Packer applicable to environment of 120 DEG C and 70 MPa

A packer and environment technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problem that the packer cannot adapt to the environment of high temperature and high pressure, achieve good sealing performance and improve construction Reliable effect of displacement and setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

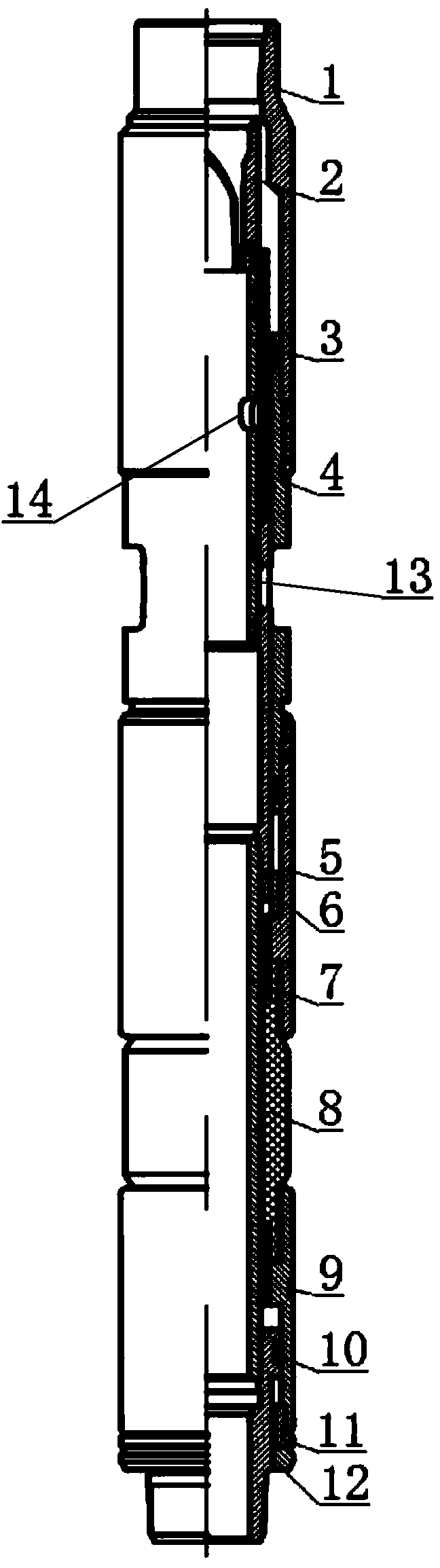

[0008] The present invention will be further described below in conjunction with accompanying drawing:

[0009] Depend on figure 1 As shown, a packer suitable for an environment of 120°C and 70MPa includes an upper joint 1 and a lower joint 10. The inner side of the lower part of the upper joint 1 is connected with a pressure guiding body 4, and the inside of the pressure guiding body 4 is connected with a sliding sleeve. 3. A variable diameter sliding sleeve 2 is installed inside the sliding sleeve 3, and a sliding sleeve sand hole 14 is opened on the side wall of the sliding sleeve 3, and a through groove is opened on the pressure guiding body 12 corresponding to the sliding sleeve sand outlet hole 14. The inside of the bottom of the sleeve 11 is connected to the central pipe 7 . The variable-diameter sliding sleeve 2 side walls have a variable-diameter sliding sleeve sand outlet 14, and the internal diameter of the variable-diameter sliding sleeve 2 top has a slope, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com