Patents

Literature

106results about How to "Increase the extension length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

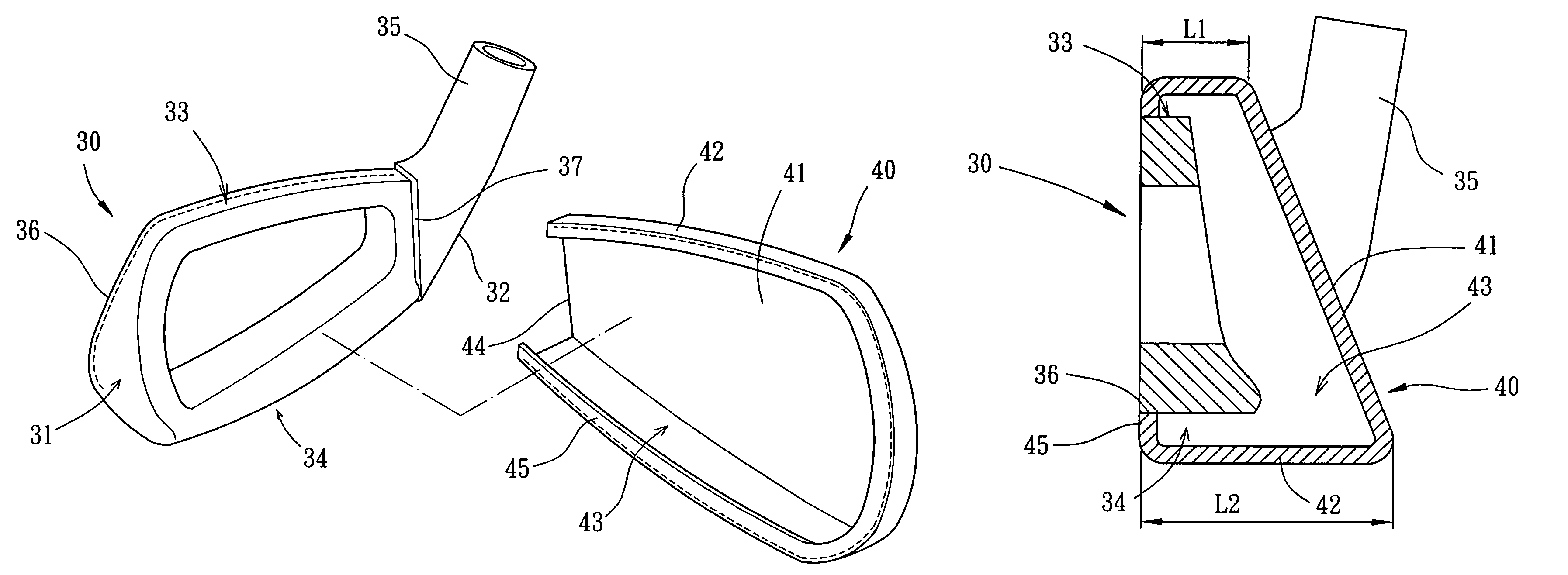

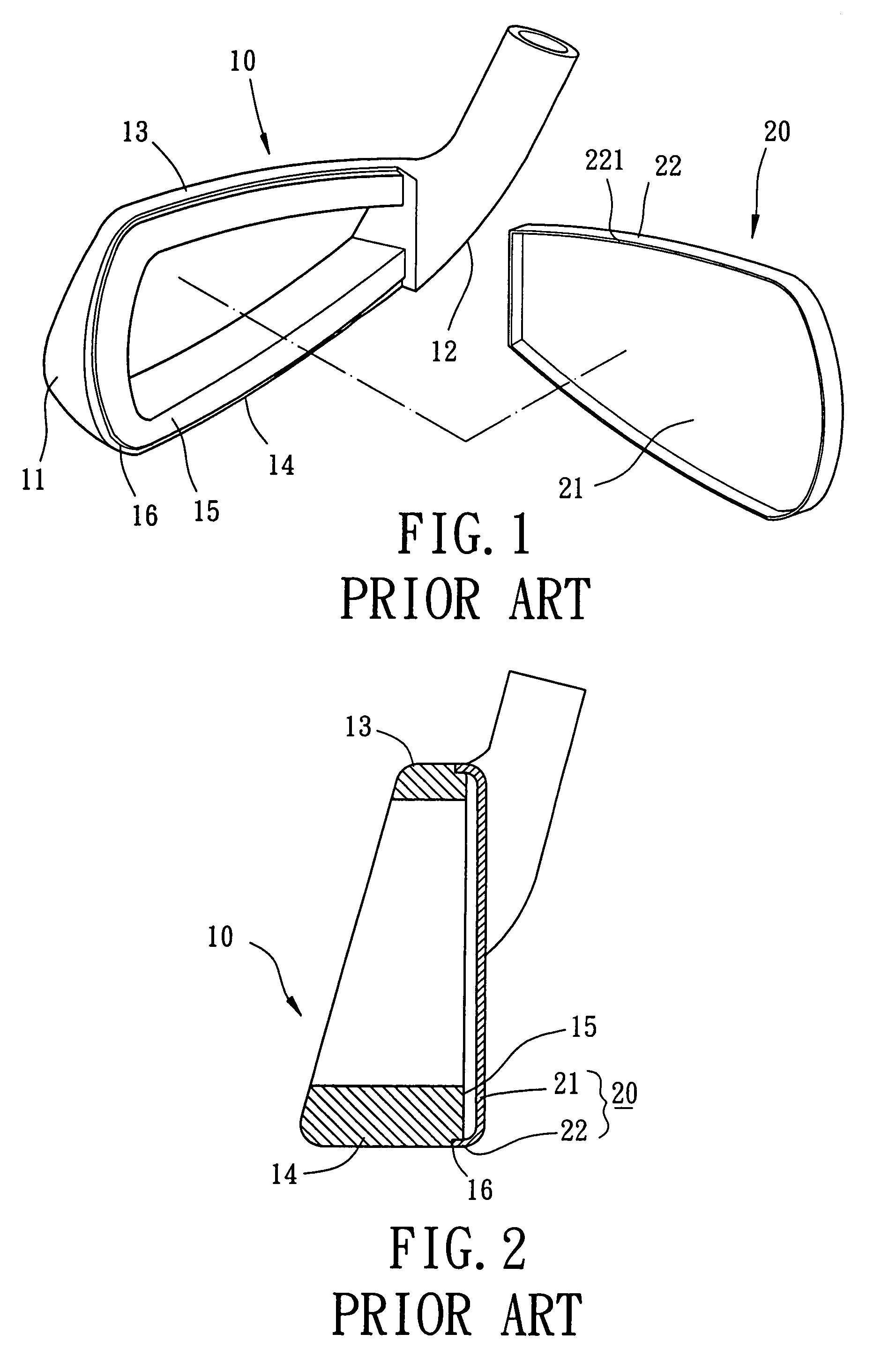

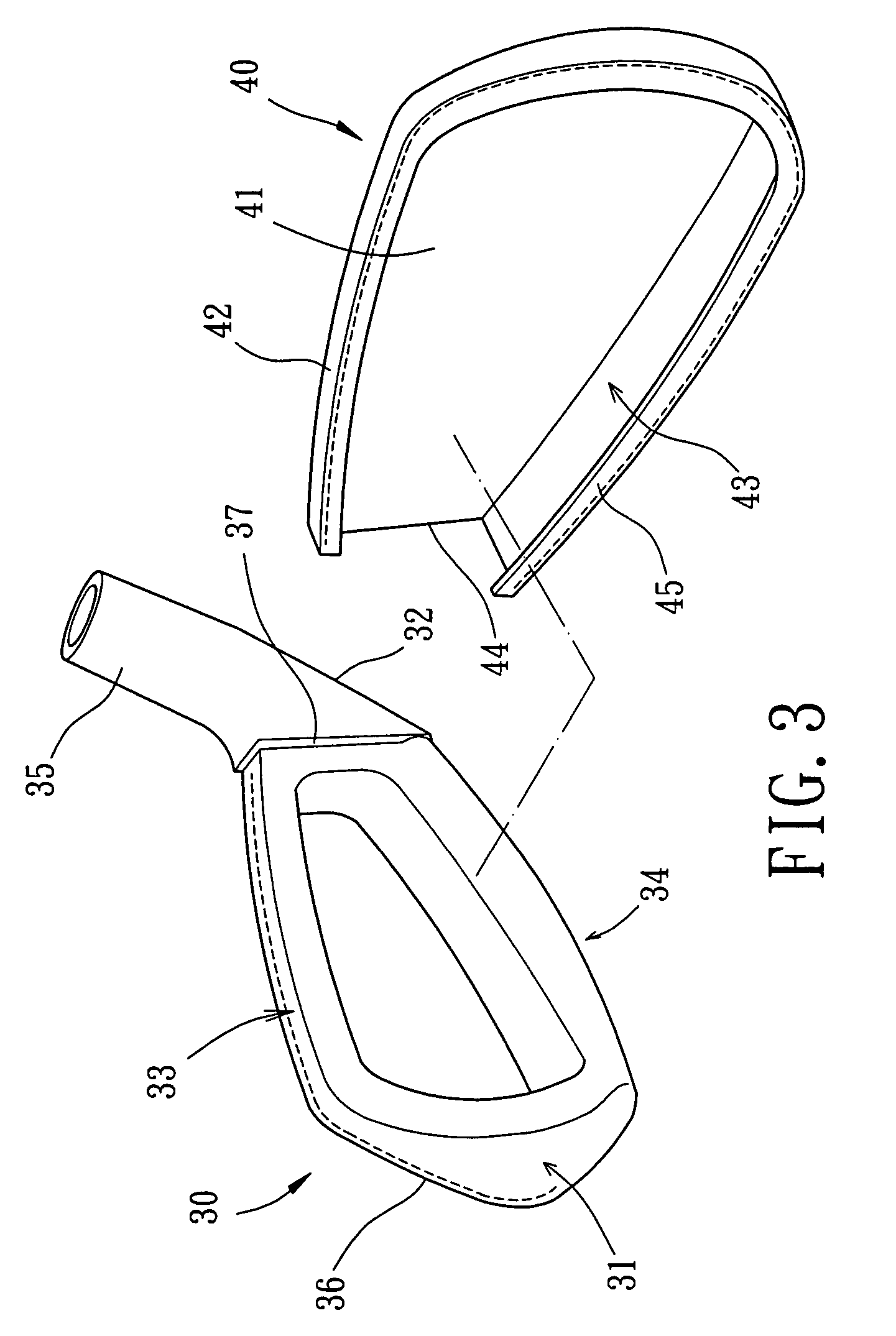

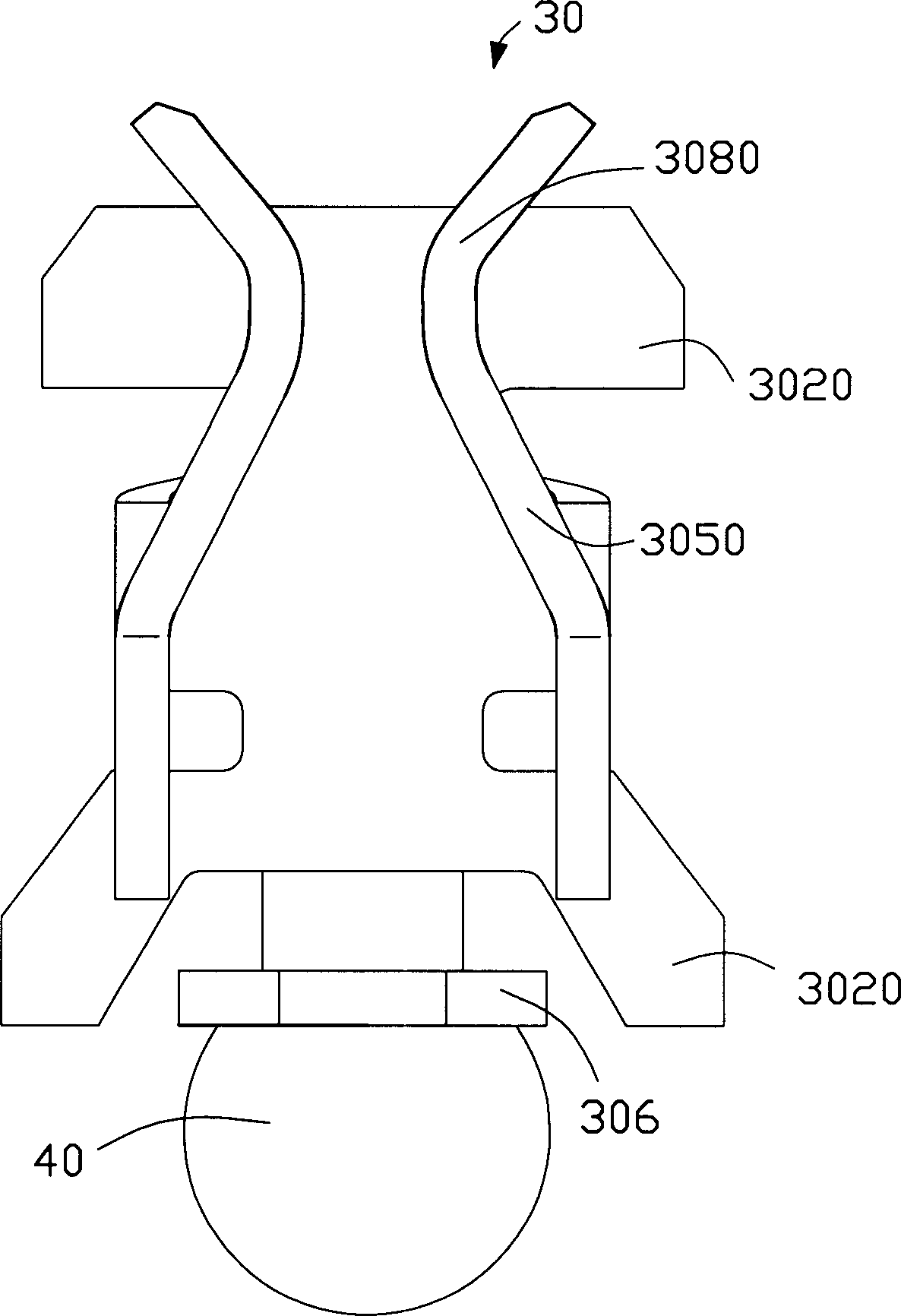

Golf club head having a connecting structure for a high degree of flexibility

InactiveUS7371188B2Increase flexibilityImprove elastic deformation abilityGolf clubsRacket sportsEngineeringGolf Ball

A golf club head includes a striking plate component and a rear-assembling component mechanically connected thereto. The striking plate component provides with a striking face and a rear-connecting wall. The rear-connecting wall is bent rearward and extended a rearward extended length from the striking face. The rear-assembling component provides with a sidewall corresponding to the rear-connecting wall of the striking plate component. In assembling, the rear-connecting wall of the striking plate component connects with the sidewall of the rear-assembling component by means of an upstanding bent edge or a rear-assembling flange such that the rear-connecting wall separates the striking face from the rear-assembling component for permitting elastic deformation.

