Elastic particle oil displacement profile control agent, displacement of reservoir oil system and displacement of reservoir oil method

A technology of elastic particles and flooding agents, applied in chemical instruments and methods, mining fluids, earth drilling and production, etc., can solve problems such as ineffective water circulation, foam flooding, gas channeling, scaling, etc., to achieve enhanced oil recovery, increase Sweep factor and the effect of improving oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

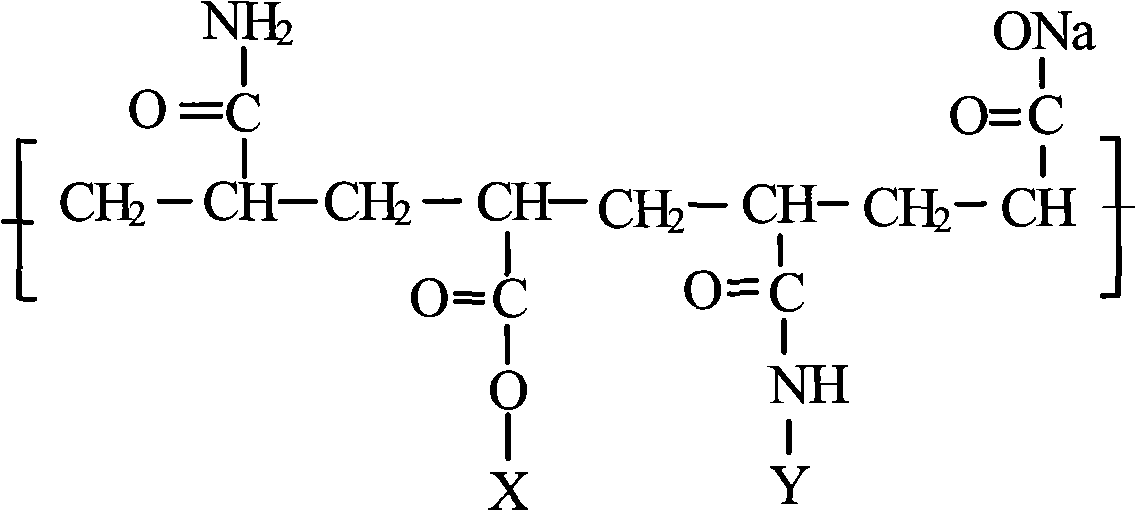

[0034] Embodiment 1, the preparation of elastic particle regulating and displacing agent

[0035] Material:

[0036] Polymer 1: Shanghai Haibo Company, functional polymer type I, viscosity greater than 100mPa.s;

[0037] Polymer 2: Shanghai Haibo Company, functional polymer type III, viscosity greater than 50mPa.s;

[0038] Elastic particles 1: Kaifeng Aode Technology Co., Ltd., AD22-104 bulky particles, 100-200 mesh;

[0039] Elastic particles 2: Linhai Yongfeng Jianghua waste tire crushing plant, rubber particles, 0-80 mesh;

[0040] Elastic granules 3: flexible granules, from Petroleum Exploration and Development Research Institute, tensile strength 28.44kPa, adjustable particle size.

[0041] Preparation:

[0042] Regulator 1: Take 1500mg of polymer 1 and add 1L of water to make a solution, then add 150 mesh (particle diameter) of 0.5g elastic particles 1, and after mixing, obtain polymer 1-body swelling with a mass concentration of elastic particles of 0.05wt%. Dispers...

Embodiment 2

[0047] Example 2. Oil displacement experiment of heterogeneous core polymer-elastic particle flooding system

[0048] Indoor physical simulation experiments are adopted.

[0049] Experimental conditions:

[0050] Heterogeneous core: 4.5×4.5×30cm, gas permeability of three layers are 100md, 1000md, 3000md respectively.

[0051] Oil: simulated crude oil, the viscosity is 10mPa·s at 45°C;

[0052] Water: Oilfield sewage;

[0053] Adjusting and displacing agent: according to embodiment 1 preparation;

[0054] Experimental temperature: 45°C;

[0055] Polymer: the functional polymer in Example 1.

[0056] experimental method:

[0057] After the initial water flooding of 2PV, inject 0.07PV, 1500mg / L type I functional polymer (viscosity 1500mPa. .s) (two rounds of injection) + 0.3PV foam (0.3% blowing agent - sodium alkylbenzene sulfonate + 500mg / L type III functional polymer), followed by water flooding 2PV.

