Method for preparing bimetallic carbide composite material through thermolysis approach

A technology of bimetallic carbides and composite materials, applied in the direction of carbides, carbon oxides/sulfur carbides, nanotechnology for materials and surface science, etc., can solve the problems of complex synthesis conditions and difficult control, and achieve preparation The process is simple, the operation is convenient, and the effect of relatively high reaction temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Heterotungstate Na 10 [Co 4 (H 2 O) 2 (PW 9 o 34 ) 2 ]·27H 2 O (0.54g, 0.1mmol) was dissolved in deionized water (30mL) to obtain heterotungstic acid solution; octadecyltrimethylammonium chloride (0.7g, 2.01mmol) was dissolved in deionized water (10mL), Obtain an organic amine solution; under the condition of stirring, add the heterotungstic acid solution dropwise to the organic amine solution, continue stirring for 1 hour after dropping, then centrifuge, wash with deionized water, and dry to obtain a solid precursor powder, which is stored in a dry place after grinding spare in the device;

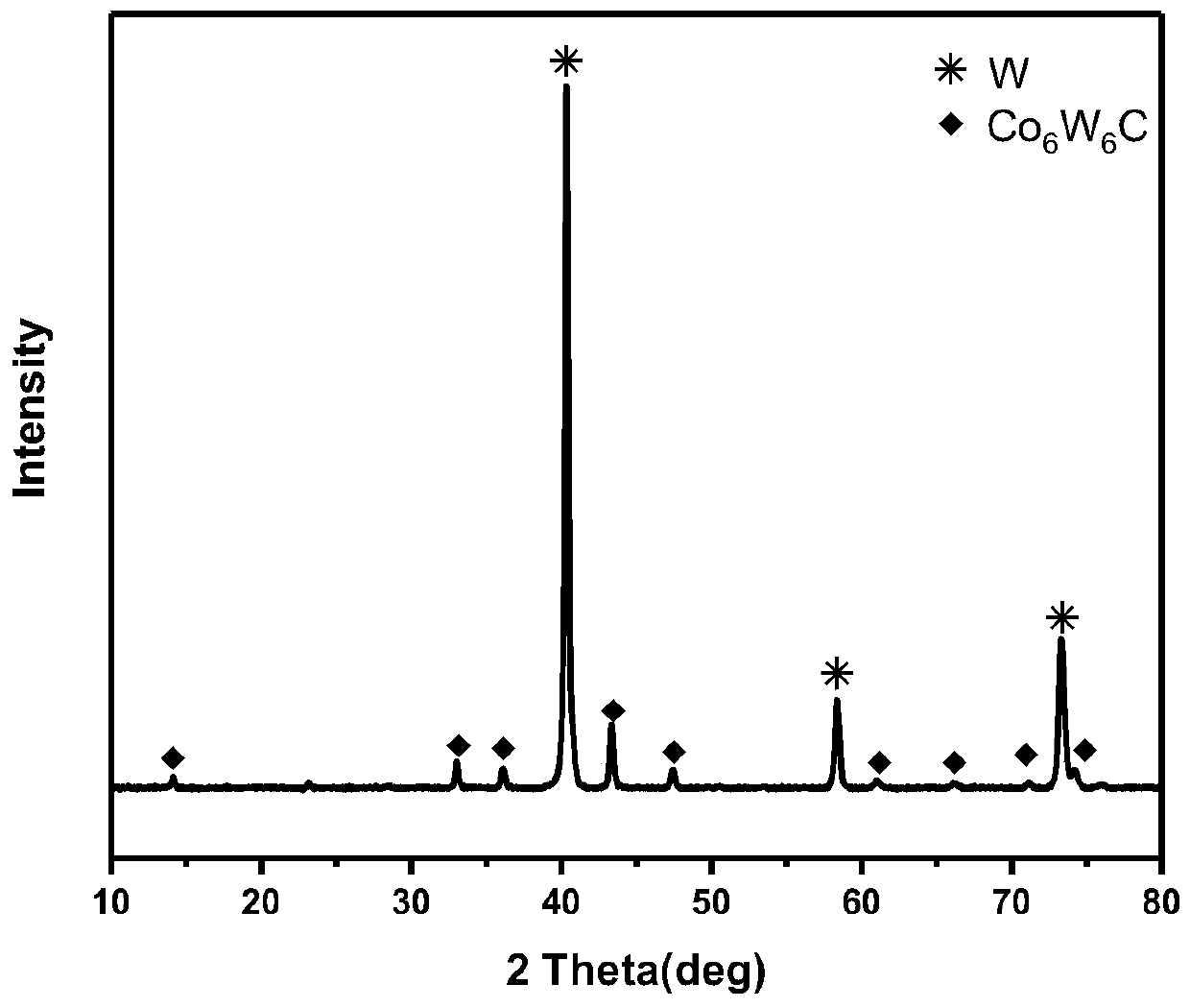

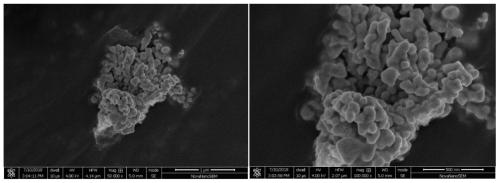

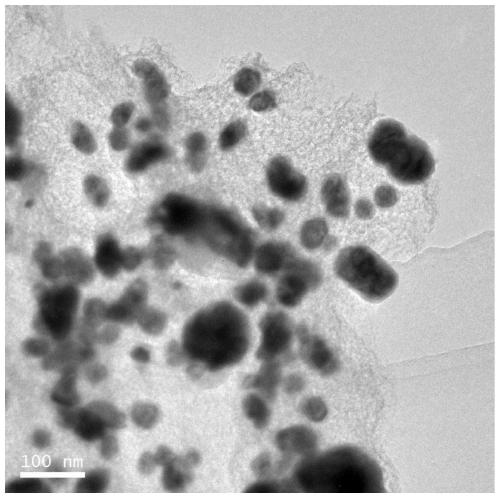

[0037] Spread the precursor solid powder in a porcelain boat, place the porcelain boat in a quartz boat, place the quartz boat in a tube furnace for temperature-programmed calcination, and the calcination procedure is as follows: first, in N 2 Under the atmosphere, the temperature was raised from room temperature to 410 °C at a rate of 2 °C / min and kept for 1 h; 2 :H 2 =8...

Embodiment 2