Owner:FUSHENG PRECISION

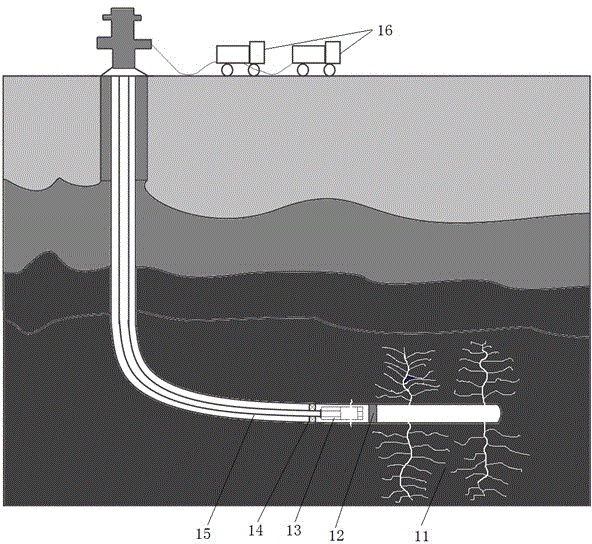

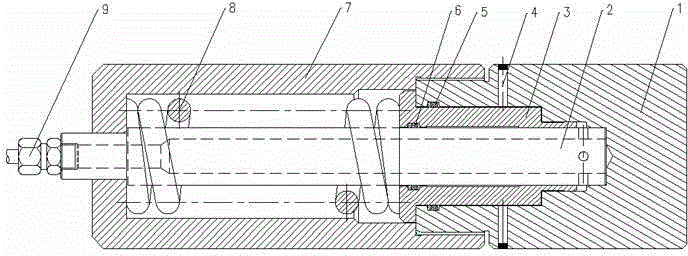

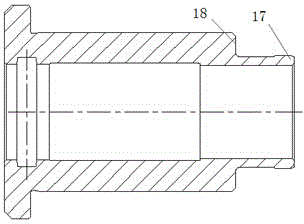

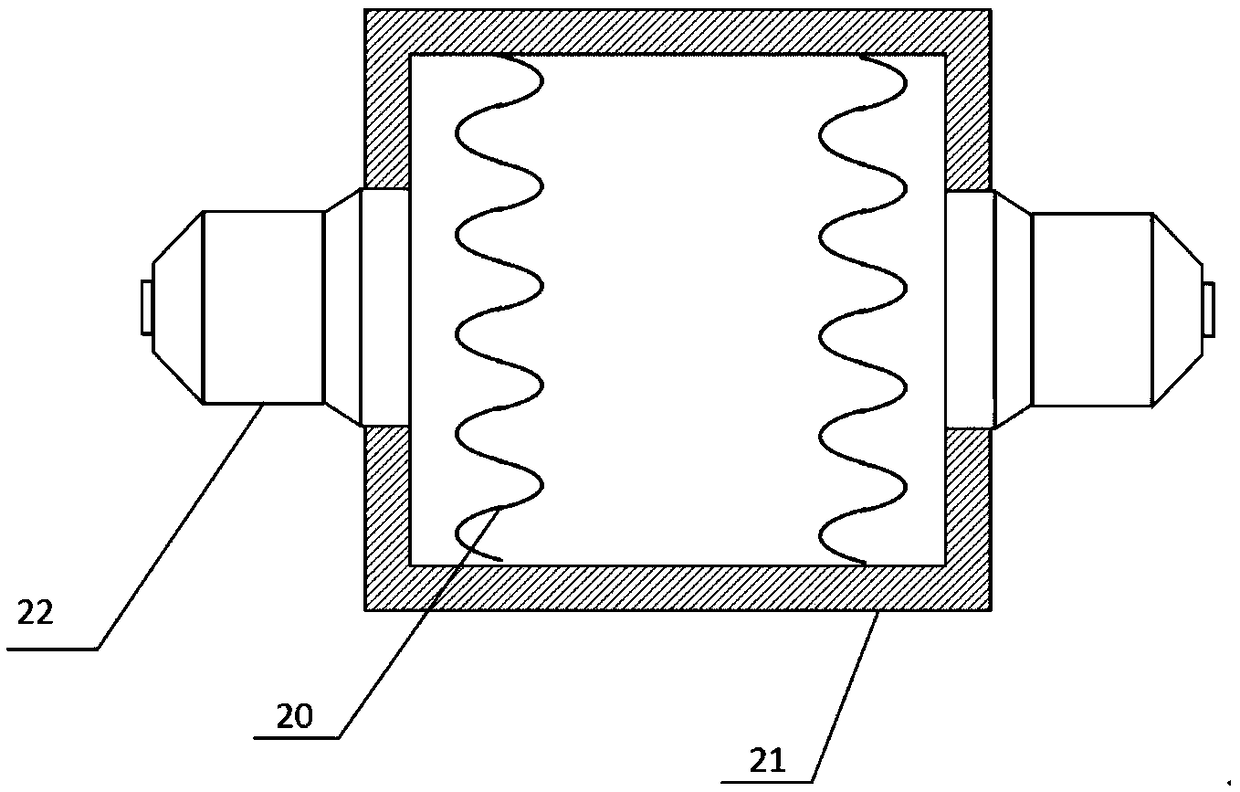

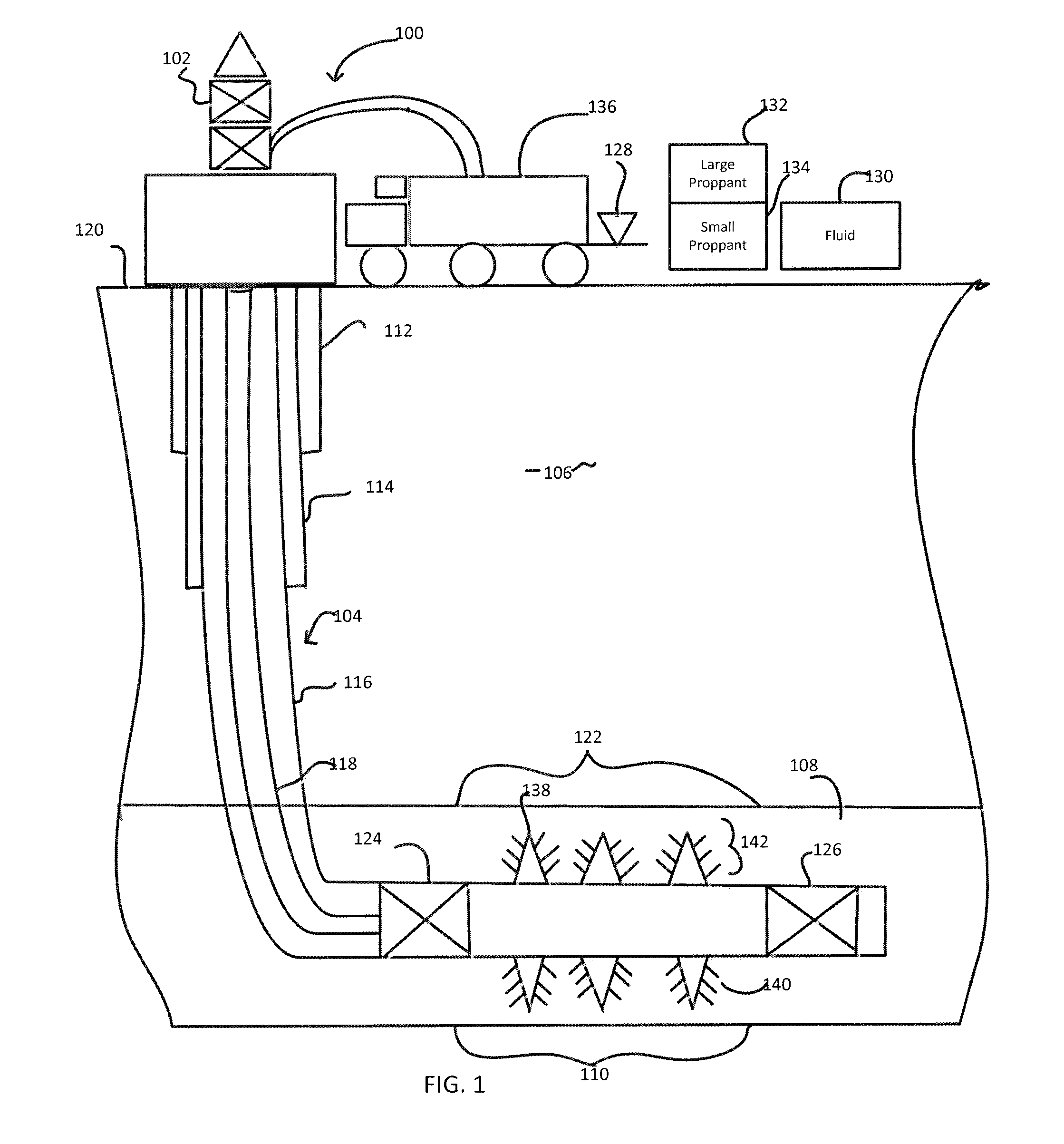

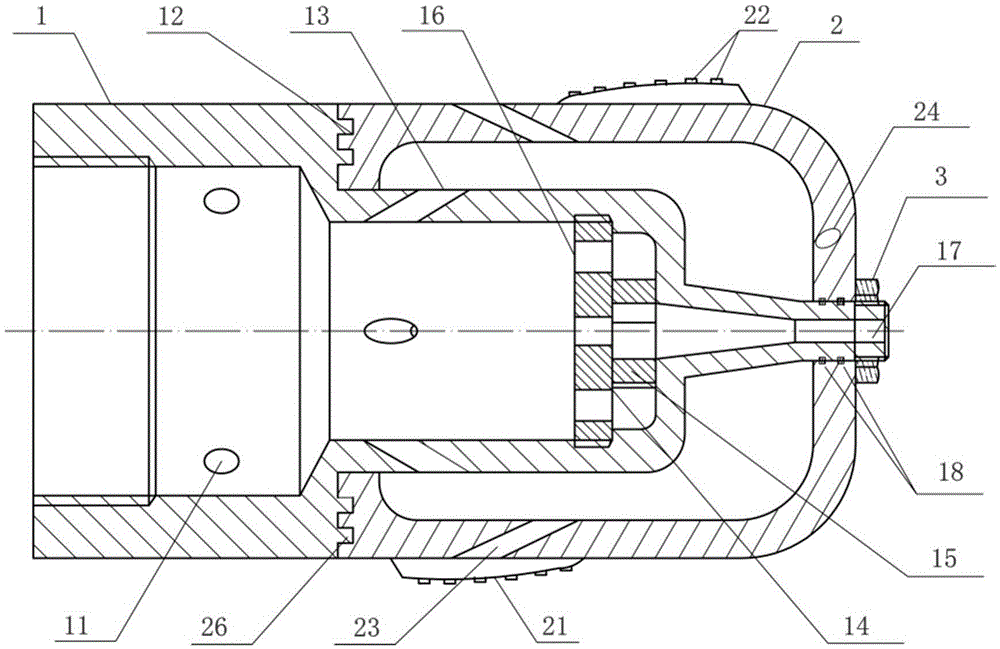

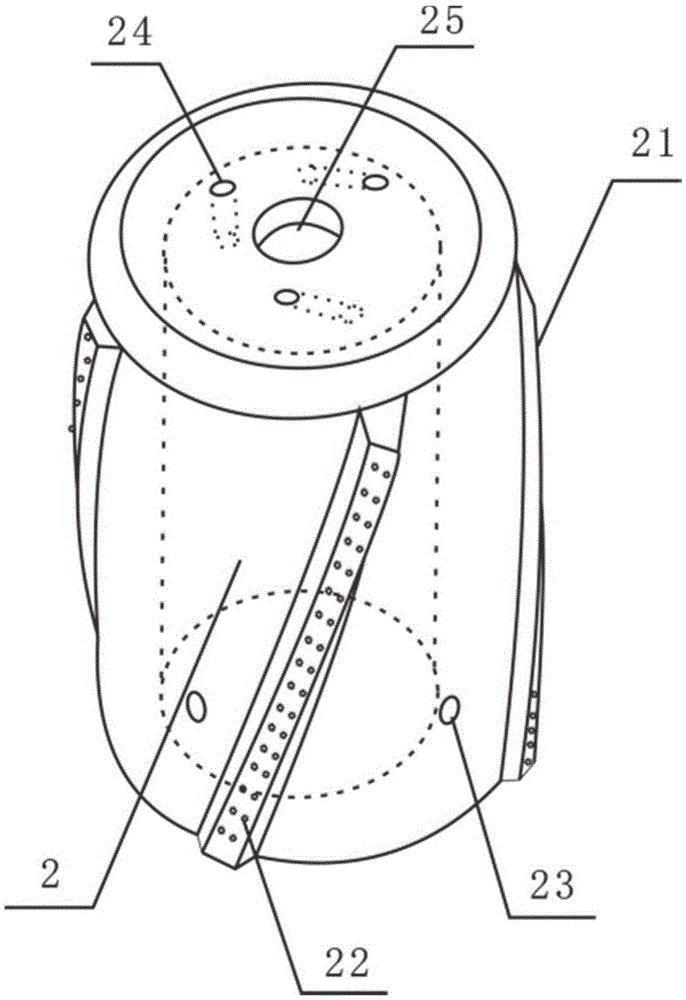

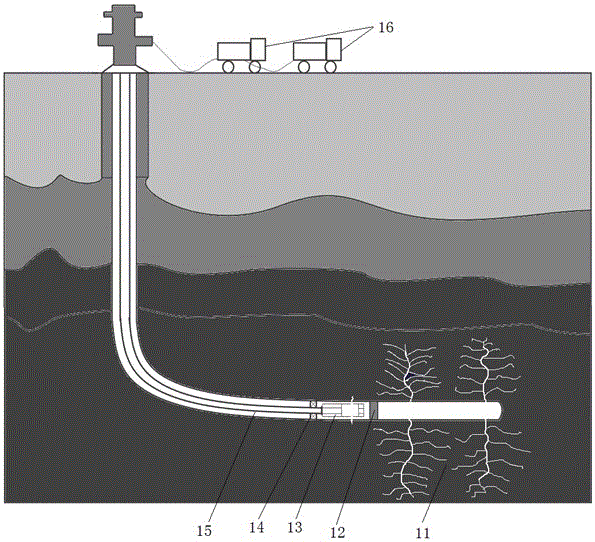

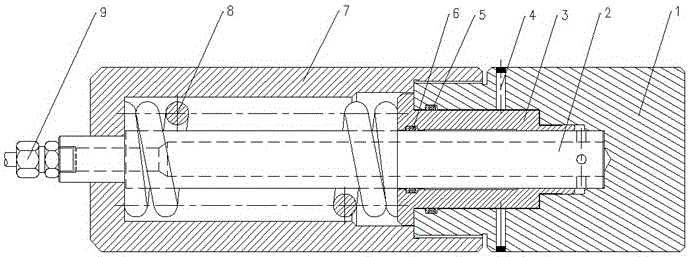

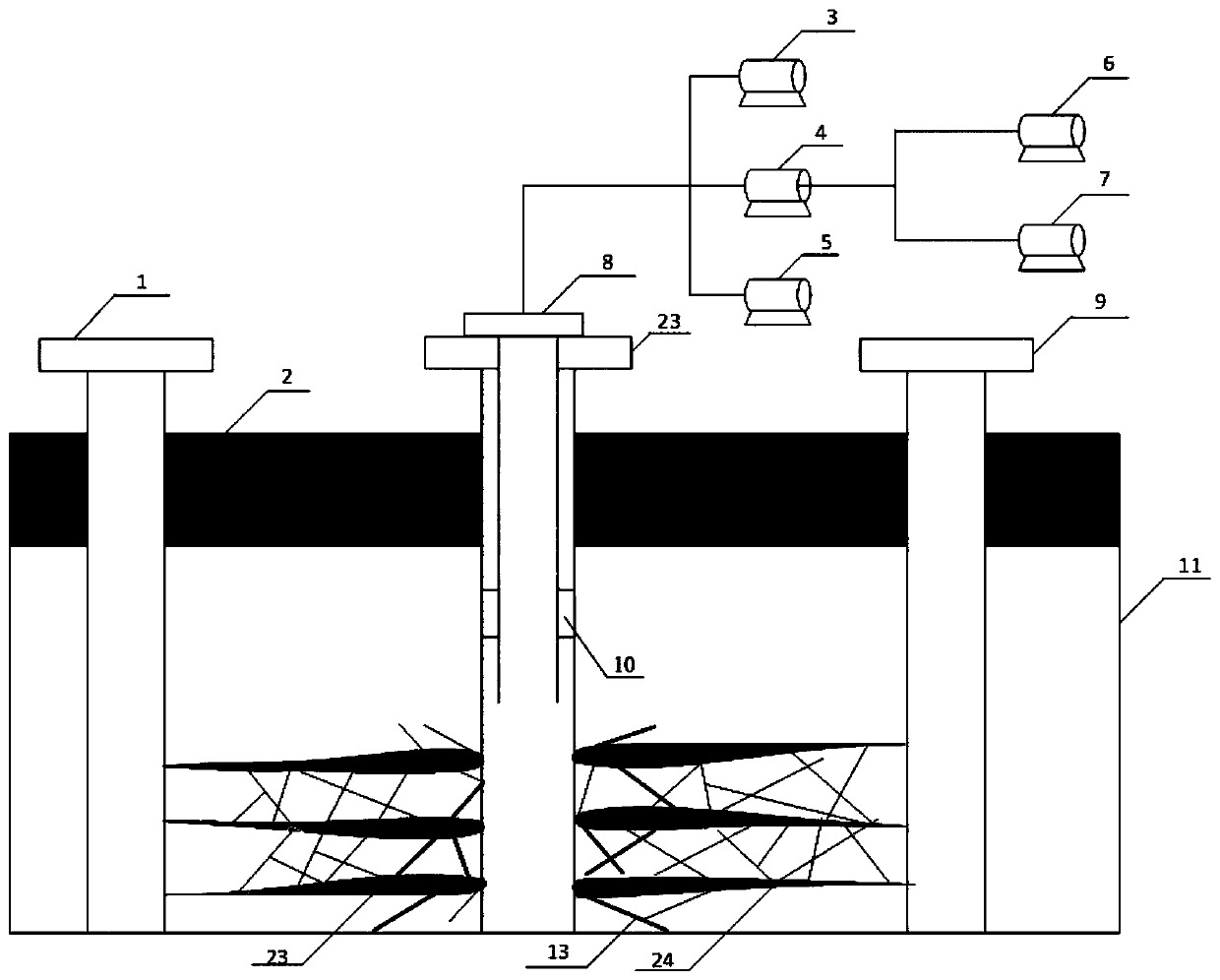

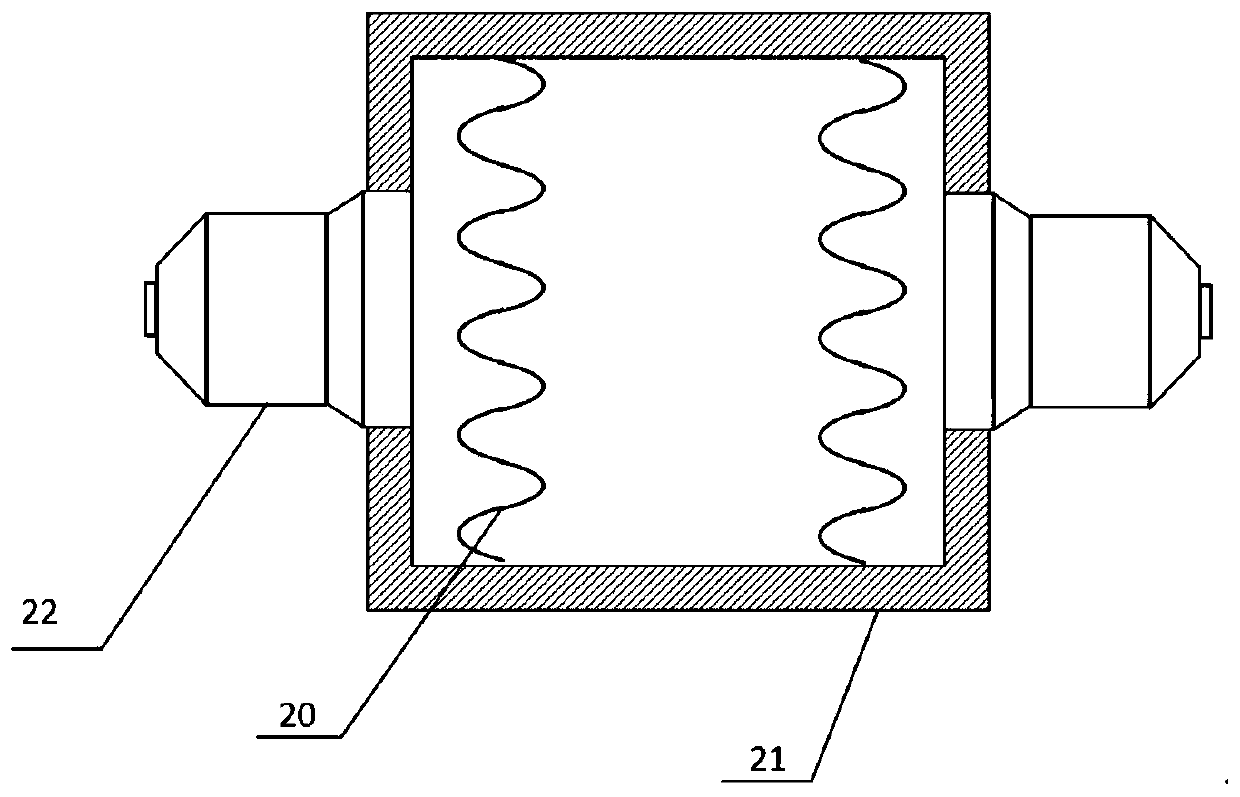

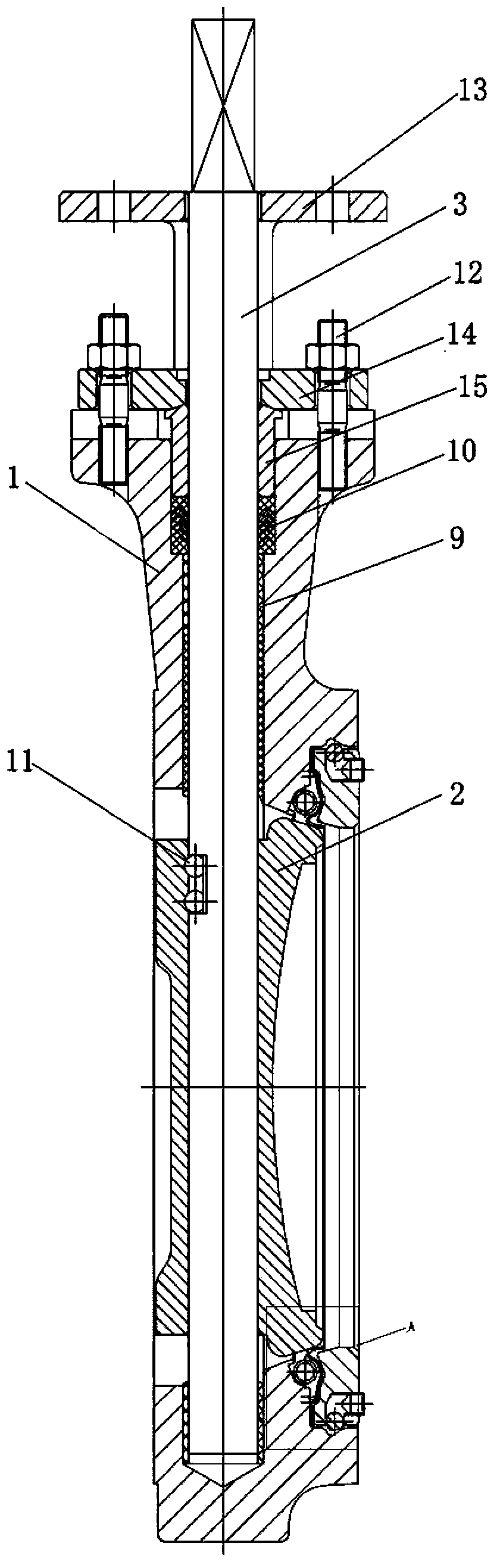

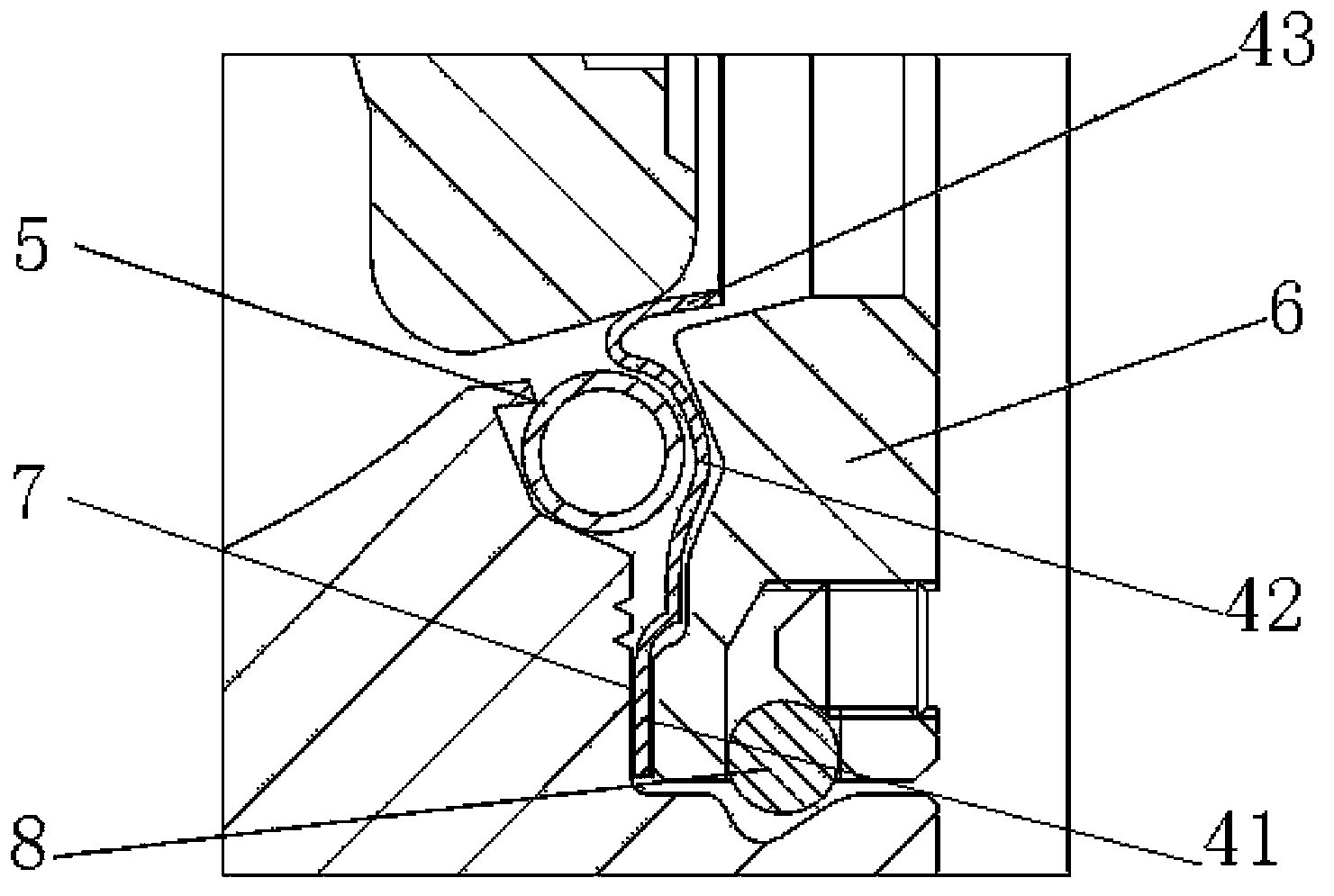

Down-hole hydraulic power pulse staged fracturing permeability-increasing device and method

ActiveCN104929605AReduce frequencyReduce displacementFluid removalWell/borehole valve arrangementsFluid controlCoiled tubing

The invention discloses a down-hole hydraulic power pulse staged fracturing permeability-increasing device and method. The device comprises a down-hole pulse fracturing device, a controllable hydraulic packer, a continuous oil pipe, a fluid control valve and a fracturing truck. The fracturing truck is connected with the controllable hydraulic packer and the down-hole pulse fracturing device through the continuous oil pipe. The controllable hydraulic packer is connected to the back end of the down-hole pulse fracturing device. The fluid control valve is arranged at the connecting opening of the continuous oil pipe. The down-hole pulse fracturing device comprises a first cylinder body, a second cylinder body, a mandrel, a sliding sleeve, a sealing ring, a spring, a nozzle and the like. Under the condition that certain construction parameters such as pumping pressure and displacement are provided for the ground fracturing truck, large-displacement low-frequency pulse fluid is generated at the shaft bottom and is injected in, and a water hammer effect is formed. The down-hole hydraulic power pulse staged fracturing permeability-increasing device is simple in structure, durable and easy to adjust, low-frequency large-displacement pulse energy can be generated, the construction technology is simple, pulse energy can be well used for breaking rocks, net-shaped complex cracks with wide extending ranges are generated, and reservoir stratum permeability is effectively improved.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

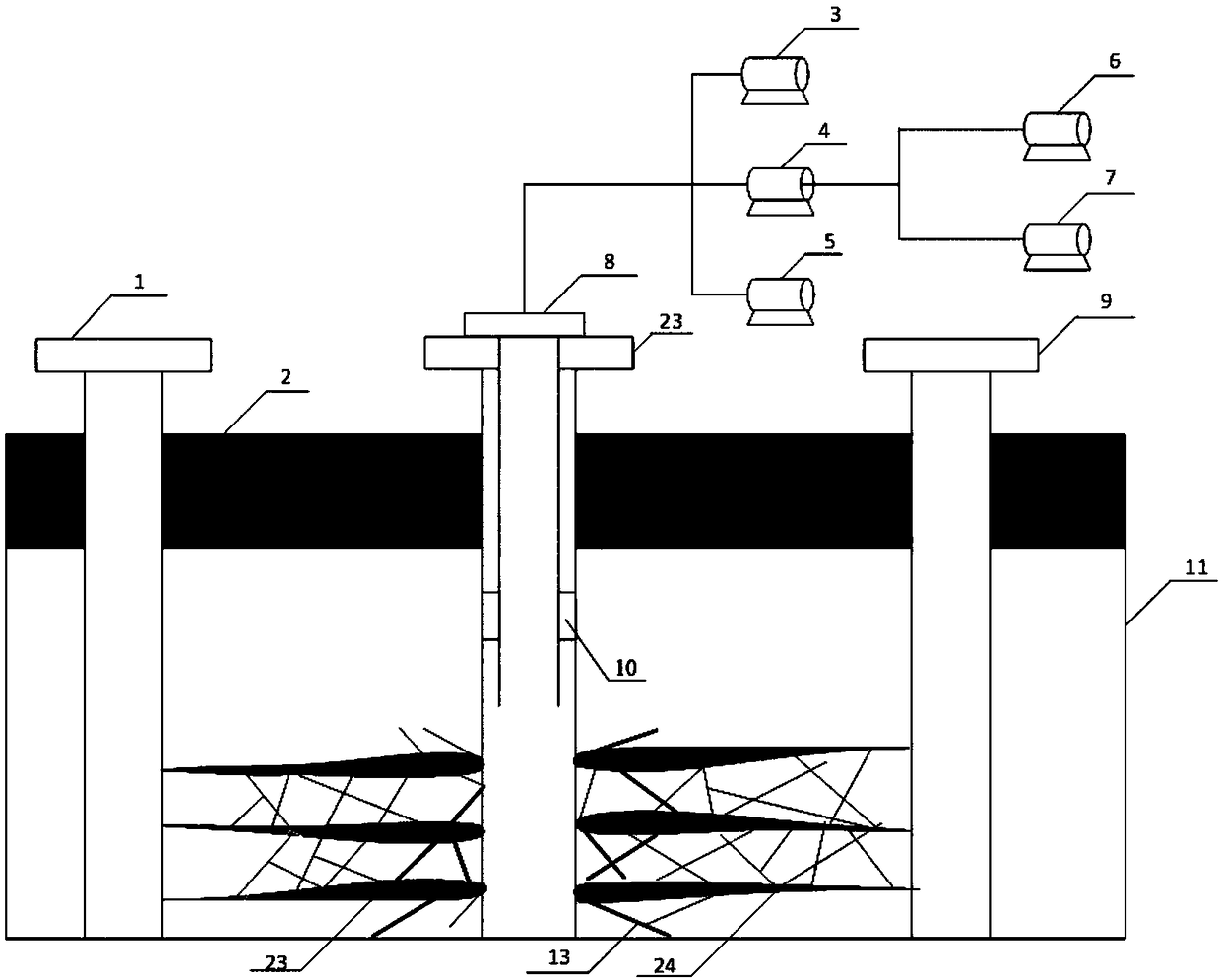

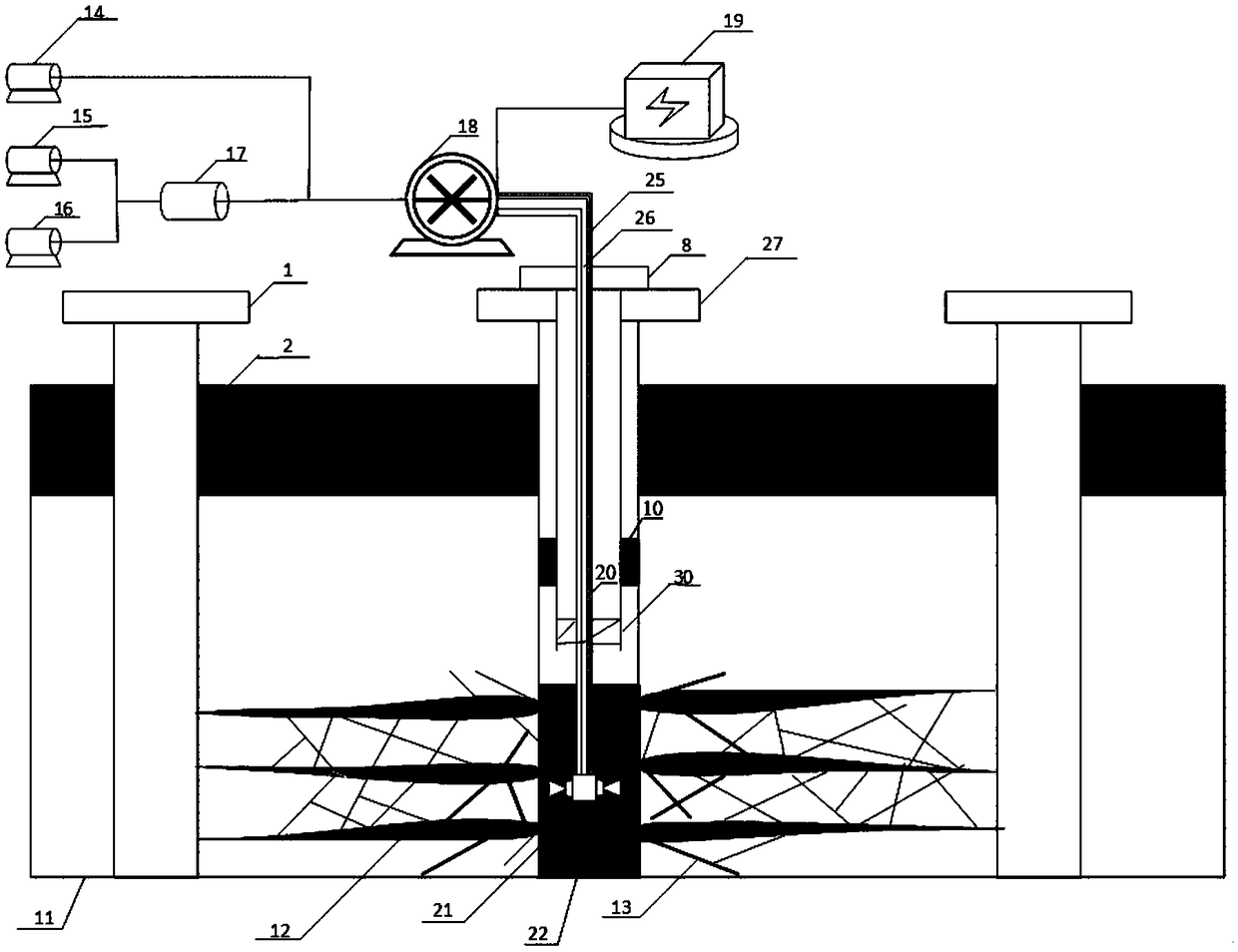

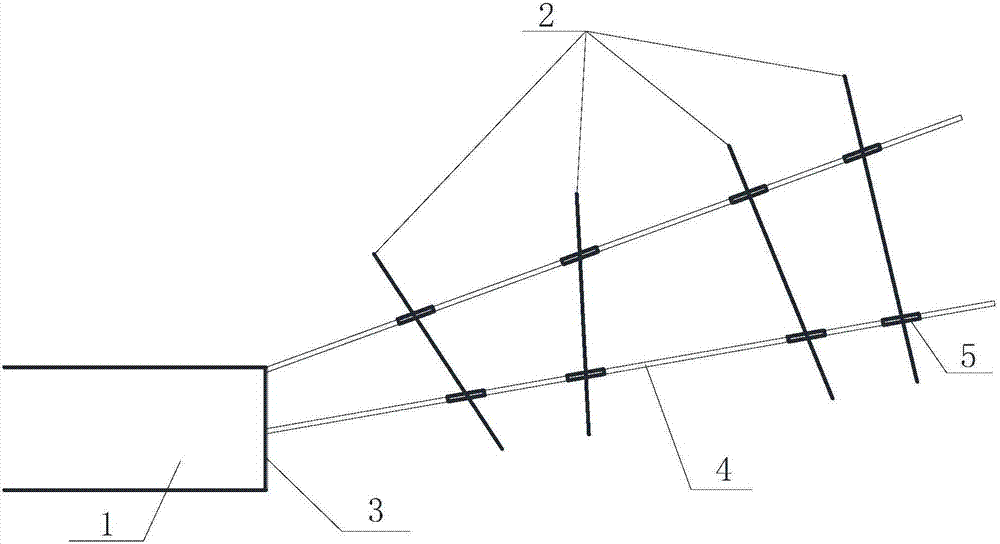

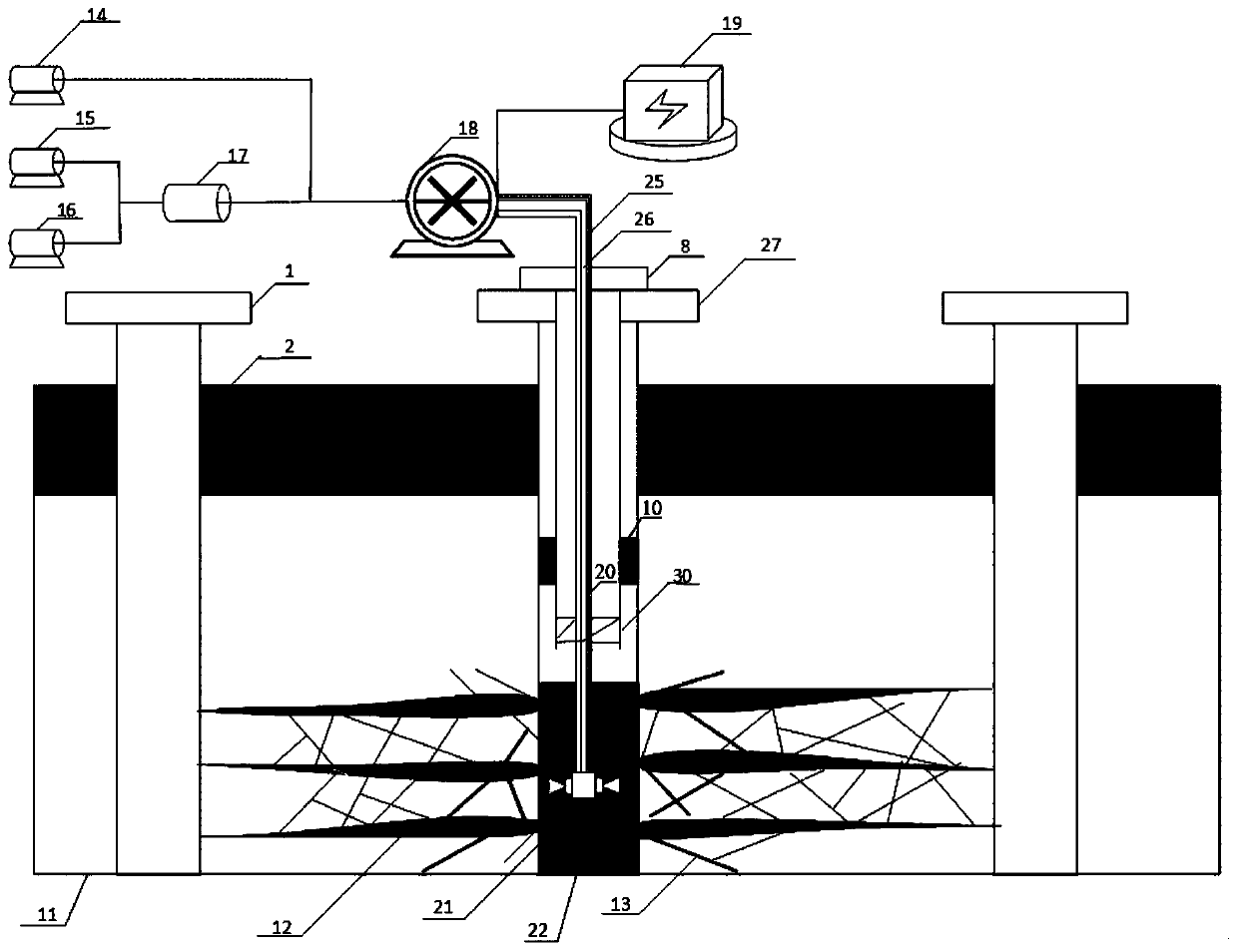

Method of forming fractures by means of hydrofracturing assisted by alternate spraying of high- and low-temperature fluids in deep hot dry rock

ActiveCN108979609AImprove the problem of difficult hydraulic fracturingIncrease the number ofFluid removalFracturing fluidMicro fracture

The invention provides a method of forming fractures by means of hydrofracturing assisted by alternate spraying of high- and low-temperature fluids in deep hot dry rock. The method herein includes: setting out a well network, and performing primary hydrofracturing to form main fractures; injecting a high-temperature high-pressure fluid and low-temperature water alternately into the main fractureswithin short alternate time; forming micro fractures in the rock at the surface of the main fractures under the thermodynamic action of a great temperature difference and the impact action of a jet; allowing multilevel fracturing to enable the micro fractures to further expand and form more micro fractures under the action of a low-temperature waterborne fracturing fluid and the action of high pressure; repeating until the main fractures and the micro fractures are in mutual lap joint and communication so that a fracture cluster and / or a fracture belt is formed between injection wells and production wells; injecting a sand-carrying fluid, a proppant and a displacing fluid, and closing the wells to complete fracture forming so as to construct an efficient heat exchange reservoir. The methodenables the quantity of the fractures to be significantly increased via the thermal stress action of the temperature difference, so that a fracture network is formed; heat exchange efficiency of a heat storage space is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

