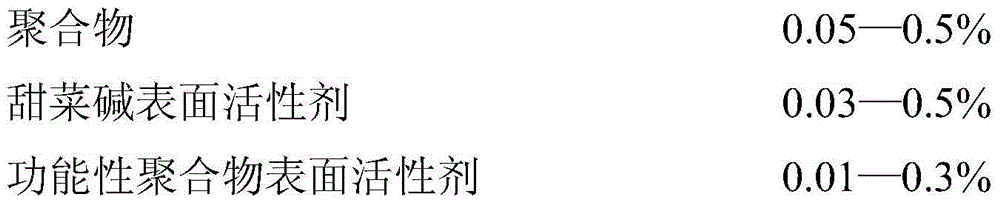

Functional polymeric surfactant-reinforced betaine composite flooding system and use thereof

A technology of surfactants and functional monomers, applied in the field of betaine composite flooding systems enhanced by functional polymer surfactants, can solve problems such as difficult industrial application, high cost, and difficult control of foam formation and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

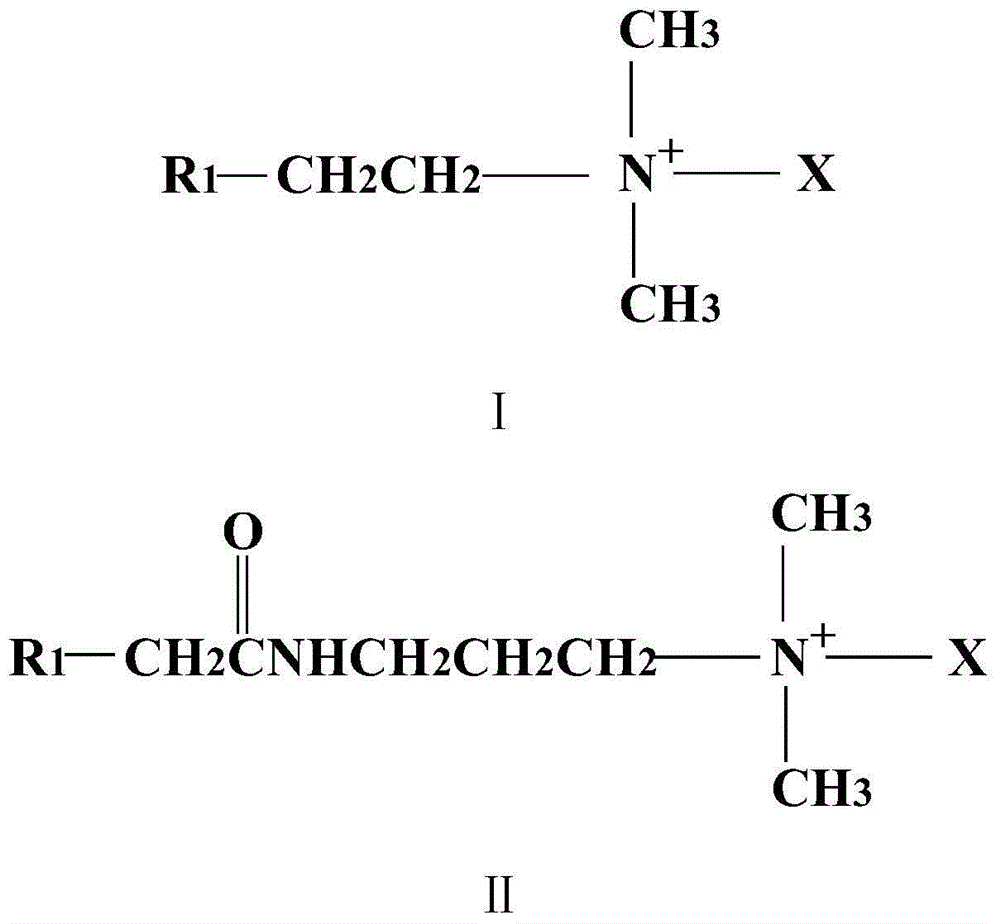

[0059] (1) Polymer: The water-soluble polymer is partially hydrolyzed polyacrylamide HPAM, produced by Daqing Refining and Chemical Company, with a molecular weight of 9 million.

[0060] (2) Betaine surfactant: a mixture of octadecyl hydroxypropyl sultaine: m-xylyl octadecamidopropyl hydroxypropyl sultaine = 30:70 (w / w).

[0061] Octadecyl hydroxypropyl sulfobetaine: the ratio of octadecyl tertiary amine to sodium 3-chloro-2-hydroxypropanesulfonate is 1:1.1 (molar ratio), methanol is used as solvent at 125°C for quaternization After 8 hours of reaction, the product was obtained by demethanolization.

[0062] m-xylyl octadecanoyl propyl hydroxypropyl sultaine: Friedel-Crafts alkylation reaction of m-xylene and oleic acid under the action of an acidic catalyst to obtain m-xylyl octadecanecarboxylic acid, and then react with N , N-dimethylpropylamine carries out amidation reaction, obtains m-xylyl octadecamidopropyl tertiary amine, and then with 3-chloro-2-hydroxypropanesulfona...

Embodiment 2

[0084] (1) Polymer: The water-soluble polymer is partially hydrolyzed polyacrylamide HPAM, produced by Daqing Refining and Chemical Company, with a molecular weight of 25 million.

[0085] (2) Betaine surfactant: octadecyl hydroxypropyl sulfobetaine: m-xylyl octadecyl hydroxypropyl sulfobetaine = 50:50 (w / w) mixture

[0086] Octadecyl hydroxypropyl sultaine: with embodiment 1.

[0087] m-Xylyl octadecyl hydroxypropyl sulfobetaine: provided by the State Key Laboratory of Enhanced Oil Recovery.

[0088] (3) functional polymer surfactant: with embodiment 1.

[0089] (4) Nonionic surfactant: stearyl alcohol polyoxypropylene (5) polyoxyethylene (20) ether, provided by Tianjin University of Technology.

[0090] The composition of strong alkali combined flooding system of the present invention:

[0091]

Embodiment 3

[0110] (1) polymer: with embodiment 2.

[0111] (2) Betaine Surfactant: Erucamide Propyl Hydroxypropyl Sultaine

[0112] Erucic acid amidopropyl hydroxypropyl sulfobetaine: erucic acid amidopropyl tertiary amine and 3-chloro-2-hydroxypropanesulfonate sodium ratio is 1:1.1 (molar ratio), 125 ℃ methanol as solvent, for quartering The amination reaction was carried out for 8 hours, and the product was obtained by demethanolization.

[0113] (3) functional polymer surfactant: with embodiment 1.

[0114] (4) Nonionic surfactant: stearyl alcohol polyoxypropylene (5) polyoxyethylene (20) ether, provided by Tianjin University of Technology.

[0115] The composition of weak alkali composite flooding system of the present invention:

[0116]

[0117]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com