Method for treating antibiotic fungi residues by percarbonate to prepare organic fertilizer

A technology of antibiotic slag and percarbonate, which is applied to organic fertilizers, inorganic fertilizers, potash fertilizers, etc., can solve the problem of high treatment cost of antibiotic slag, and achieve the effects of easy operation, high safety and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

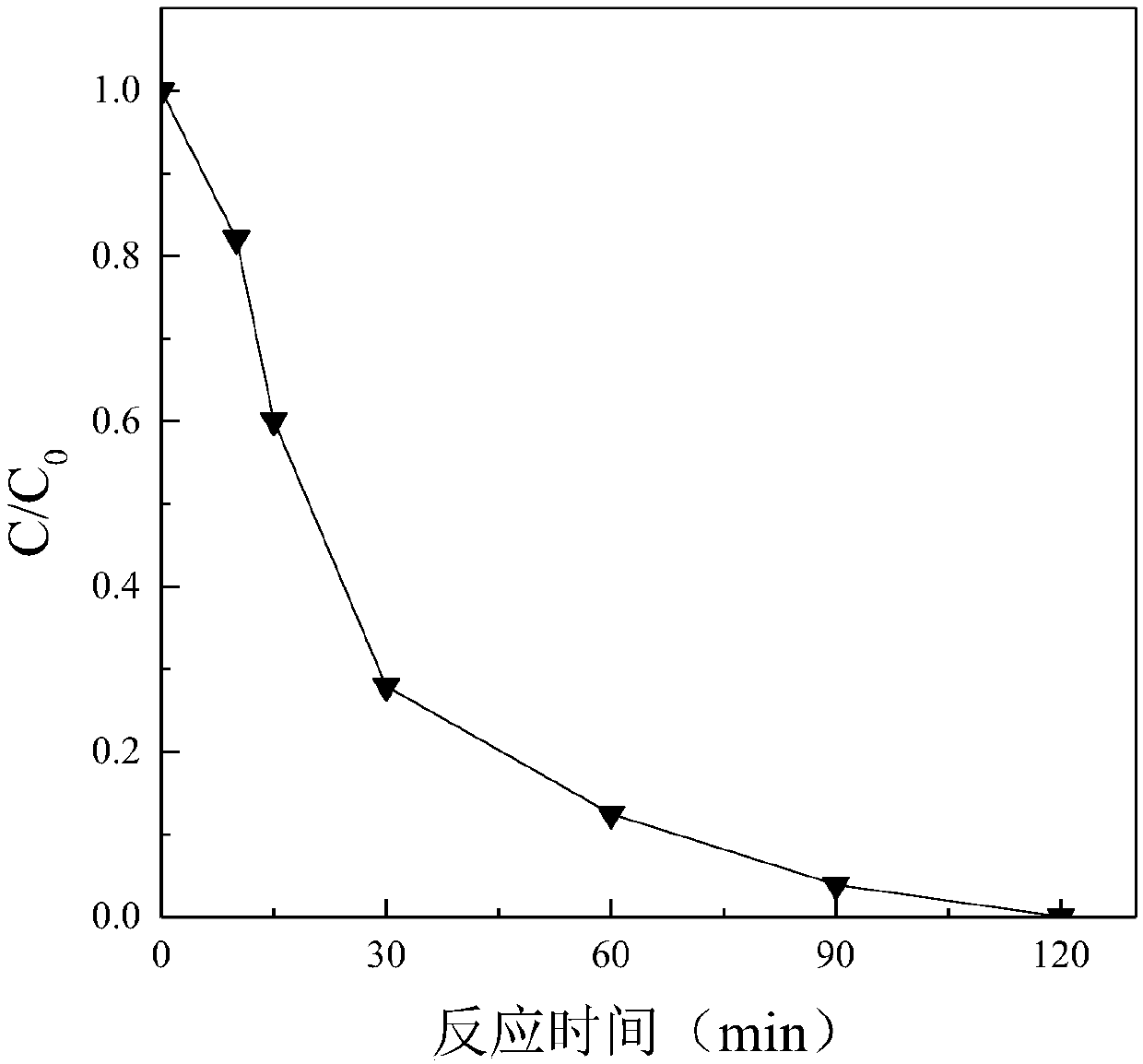

[0024] Specific embodiment one: a kind of method of utilizing antibiotic scum to produce organic fertilizer of the present embodiment is characterized in that it is carried out according to the following steps:

[0025] 1. Collect antibiotic slag, adjust the solid content to 8-10%, and obtain the slag liquid to be treated. Take 1L of the slag liquid to be treated, add percarbonate in the reaction tank, and stir to mix evenly;

[0026] 2. Heat the antibiotic bacteria residue reaction tank containing percarbonate to 60-80°C, and keep it warm for 2 hours under uniform stirring;

[0027] 3. After the reaction is completed, the bacterial residue is centrifuged, and the obtained bacterial residue precipitate is mixed with humic acid or bentonite as an auxiliary material, stirred, dried and granulated to make organic fertilizer;

[0028] The residual amount of antibiotics in the antibiotic bacteria residue liquid is 600-700 mg / L, pH=4.0-7.8;

[0029] The molar ratio of antibiotic to...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the molar ratio of the antibiotic to percarbonate is 1:300-400. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the molar ratio of the antibiotic to percarbonate is 1:400-500:1. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com