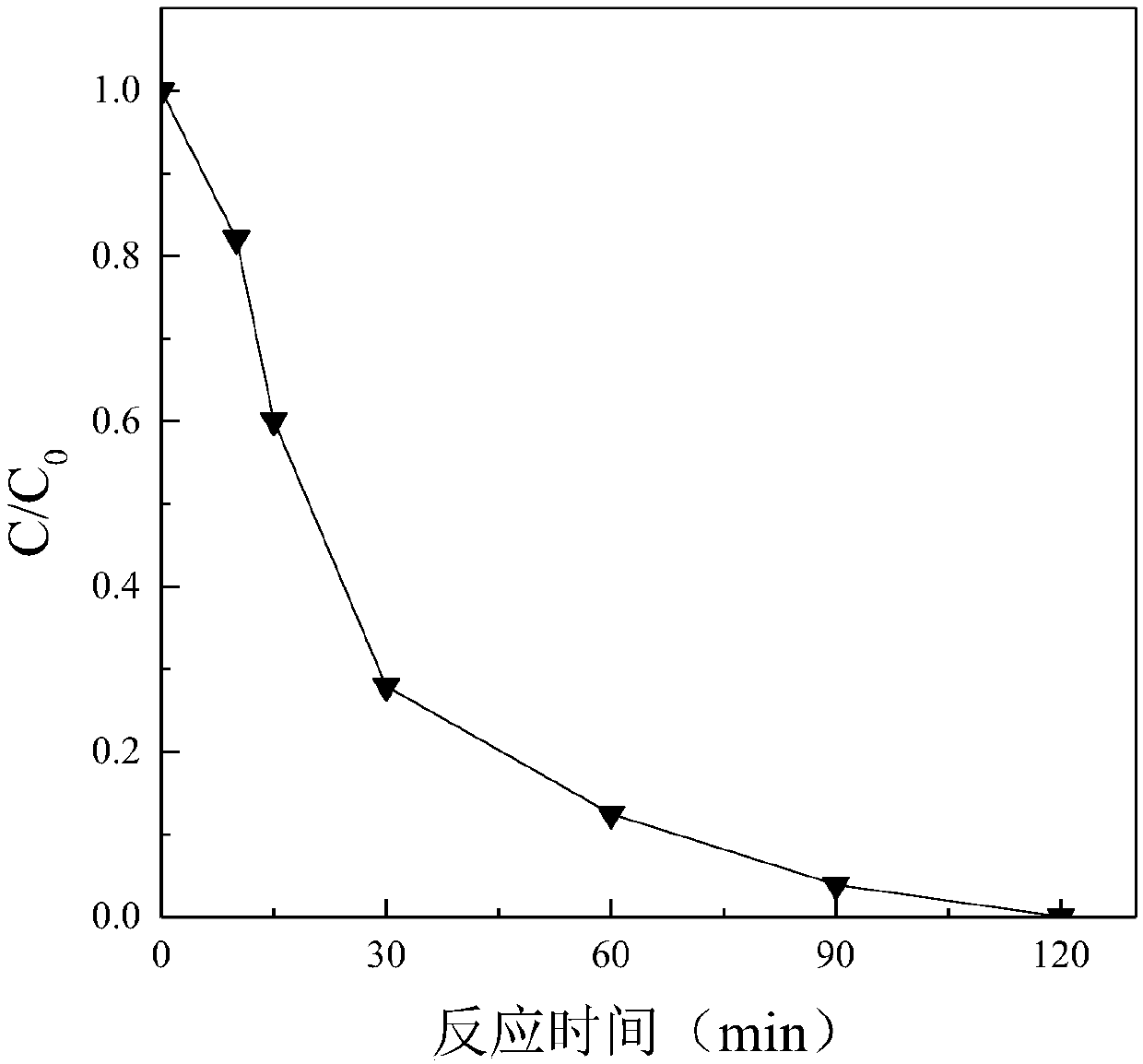

A kind of preparation method of bismuth vanadate nanowire-graphene photocatalyst

InactiveCN106179318BShort production costImprove photocatalytic performanceMetal/metal-oxides/metal-hydroxide catalystsOXALIC ACID DIHYDRATEHydration reaction

