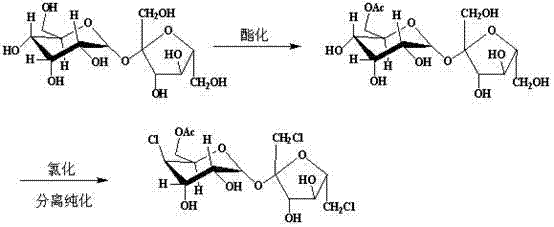

Method for preparing sucralose-6-acetate by tandem reaction

A technology of sucralose and series reaction, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of high reaction temperature requirements, increased difficulty in operation, long reaction time, etc., and reach the reaction temperature Low requirements, short reaction time, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In a 250 ml three-necked flask, add 34.2 g (0.1 mol) of sucrose, 16.8 g (0.14 mol) of trimethyl orthoacetate and 6.8 g of p-toluenesulfonic acid, stir and react at 40°C for 5 hours, then add appropriate amount of deionized water 4 ml , stirred at room temperature for 2 hours, then added 92.5 grams (0.5 moles) of tri-tert-butylamine, and after stirring at room temperature for 5 hours, added 63.3 grams (0.5 moles) of benzyl chloride, reacted at 100 ° C for 10 hours, and used ethyl acetate 100 × 3 ml Extraction, concentration, and recrystallization yielded 19 grams of sucralose-6-acetate product, with a yield of 48%. Melting point: 75~77℃; the purity of the product is over 98.0% by HPLC.

Embodiment 2

[0031] In a 250 ml three-necked flask, add 34.2 g (0.1 mol) of sucrose, 16.8 g (0.14 mol) of trimethyl orthoacetate and 5.1 g of p-toluenesulfonic acid, stir and react at 40°C for 5 hours, then add an appropriate amount of deionized water 5 ml , stirred at room temperature for 2 hours, then added 55.5 g (0.3 mol) of tri-tert-butylamine, after stirring at room temperature for 5 hours, added 38 g (0.3 mol) of benzyl chloride, reacted at 110 ° C for 6 hours, and added 100 × 3 ml of ethyl acetate Extraction, concentration, and recrystallization yielded 19 grams of sucralose-6-acetate product, with a yield of 48%. Melting point: 75~77℃; the purity of the product is over 98.0% by HPLC.

Embodiment 3

[0033] In a 250 ml three-necked flask, add 34.2 g (0.1 mol) of sucrose, 16.8 g (0.14 mol) of trimethyl orthoacetate and 0.5 g of p-toluenesulfonic acid, stir and react at 40°C for 5 hours, then add an appropriate amount of deionized water 3 ml , stirred at room temperature for 2 hours, then added 55.5 grams (0.3 moles) of tri-tert-butylamine, after stirring at room temperature for 5 hours, added 38 grams (0.3 moles) of benzyl chloride, reacted at 90 ° C for 10 hours, and used ethyl acetate 100 × 3 ml Extraction, concentration, and recrystallization yielded 19 grams of sucralose-6-acetate product, with a yield of 48%. Melting point: 75~77℃; the purity of the product is over 98.0% by HPLC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com