Directional hydraulic injection tool string and construction method for coal-bed gas horizontal well

A technology for hydraulic jetting and horizontal wells, which is applied to drilling equipment, earthwork drilling, boreholes/well components, etc. It can solve the problems of poor effect of staged fracturing of horizontal wells, small construction displacement, poor safety, etc., to achieve Improve fracturing construction displacement and sand carrying efficiency, increase hydraulic jet displacement, high stability and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

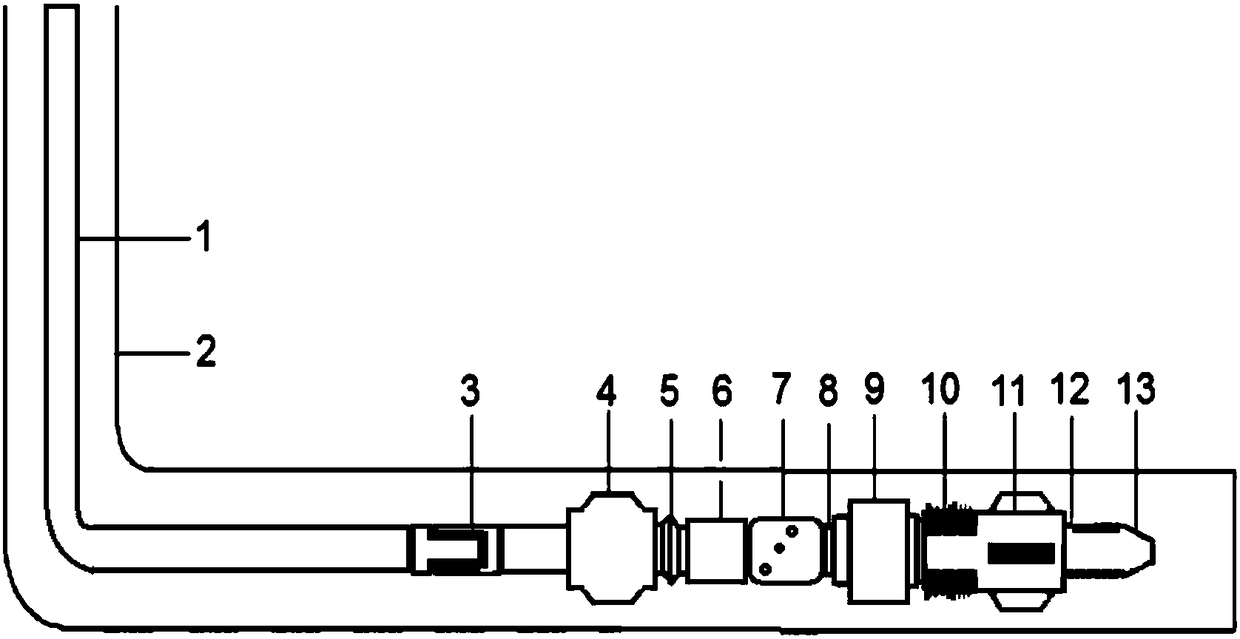

[0038] see figure 1 , shows the directional hydraulic injection tool string of the coalbed methane horizontal well of the present invention.

[0039]The directional hydraulic injection tool string of the coalbed methane horizontal well can be put into the horizontal well 2, which includes a guide cone 13, a screen pipe 12, a centralizer check valve 11, a hydraulic anchor 10, a packer 9, and an injector connected in sequence. 7. The hydraulic eccentric orientator 6, the upper centralizer 4, the hydraulic hand 3 and the oil pipe 1, the hydraulic eccentric orientator 6 and the injector 7 are connected in a fixed manner, the upper end of the hydraulic eccentric orientator 6 and the lower end of the injector 7 It is connected to the upper centralizer 4 and the packer 9 through the upper movable bearing 5 and the lower movable bearing 8 respectively.

[0040] Wherein, the outer diameter of the injector 7 is set to 102 mm, and the outer diameter of the injector 7 is relatively reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com