Method for preparing alanyl-glutamine dipeptide through biological enzyme conversion

A technology of glutamate dipeptide and biological enzyme is applied in the field of preparation of glutamate dipeptide, which can solve the problems of high cost, long production cycle, large environmental pollution and the like, and achieve the effects of high catalytic conversion reaction efficiency, easy control of quality indicators and high catalytic conversion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 350g of biological enzyme and dissolve it in 3000ml of dipotassium hydrogen phosphate-phosphate buffer solution, adjust the pH to 7.5, and control the temperature at 5-10°C to prepare the biological enzyme solution. The detected enzyme activity is 5122U. Use purified water to prepare dilute hydrochloric acid and dilute ammonia water with a mass fraction of 15% respectively with hydrochloric acid and ammonia water for later use.

[0023] Take 5kg of the reaction substrate isopropyl alanine and 2.5kg of glutamine and dissolve it in 50L of purified water, slowly and evenly add the biological enzyme solution into the reaction substrate, control the addition rate at 15ml / min, and monitor the pH of the reaction solution in real time. Add the prepared dilute hydrochloric acid and dilute ammonia water to the reaction substrate, control the pH of the reaction solution at 5-10, and maintain the temperature at 15-25°C. Sampling detection in the reaction process, liquid chrom...

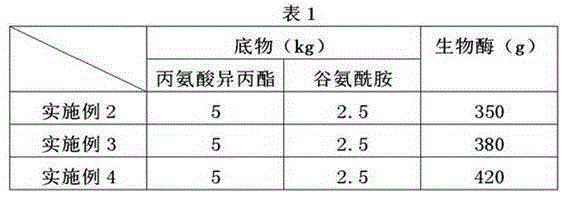

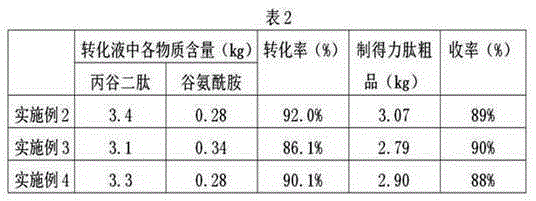

Embodiment 2-4

[0026]

[0027]

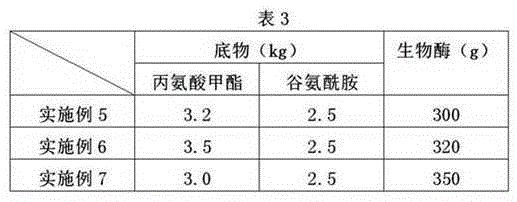

Embodiment 5-7

[0030]

[0031]

[0032] It should be noted that the dilute hydrochloric acid and dilute ammonia water used to regulate the pH in the reaction solution can be prepared in different concentrations according to the needs, which is convenient for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com