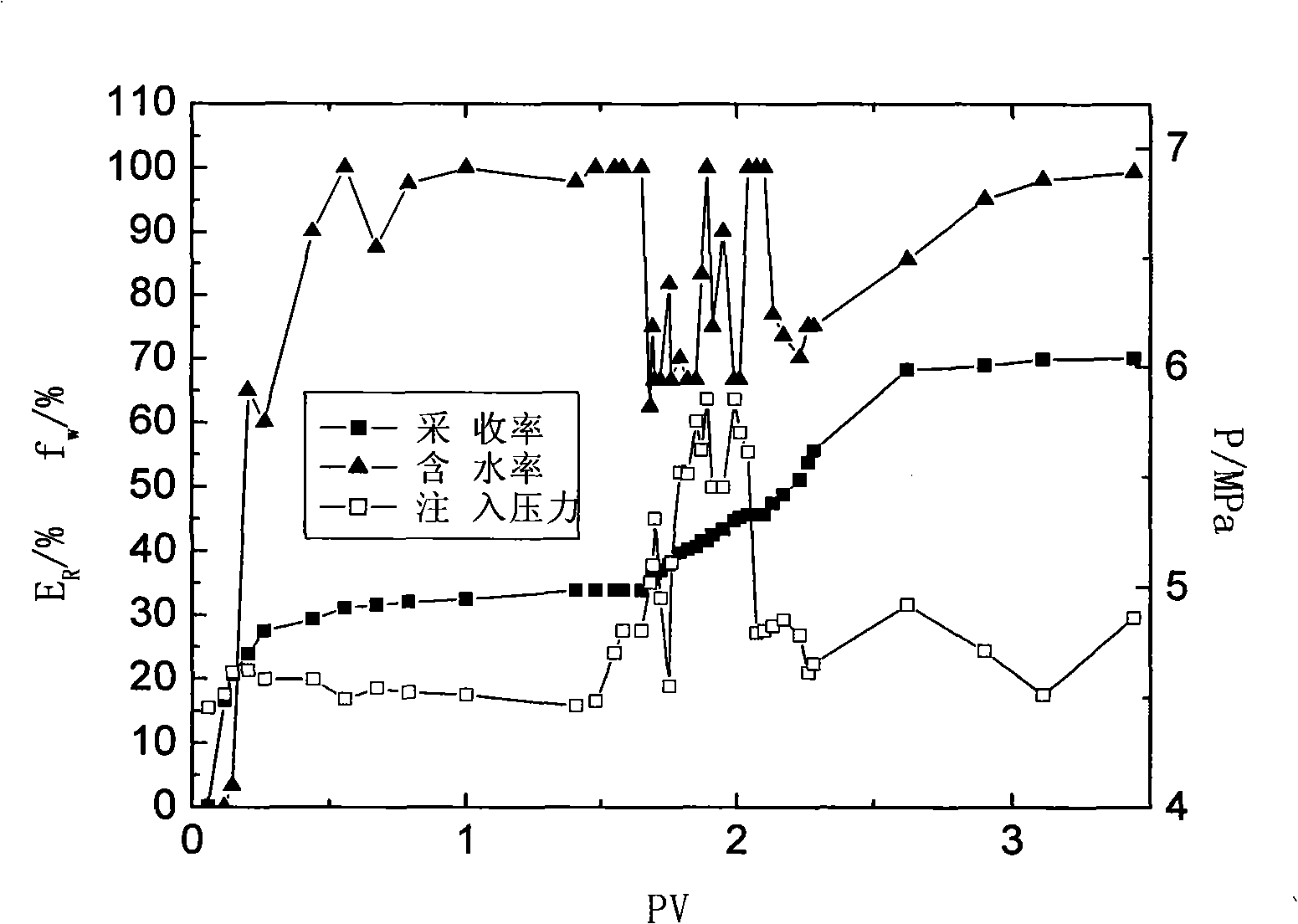

[0058] Oil displacement results: see figure 1 . It shows that th...

Embodiment 3

[0060] Example 3. Oil displacement experiment of polymer-elastic particles-foam flooding system

[0061] Indoor physical simulation experiments are adopted.

[0062] Experimental conditions:

[0063] Heterogeneous core: 4.5×4.5×30cm, gas permeability of three layers are 100md, 1000md, 3000md respectively.