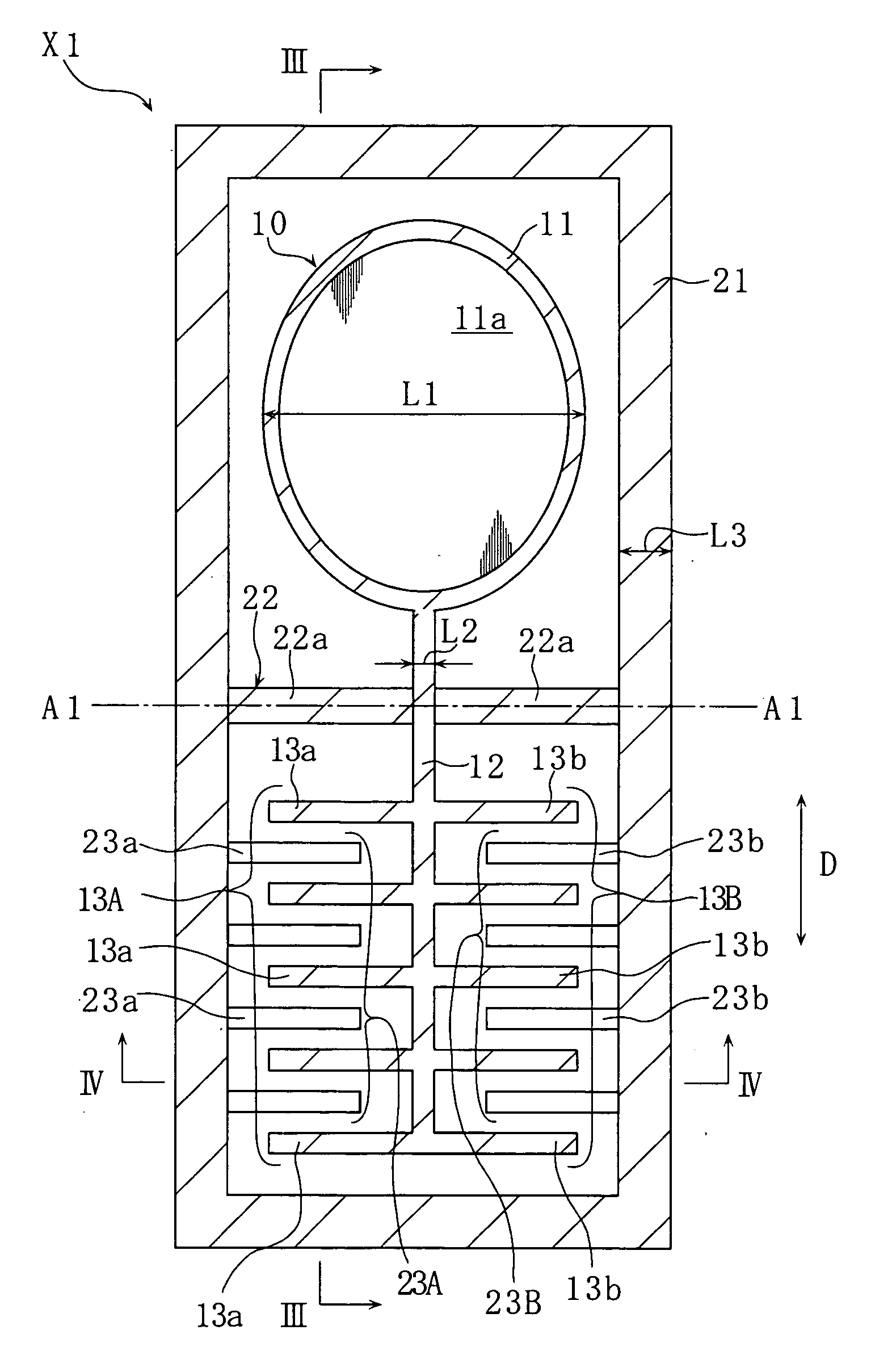

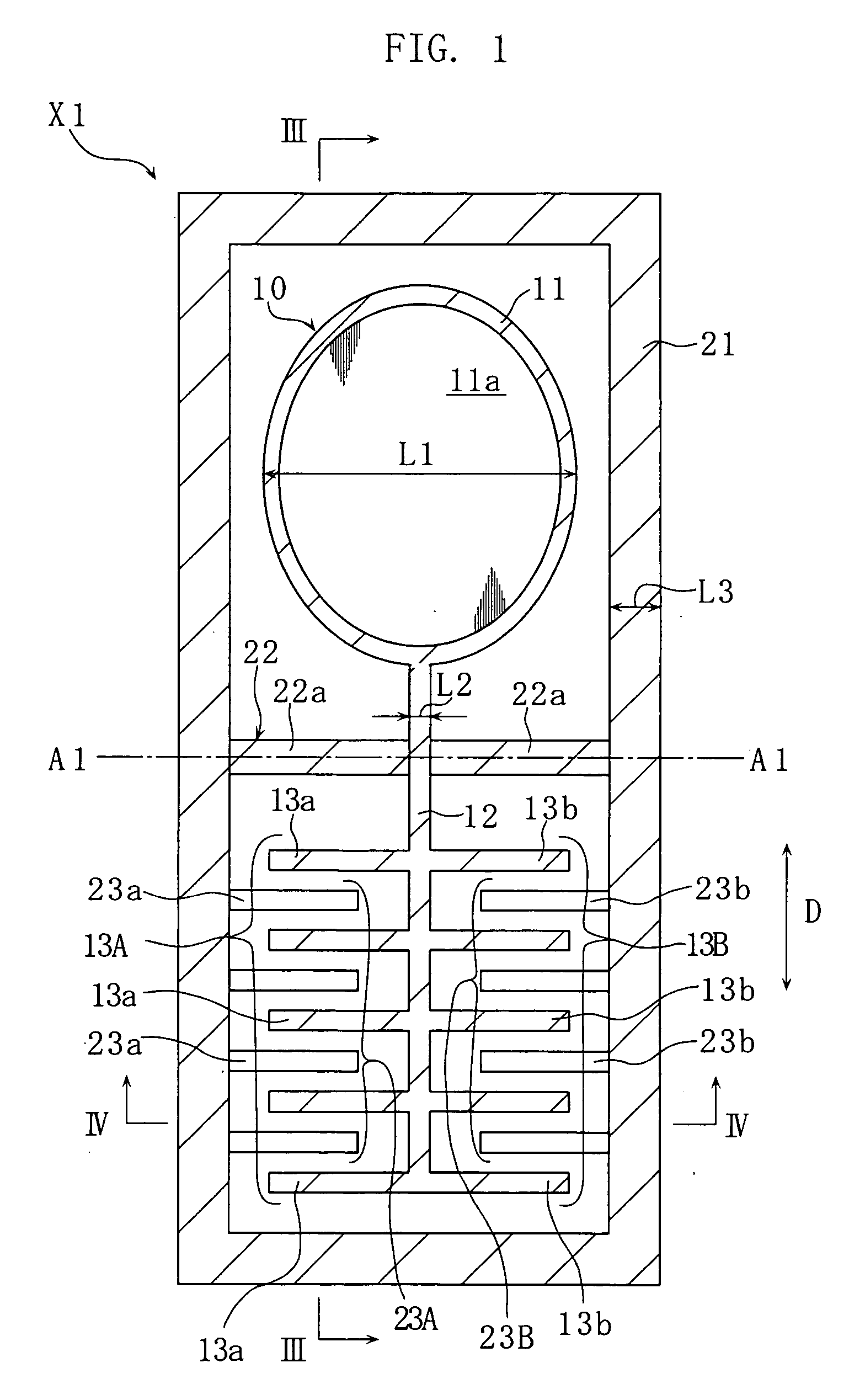

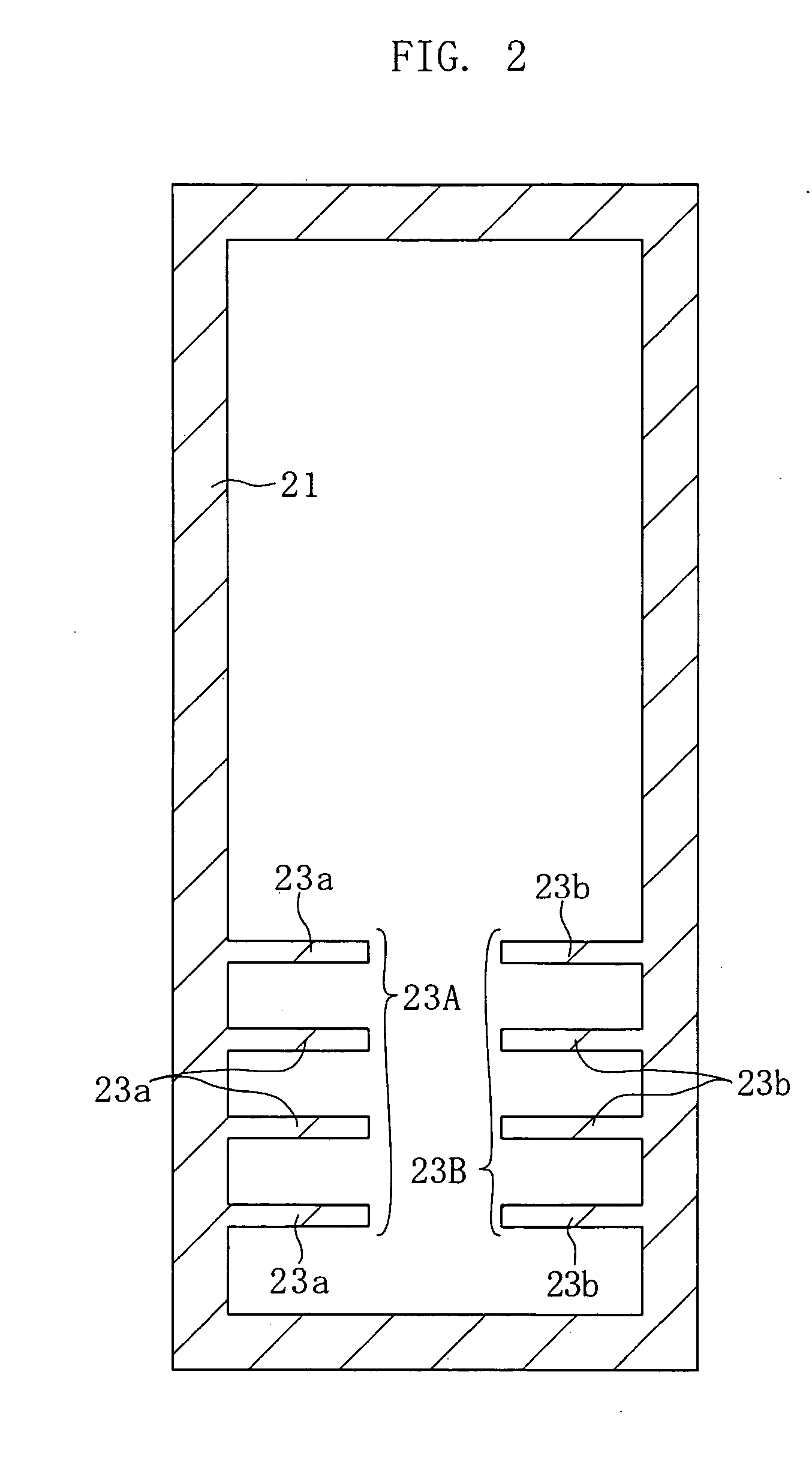

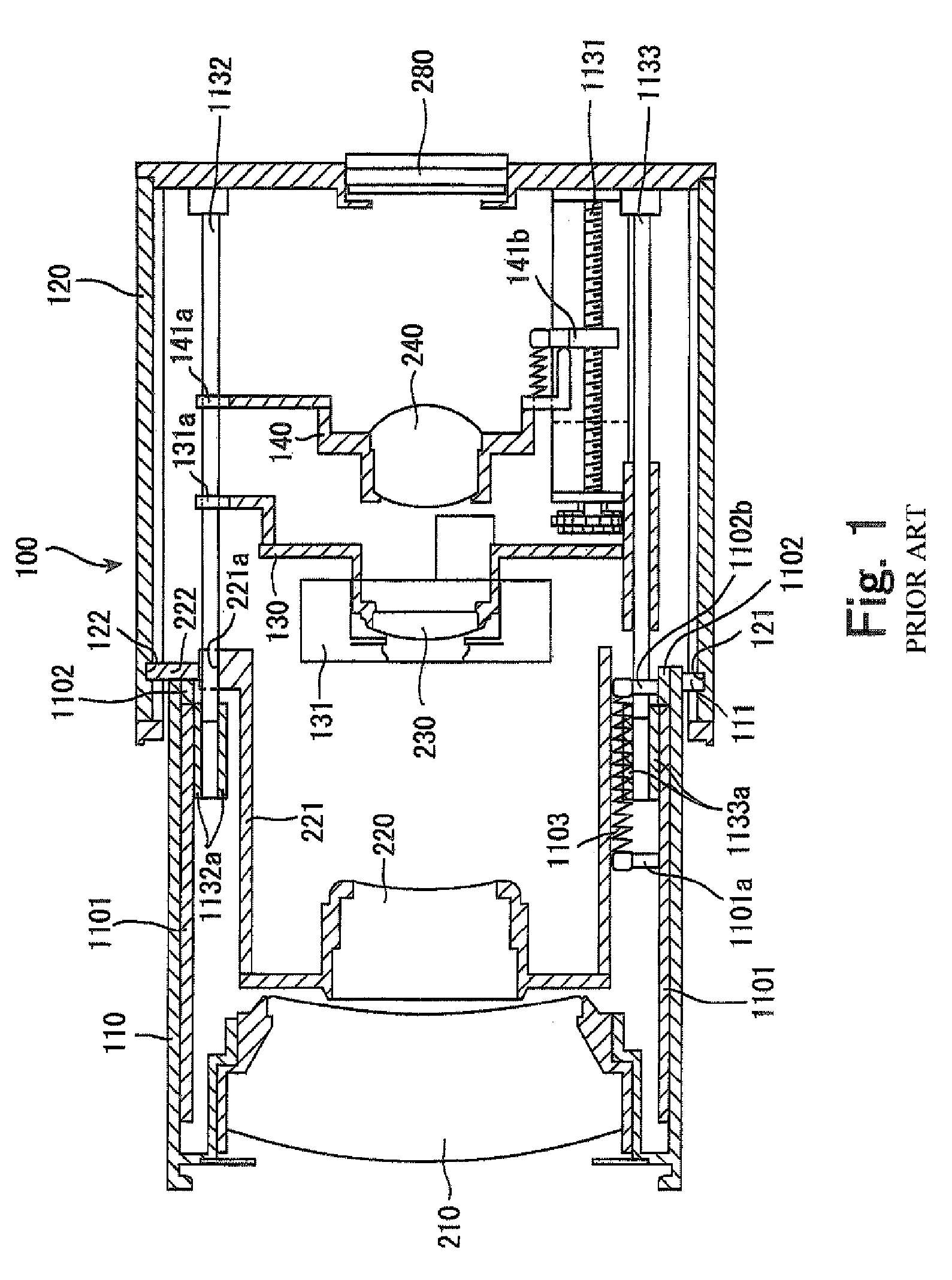

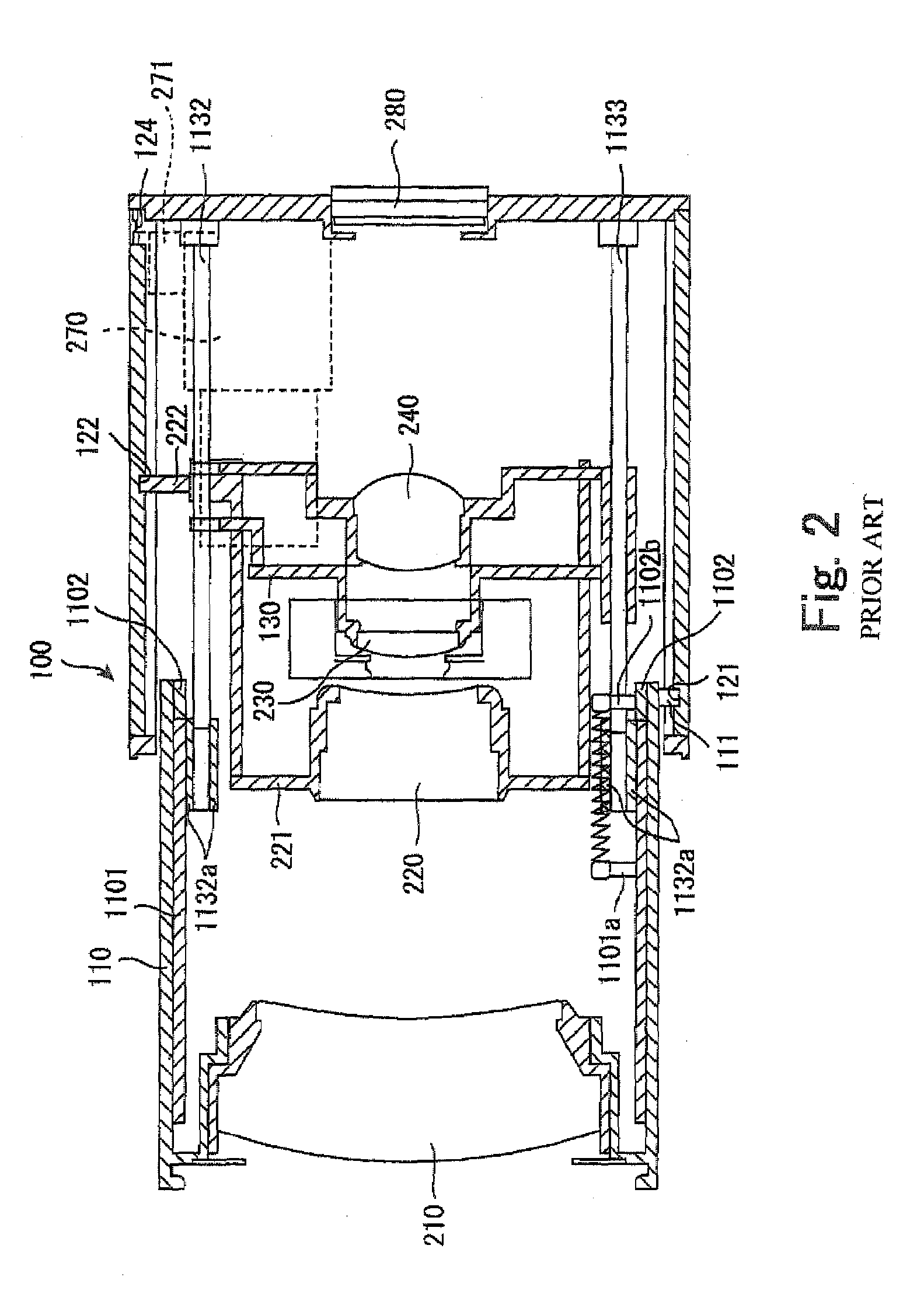

Micro oscillating element

InactiveUS20060119216A1Control displacementReduce widthElectrostatic motorsPiezoelectric/electrostrictive devicesEngineeringElectrode

A micro oscillating element includes a frame and an oscillation section connected to the frame via a torsional joining section. The oscillation section includes a movable functional section, an arm section and a first comb-tooth electrode. The arm section extends from the functional section. The first comb-tooth electrode includes first electrode teeth extending from the arm section in a direction intersecting the arm section. The micro oscillating element further includes a second comb-tooth electrode to cooperate with the first comb-tooth electrode for causing the oscillation section to oscillate about an oscillation axis defined by the torsional joining section. The second comb-tooth electrode includes second electrode teeth extending from the frame in a direction intersecting the arm section.

Owner:FUJITSU LTD

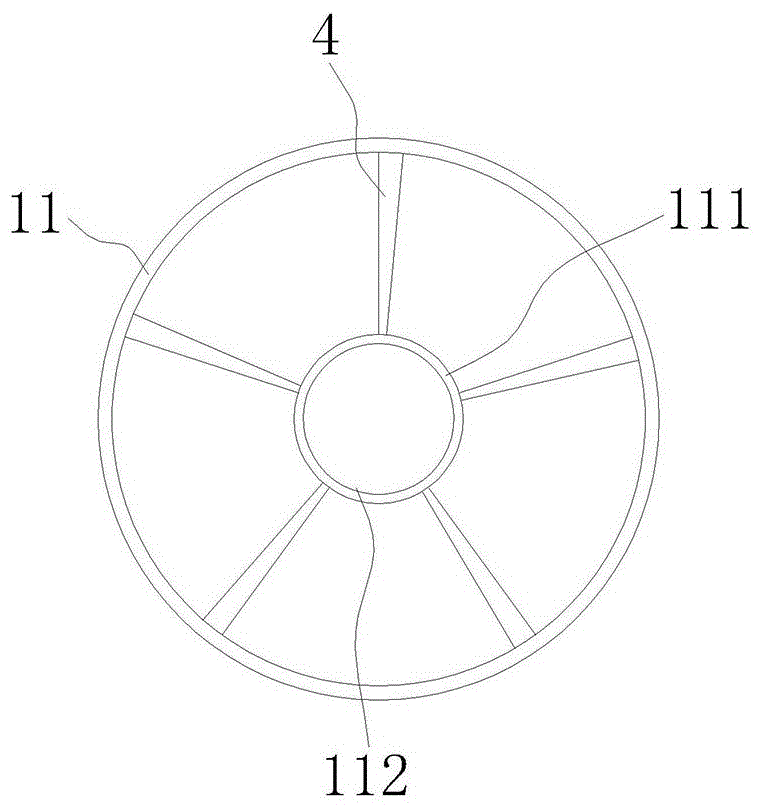

Heat dissipation fan

InactiveUS20070172352A1Improve cooling efficiencyIncrease the areaPump componentsDigital data processing detailsEngineeringFan blade

A heat dissipation fan used in a frame server, includes a rotation axis and a plurality of fan blades. The rotation axis is composed of a main portion and an extension portion, and the diameter of the main portion is greater than that of the extension portion. The fan blades extend outward from the rotation axis, and are utilized to drive the wind from one side of the rotation axis to the other side of the rotation axis in a direction perpendicular to the rotation axis. As such, greatly increase the air cutting area of the fan blades. In this manner, in the server frame studded with electronic devices and having very limited heat dissipation space, the heat dissipation efficiency of the server can be raised significantly, so that the electronic devices may function normally and efficiently.

Owner:ASUSTEK COMPUTER INC

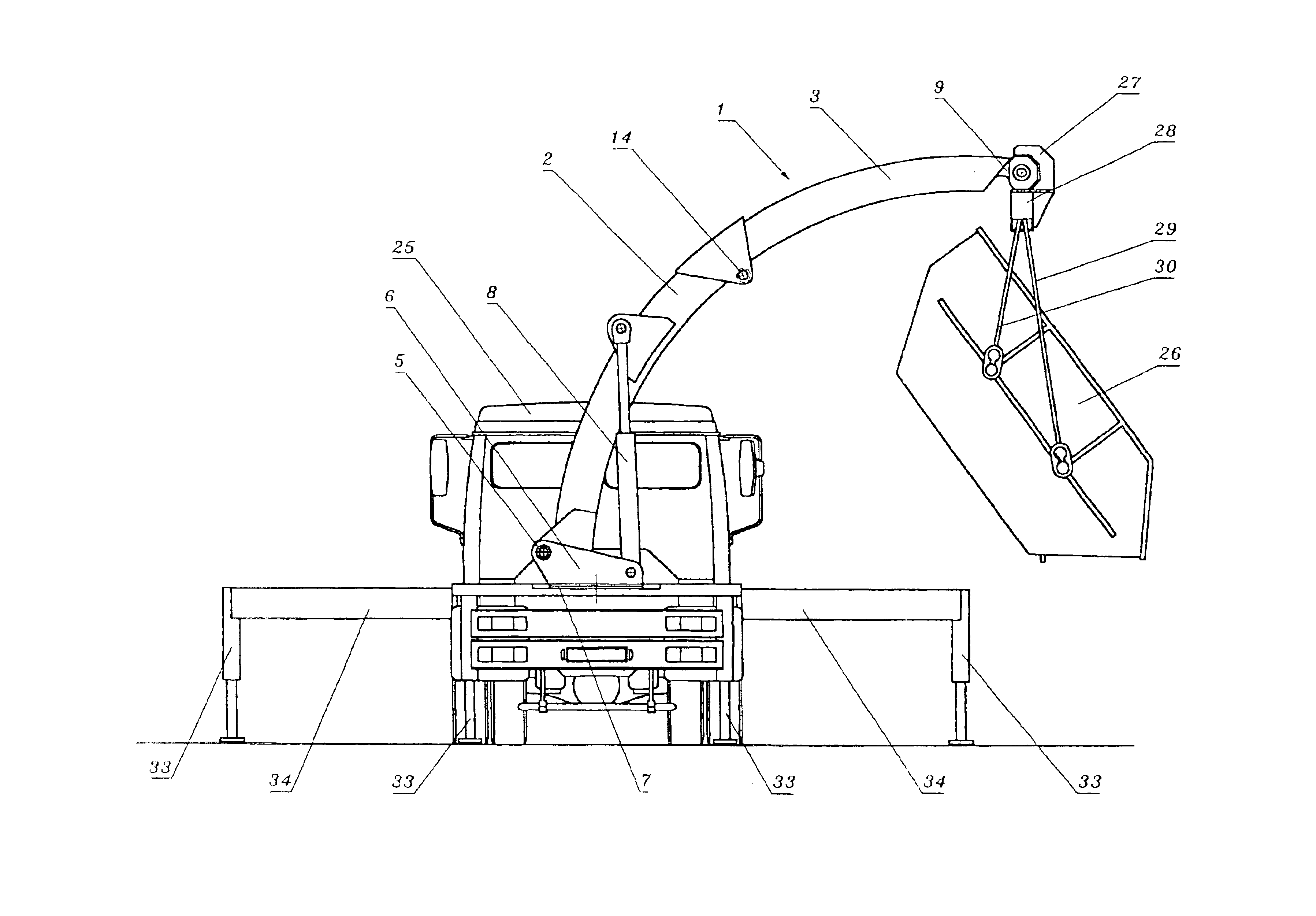

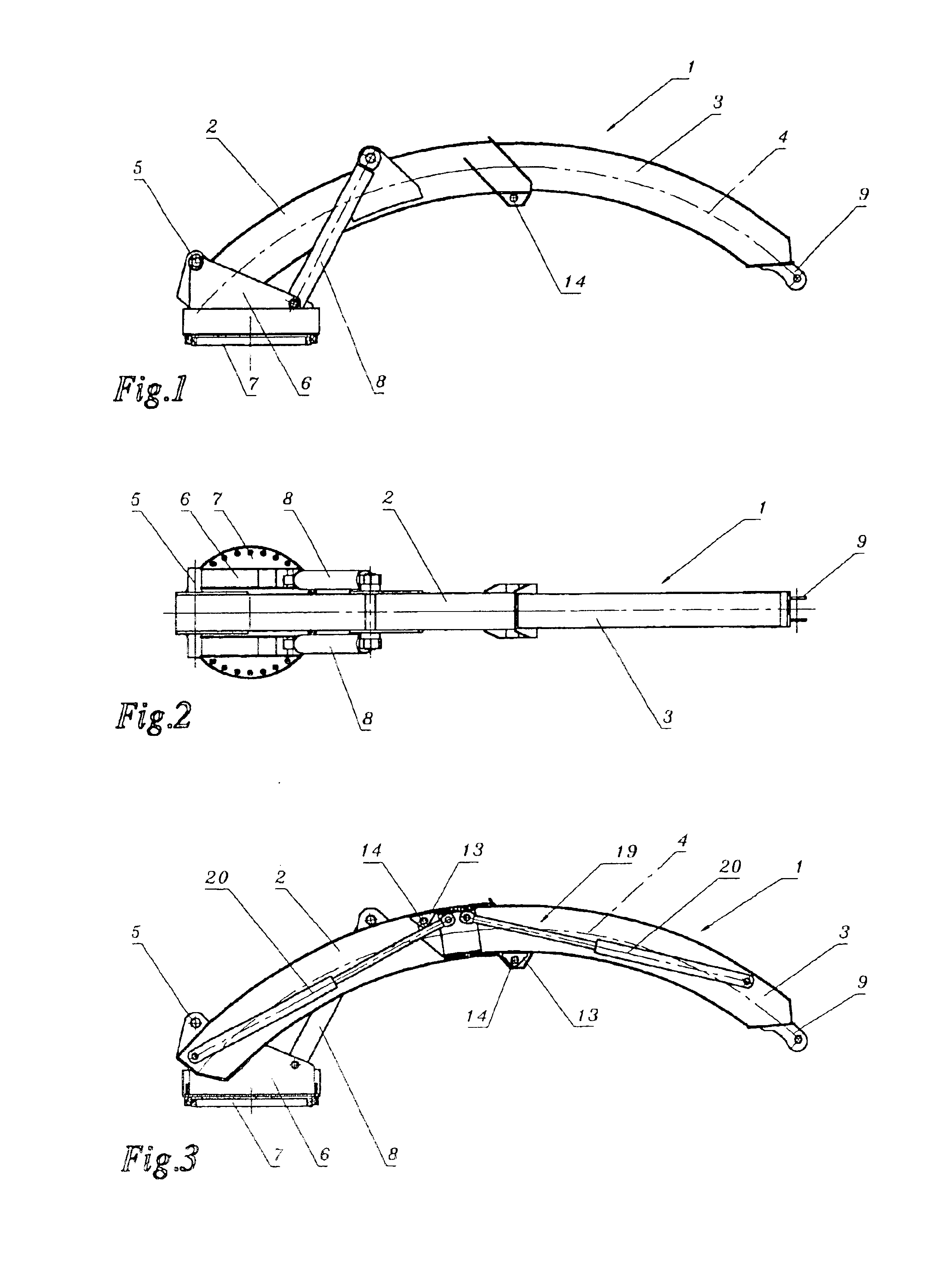

Telescopic jib for a motor vehicle or a crane

InactiveUS6881021B1Increase the extension lengthSimple displacementArticle unpackingRefuse receptaclesStructural conditionEngineering

A telescopic boom (1) for a vehicle (25) or a hoist with a storage rack (6) for at least two box girders (2, 3) guided displaceably in one another in the direction of their longitudinal axes, which are mounted to pivot about a horizontal pivot axle (5) in the storage rack (6) and which can be displaced reciprocally by means of a servo-drive (19) is described. In order to create advantageous structural conditions it is proposed that the longitudinal axles of the box girders (2, 3) form an upwards arched arc of a circle (4) which runs concentrically to a common axis parallel to the pivot axis (5).