A method for preparing a bismuth vanadate nanowire-graphene composite photocatalyst. Bismuth salt, ammonium metavanadate, and oxalic acid dihydrate are dissolved in distilled water in a certain proportion, mixed ultrasonically to form a mixed solution, and then graphene oxide is added. Add to the above mixed liquid, ultrasonic mixing to obtain a precursor, and finally move the precursor into a high-pressure reactor containing a substrate for hydrothermal reaction. After the reaction is completed, the substrate loaded with the product is washed and dried to obtain the described A bismuth vanadate nanowire-graphene composite photocatalyst. The preparation process of the present invention is simple, the reaction conditions are mild and the reaction time is short. The prepared bismuth vanadate nanowires and graphene can be closely contacted and combined, which is beneficial to the separation of photogenerated electron holes, thereby improving the photocatalytic efficiency and providing a A low-cost, simple and easy preparation method for highly visible light active photocatalysts.

Owner:ANYANG NORMAL UNIV

Production process for secondary extraction of heparin sodium from enzymolysis adsorption waste liquid

The invention relates to a production process for secondary extraction of heparin sodium from enzymolysis adsorption waste liquid. The production process comprises steps of flocculation reaction, ultrafiltration and concentration, alcohol precipitation, purification and refining, wastewater treatment, etc. According to the production process disclosed by the invention, by regulating PH value of fresh enzymolysis waste liquid for several times and adding composite flocculants different in components, free protein in mixed liquid is completely separated out during reaction and most impurities are removed through flocculation and precipitation, thus forming heparin sodium which is high in purity and reasonable in titer; the entire process is scientific and reasonable, low in production cost, short in cycle and not high in requirement on reaction temperature, the produced heparin sodium is high in purity and the extracting rate nearly reaches 100%; and emissions completely meet an environment-friendly emission standard.

