Foam-assisted gravity oil driving method

An auxiliary gravity and foam technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., to achieve the effects of improving sweep coefficient, inhibiting gas channeling, and improving oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

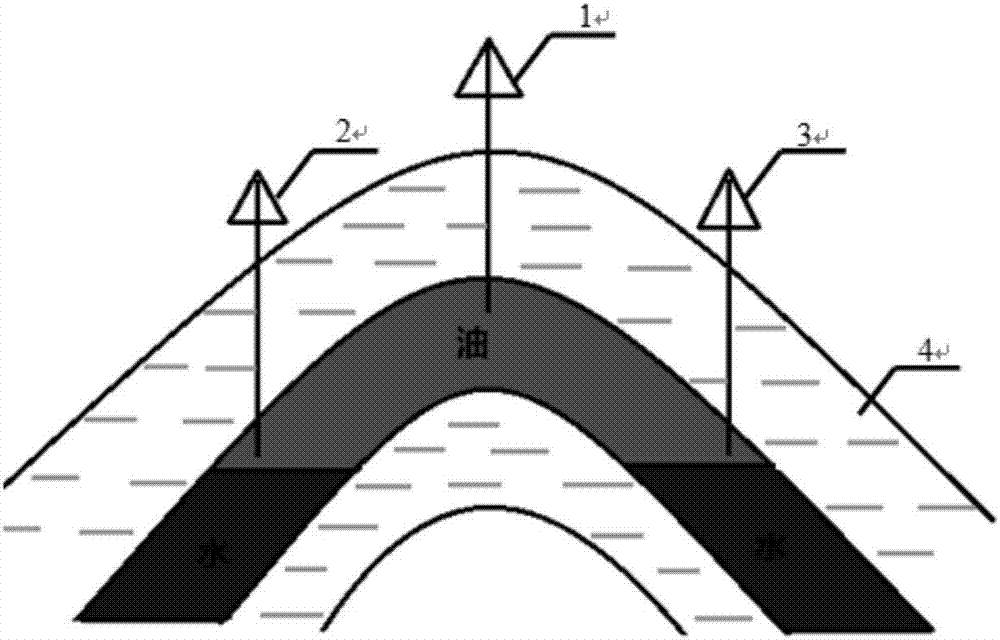

[0026] There are natural fractures in semi-anticline structural oil reservoirs, which are cut and sealed by faults, and the formation dip angle is about 15°. After water flooding, the water content of the produced oil has reached more than 90%.

[0027] A foam-assisted gravity flooding method for semi-anticline structure reservoirs. A horizontal well is drilled inside the oil-water transition zone as a production well, and a vertical well is drilled at the top of the reservoir as an injection well. The pre-generated oil is continuously injected from the injection well at the top of the reservoir. Foam, the volume injected into the foam is 0.05PV, the quality of the foam is 70%, and the concentration of the foaming agent is 1%. Because the foam has the property of selectively blocking high-permeability bands or cracks, it can effectively control gas channeling. Moreover, the foam can play a good role in profile control, so that the foam can enter more low-permeability parts, so ...

Embodiment 2

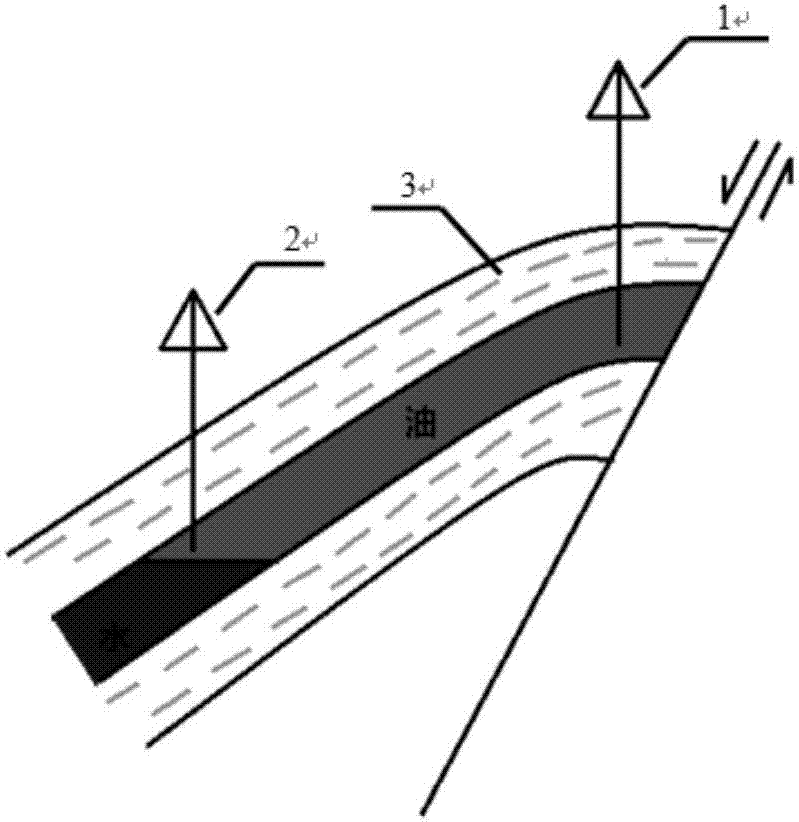

[0029] There are natural fractures in the Duanbi structural oil reservoir, which are cut and sealed by faults, and the formation dip angle is about 15°. After water flooding, the water content of the produced oil has reached more than 90%.

[0030] A foam-assisted gravity flooding method for a faulted-nose structure reservoir. A vertical well is drilled inside the oil-water transition zone as a production well, and a vertical well is drilled at the top of the reservoir as an injection well, and the pre-generated foam is continuously injected from the injection well at the top of the reservoir. The volume of the injected foam is 0.12PV, the mass of the foam is 65%, and the concentration of the foaming agent is 0.6%. Because the foam has the property of selectively blocking hyperpermeable bands or cracks, it can effectively control gas channeling. Moreover, the foam can play a good role in profile control, so that the foam can enter more low-permeability parts, so that the high a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com