Owner:WINTER UDO +2

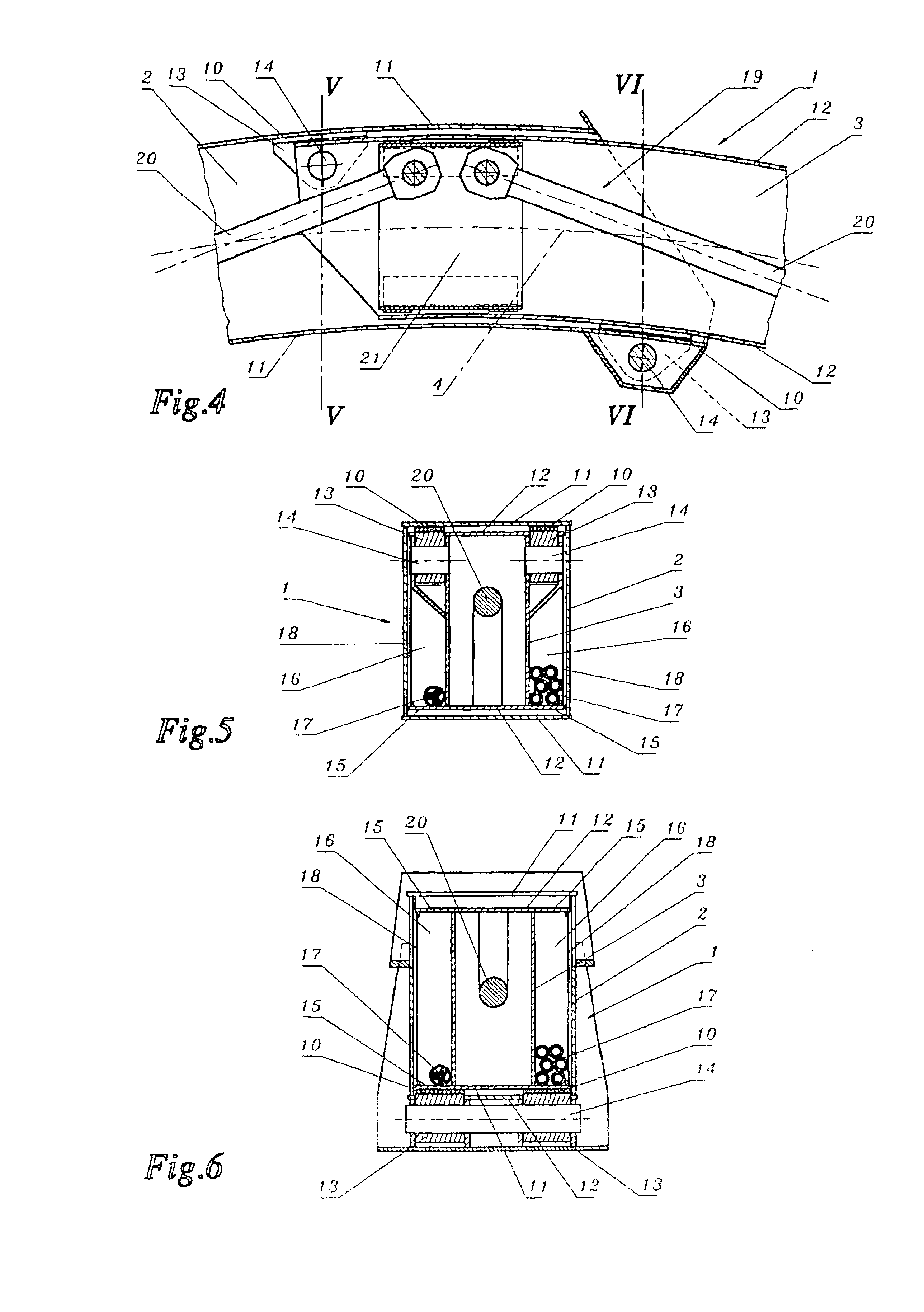

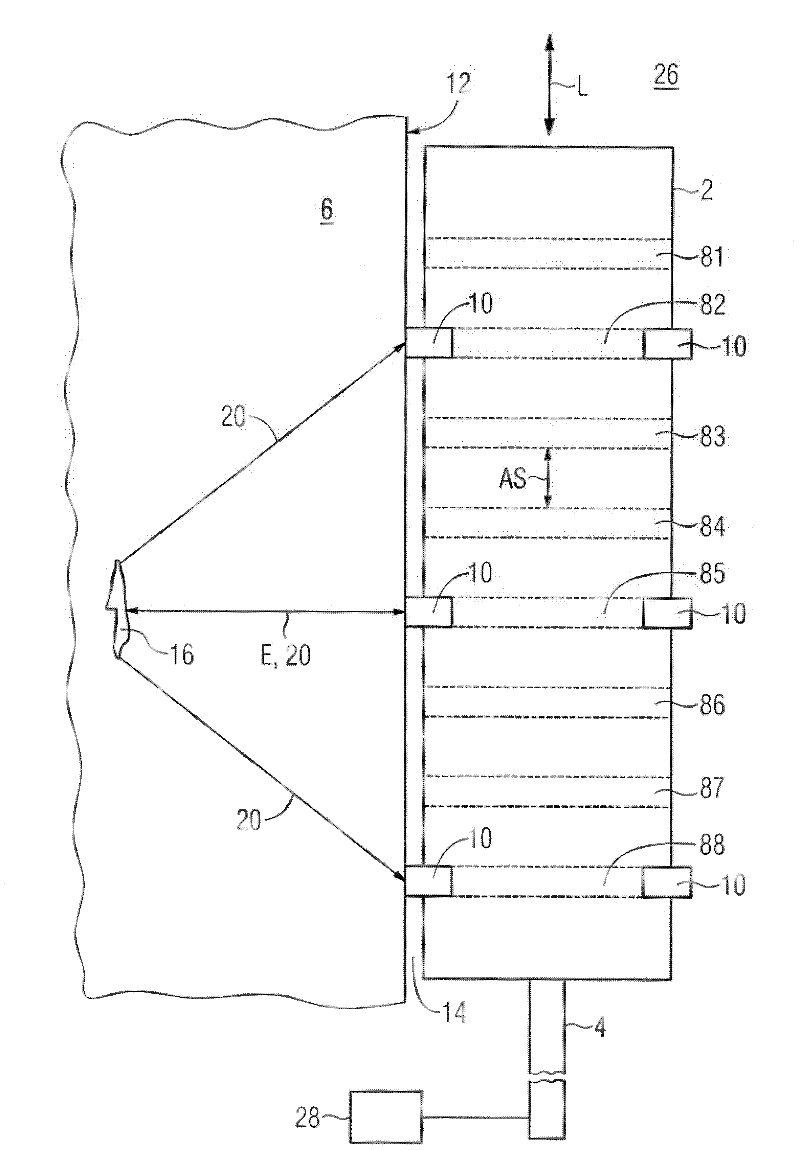

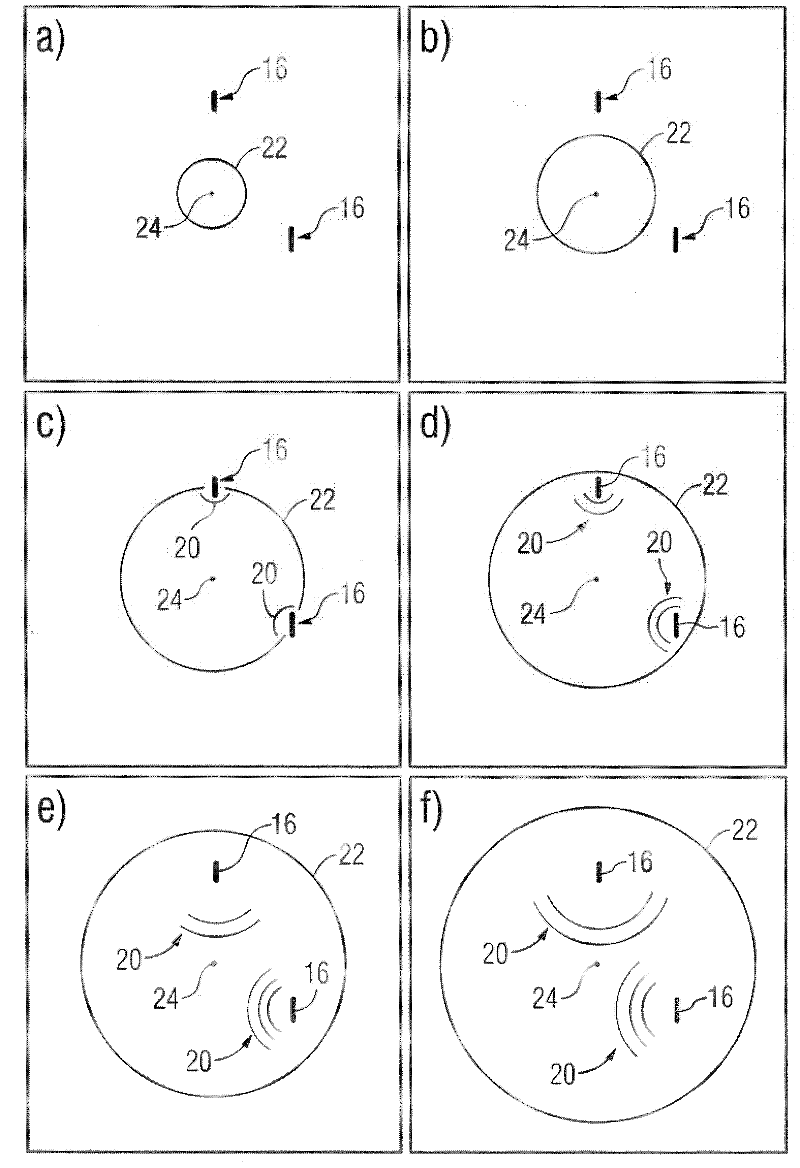

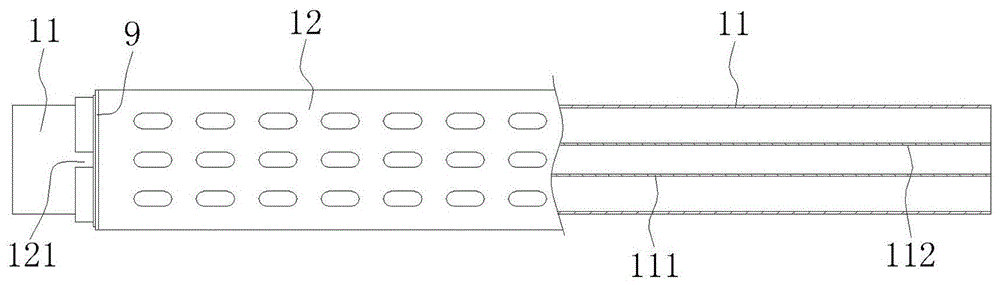

Method and device for ultrasonic testing

InactiveCN102648408AIncrease the probability of receiving attached echo signalsAdvantages of detection speedAnalysing solids using sonic/ultrasonic/infrasonic wavesTransducerUltrasonic testing

The invention relates to a method for ultrasonically testing a test specimen (6), which comprises a bore (26) extending in an axial direction (L), wherein the probe (2) is disposed inside the bore (26) and extends in the axial direction (L). The probe (2) comprises a plurality of sensor rings (81-88) disposed behind one another in the axial direction (L) and spaced apart from each other, said sensor rings extending in a plane perpendicular to the axial direction (L) and comprising a plurality of ultrasonic transducers (10) spaced apart from each other. The ultrasonic transducers (10) are disposed in a segment (30) of a particular sensor ring (81-88), which extends in the circumferential direction of the particular sensor ring (81-88) on at least a partial section of a circumference of the particular sensor ring (81-88). For the ultrasonic testing of the test specimen (6), an ultrasonic test pulse originating from the ultrasonic transducers (10) of a segment (30) of a sensor ring (81-88) is coupled into the test specimen (6). Then a plurality of echo signals (20) are received with a first and a second ultrasonic transducer (10), wherein said transducers are disposed spatially apart from each other. The echo signals (20) are caused by reflection of the coupled-in ultrasonic test pulse from one and the same defect (16) present in the test specimen (6).

Owner:INTELLIGENDT SYST & SERVICES

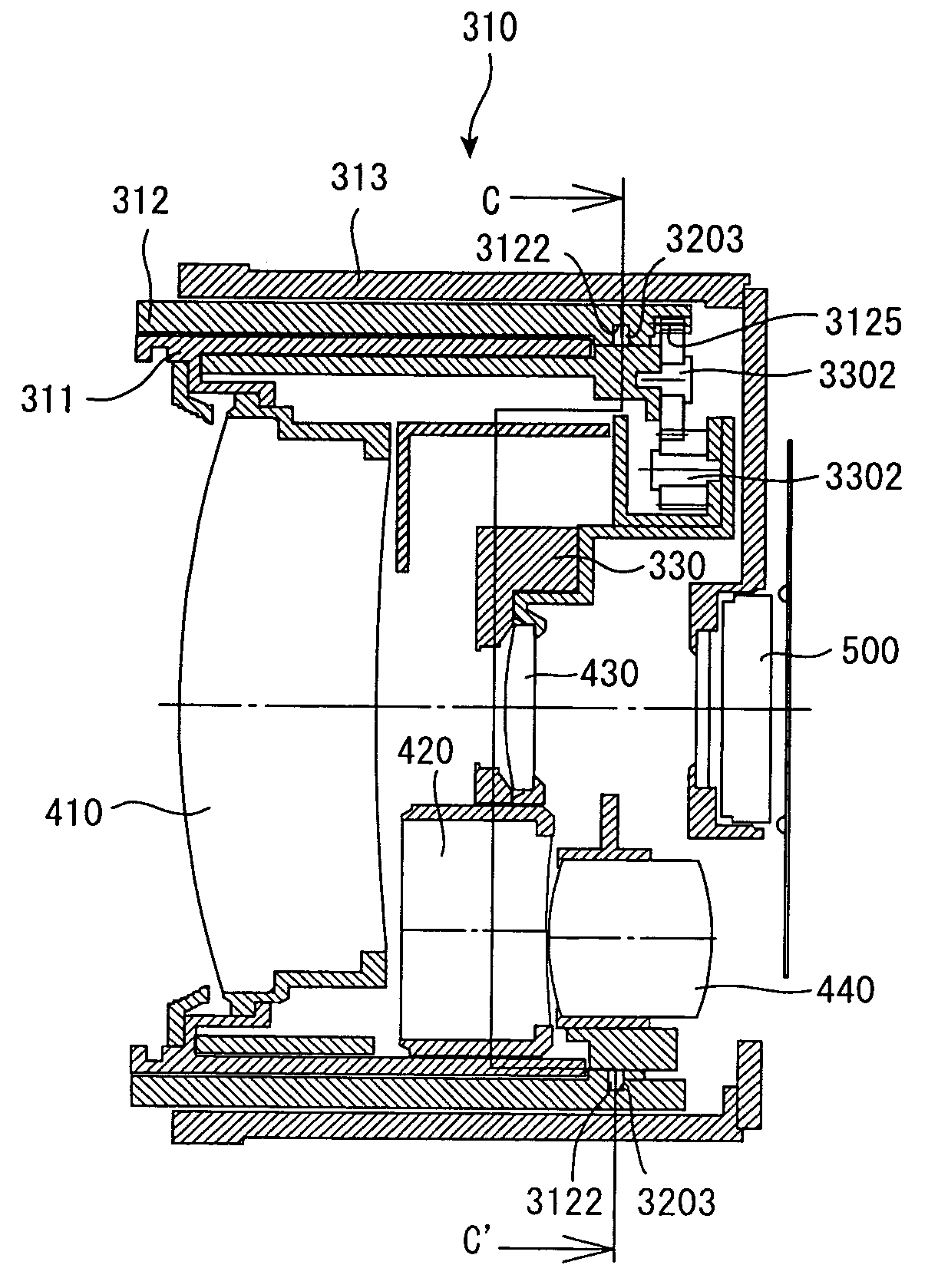

Lens barrel, photographic apparatus, and optical apparatus

InactiveUS7194203B2Shorten the lengthIncrease the extension lengthPrintersProjectorsOptical axisMechanical engineering

A lens barrel has its collapsed length which can be further decreased and its extended length which can be further increased. A photographic apparatus incorporates the lens barrel into its body. A lens barrel is equipped with a first gear which is rotatably supported by a straight-ahead key ring and rotates being driven by rotation of a middle tube and a second gear which receives driving force from the first gear and retracts a second lens group to a predetermined retracted position off the optical axis of a zoom lens during collapse and advances the second lens group onto the optical axis during extension. The second gear lacks teeth in that part which faces the first gear when the second lens group is at the retracted position during collapse. Consequently, the first gear runs idle while facing that part thereby holding the second lens group at the retracted position.

Owner:FUJI PHOTO OPTICAL CO LTD +2

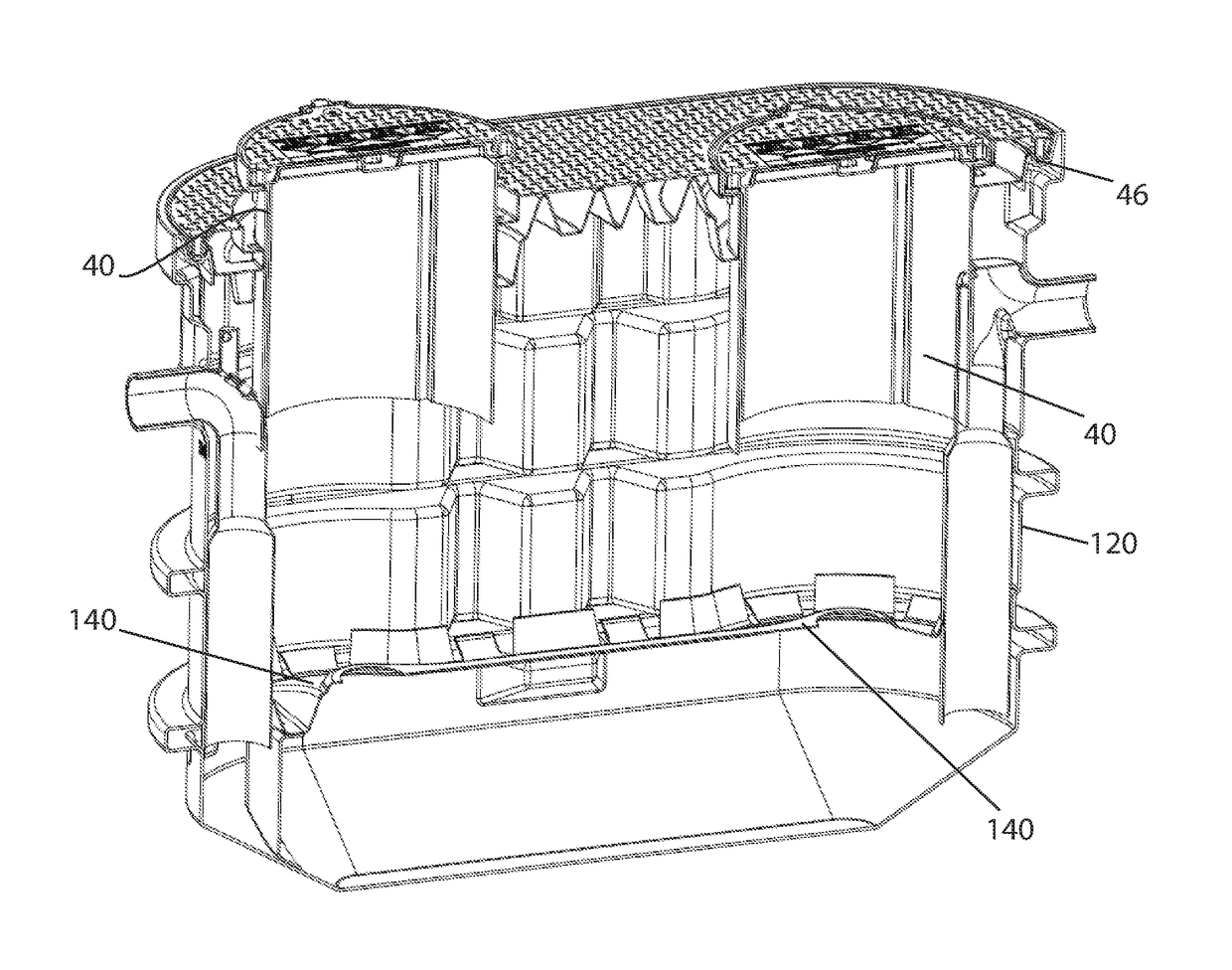

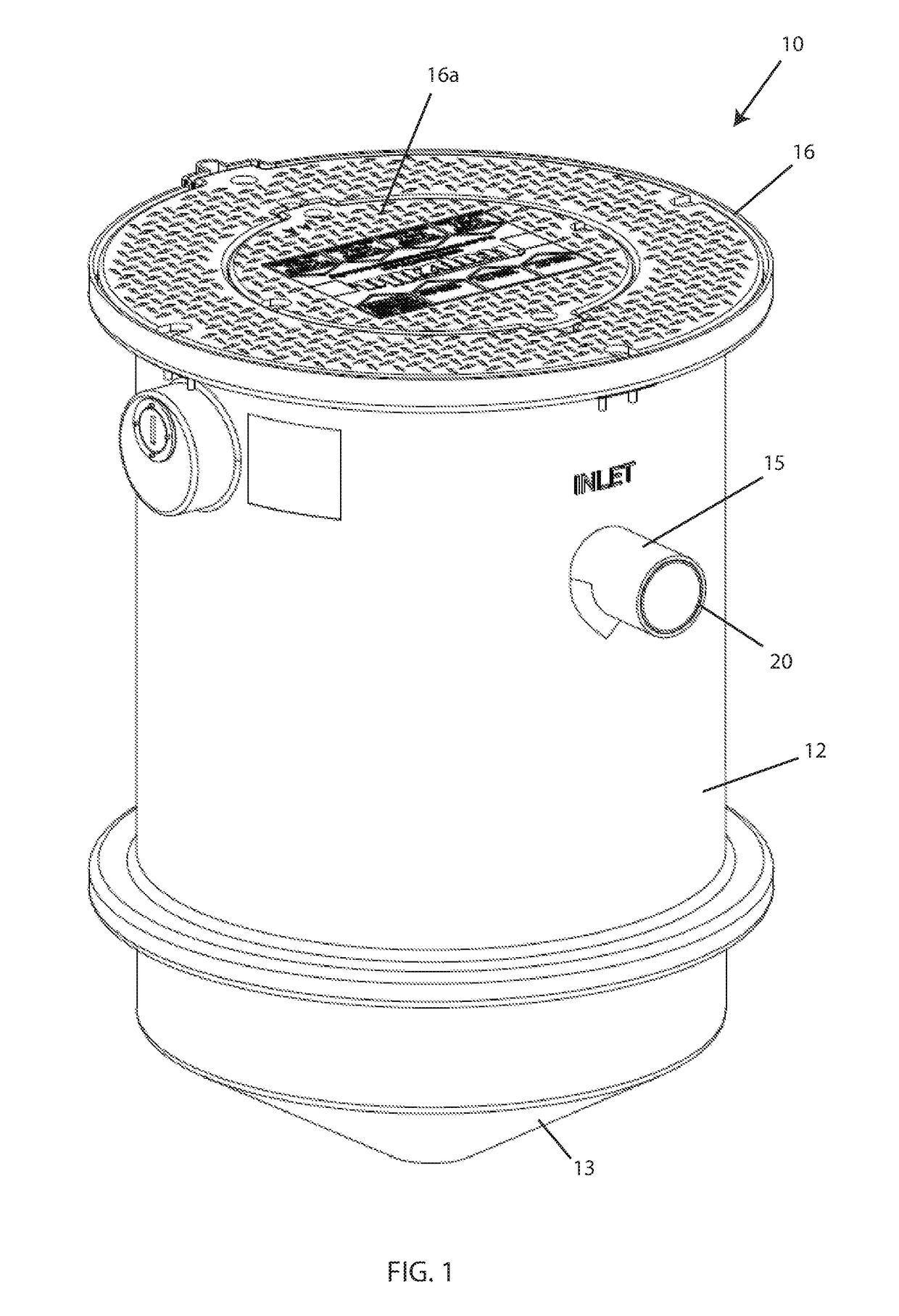

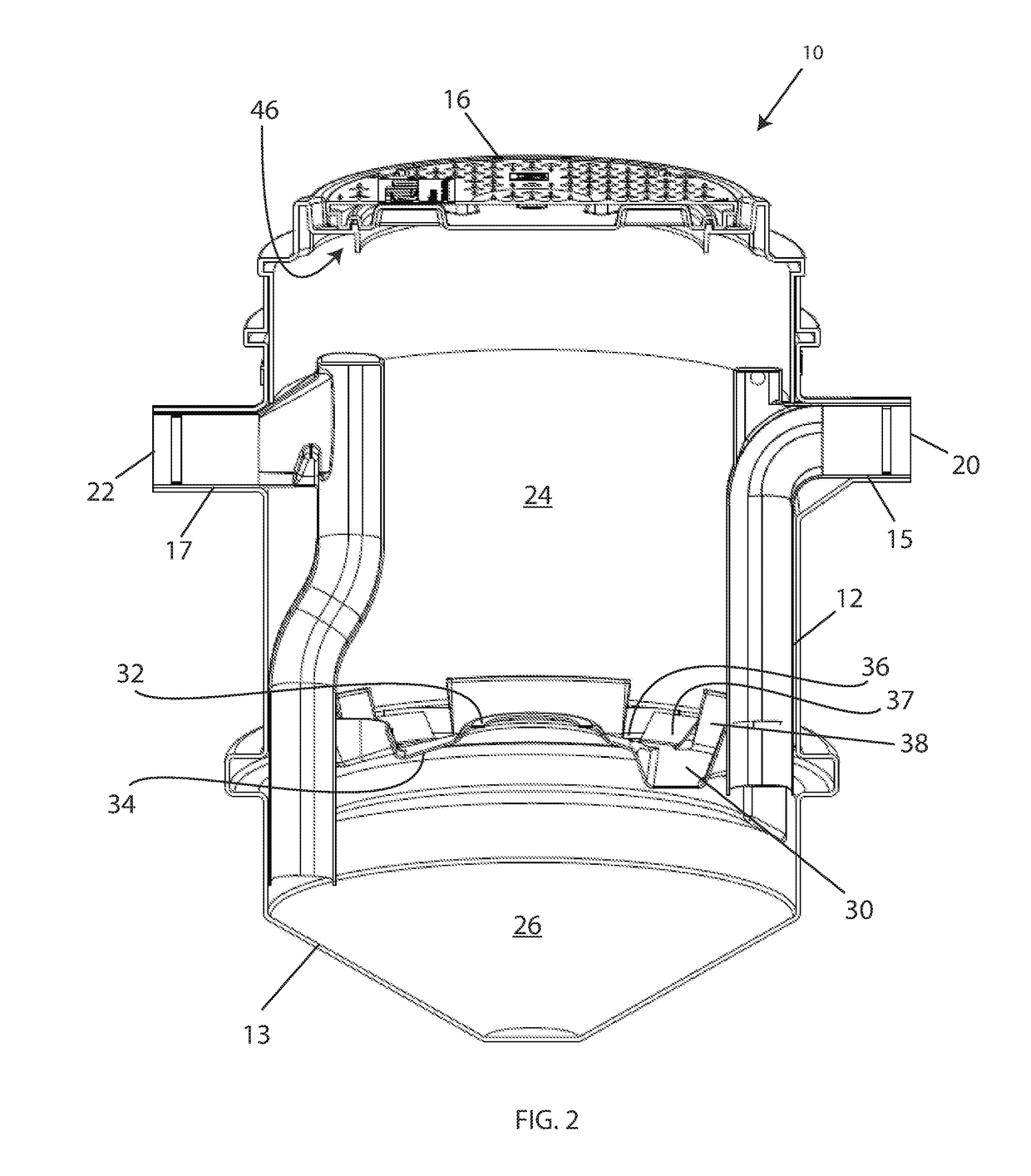

Passive grease trap using separator technology

ActiveUS9932247B1Increase capacityIncrease the extension lengthFatty/oily/floating substances removal devicesSewerage structuresFuel tankGrease trap

An apparatus and method for a grease trap for separating grease and solid waste from waste water. The grease trap includes a tank having a downwardly shaped bottom. An upwardly shaped baffle insert divides the tank into an upper chamber and a lower chamber. An outlet port near an upper part of the baffle allows waste into the upper chamber. An inlet invert in the tank receives incoming waste water, while an outlet invert removes water from the tank. A removable cover covers the tank and allows access for removal of accumulated grease and solid wastes.