Owner:重庆市友谊畜产品有限公司

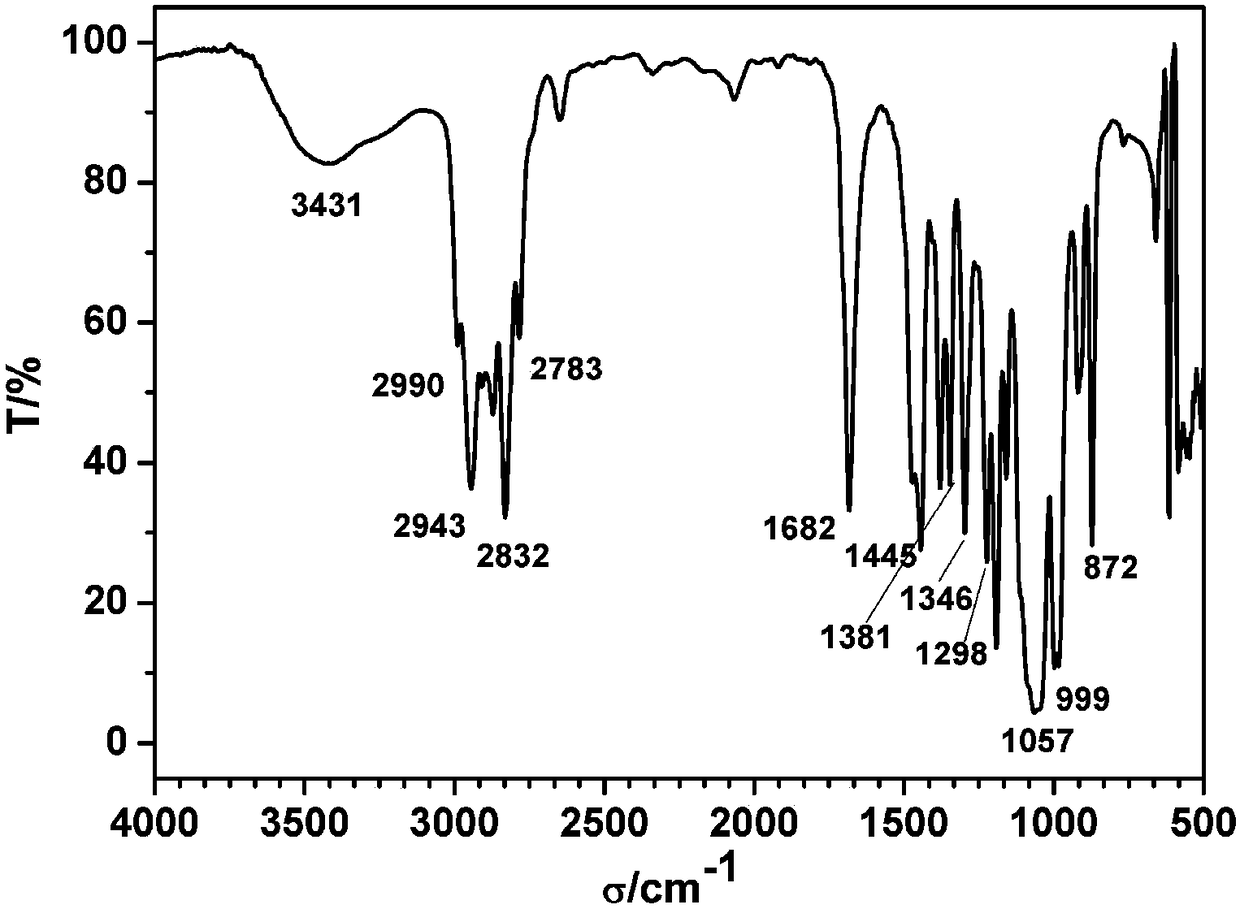

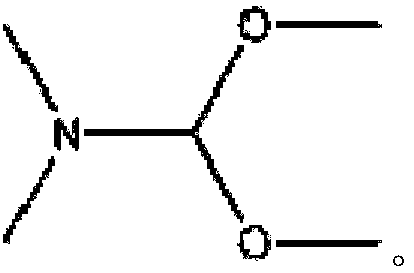

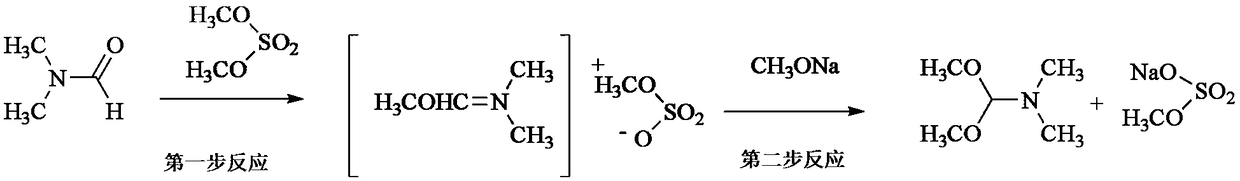

A kind of synthetic method of n,n-dimethylformamide dimethyl acetal

ActiveCN106083611BLower reaction conditionsMild reaction conditionsOrganic compound preparationSulfuric acid esters preparationAlkaneN dimethylformamide

Owner:HENAN CHEM IND RES INST

Synthesis method of hexabromobenzene

InactiveCN109776254AReduce usageImprove catalytic performanceHalogenated hydrocarbon separation/purificationWater bathsSynthesis methods

The invention relates to a synthesis method of hexabromobenzene, and belongs to the technical field of synthesis of bromine-containing flame retardants. The method includes the following steps that bromine, anhydrous aluminum trichloride and fuming sulfuric acid are added in a glass-enameled reaction kettle, and benzene is added in a head tank; stirring starts, the reaction kettle is heated in water bath, the temperature in the kettle is maintained not more than 50 DEG C, benzene is dropwise added, the dripping speed of benzene is controlled for reaction, the reaction system is subjected to heat preservation, and hydrogen bromide is discharged from the system, wherein 48-52 kg of benzene is dripped at constant speed every 35-45 minutes; pure water is added in the kettle, steam is introduced into the reaction kettle for steam stripping until remaining bromine is completely steamed out, and red products in the reaction kettle are changed into opalescent crystals; after cooling to room temperature and filtering, a filter cake is washed with water and dried to obtain the product. Anhydrous aluminum trichloride serves as a catalyst, the catalytic effect is better, the reaction temperature requirement is low, the product yield is increased by about 10%, meanwhile the use of organic solvents is effectively reduced, and the method is more environmentally friendly and safe.