[0064] Oil: simulated crude oil, the viscosity is 10mPa·s at 45°C;

[0065] water: sewage;

[0066] Chemical agent: functional polymer and elastic particles in embodiment one, foaming agent sodium alkylbenzene sulfonate;

[0067] Experimental temperature: 45°C;

[0068] Foam: The volume ratio of foaming liquid to compressed air is 0.4:1;

[0069] experimental method:

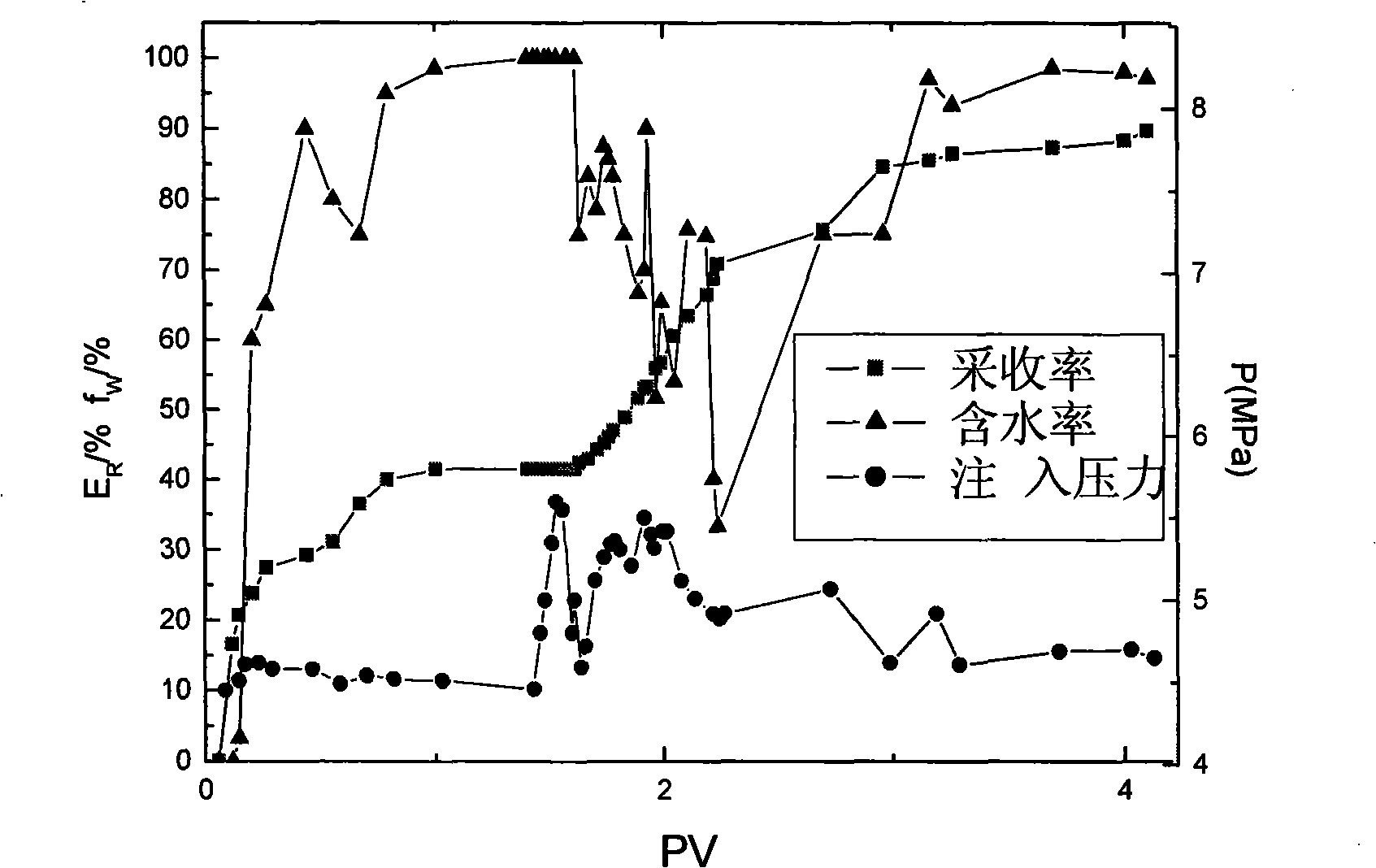

[0070] The water content of water flooding is above 98%. After the initial water flooding of 2PV, inject a group of combined slugs, followed by: 0.08PV polymer 1 plus bulky particles (polymer viscosity 2400mPa.s, bulky particle size 150 mesh, concentration 0.5wt%), 0.1PV polymer 1 plus volume expansion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com