Owner:THERMACO INC

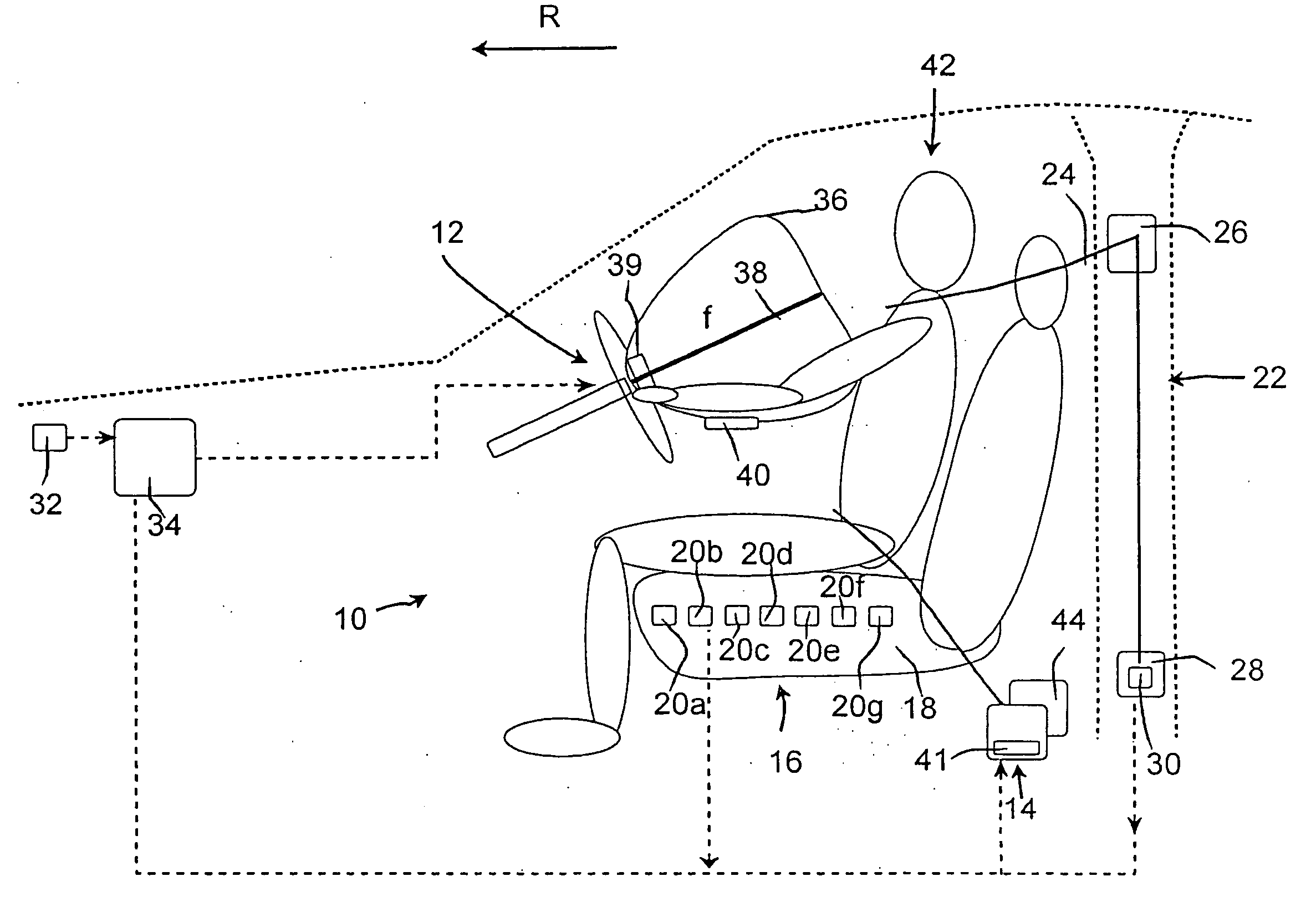

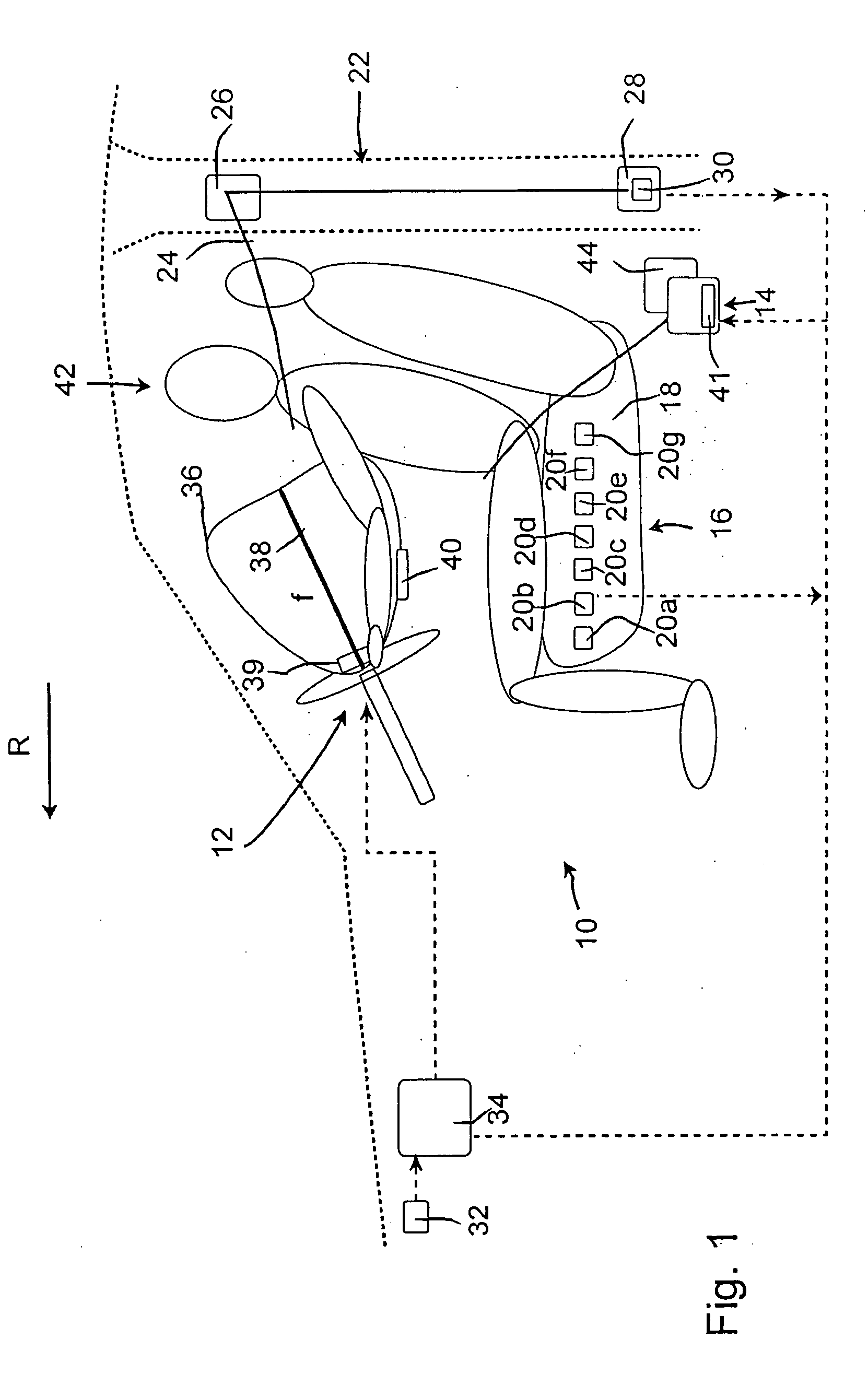

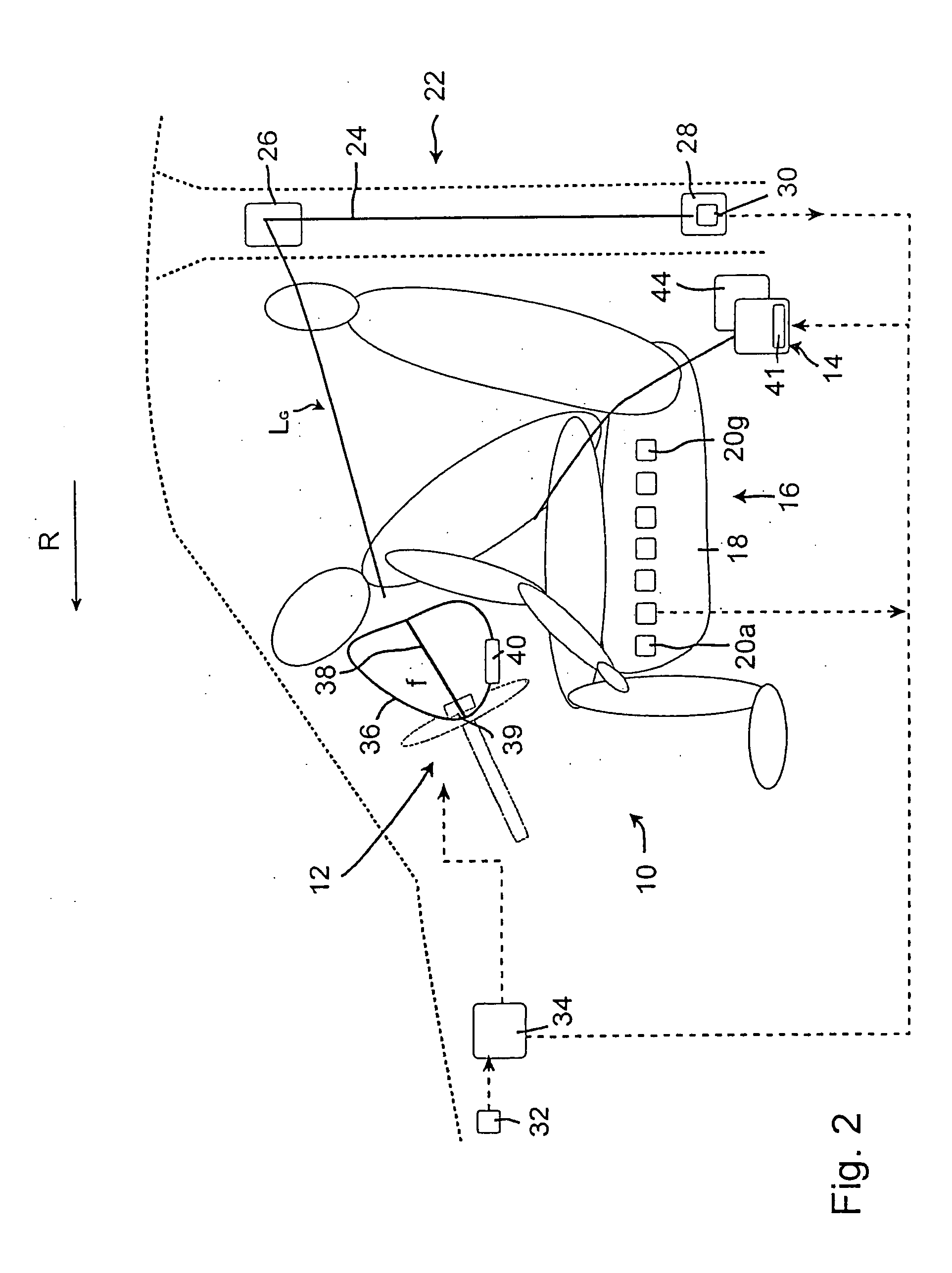

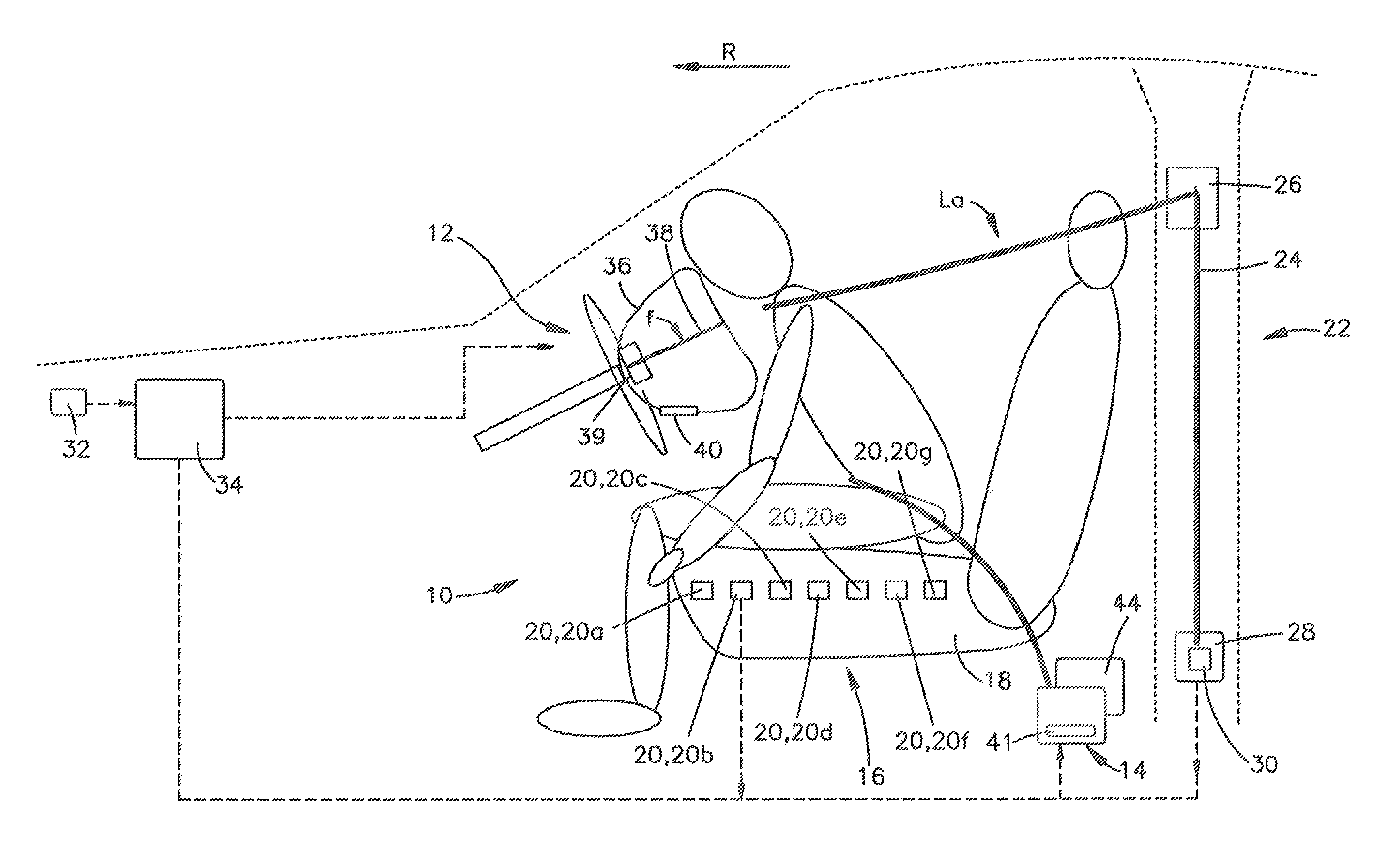

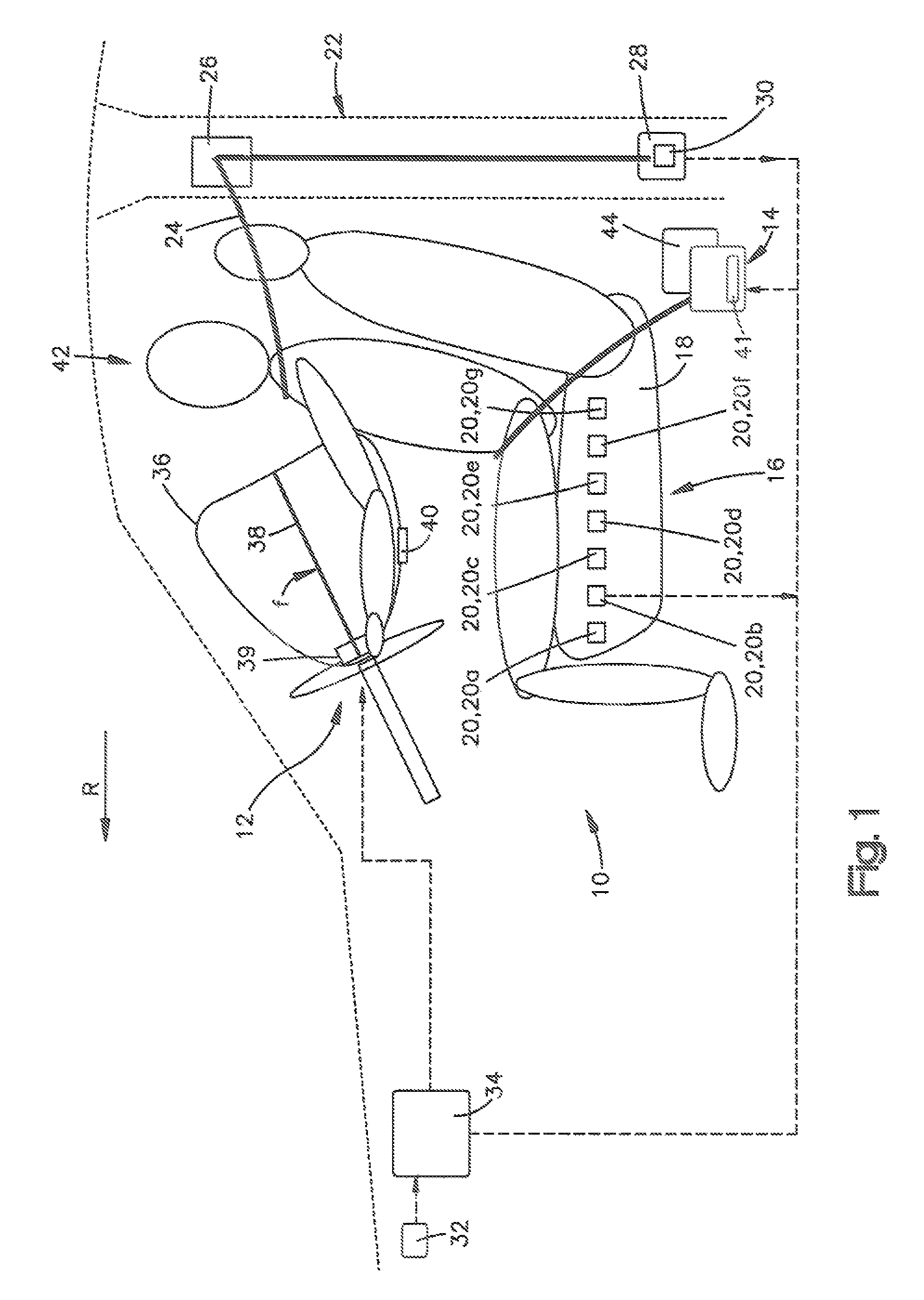

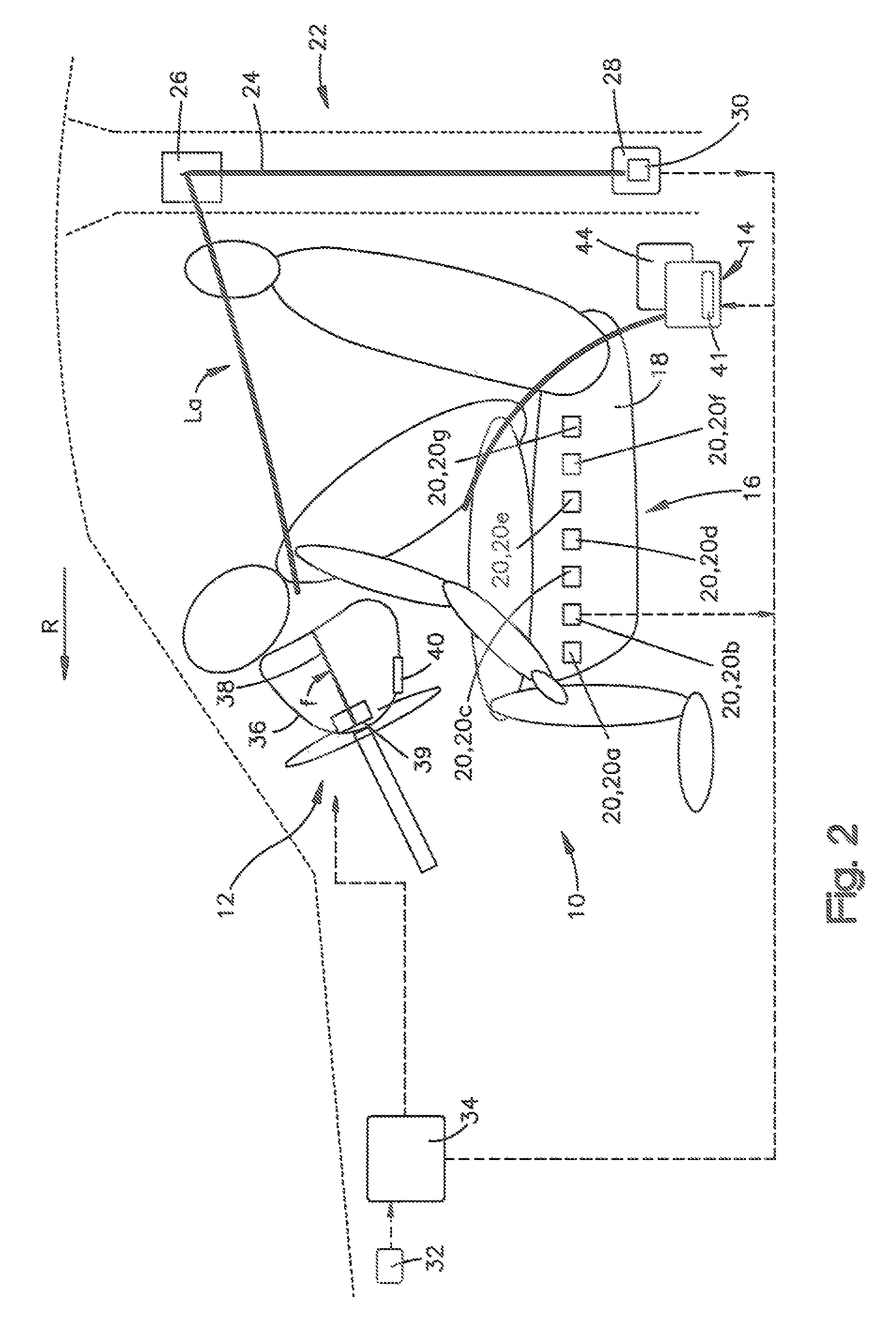

Vehicle occupant safety system and method for detecting the position of a vehicle occupant

ActiveUS20070257474A1Simple wayEasy to detectDigital data processing detailsPedestrian/occupant safety arrangementOccupant safetyBelt safety

A vehicle occupant safety system has at least one restraint device having at least one adjustable parameter, a vehicle seat having at least one seat sensor detecting the sitting position of a vehicle occupant, a seatbelt system having at least one belt extension sensor detecting the belt extension length, and a control unit determining from the values from the seat sensor and from the belt extension sensor whether a vehicle occupant is in a forward-leaning position. The control unit then specifies the value of the adjustable parameter of the restraint device as a function of a forward-leaning position of the vehicle occupant.

Owner:TRW AUTOMOTIVE GMBH

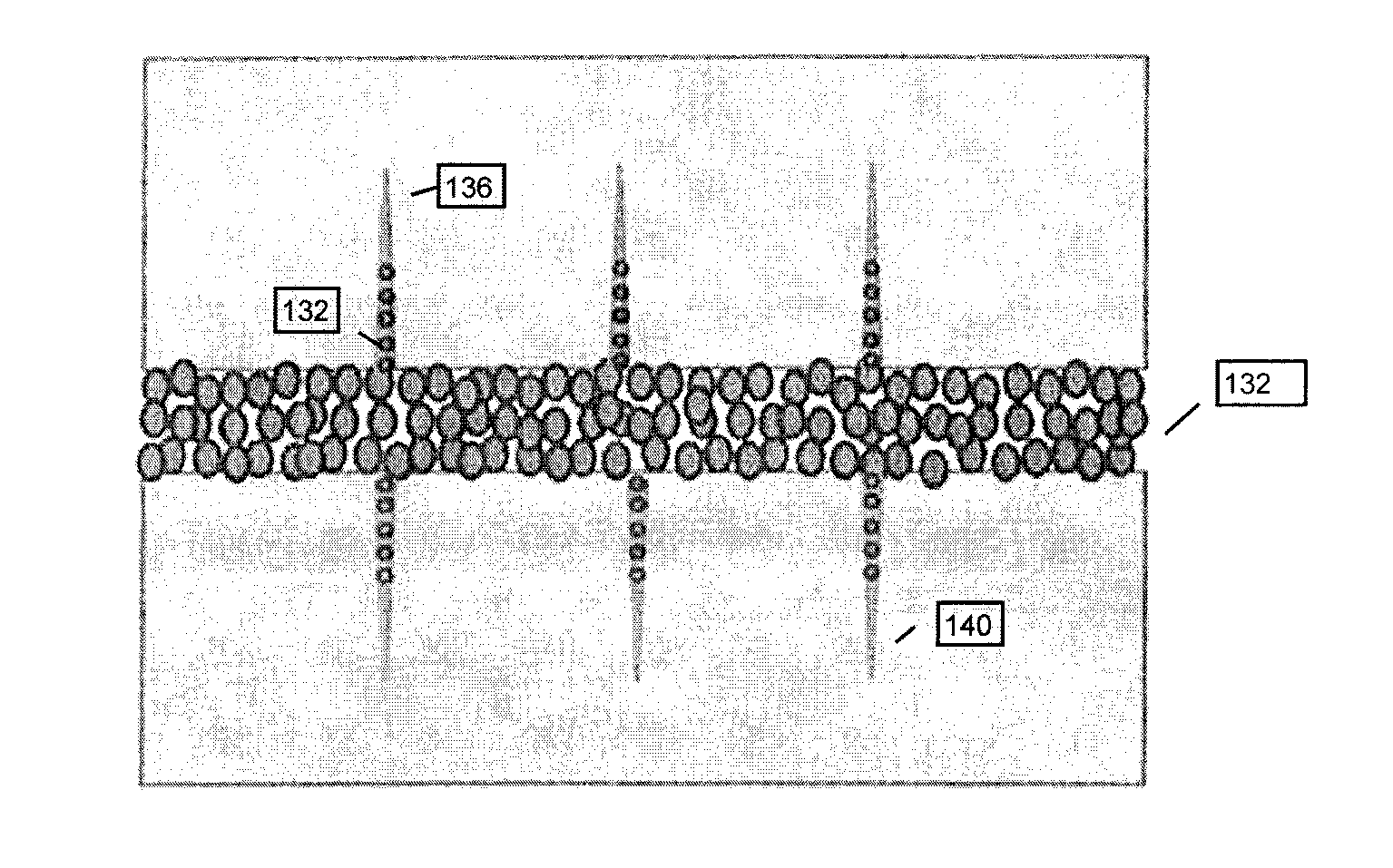

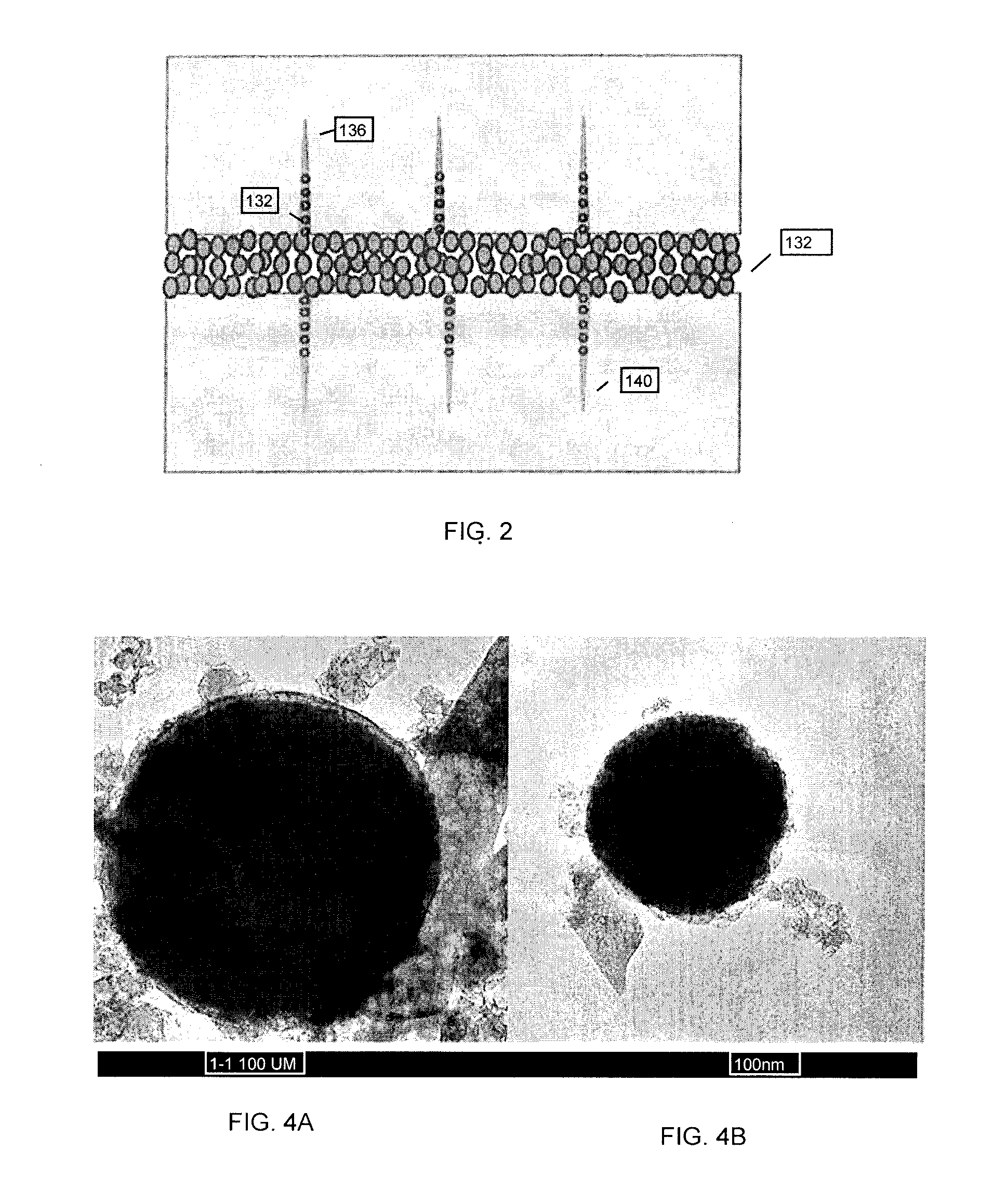

Nano-proppants for fracture conductivity

InactiveUS20160355727A1Increase the extension lengthImprove conductivityFluid removalDrilling compositionMetallurgyFracturing fluid

Methods of hydraulic fracturing are disclosed. One method of hydraulic fracturing which is performed on a geologic stratum includes using a nano-proppant dominantly formed of particles having an average diameter of less than 1 μm dispersed in a fracturing fluid. A material for use in hydraulic fracturing may include a fracturing fluid and a nano-proppant dominantly formed of particles having an average diameter of less than 1 μm dispersed in the fracturing fluid.