Owner:LIANYUNGANG TECHN COLLEGE

A method for preparing bimetallic carbide composite material by thermal decomposition

ActiveCN110104649BUniform sizeAvoid corrosionMaterial nanotechnologyOxy/sulfo carbidesElectrolytic agentPtru catalyst

Owner:ZHEJIANG UNIV OF TECH

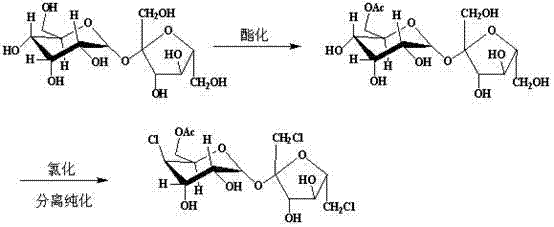

Method for preparing sucralose-6-acetate by tandem reaction

ActiveCN102690299BEasy to operateLow reaction temperature requirementEsterified saccharide compoundsSugar derivativesReaction temperatureWater chlorination

The invention aims at providing a method for preparing sucralose-6-acetate by tandem reaction of quaternary ammonium salt chlorination. The tandem reaction is adopted to finish three steps of a production process, a first-step reaction is esterification of sucrose C-6 hydroxy, the second-step reaction is chlorination of sucrose C-6 acetic acid ester, and the third-step reaction is separation purification of sucralose-6-acetate. The method for preparing the sucralose-6-acetate by the tandem reaction has the advantages that the method is low in requirements on reaction temperature, short in reaction time, good in technical performance, free of hydrogen chloride and sulfur dioxide, few in three wastes (waste water, waste gas and waste residues), convenient for post-treatment and reusable in reaction system and is an economical and practical environment-friendly technology.

Owner:ZHEJIANG HAISEN PHARMACY CO LTD

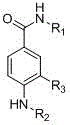

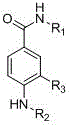

A kind of synthetic method of n-methyl-4-(methylamino)-3-nitrobenzamide

InactiveCN104356022BWide variety of sourcesLow priceOrganic compound preparationCarboxylic acid amides preparationCarbylamine reactionSynthesis methods

Owner:SHANGHAI INST OF TECH

Method for preparing potassium-containing hydroxyapatite powder

InactiveCN106430139AHigh purityFine particleCosmetic preparationsToilet preparationsHydroxyapatitesGreek letter alpha

The invention relates to the technical field of functional materials, in particular to a method for preparing potassium-containing hydroxyapatite powder. The method for preparing the potassium-containing hydroxyapatite powder includes the steps that a certain amount of Ca(NO3)2 and a certain amount of H3PO4 are weighed in the molar ratio of 3:2, the Ca(NO3)2 and the H3PO4 are dissolved into 300 mL of distilled water respectively, then two solutions are mixed, stirred for a period, drawn, filtered, centrifuged and dried, and Ca3(PO4)2 powder is prepared; the powder is put into a corundum crucible and calcined for 2 h at the high temperature of about 1,300 DEG C, then the product is taken out of a furnace immediately and cooled to be at the room temperature, and the alpha-Ca3(PO4)2 powder is obtained; a KOH solution is prepared, then the alpha-Ca3(PO4)2 powder is put into the KOH solution respectively, a beaker opening is sealed with a preservative film, a bearer is put into a drying oven, the temperature is set as 120 DEG C, the product is taken out of the drying oven after 3 days, drawn, filtered, repeatedly washed and dried, and the potassium-containing hydroxyapatite powder is obtained. According to the experiment, as the chemical precipitation method is adopted, the requirement of the reaction temperature is low, the purity of the synthetic product is high, particles are fine, the operating process is simple, the synthetic cost is low, and industrial production is facilitated.

