Treatment method of oily sludge

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of high energy consumption, and achieve low energy consumption and economic benefits Great effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

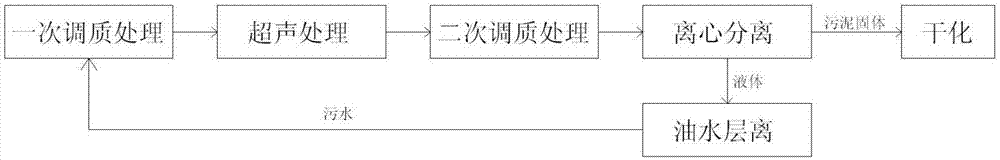

[0053] A treatment method for oily sludge, which is innovative in that it includes the following steps:

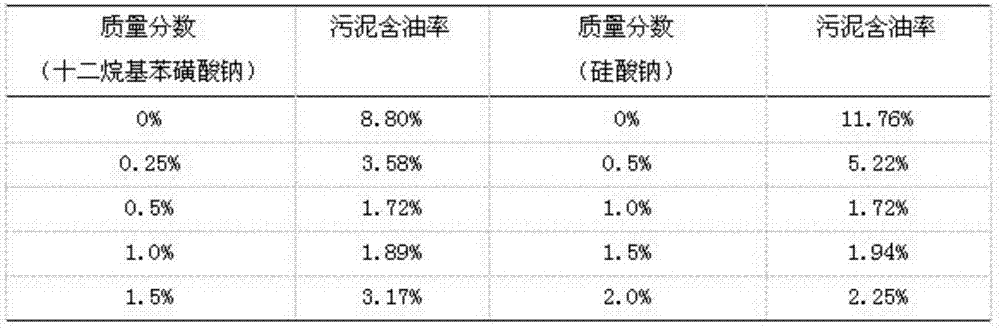

[0054] (1) For a conditioning treatment, 100g of sludge, 500g of water, 0.5g of sodium dodecylbenzenesulfonate, and 0.9g of polyaluminum chloride are thoroughly mixed by mechanical stirring, and the sludge is diluted from viscous is in a fluid state;

[0055] (2) Ultrasonic treatment. Ultrasonic treatment is performed on the mud-water mixture after the primary quenching and tempering treatment through ultrasonic equipment, and it is taken out after 30 minutes of action. The mechanical vibration and cavitation of ultrasonic waves are used to treat the oily sludge, forming a strong turbulent flow for the emulsion, thereby Make the oil, water, and mud in the sludge overcome the interfacial tension due to friction and separate from each other, especially for the cavitation of the sludge interface, it can quickly separate oil and solids;

[0056] (3) Secondary tempering treatm...

Embodiment 2

[0062] (1) Once conditioning treatment, 105g of sludge, 525g of water, 0.525g of sodium dodecylbenzenesulfonate, and 1.4g of polyaluminum chloride were mixed thoroughly by mechanical stirring, and the sludge was diluted from viscous is in a fluid state;

[0063] (2) Ultrasonic treatment. Ultrasonic treatment is performed on the mud-water mixture after the primary quenching and tempering treatment through ultrasonic equipment, and it is taken out after 30 minutes of action. The mechanical vibration and cavitation of ultrasonic waves are used to treat the oily sludge, forming a strong turbulent flow for the emulsion, thereby Make the oil, water, and mud in the sludge overcome the interfacial tension due to friction and separate from each other, especially for the cavitation of the sludge interface, it can quickly separate oil and solids;

[0064] (3) Secondary tempering treatment, adding 1.05 g of sodium silicate and 1.26 g of polyacrylamide, performing secondary conditioning tr...

Embodiment 3

[0070] A treatment method for oily sludge, which is innovative in that it includes the following steps:

[0071] (1) For a conditioning treatment, 110g of sludge, 550g of water, 0.55g of sodium dodecylbenzene sulfonate, and 1.3g of polyaluminum chloride are thoroughly mixed by mechanical stirring, and the sludge is diluted from viscous is in a fluid state;

[0072] (2) Ultrasonic treatment. Ultrasonic treatment is performed on the mud-water mixture after the primary quenching and tempering treatment through ultrasonic equipment, and it is taken out after 30 minutes of action. The mechanical vibration and cavitation of ultrasonic waves are used to treat the oily sludge, forming a strong turbulent flow for the emulsion, thereby Make the oil, water, and mud in the sludge overcome the interfacial tension due to friction and separate from each other, especially for the cavitation of the sludge interface, it can quickly separate oil and solids;

[0073] (3) Secondary tempering trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loss on ignition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com