Owner:UNIVERSITY OF KANSAS

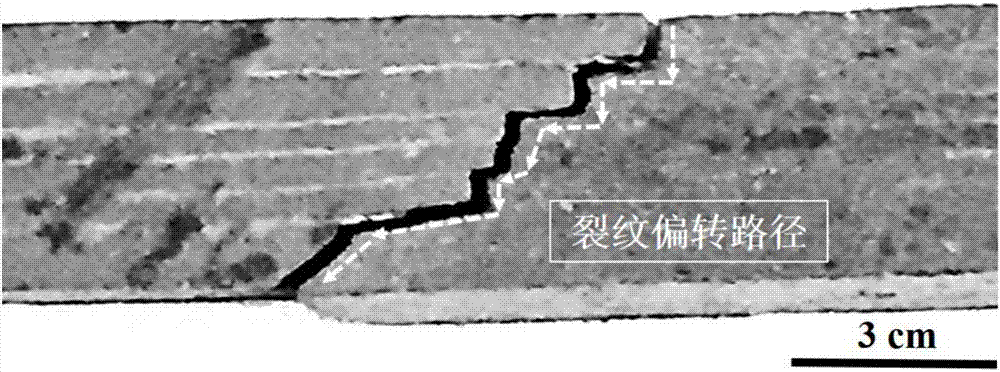

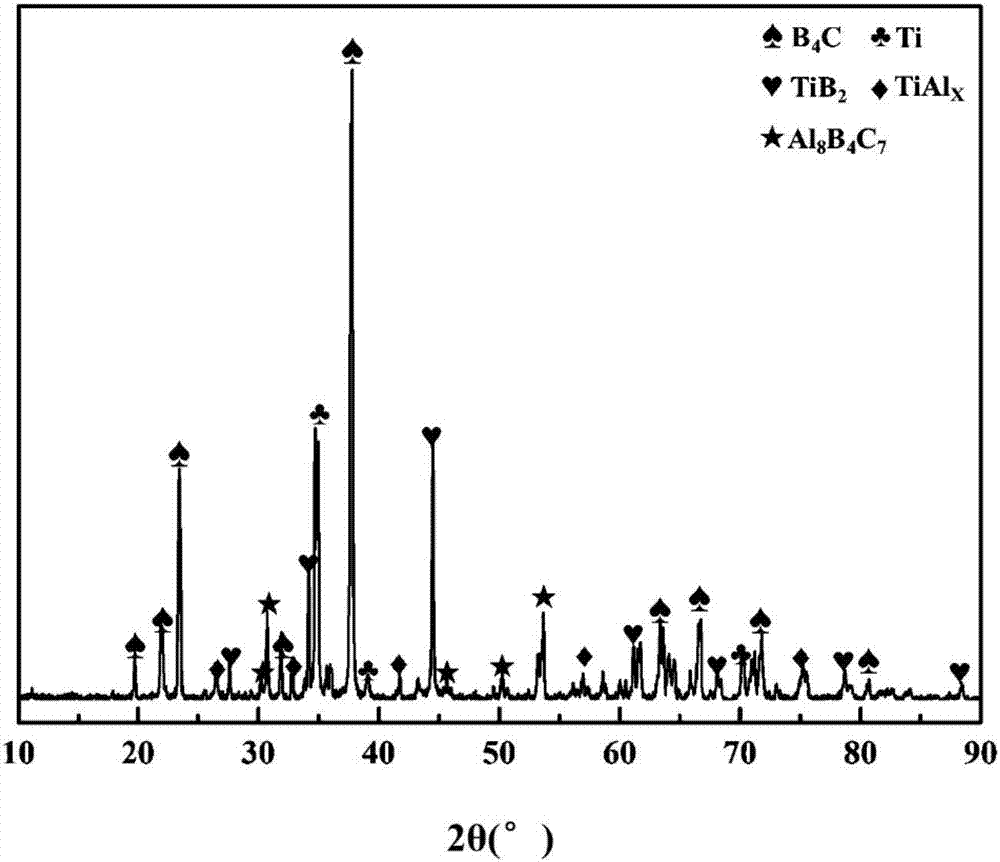

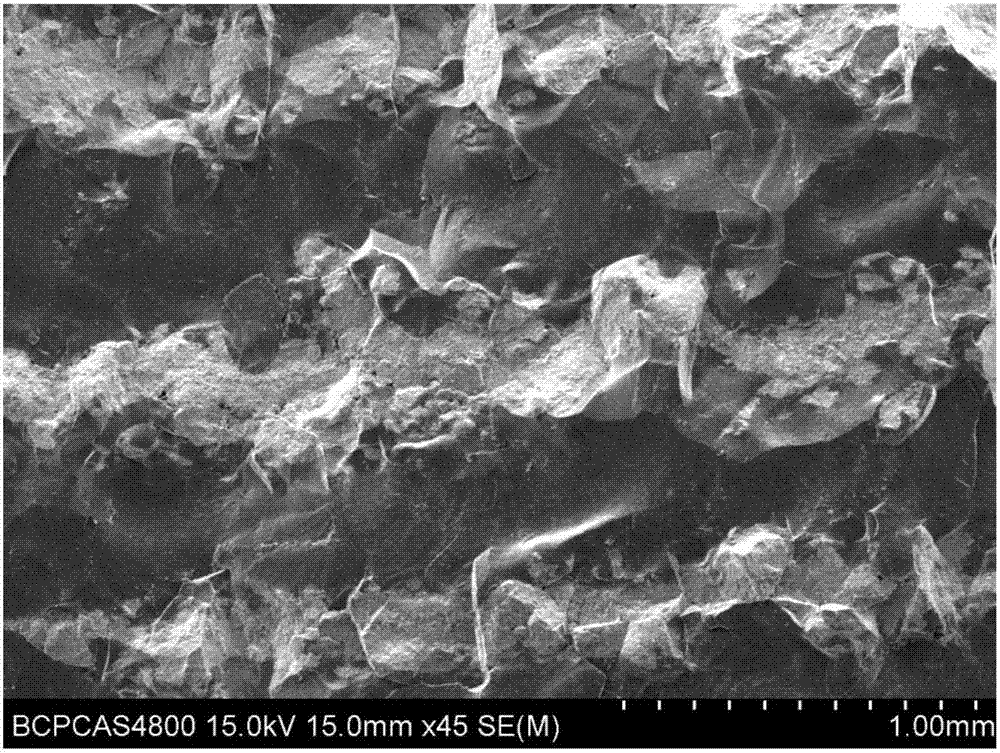

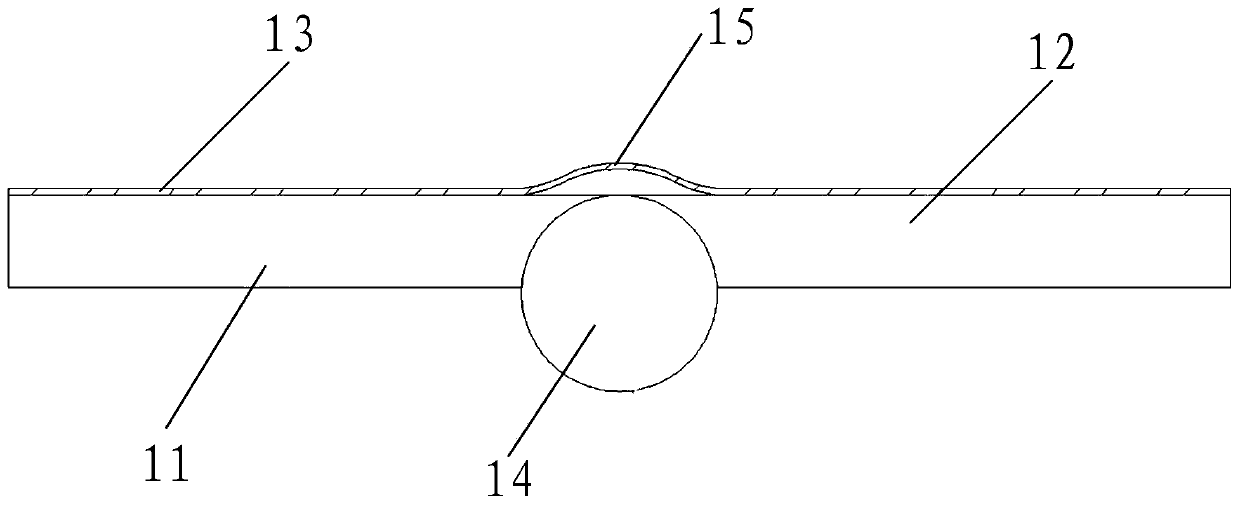

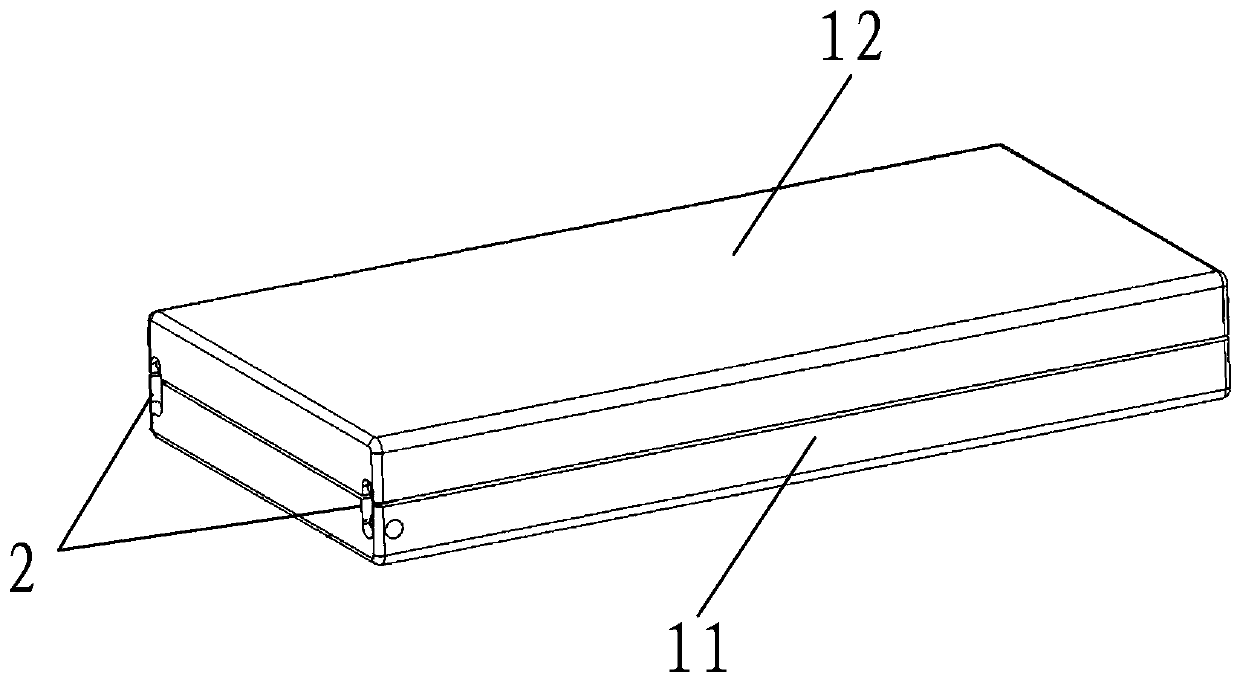

Laminar Ti/B4C composite material and preparation method thereof

InactiveCN107117981AIncrease the extension lengthImprove fracture toughnessPorosityCeramic composite

The invention relates to a laminar Ti / B4C composite material and a preparation method thereof, and belongs to the technical field of metal enhanced ceramic composite materials. The composite material is formed by alternately overlying a Ti layer and a B4C layer in sequence; Ti and B4C have different thermal expansion coefficients and elastic modulus, so that cracks deflect when the cracks are extended in the composite material, fracture energy is gradually consumed, and the fracture toughness of the composite material is easy to improve; furthermore, less Al is added, and the interface strength can be improved, so that the mechanical properties of the composite material are improved; moreover, the interface reaction extent between the Ti layer and the B4C layer is reduced by utilizing a surface contact manner of particles between the Ti layer and the B4C layer. The method provided by the invention has a simple process, is easy to operate and has a very good industrial application prospect; the prepared laminar Ti / B4C composite material has a good microscopic structure, relatively low porosity and good mechanical properties.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Vehicle occupant safety system and method for detecting the position of a vehicle occupant

ActiveUS7997374B2Easy to detectIncrease the extension lengthDigital data processing detailsPedestrian/occupant safety arrangementOccupant safetyBelt safety

A vehicle occupant safety system has at least one restraint device having at least one adjustable parameter, a vehicle seat having at least one seat sensor detecting the sitting position of a vehicle occupant, a seatbelt system having at least one belt extension sensor detecting the belt extension length, and a control unit determining from the values from the seat sensor and from the belt extension sensor whether a vehicle occupant is in a forward-leaning position. The control unit then specifies the value of the adjustable parameter of the restraint device as a function of a forward-leaning position of the vehicle occupant.

Owner:TRW AUTOMOTIVE GMBH

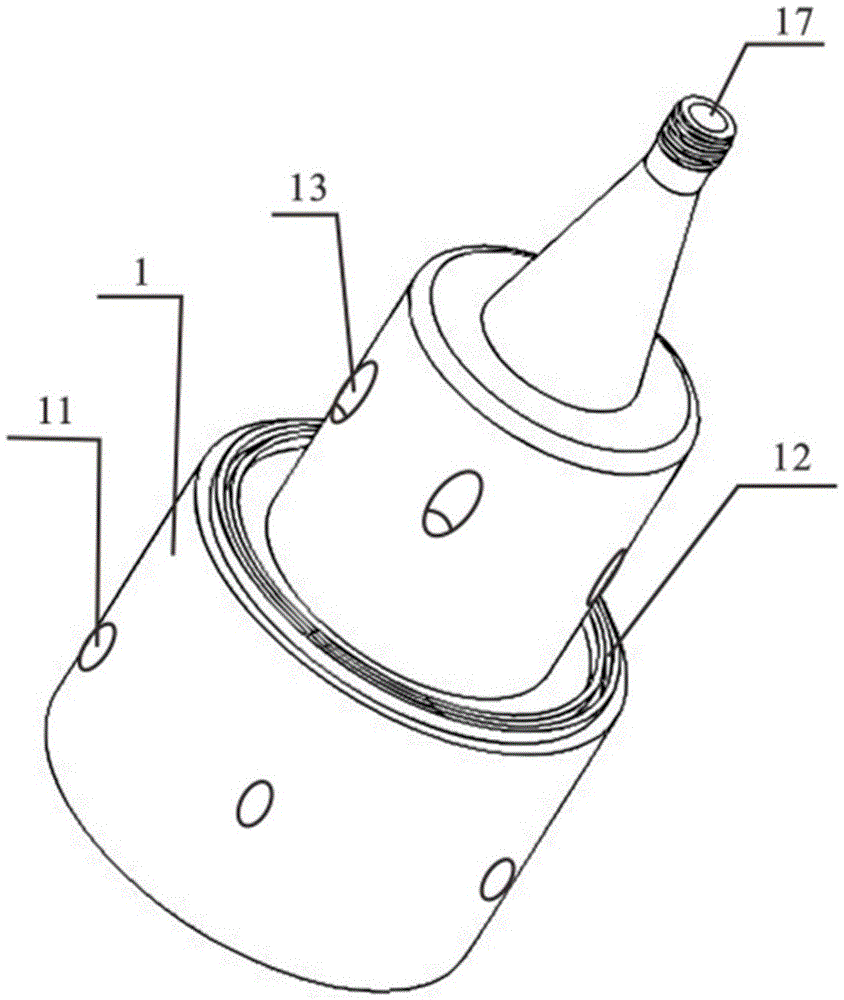

Rotary self-propelled mixing jet bit with cutting wing ribs

The invention relates to a rotary self-propelled mixing jet bit with cutting wing ribs, and the rotary self-propelled mixing jet bit is applied to well drilling of a hydraulic jet radial horizontal well. The rotary self-propelled mixing jet bit comprises a bit body, a rotary shell and a positioning nut; the rear end of the bit body is provided with a hollow variable diameter cylinder, and the front end of the bit body is provided with a central nozzle with a mixing cavity; the hollow cylinder arranged at the rear end of the bit body is provided with first-level backward nozzles, multiple forward holes are formed in a hollow cylinder arranged at the front end of the bit body, and flow guiding valves are installed in the forward holes; the central nozzle is coaxial with a flow channel of the bit body, a thread is formed on the exterior of the central nozzle, and the rotary shell is positioned through the positioning nut; forward nozzles facing laterally and forwards are arranged at the front end of the rotary shell, the outer wall of the rotary shell is provided with the spiral cutting wing ribs, hard alloy cutting teeth are fixedly arranged on the surfaces of the cutting wing ribs, and second-level backward nozzles are arranged in flow guiding grooves formed among the cutting wing ribs. According to the rotary self-propelled mixing jet bit with the cutting wing ribs, the problems that in the hydraulic jet radial horizontal well drilling process, the mechanical drilling rate is low, the well diameter is small, and well holes are irregular.

Owner:SOUTHWEST PETROLEUM UNIV

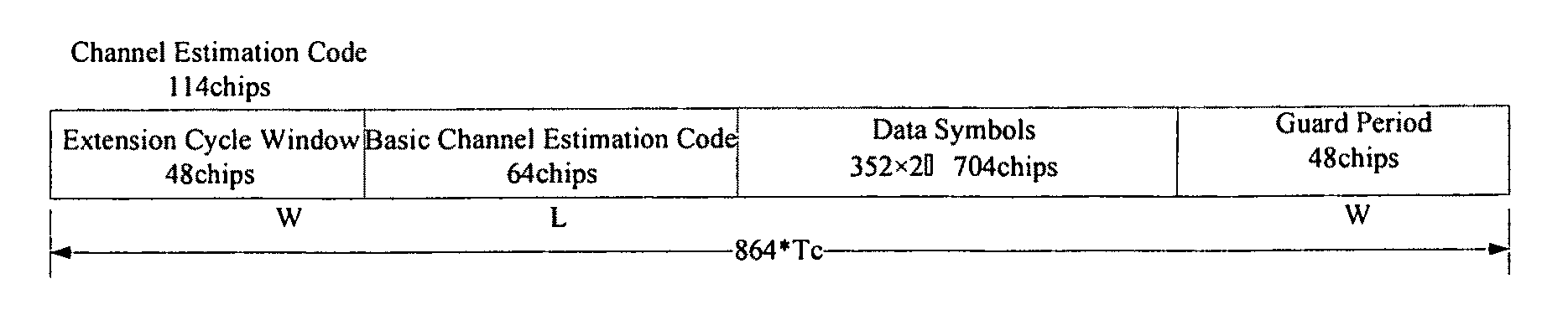

Method and device of iteration channel estimation based on asymmetrical training sequence filled block transmission system

ActiveCN103067314AImprove estimation accuracyIncrease the extension lengthTransmitter/receiver shaping networksChannel impulse responseAlgorithm

The invention discloses a method and a device of iteration channel estimation based on an asymmetrical training sequence filled block transmission system. The method comprises the following steps: S0, a signal frame comprises a frame head and a frame body, the frame head is composed of a first section training sequence and a second training sequence, the length of the second training sequence is N, and the frame body is single carrier data block or orthogonal frequency division multiplexing (OFDM) data block; S1, an initial estimation result of frame channel impulse response is obtained; S2, the second section training sequence and the first section training sequence of the current signal frame are decreased gradually, the sequence which is decreased and the estimated linear convolution of the channel are calculated, the sequence after an Nth signal of a linear convolution is used as a reconstruction item of the second section training sequence; S3, according to the reconstruction item, the second section training sequence and the circulating convolution of the channel impact response are reconstructed; S4, channel estimation is conducted by using the reconstructed circulating convolution, the estimation result of the channel impact response is updated, and postprocessing of the channel estimation is conducted; and S5, the estimation result of the channel impact response is output or the step S1 is returned.

Owner:TSINGHUA UNIV

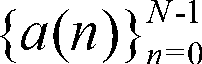

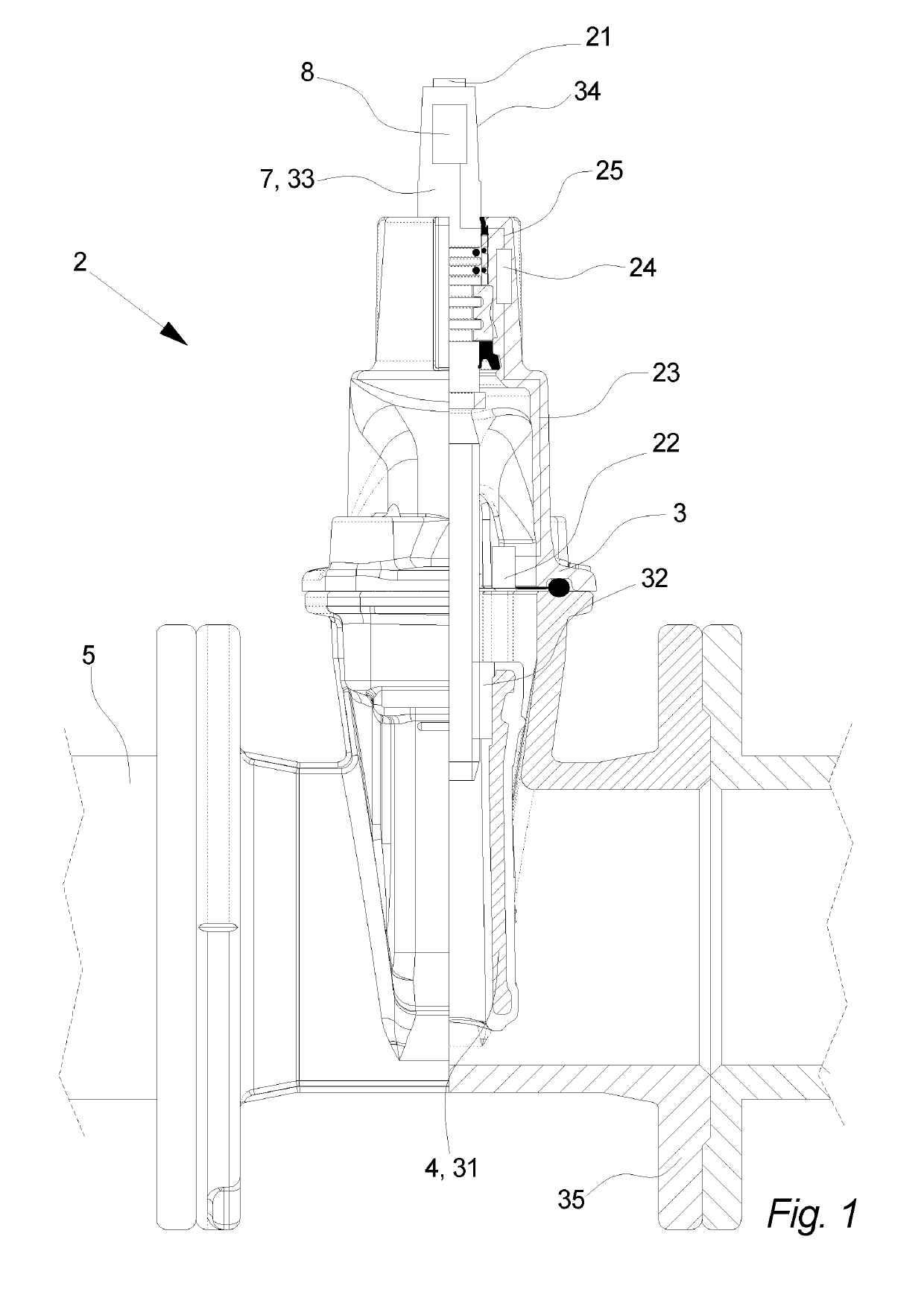

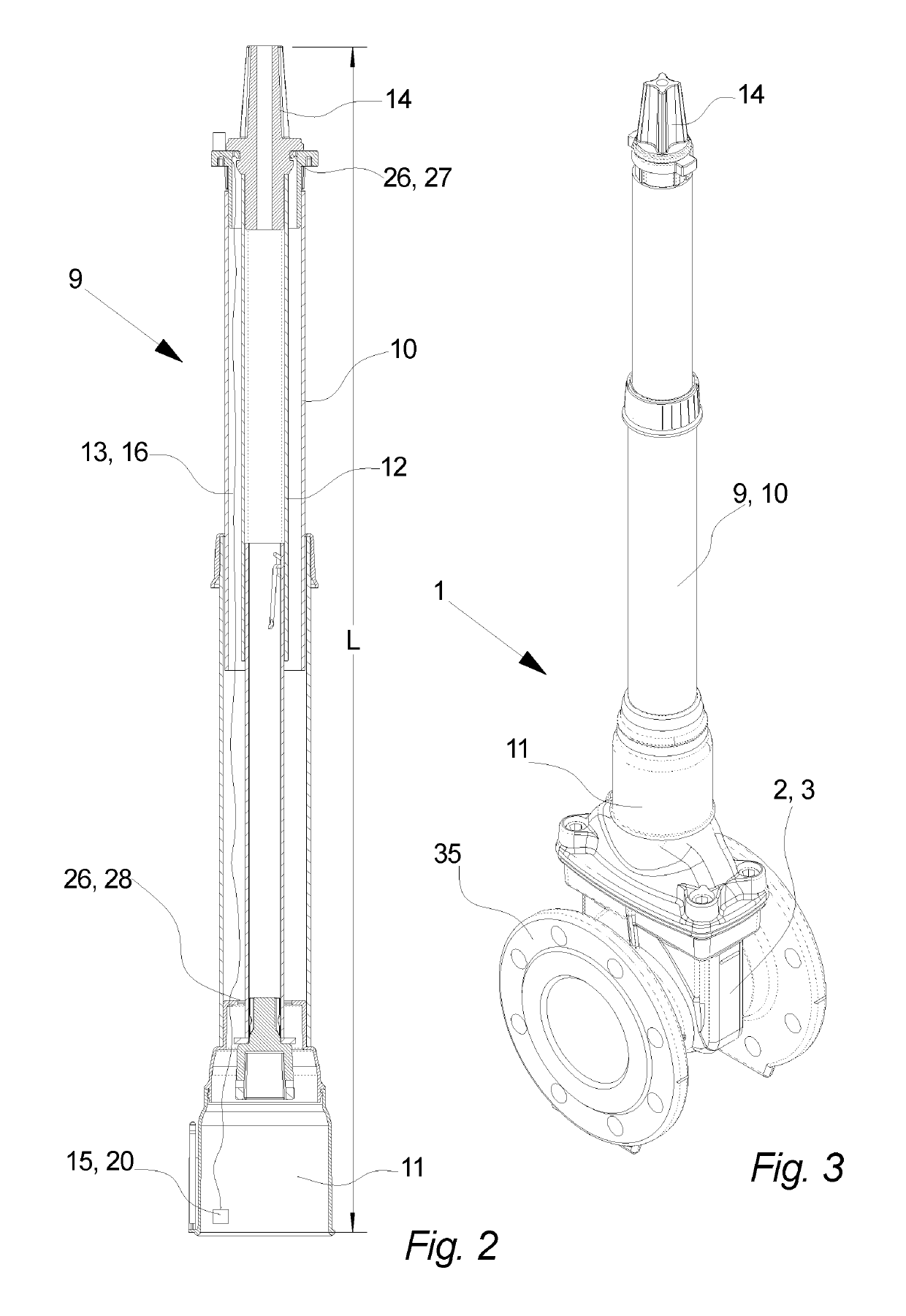

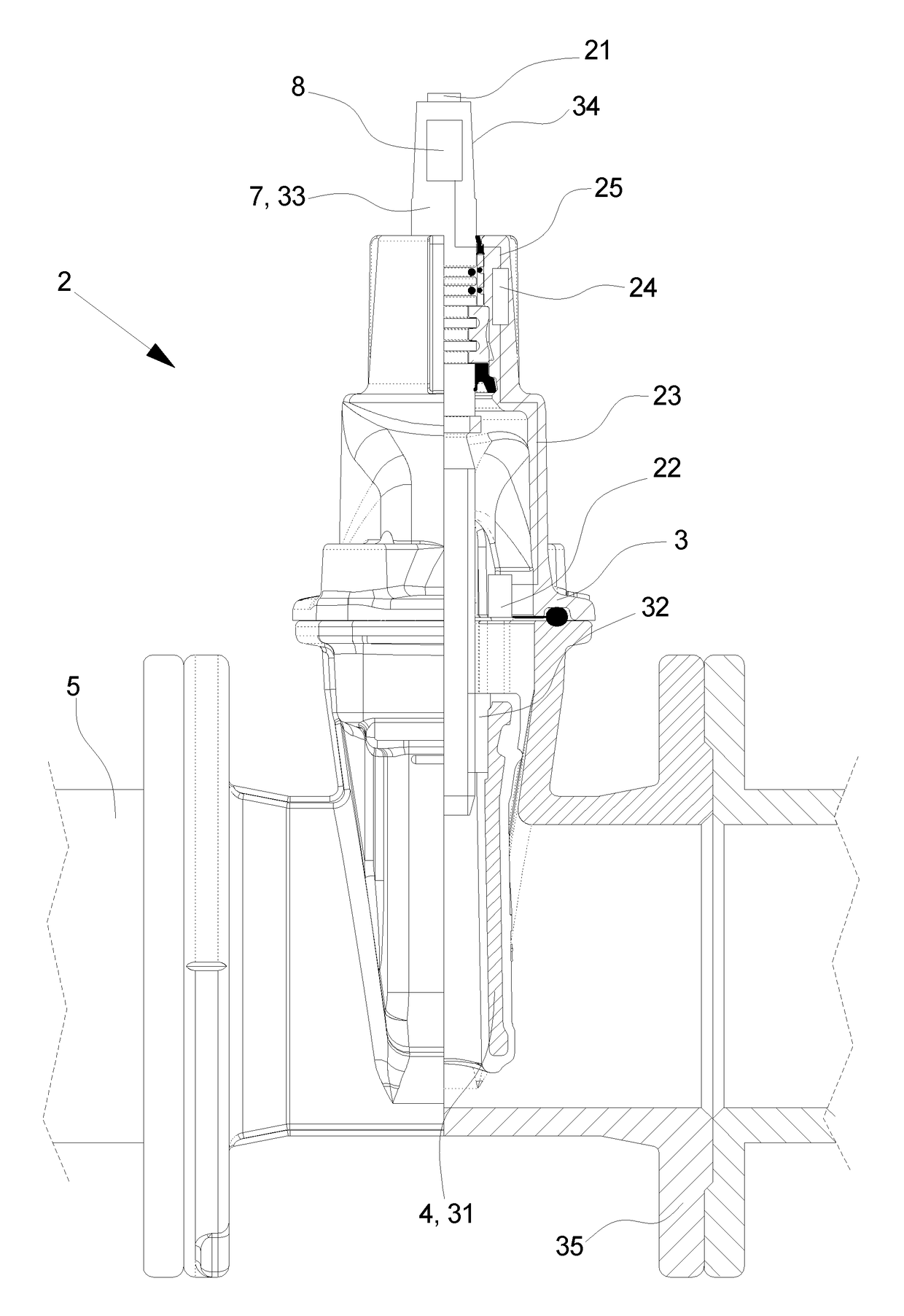

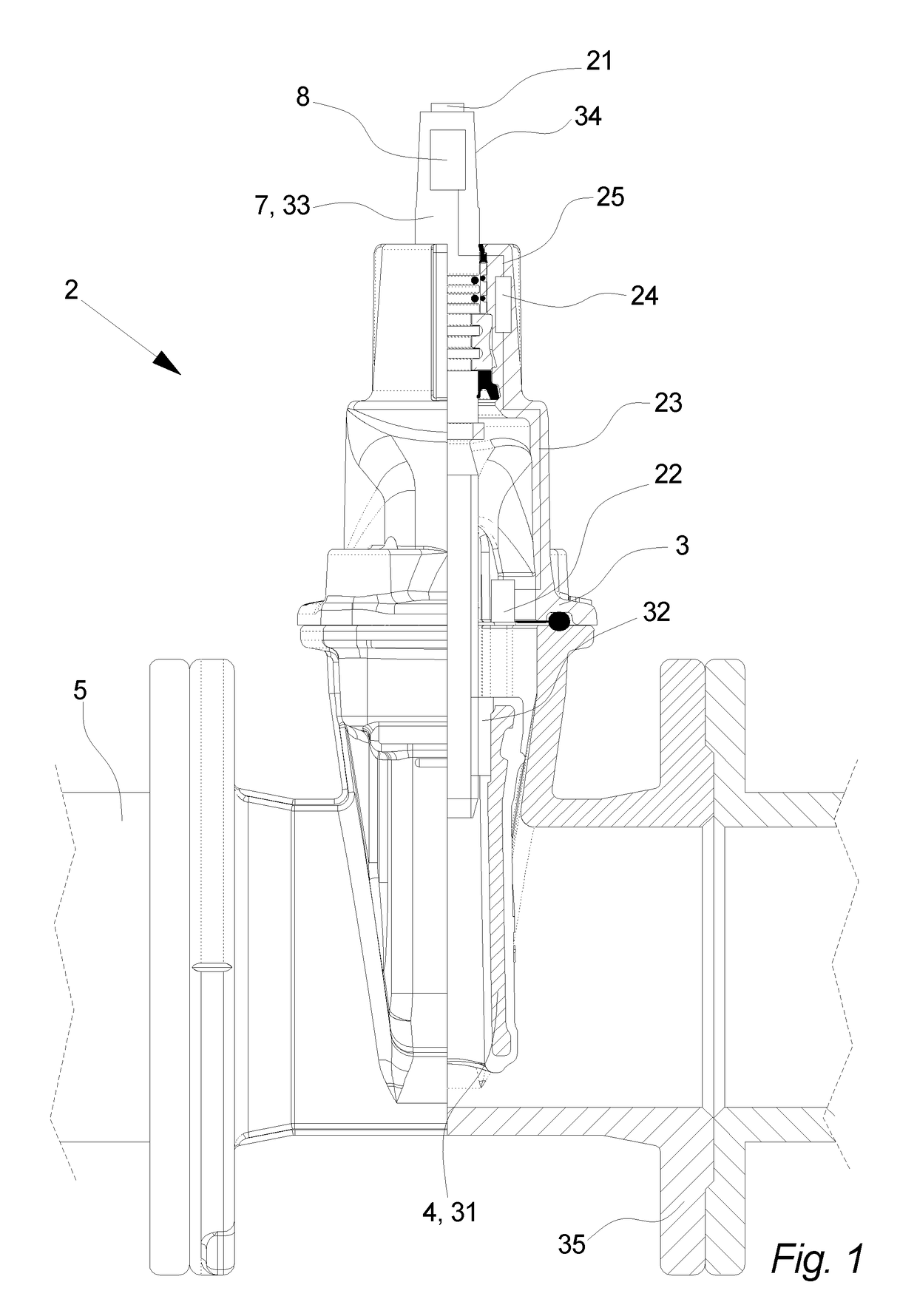

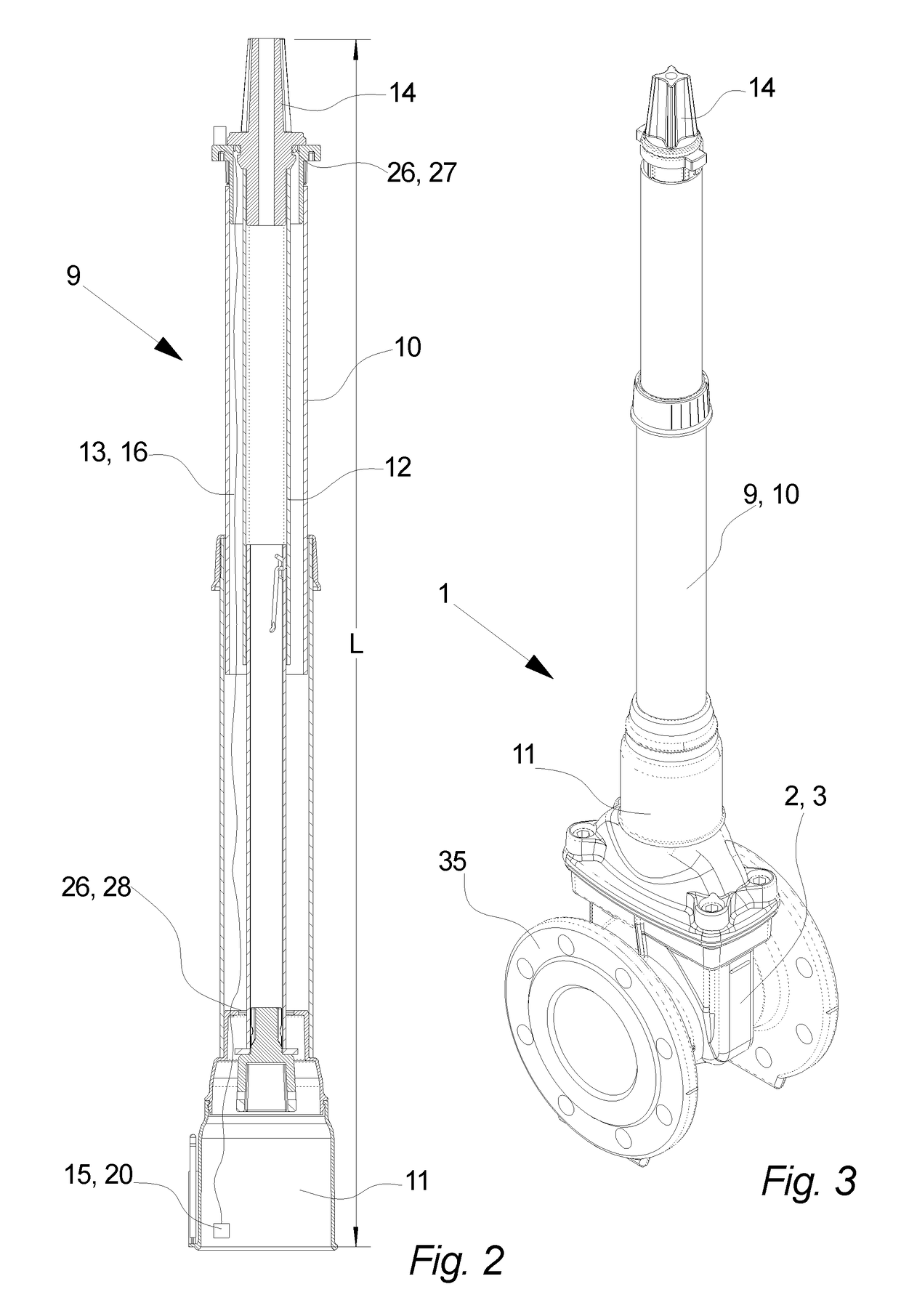

Valve arrangement, a method for identifying an underground valve of a valve arrangement and use of a use of valve arrangement

ActiveUS10451193B2Reliable wayIncrease the extension lengthValve arrangementsFire rescueFluid controlEngineering

Disclosed is a valve arrangement for underground control of a fluid flow and an associated method, the arrangement including a valve having a valve housing containing fluid control means for controlling a flow of fluid through pipe means arranged below the surface of the ground, where the fluid control means is actuated by means of mechanical manipulation of an operating device of the valve and the operating device is coupled to the fluid control means, the valve having valve identification means including data regarding the specific valve type, where the valve arrangement further includes an extension device including an extension device housing surrounding an extension rod, where the extension rod is rotatably supported by the extension device housing, where the extension rod is mechanically coupled to the operating device to enable the mechanical manipulation being performed at the ground surface, and the extension device further includes dedicated connection means extending between a valve end and a ground surface end of the extension device, and the valve end is arranged at the valve housing and the ground surface end is arranged at the opposite end of the extension device, where the dedicated connection means enable that the data regarding the specific valve type may be communicated to the ground surface.

