High-temperature microemulsion cleanup additive used for fracturing, and preparation method thereof

A technology of microemulsion and drainage aid, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effect of improving flowback effect, improving flow capacity and preventing emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

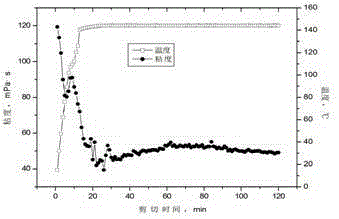

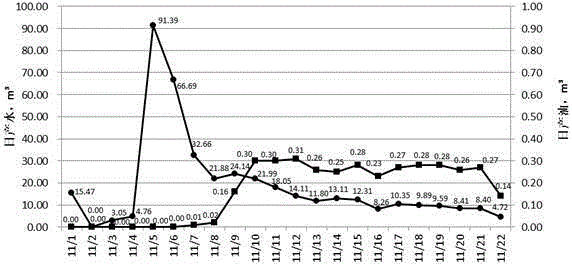

AI Technical Summary

Problems solved by technology

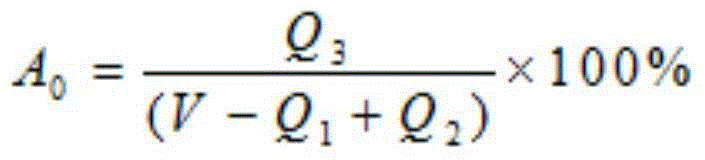

Method used

Image

Examples

Embodiment 1

[0062] The preparation method of the high-temperature microemulsion drainage aid for fracturing is carried out as follows:

[0063] a. First add 10 parts by mass of water into the reactor, then add 60 parts by mass of ethanol into the water, and stir until completely dissolved at room temperature;

[0064] b. Get 40 parts by mass of ethylene didodecyl dimethyl ammonium chloride and 4 parts by mass of coconut oil fatty acid monoethanolamide and add them to the reactor successively, then add water until the mixture in the reactor is 100 parts by mass, at room temperature Stir evenly to obtain the product.

Embodiment 2

[0066] The preparation method of the high-temperature microemulsion drainage aid for fracturing is carried out as follows:

[0067] a. First add 20 parts by mass of water into the reactor, then add 40 parts by mass of ethanol into the water, and stir until completely dissolved at room temperature;

[0068] b. Get 20 parts by mass of ethylene didodecyl dimethyl ammonium chloride and 3 parts by mass of coconut oil fatty acid monoethanolamide and add them to the reactor successively, then add water until the mixture in the reactor is 100 parts by mass, at room temperature Stir evenly to obtain the product.

Embodiment 3

[0070] The preparation method of the high-temperature microemulsion drainage aid for fracturing is carried out as follows:

[0071] a. First add 15 parts by mass of water into the reactor, then add 50 parts by mass of ethanol into the water, and stir until completely dissolved at room temperature;

[0072] b. Get 30 parts by mass of ethylene didodecyl dimethyl ammonium chloride and 3.5 parts by mass of coconut oil fatty acid monoethanolamide and add them to the reactor successively, then add water until the mixture in the reactor is 100 parts by mass, at room temperature Stir evenly to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com