Treatment method and application of antibiotic bacterial residues

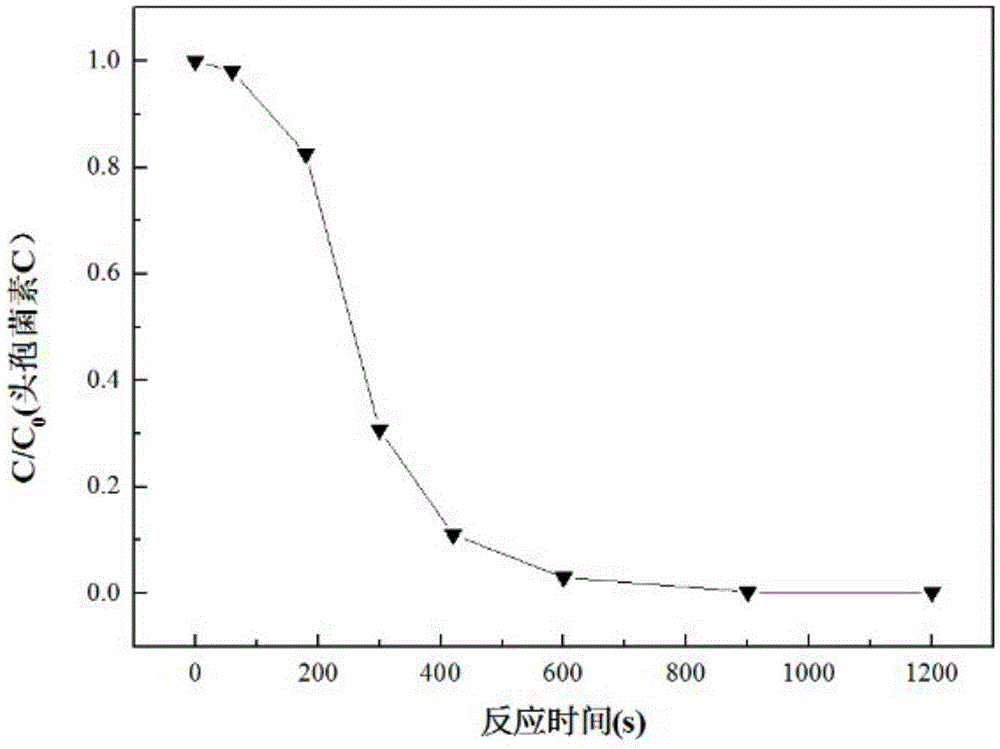

A technology of antibiotic bacteria residue and treatment method, which is applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve environmental risks, long cycle and other problems, and achieve shortened treatment time, short reaction time and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

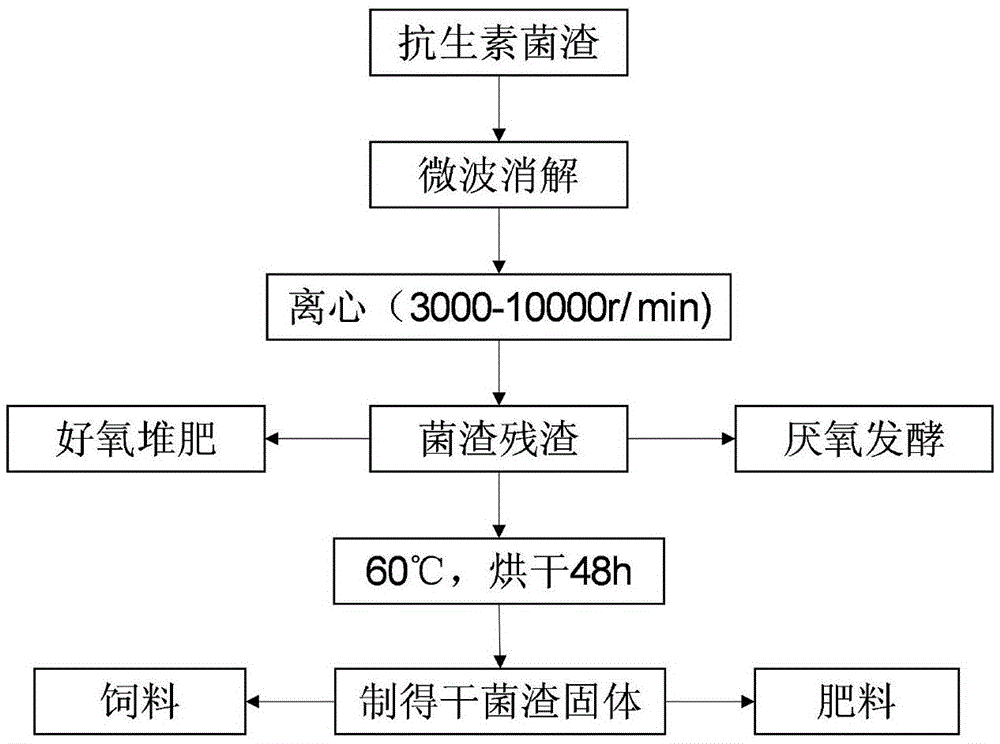

[0022] Specific embodiment one: the processing method of kind antibiotic bacterium residue of the present embodiment, it is to carry out according to the following steps:

[0023] 1. Put the fresh antibiotic residue in the reaction tank, control the water content to 85-95%, and stir and mix evenly;

[0024] 2. Put the reaction tank containing the antibiotic residue into the microwave reactor, control the microwave power of the microwave generator to 100-900W, heat the antibiotic residue to 100°C, and keep it for 10-15min;

[0025] 3. Centrifuge the antibiotic scum after heating in step 2, and dry the obtained slag to complete the treatment of the antibiotic slag.

[0026] The antibiotic in the antibiotic slag described in the present embodiment refers to: (cephalosporin C, penicillin G); (Strain: Penicillium chrysogenum).

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in Step 2, the microwave power is controlled, and the antibiotic residue is heated to 100° C. within 3 to 10 minutes. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment is different from Embodiment 1 in that: in step 2, control the microwave power to 300W and heat the antibiotic residue to 100° C. within 5-6 minutes. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com