Owner:AVK HLDG AS

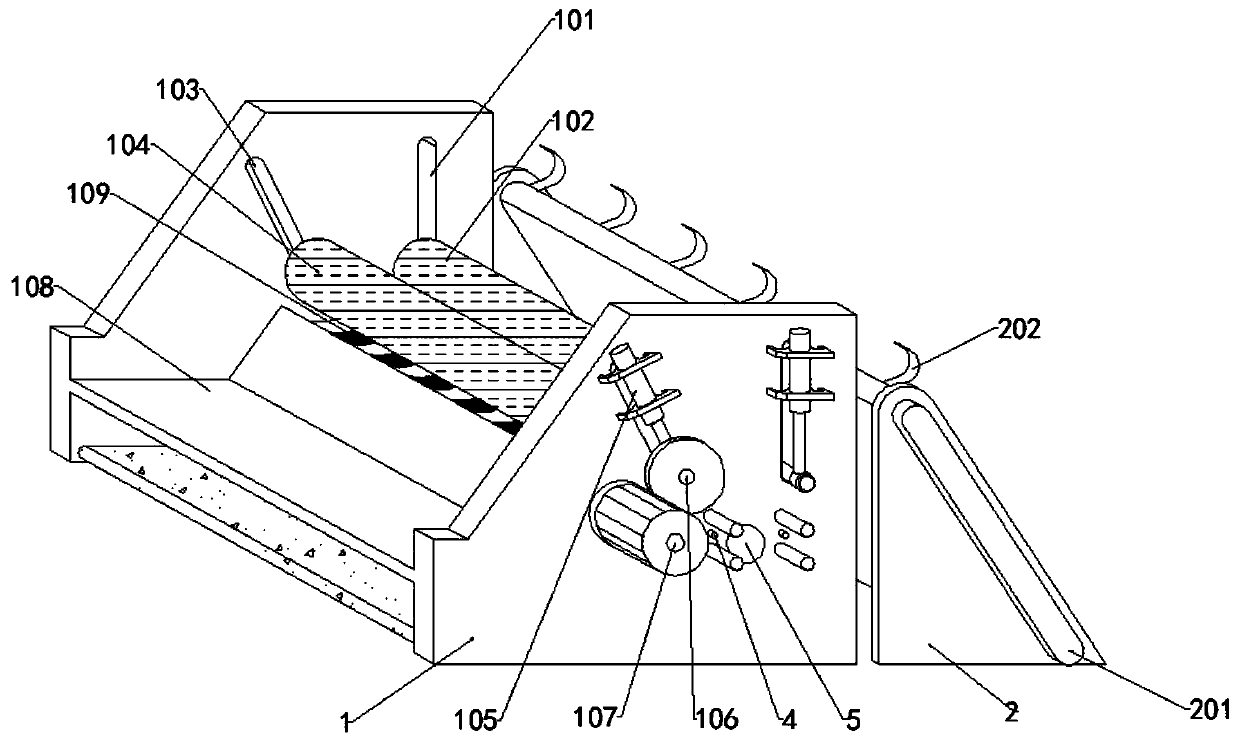

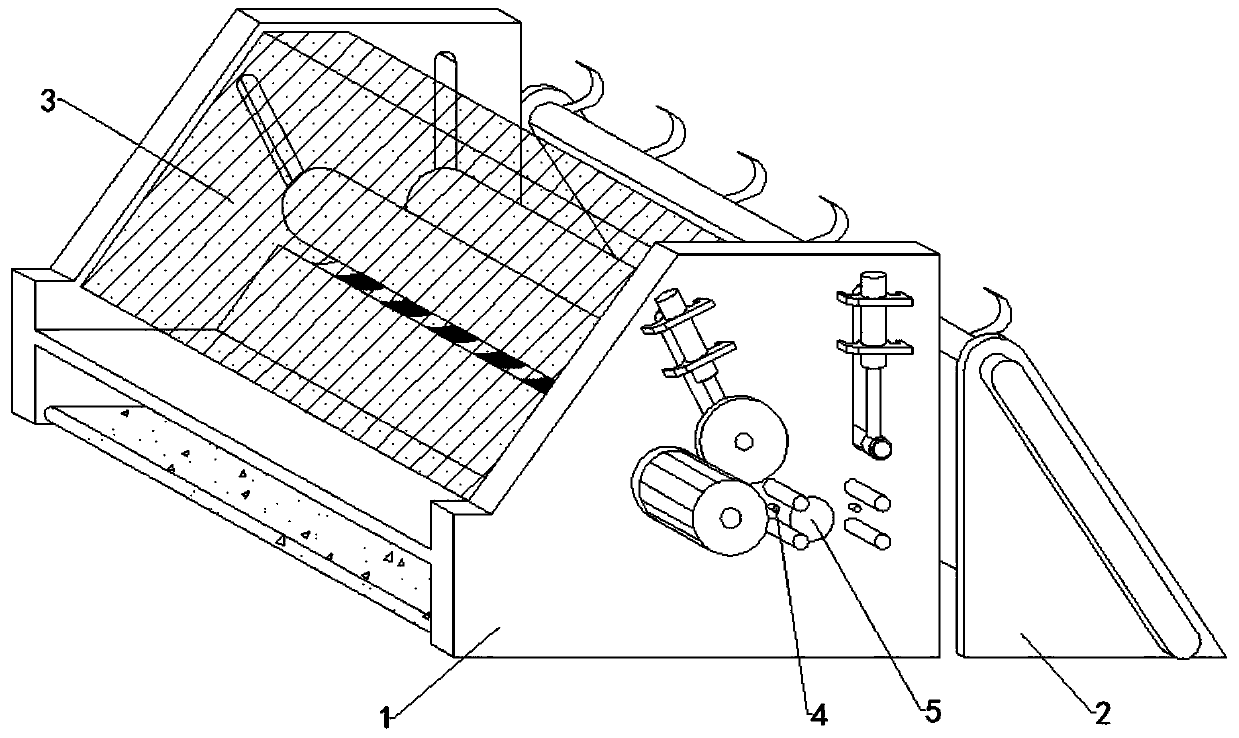

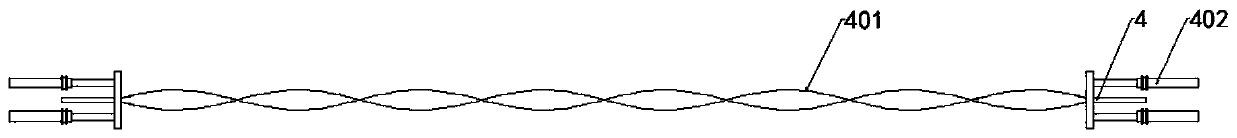

Multi-clamping-point type semi-automatic rounding device for log rounding machining

ActiveCN110216534AEfficient circle findingIncrease the angleRevolution surface grinding machinesGrinding drivesGlass coverSlag

The invention provides a multi-clamping-point type semi-automatic rounding device for log rounding machining, and belongs to the technical field of log machining. The device comprises a device shell,vertical sliding grooves, grinding rollers, inclined sliding grooves, second grinding rollers, hydraulic rods, gears, an electric motor, a guide-out plate, a slag outlet hole, a lifting support, a conveying belt, arc inverted hooks, a glass cover, an auxiliary grinding pile, a steel bar, a second hydraulic rod, a guide wheel, a telescopic support, an infrared generator and an infrared receiver. The vertical sliding grooves are embedded in the front and back surfaces of the right side of the device shell, the grinding rollers are rotatably connected into the vertical sliding grooves through bearings, the inclined sliding grooves are embedded on the front and back surfaces of the right side of the device shell, and are located on the right sides of the vertical sliding grooves, the second grinding rollers are rotatably connected to the inner side surfaces of the inclined sliding grooves through bearings, the hydraulic rods are fixedly connected to the outer side surfaces of the verticalsliding grooves and the inclined sliding grooves, and are located on the front and back sides of the device shell, and the gears are fixedly connected to the outer side surfaces of one sides of the second grinding rollers.

Owner:ZHEJIANG DAFENGFAN FURNITURE CO LTD

Mobile terminal

ActiveCN109981850AAvoid wrinklesGuaranteed to unfold flatTelephone set constructionsComputer terminalEngineering

Owner:VIVO MOBILE COMM CO LTD

Active control method for rockburst of hard-rock tunnel

The invention discloses an active control method for a rockburst of a hard-rock tunnel, relates to the technical field of stress of surrounding rock at rockburst release sections in underground construction, and aims to solve the problems that a conventional method for actively controlling rockburst through blasting can judge neither the accurate position or the range of a high in-situ stress region nor the accurate position of a surrounding rock structural face, is poor in blasting accuracy and low in efficiency, and cannot guarantee the construction safety. The adopted technical scheme is that by use of tunnel advanced geological prediction, construction prestress release blastholes, borehole TVs, surrounding rock structural face tandem delayed presplitting blasting and in-hole high-pressure water injection, the opening degree of the surrounding rock structural face is increased by targeted comprehensive application of the method according to the characteristics of the tunnel surrounding rock structural face; meanwhile, the extension length of the structural face is increased, and the integrity degree of surrounding rock is reduced, so that the high ground stress of surrounding rock is released, the rockburst energy is reduced or eliminated, the rockburst prevention accuracy and efficiency are improved, and the construction safety is ensured.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

A valve arrangement, a method for identifying an underground valve of a valve arrangement and use of a use of valve arrangement

ActiveUS20170307103A1Reliable wayIncrease the extension lengthValve arrangementsFire rescueFluid controlEngineering

Disclosed is a valve arrangement for underground control of a fluid flow and an associated method, the arrangement including a valve having a valve housing containing fluid control means for controlling a flow of fluid through pipe means arranged below the surface of the ground, where the fluid control means is actuated by means of mechanical manipulation of an operating device of the valve and the operating device is coupled to the fluid control means, the valve having valve identification means including data regarding the specific valve type, where the valve arrangement further includes an extension device including an extension device housing surrounding an extension rod, where the extension rod is rotatably supported by the extension device housing, where the extension rod is mechanically coupled to the operating device to enable the mechanical manipulation being performed at the ground surface, and the extension device further includes dedicated connection means extending between a valve end and a ground surface end of the extension device, and the valve end is arranged at the valve housing and the ground surface end is arranged at the opposite end of the extension device, where the dedicated connection means enable that the data regarding the specific valve type may be communicated to the ground surface.

