Comprehensive utilization method of ferriferous fayalite material

A technology of olivine and materials, applied in the direction of improving process efficiency, etc., can solve the problems of unrecoverable iron, poor technical economy, and difficult separation of ferrosilicon, so as to reduce consumption, high comprehensive utilization rate of resources, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

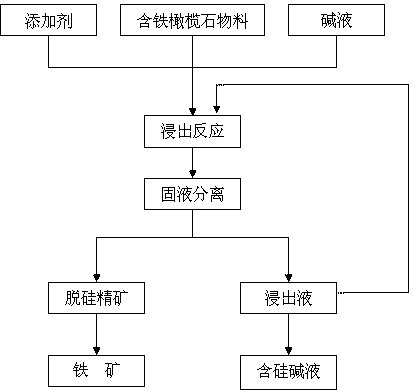

[0032] Such as figure 1 Shown, a kind of processing method of iron-containing olivine material comprises the following steps:

[0033] Contains Fe35.32%, SiO 2 32.56% iron-containing olivine iron ore was mixed with 50g / L NaOH solution and additives at 90°C for 5 hours, the liquid-solid ratio was 30, and the amount of additives was 0.5% of the silicon content in the iron ore. SiO was obtained by centrifugation 2 9.35g / L silicon-containing alkali solution, and Fe61.94%, SiO 2 4.57% desiliconized concentrate. The leachate circulation is used in the leaching process, and when the molecular ratio of silicon dioxide to sodium oxide in the solution is greater than 0.7, it is used for the production of sodium silicate.

Embodiment 2

[0035] Such as figure 1 Shown, a kind of processing method of iron-containing olivine material comprises the following steps:

[0036] The composition is Fe38.32%, SiO 2 30.83% of a copper slag was mixed with 500g / L KOH solution for 10 minutes at 280°C, the liquid-solid ratio was 5, and the amount of additive was 1% of the silicon content in the copper slag. Filter to get SiO 2 48.98g / L leachate, and Fe60.81%, SiO 2 8.07% desiliconized concentrate. The leachate circulation is used in the leaching process, and when the molecular ratio of silicon dioxide to potassium oxide in the solution is greater than 0.8, it is used for the production of potassium silicate.

Embodiment 3

[0038] Such as figure 1 Shown, a kind of processing method of iron-containing olivine material comprises the following steps:

[0039] Fe42.41%, SiO 2 27.56% ferronickel slag was mixed and reacted with 100g / L NaOH and KOH solution at 150°C for 2 hours, and the liquid-solid ratio was 10. SiO was obtained by centrifugation 2 24.74g / L silicon-containing lye, and Fe65.05%, SiO 2 3.92% desiliconized concentrate. The leachate circulation is used in the leaching process and is used for the production of sodium potassium silicate when the molecular ratio of silicon dioxide to sodium oxide and potassium oxide in the solution is greater than 0.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com