Intelligent separation production string

An intelligent technology for producing pipe strings, applied in the direction of drilling pipes, casings, and production fluids, etc., can solve the problems of continuous monitoring, poor reliability, and small displacement, so as to save labor costs, prolong working life, and improve production timeliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

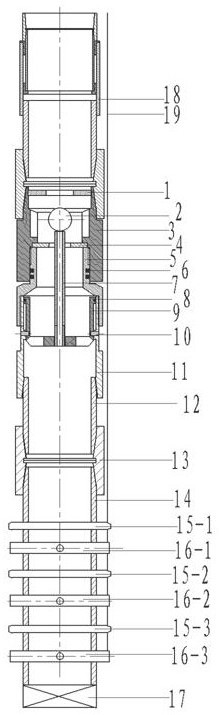

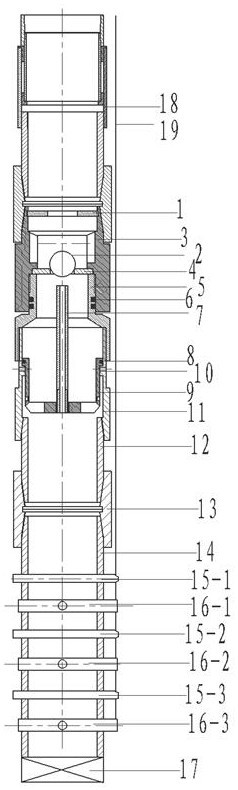

[0052] Embodiment 1: as figure 1 As shown, the production string of intelligent separate mining includes bonnet 1, valve ball 2, upper joint 3, valve seat 4, sleeve 5, sealing ring 6, push rod 7, sealing ring 8, sliding sleeve 9, and shear pin 10 , lower joint 11, tubing nipple 12, tubing collar 13, tubing 14, packer 15, layered control switch 16, plug 17, compensator 18, control cable 19, etc. The upper end of the sleeve 5 is connected to the upper joint 3 through a screw, the upper end of the upper joint 3 is connected to the valve cover 1 through a screw, the valve seat 4 is fixed in the groove of the upper joint 3 and the sleeve 5, and the lower end of the sleeve 5 is connected to the lower end through the screw. The joint 11 is connected, the sliding sleeve 9 is located inside the lower joint 11, the sliding sleeve 9 and the lower joint 11 are fixed by the shear nails 10, the upper end of the push rod 7 is connected with the valve ball 2, and the lower end of the push rod...

Embodiment 2

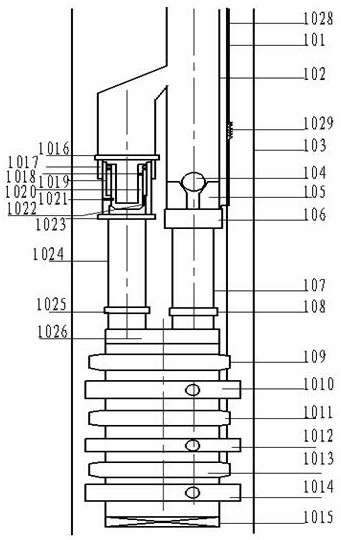

[0055] Embodiment 2: as image 3As shown, the intelligent separate mining production string may also include: 101-control cable, 102-upper joint, 103-casing, 104-valve ball, 105-valve seat, 106-electric pump, 107-first oil pipe, 108-coupling, 109-layered packer 1, 1010-layered switch 1, 1011-layered packer 2, 1012-layered switch 2, 1013-layered packer 3, 1014-layered Switch 3, 1015-screw plug, 1016-coupling, 1017-upper nipple, 1018-through hole A, 1019-lower nipple, 1020-sliding sleeve, 1021-shear nail, 1022-through hole B, 1023-connection Hoop, 1024-second oil pipe, 1025-coupling, 1026-bottom joint, 1027-sealing ring, 1028-power cable, 1029-spiral cable, etc. The intelligent separate mining production string is lifted by an electric pump, and the string is in an inverted Y shape. The bottom of the string is connected with a plug 1015, a layered packer 109, 1011, 1013, and a layered switch 1010, 1012 from bottom to top. , 1014 and lower joint 1026; the upper end of the lower...

Embodiment 3

[0059] Embodiment 3: as Figure 6 As shown, the intelligent separate production string can also include: 201-oil pipe, 202-concentric joint, 203-flow hole, 204-valve ball, 205-ball seat, 206-electric pump, 207-oil pipe, 208 -Scissors, 209-Layer Packer 1, 2010-Layer Control Switch 1, 2011-Layer Packer 2, 2012-Layer Control Switch 2, 2013-Layer Packer 3, 2014-Min Layer control switch 3, 2015-plug, 2016-flow hole, 2017-upper sub, 2018-outer pipe, 2019-lower sub, 2020-flow hole, 2021-control cable, 2022-sleeve, etc. . The intelligent separate mining production string adopts a concentric structure, the lifting electric pump system is located in the middle of the string, the overcurrent pressure channel is connected to the outside of the electric pump string through the concentric joint 202, and the bottom of the overcurrent pressure string is connected with layered isolation The upper sub-joint 2017 and the lower sub-joint 2019 are respectively connected by screws. Before the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com