Device and method for tail gas denitrification by activated carbon method for ships

An activated carbon and denitrification technology, which is applied in the direction of exhaust devices, separation methods, and noise reduction devices, can solve the problems of high reaction temperature, large space occupation, and high economic cost, and achieve high removal efficiency, low requirements for reaction temperature, and high The effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

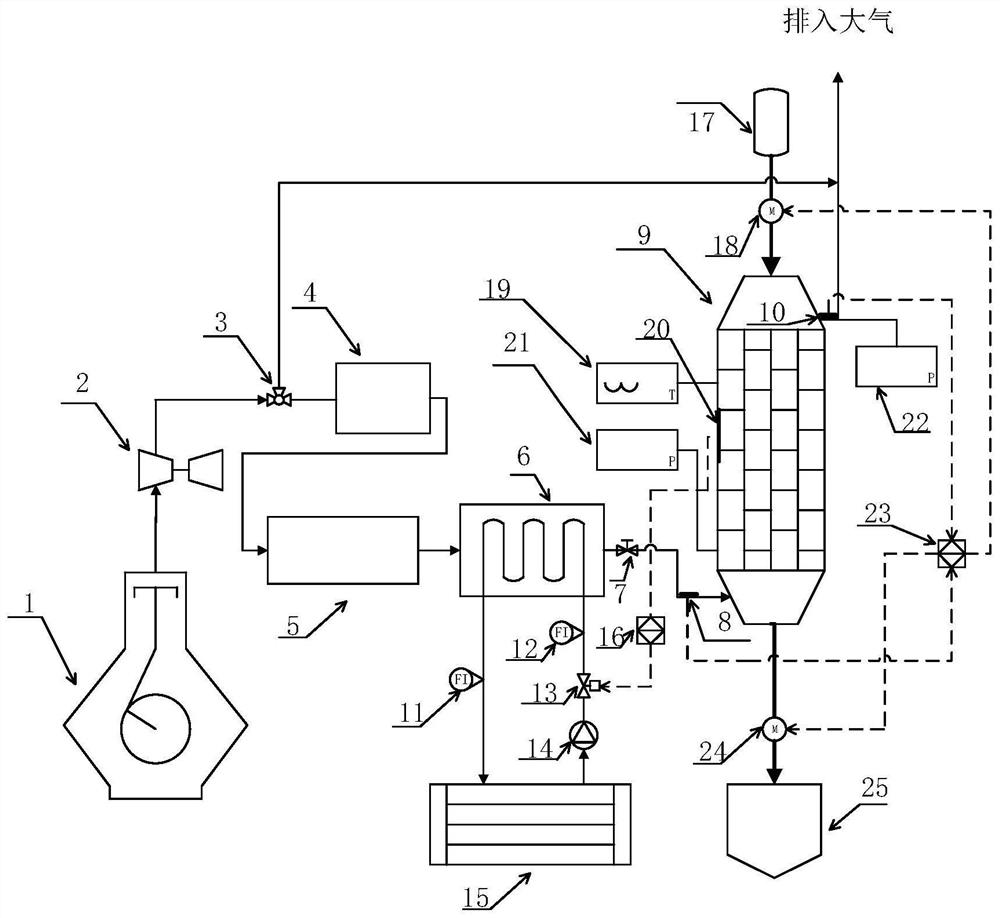

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] combine figure 1 : Among them, 1 is marine diesel engine, 2 is exhaust gas turbocharger, 3 is flue gas three-way valve, 4 is PM removal device, 5 is NO oxidizer, 6 is flue gas cooler, and 7 is reactor flue gas control Valve, 8 is the NOx concentration sensor at the reactor inlet, 9 is the reactor, 10 is the NOx concentration sensor at the reactor outlet, 11 is the coolant outlet flowmeter, 23 is the coolant inlet flowmeter, 13 is the electromagnetic flow control valve, 14 is Coolant supply pump, 15 is coolant storage, 16 is temperature control unit, 17 is activated carbon storage cabinet, 18 is activated carbon installation device, 19 is temperature indicator, 20 is reactor temperature sensor, 21 is flue gas inlet pressure Indicator, 22 is the flue gas outlet pressure indicator, 23 is the activated carbon delivery control unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com