Process of afloat ship twin-islet jointing

A craft and ship technology, which is applied in the field of ship closing technology, can solve the problems of no specific disclosure method and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

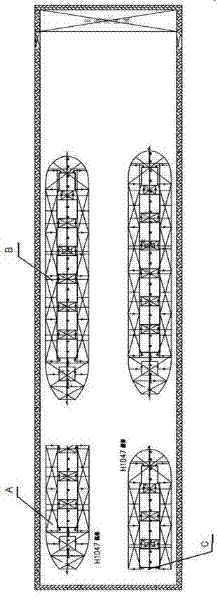

[0020] See the layout of 2# dock figure 1 , in order to shorten the construction period, it was decided to divide the H1047 ship into two half-ships, A and C, to be built at the same time, so that the space in the dock can be maximized. After the construction, the previous ships are undocked one after another, and then the two and a half ships of H1047 are moved to the pier position where the original ship B is located, the dock door is closed, the positions of the two and a half ships of H1047 are adjusted, and the water is pumped to make it fall to the final position. Welding into a whole ship is a brand-new technology, which is different from foreign and domestic related water docking and closing technologies.

[0021] Because the technical application of the present invention has certain requirements to the design of the hull, therefore, the main dimensions and the volume design of the ship of the present embodiment are:

[0022] The main dimensions of the ship: the overa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com