A kind of preparation method of bismuth vanadate nanowire-graphene photocatalyst

A bismuth vanadate nanometer, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of small size of microwave generators, microwave generators Expensive price, long hydrothermal treatment time and other problems, to achieve the effect of simple and easy production cost, improved photocatalytic performance, and low reaction temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

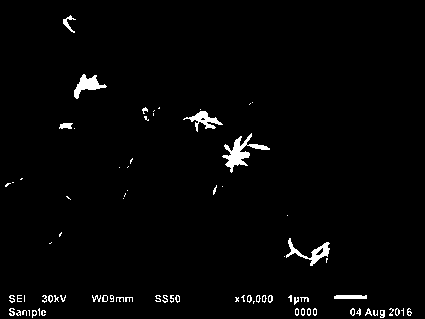

Image

Examples

Embodiment 1

[0018] a: Add bismuth nitrate, ammonium metavanadate, oxalic acid dihydrate, and polyethyleneimine into deionized water, and ultrasonically mix to form a mixed solution, in which the concentration of ammonium metavanadate is 0.2mol / L, and the concentration of bismuth nitrate is 0.04mol / L, the concentration of oxalic acid dihydrate is 0.4mol / L, and the concentration of polyethyleneimine is 0.04mol / L;

[0019] b: Sodium lauryl sulfate and graphene oxide were added to deionized water, and ultrasonically mixed to form a surface-treated graphene oxide solution;

[0020] c: adding the surface-treated graphene oxide solution in step b to the mixed solution prepared in step a, and ultrasonically mixing to obtain a precursor solution, wherein the concentration of graphene oxide is 0.2mol / L;

[0021] d: Clean the carbon cloth, put the cleaned carbon cloth into the inner lining of the autoclave;

[0022] e: After transferring the precursor solution prepared in step c to the inner lining...

Embodiment 2

[0026] a: Add bismuth carbonate, ammonium metavanadate, oxalic acid dihydrate, and polyacrylamide into deionized water, and mix ultrasonically to form a mixed solution, in which the concentration of ammonium metavanadate is 1mol / L, and the concentration of bismuth carbonate is 0.03mol / L, the concentration of oxalic acid dihydrate is 1.8mol / L, and the concentration of polyacrylamide is 0.18mol / L;

[0027] b: Sodium dodecylbenzenesulfonate and graphene oxide were added to deionized water, and ultrasonically mixed to form a surface-treated graphene oxide solution;

[0028] c: adding the surface-treated graphene oxide solution in step b to the mixed solution prepared in step a, and ultrasonically mixing to obtain a precursor solution, wherein the concentration of graphene oxide is 0.8mol / L;

[0029] d: Clean the stainless steel wire mesh, and put the cleaned stainless steel wire mesh into the inner lining of the high-pressure reactor;

[0030] e: After transferring the precursor...

Embodiment 3

[0034] a: Add bismuth acetate, ammonium metavanadate, oxalic acid dihydrate, and polyvinylpyrrolidone into deionized water, and mix ultrasonically to form a mixed solution. The concentration of ammonium metavanadate is 0.5mol / L, and the concentration of bismuth acetate is 0.05mol / L, the concentration of oxalic acid dihydrate is 0.15mol / L, and the concentration of polyvinylpyrrolidone is 0.15mol / L;

[0035] b: Sodium stearate and graphene oxide are added to deionized water, and ultrasonically mixed to form a surface-treated graphene oxide solution;

[0036] c: adding the surface-treated graphene oxide solution in step b to the mixed solution prepared in step a, and ultrasonically mixing to obtain a precursor solution, wherein the concentration of graphene oxide is 0.4mol / L;

[0037] d: Clean the foamed nickel, put the cleaned foamed nickel into the lining of the autoclave;

[0038] e: After transferring the precursor solution prepared in step b to the lining of the autoclave e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com