Owner:SHAANXI SHENGMAI PETROLEUM

Preparation process of p-bromofluoro benzene

ActiveCN100376524CReduce escapeImprove conversion rateHalogenated hydrocarbon preparationHydrogen chlorideFluorobenzene

The present invention discloses preparation process of p-bromofluoro benzene. Liquid fluoro benzene and elementary substance bromine as reactants are made to produce bromination in the presence of catalyst to produce p-bromofluoro benzene and hydrogen bromide. The preparation process features that chlorine gas is introduced into the reaction system for oxidation reaction with hydrogen bromide to produce oxide of hydrogen chloride and hydrogen bromide, and the oxide of hydrogen bromide further reacts with fluoro benzene to produce p-bromofluoro benzene. After the bromination, the product is used as final product or post-treated to eliminate at least one of produced hydrogen chloride, p-chlorofluoro benzene and m-bromofluoro benzene for raised purity of p-bromofluoro benzene product. The process has the advantages of low liquid bromine consumption and low cost.

Owner:宗铿

A kind of multi-substituted 3-phenylphenol derivatives and its preparation method

ActiveCN106748769BShort reaction timeLow reaction temperature requirementOrganic compound preparationCarboxylic acid esters preparationPhenol derivativeChemistry

The invention provides poly-substituted 3-phenyl phenol derivatives and a preparation method thereof. Compared with the prior art, a series of novel poly-substituted 3-phenyl phenol derivatives is provided. Compared with common poly-substituted 3-phenyl phenol derivatives, the prepared poly-substituted 3-phenyl phenol derivatives have a multi-ring structure, the structure is more complicated, and thus the provided derivatives have a wide application in industries such as chemical engineering, clinical medicine, materials, and the like. Furthermore, the provided preparation method has the advantages of simpleness, high efficiency, and short reaction time.

Owner:陕西巴斯腾科技有限公司

Catalyst for decomposing hydrogen sulfide by photocatalysis and preparation method of hydrogen and liquid sulfur by employing same

ActiveCN101590410BRealize comprehensive utilizationHigh activityDispersed particle separationSulfur preparation/purificationAlkaline earth metalVanadate

The invention relates to a catalyst for decomposing hydrogen sulfide by photocatalysis and a preparation method of hydrogen and liquid sulfur by employing same. The catalyst comprises a carrier, active component and assistant and has the characteristics that the carrier is one or more selected from vanadate, niobate and tantalate, the active component is one or more selected from alkali metal hydroxide, alkaline earth metal hydroxide, alkali metal nonmetal oxysalt, alkali metal nonoxysalt, alkaline earth metal nonmetal oxysalt and alkaline earth metal nonoxysalt and the assistant is lanthanide oxide or VIII group oxide. The catalyst of the invention can be used for preparing hydrogen and liquid sulfur so that the produced sulfur is easy to be separated from the catalyst, the catalyst can be recycled and the sulfur contained in hydrogen sulfide can be fully recycled, thus realizing the comprehensive utilization of hydrogen sulfide.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Device and method for tail gas denitrification by activated carbon method for ships

ActiveCN108612577BSmall sizeSimple compositionExhaust apparatusDispersed particle separationActivated carbonTemperature control

The present invention provides a tail gas denitrification device by activated carbon method for ships, which includes an exhaust gas turbocharger 2, a flue gas three-way valve 3, a PM removal device 4, a flue gas cooler 5, and also includes a NO oxidizer 5, a reactor 9, Activated carbon delivery control unit 23 and temperature control unit 16. Compared with the existing ship denitrification device, the system composition of the device is relatively simple, and the activated carbon acts as the adsorbent and the reducing agent in the present invention. Because activated carbon has strong adsorption and reduction capabilities, the size of the reactor of the denitrification system in the present invention is much smaller than that of the existing urea-based SCR denitrification system for ships. The existing ship SCR denitrification systems basically use NH3 produced from urea aqueous solution as the reducing agent. The urea aqueous solution is easy to form urea crystals on the surface of the mixer and catalyst, resulting in a decrease in the performance of the denitrification system. The consumable of the present invention is only activated carbon, which has obvious advantages.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com