[0039] Heterotungstate Na 10 [Co 4 (H 2 O) 2 (PW 9 o 34 ) 2 ]·27H 2 O (0.54g, 0.1mmol) was dissolved in deionized water (30mL) to obtain heterotungstic acid solution; octadecyltrimethylammonium chloride (0.7g, 2.01mmol) was dissolved in deionized water (10mL), Obtain an organic amine solution; under the condition of stirring, add the heterotungstic acid solution dropwise to the organic amine solution, continue stirring for 1 hour after dropping, then centrifuge, wash with deionized water, and dry to obtain a solid precursor powder, which is stored in a dry place after grinding spare in the device;

[0040] Spread the precursor solid powder in a porcelain boat, place the porcelain boat in a quartz boat, place the quartz boat in a tube furnace for temperature-programmed calcination, and the calcination procedure is as follows: first, in N 2 Under the atmosphere, the temperature was raised from room temperature to 410 °C at a rate of 2 °C / min and kept for 1 h; 2 :H 2 =9...

Embodiment 3

[0042] Heterotungstate Na 10 [Co 4 (H 2 O) 2 (PW 9 o34 ) 2 ]·27H 2 O (1.08g, 0.2mmol) was dissolved in deionized water (40mL) to obtain heterotungstic acid solution; octadecyltrimethylammonium chloride (1.4g, 4.02mol) was dissolved in deionized water (20mL), Obtain an organic amine solution; under the condition of stirring, add the heterotungstic acid solution dropwise to the organic amine solution, continue stirring for 1 hour after dropping, then centrifuge, wash with deionized water, and dry to obtain a solid precursor powder, which is stored in a dry place after grinding spare in the device;

[0043] Spread the precursor solid powder in a porcelain boat, place the porcelain boat in a quartz boat, place the quartz boat in a tube furnace for temperature-programmed calcination, and the calcination procedure is as follows: first, in N 2 Under the atmosphere, the temperature was raised from room temperature to 410 °C at a rate of 2 °C / min and kept for 1 h; 2 :H 2 =95:5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com