Owner:AVK HLDG AS

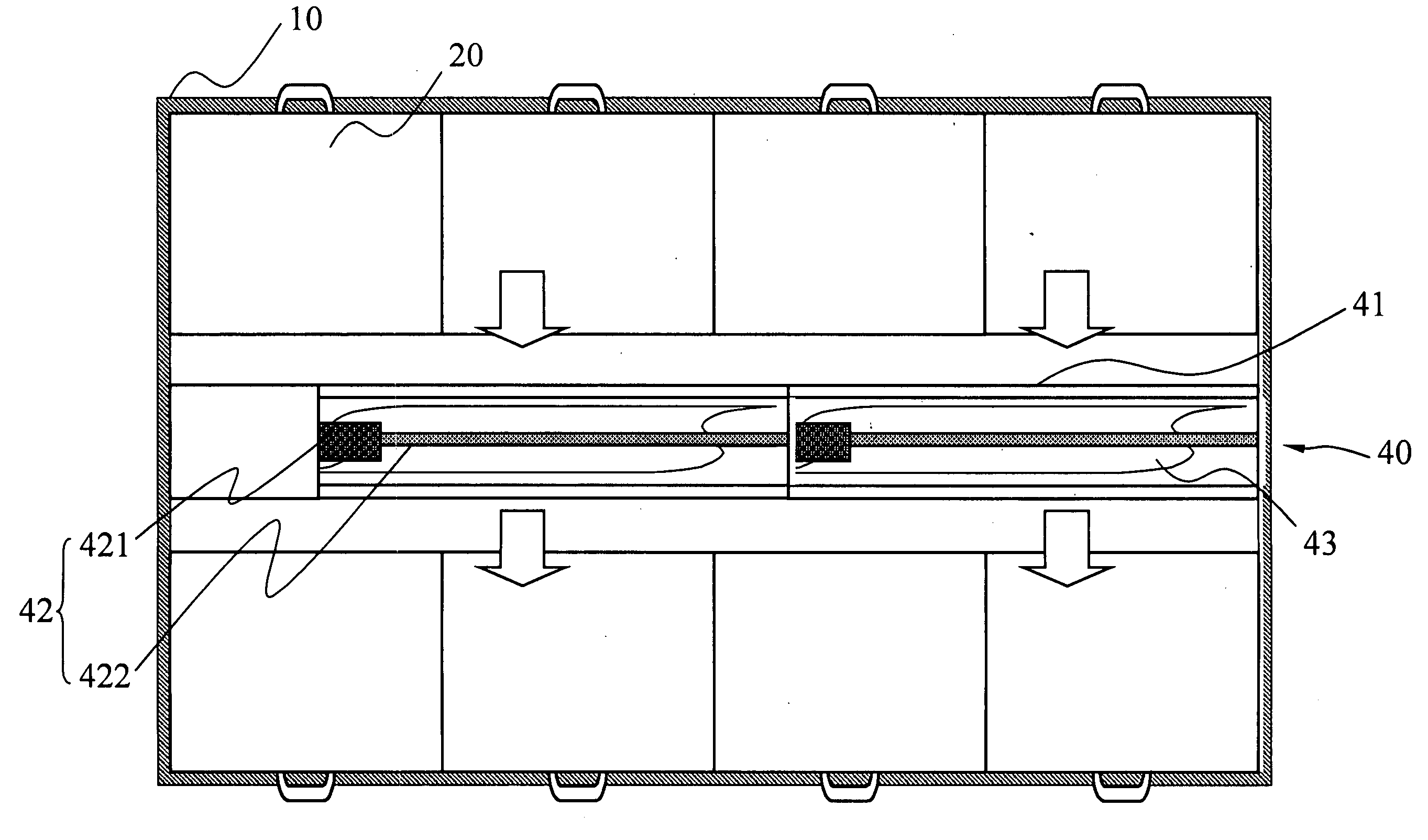

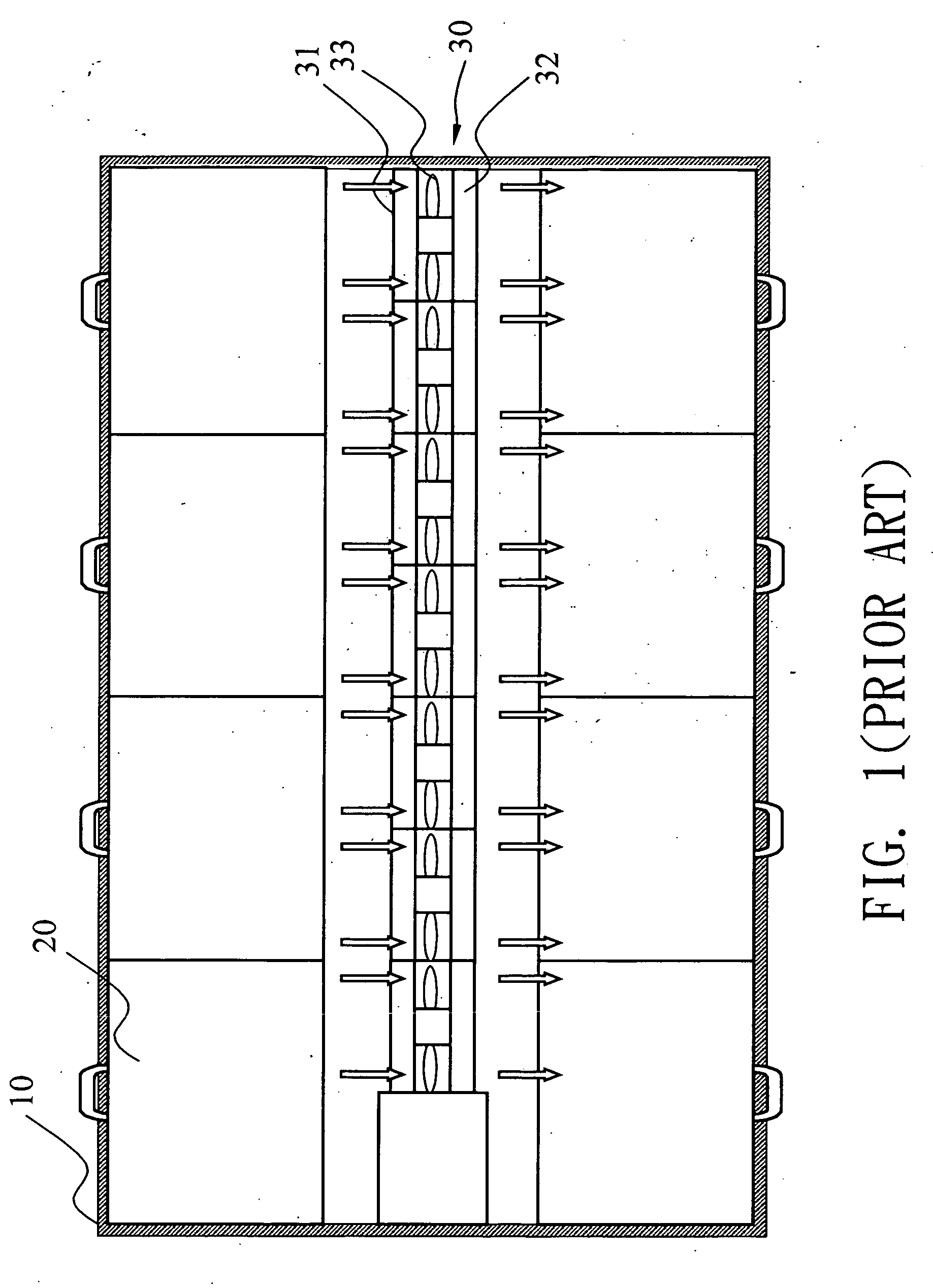

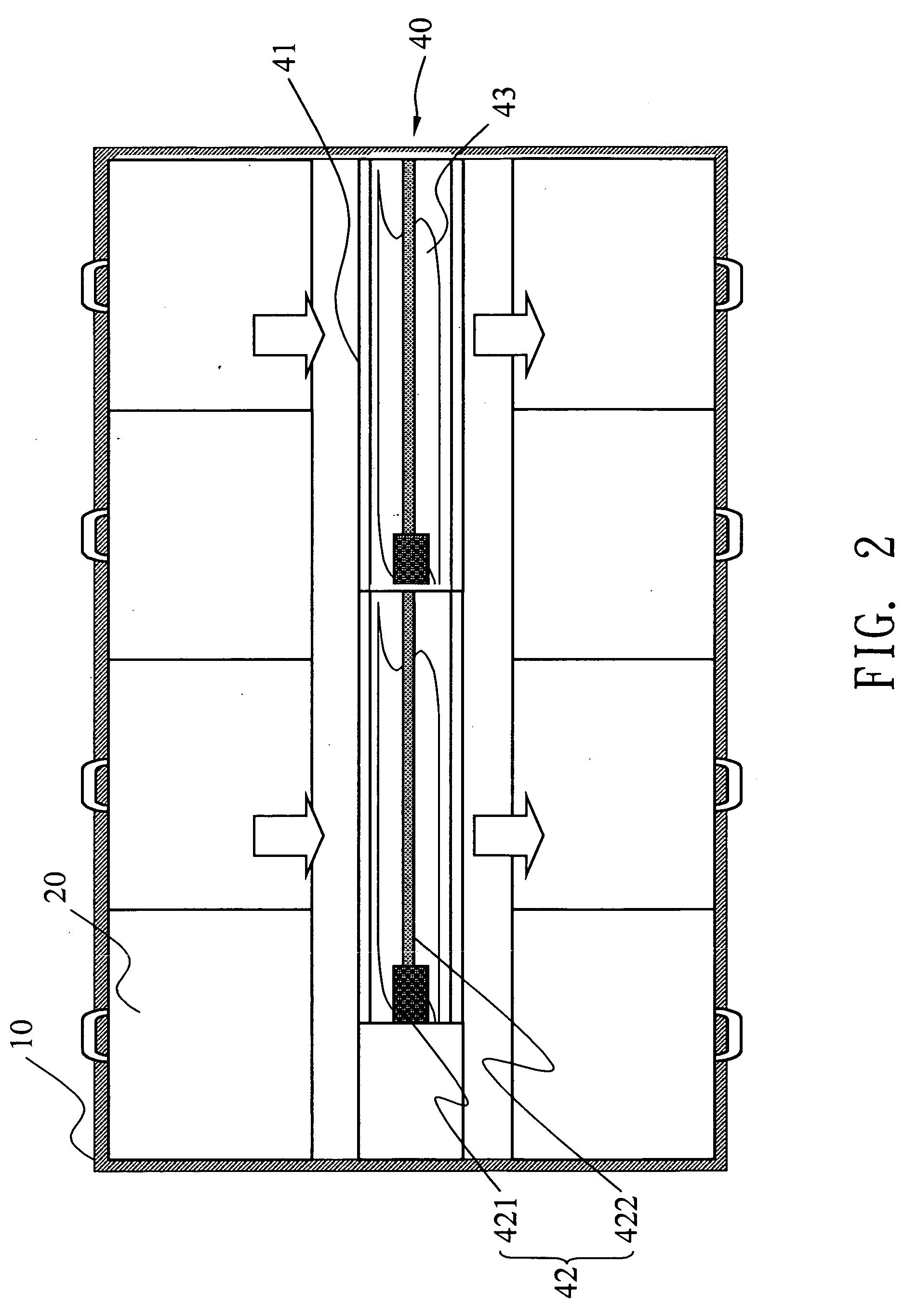

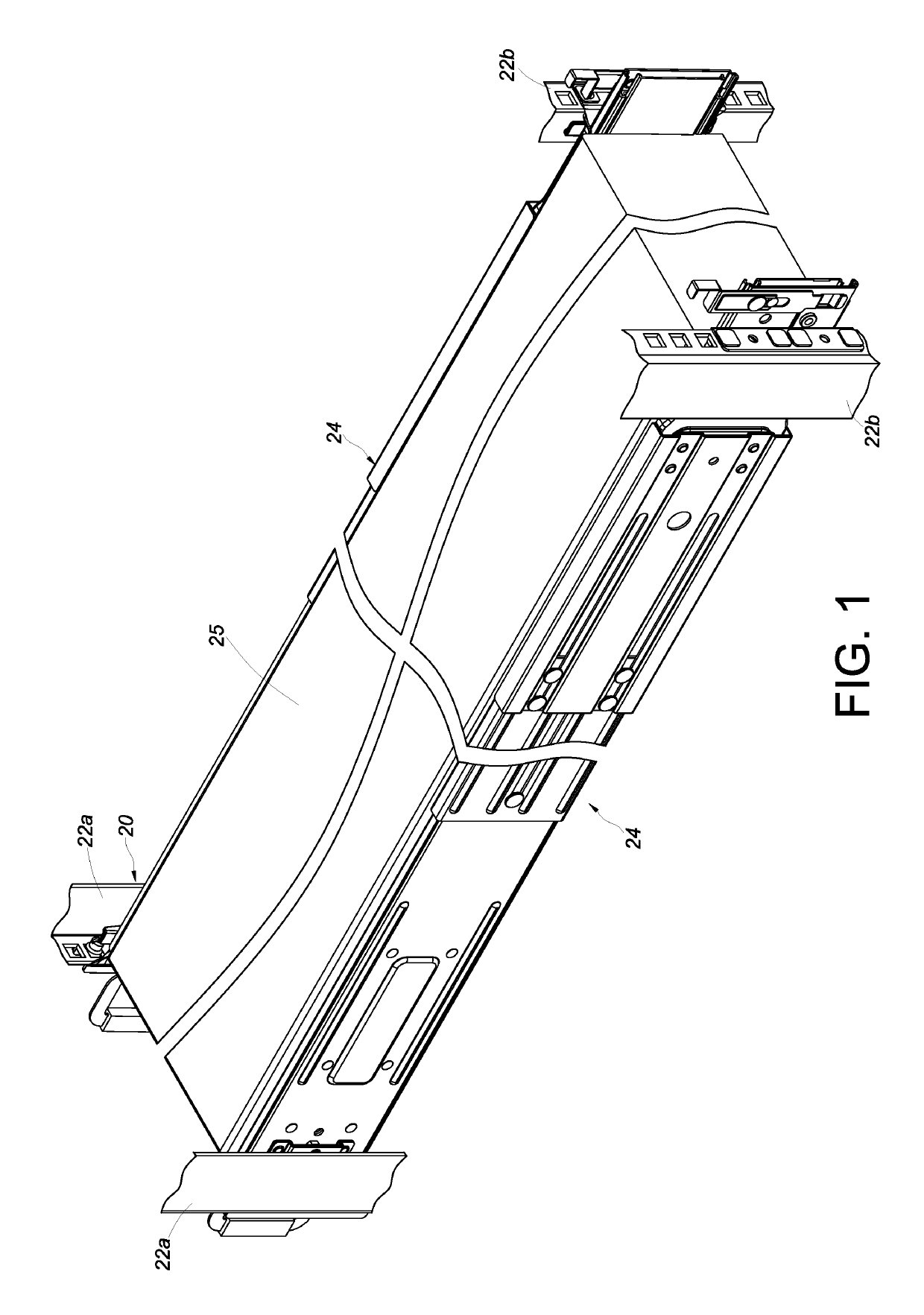

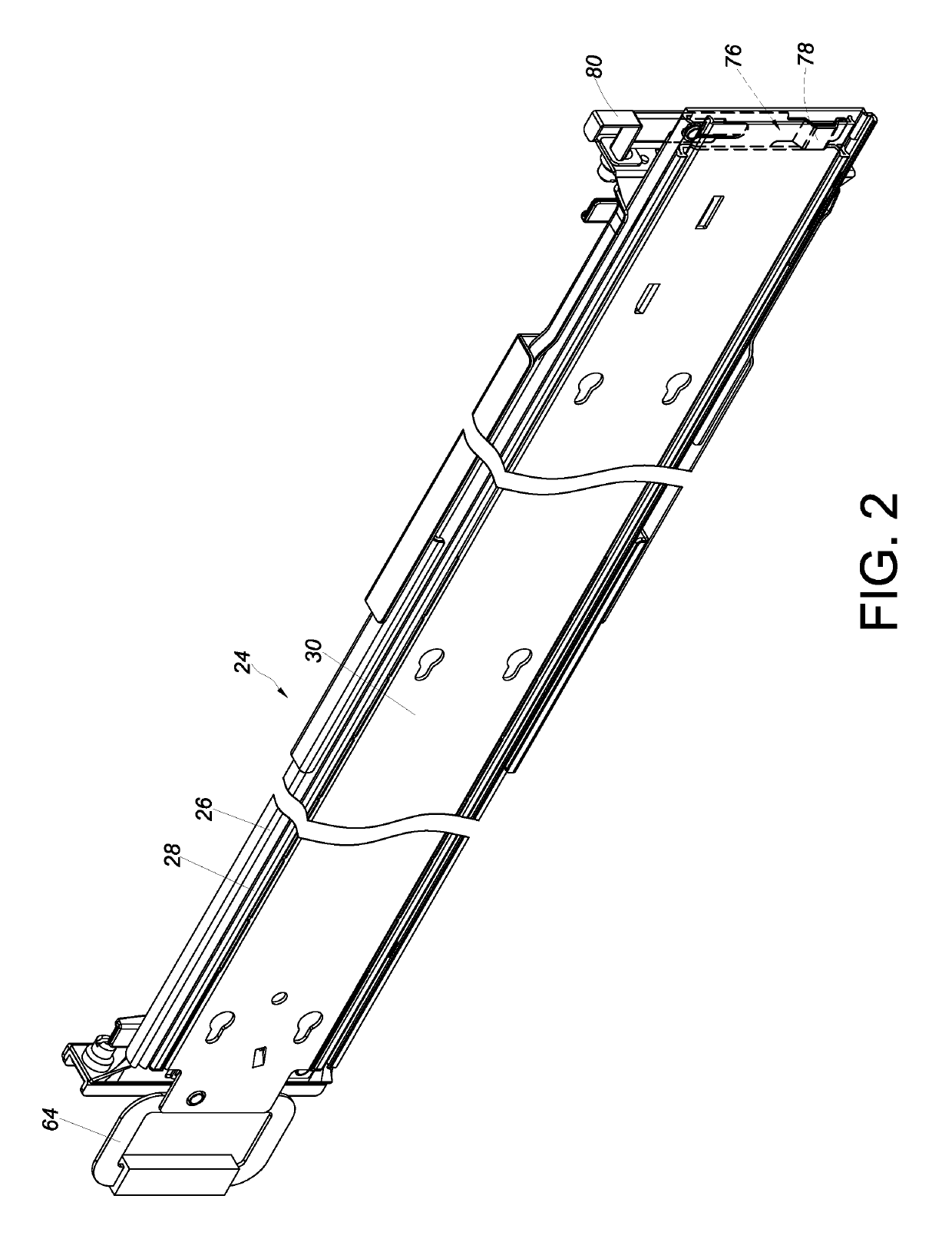

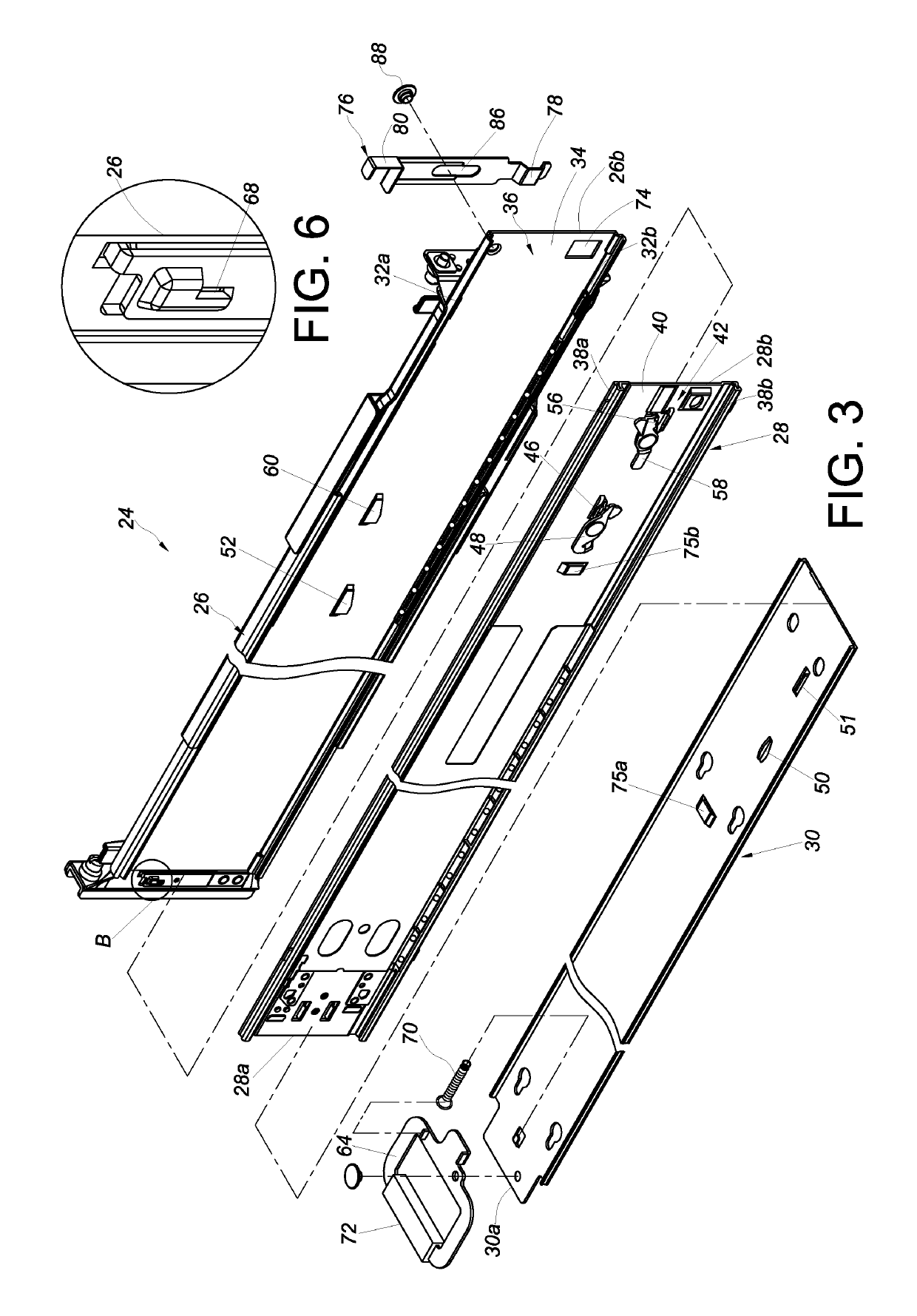

Slide rail assembly and rack system

A slide rail assembly includes a first rail, a second rail, and a blocking member. The blocking member is arranged adjacent to the rear end of the first rail and can be operated so as to enter or exit a blocking state. The blocking member in the blocking state serves to block the rear end of the second rail. When the blocking member is not in the blocking state, and the second rail reaches a rearwardly extended position after displacement with respect to the first rail, the rear end of the second rail extends beyond the rear end of the first rail.

Owner:KING SLIDE WORKS CO LTD +1

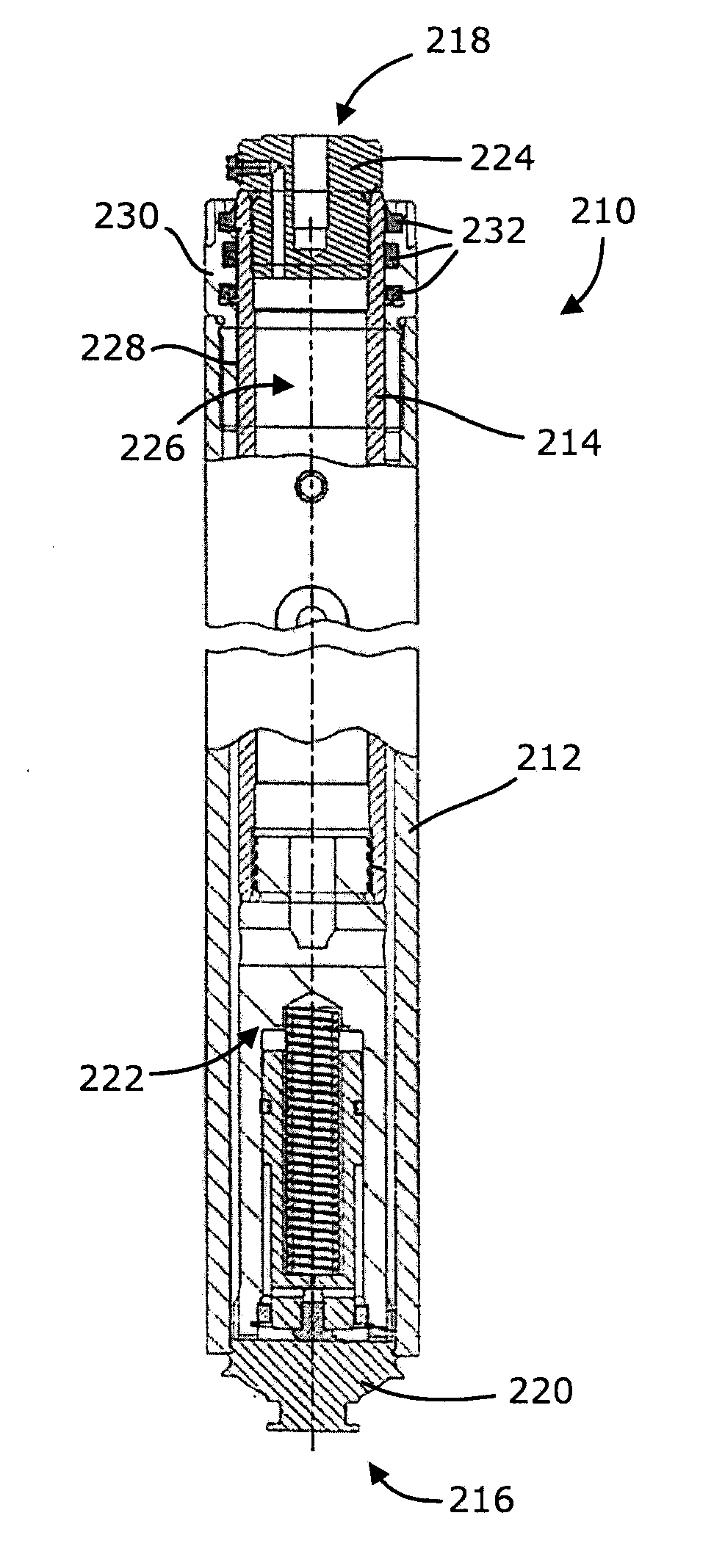

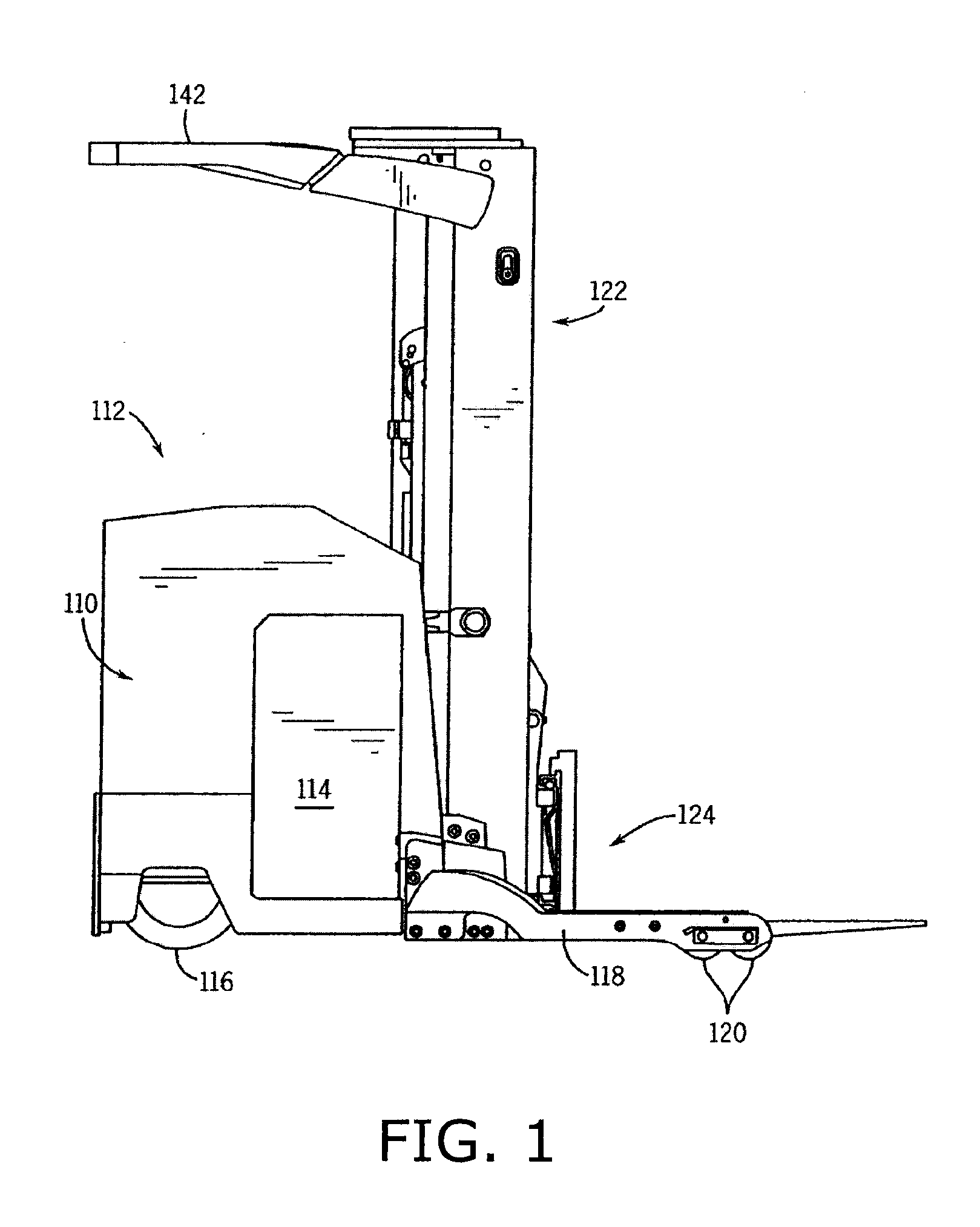

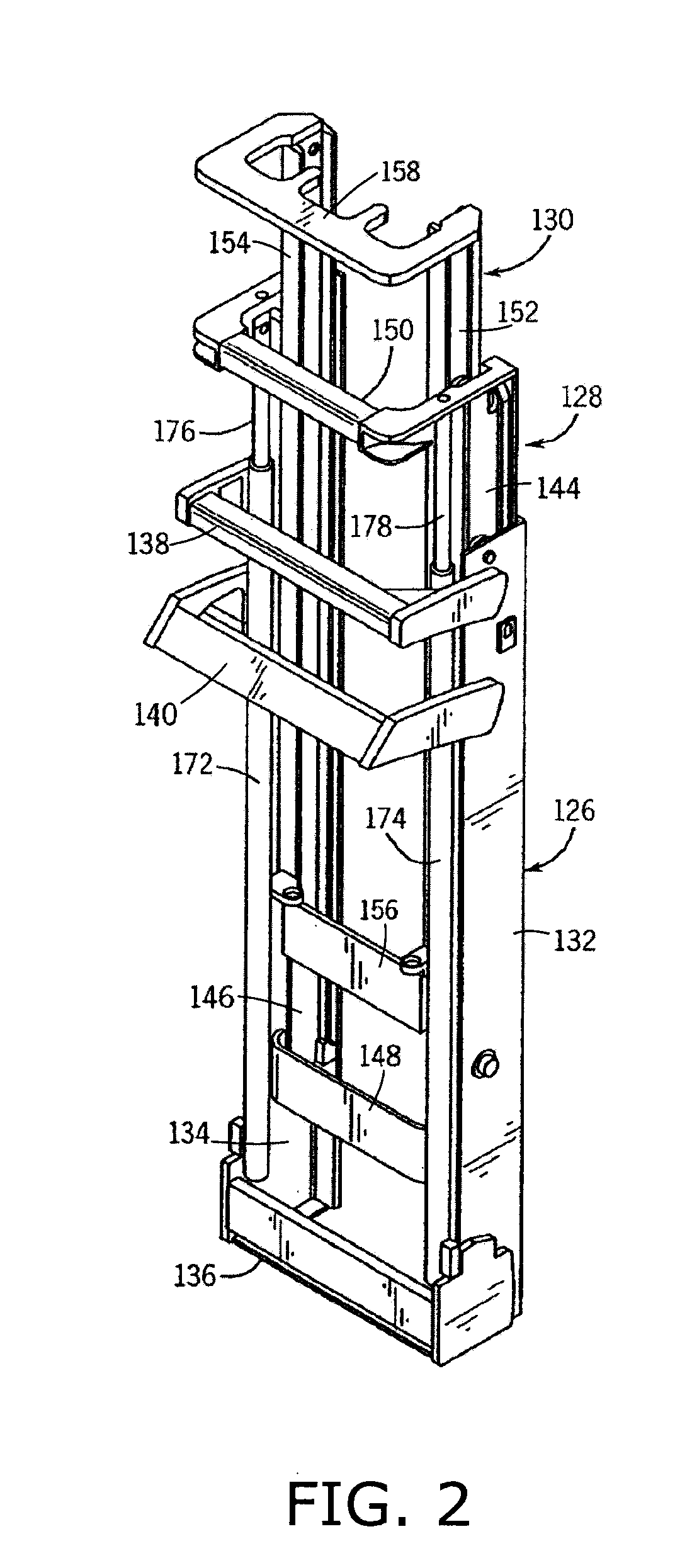

Buckling-Resistant Lift Cylinders

InactiveUS20140262626A1Increased buckling strengthIncrease the extension lengthLifting devicesFluid-pressure actuatorsEngineeringMechanical engineering

A lift cylinder for a mast assembly of a vehicle and a vehicle implementing the same. The lift cylinder includes a cylinder housing with a piston received therein. The piston is movable along an axis of extension between an extended position and a retracted position. The piston is formed of a composite material having a reinforcement phase oriented along the axis of extension of the piston, thereby increasing the buckling resistance of the piston. This improved buckling resistance potential allows for increased lift cylinder extension and / or more compact lift cylinder design.

Owner:RAYMOND LTD

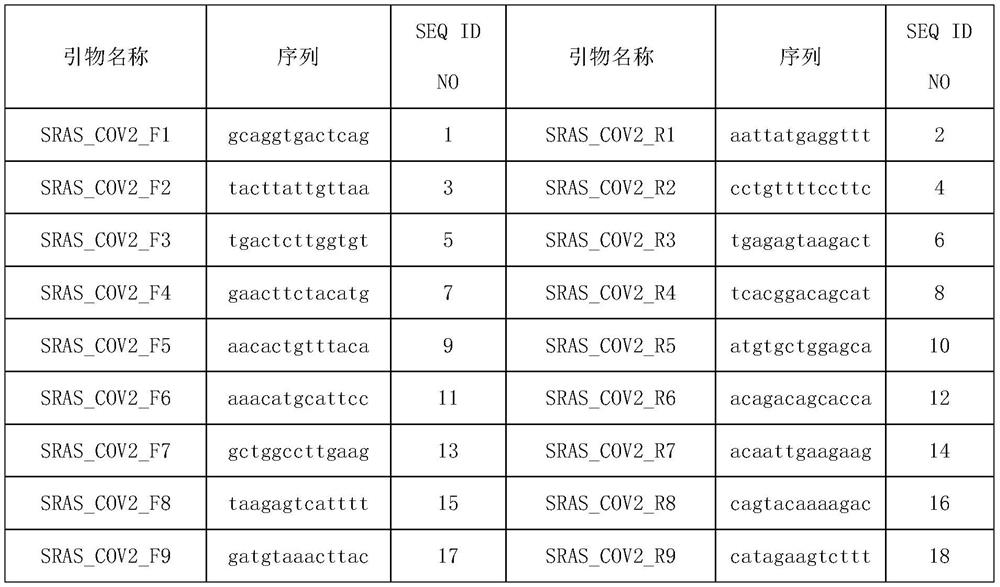

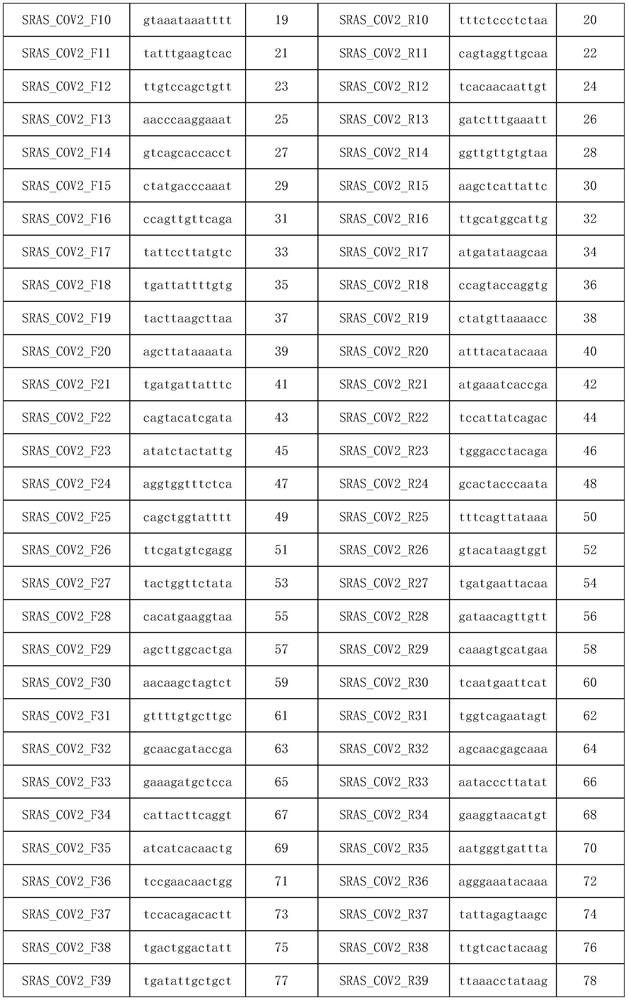

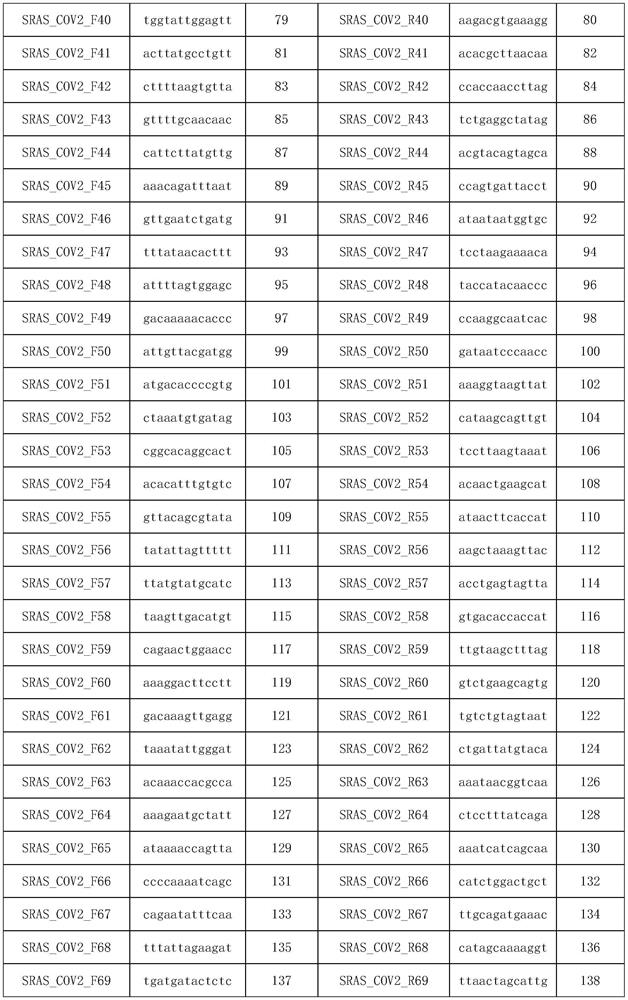

Method for detecting COVID-19 based on mNGS and application of method

ActiveCN113337639AImprove reverse transcription efficiencyLow pollution rateMicrobiological testing/measurementLibrary creationNucleotideVariant virus

The invention provides a method for detecting COVID-19 based on mNGS and application of the method. According to the method, a multiple genome specific reverse transcription primer group of COVID-19 is designed and prepared, so that the reverse transcription efficiency of RNA of COVID-19 is improved, the aerosol pollution problem is reduced, and meanwhile, the enrichment capacity of different variant virus nucleotide sequences is improved.

Owner:天津金匙医学科技有限公司

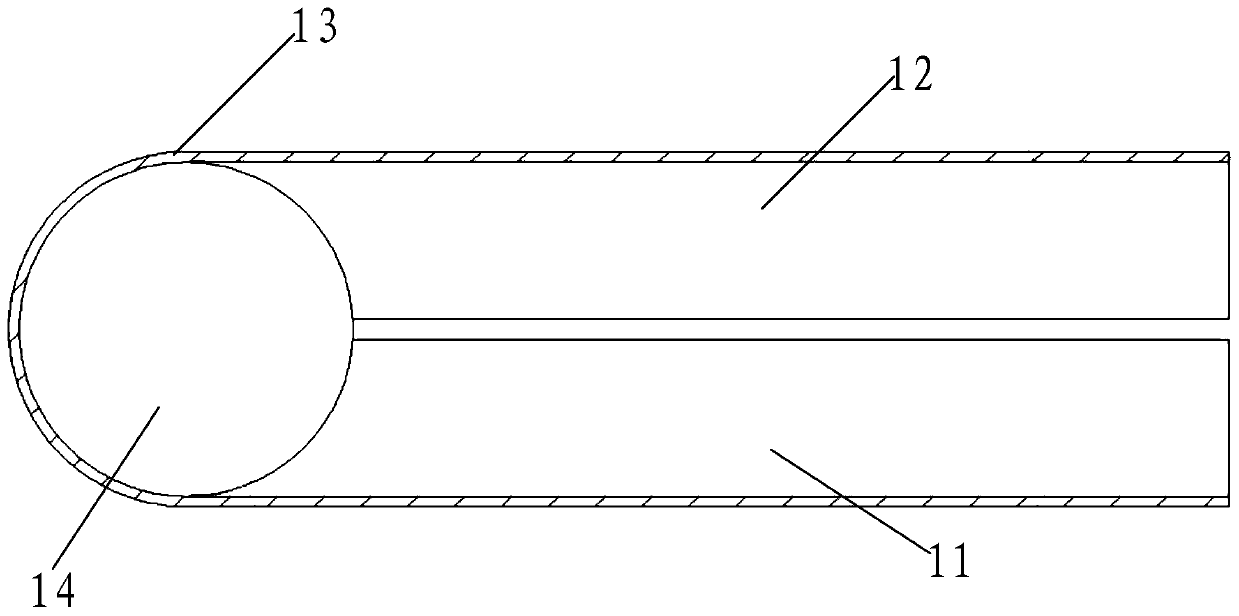

Safety handrail

The invention discloses a safety handrail. The safety handrail comprises a handrail tube and mounting bases arranged at the left end and the right end of the handrail tube. The handrail tube comprises an inner tube and a protecting case wrapping the inner tube. Each mounting base comprises a fixing disk and a connecting tube connected with the handrail tube. Each connecting tube is provided with a protecting cover in a penetrating mode, and the protecting cover is connected with the corresponding fixing disk in a clamped mode. The two ends of the inner tube are each internally provided with a connecting column with an internal thread. Reinforcing ribs are connected between the periphery of each fixing column and the inner surface of the corresponding connecting tube. A threaded rod extending out of the corresponding connecting tube is mounted in the fixing column of the connecting tube. The extension part of each threaded rod is provided with an external thread matched with the corresponding internal thread. The inner surface of the end of the left connecting tube is provided with an annular limiting flange which is provided with at least one boss extending in the radial direction. The outer diameter of the left end of the protecting case is matched with the inner diameter of the left connecting tube. The left end of the protecting case is provided with a clamping groove matched with the corresponding boss. The outer diameter of the protecting case is equal to the outer diameter of the left connecting tube and the outer diameter of the right connecting tube.

Owner:CHONGQING QINGZHIDU BUILDING MATERIAL CO LTD

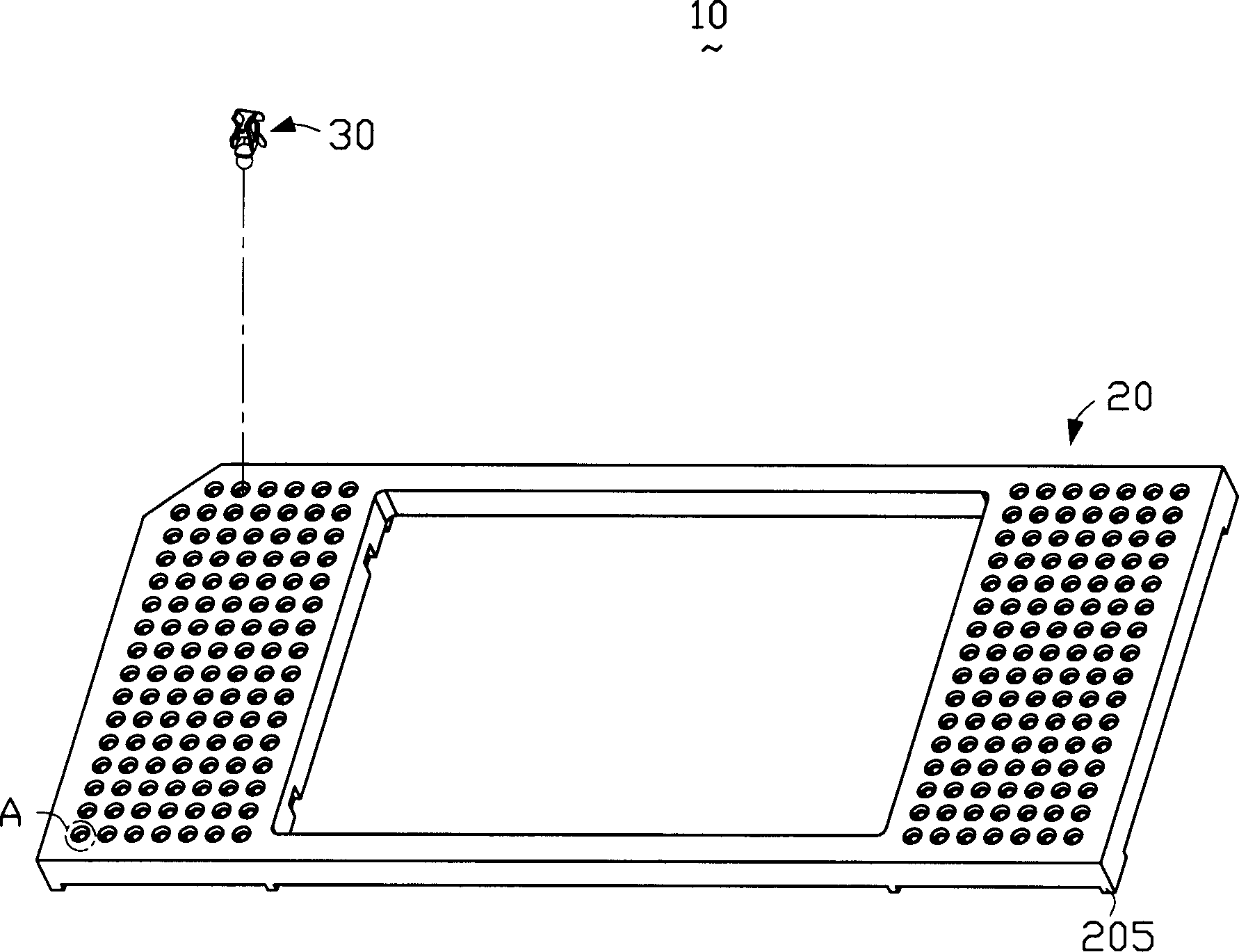

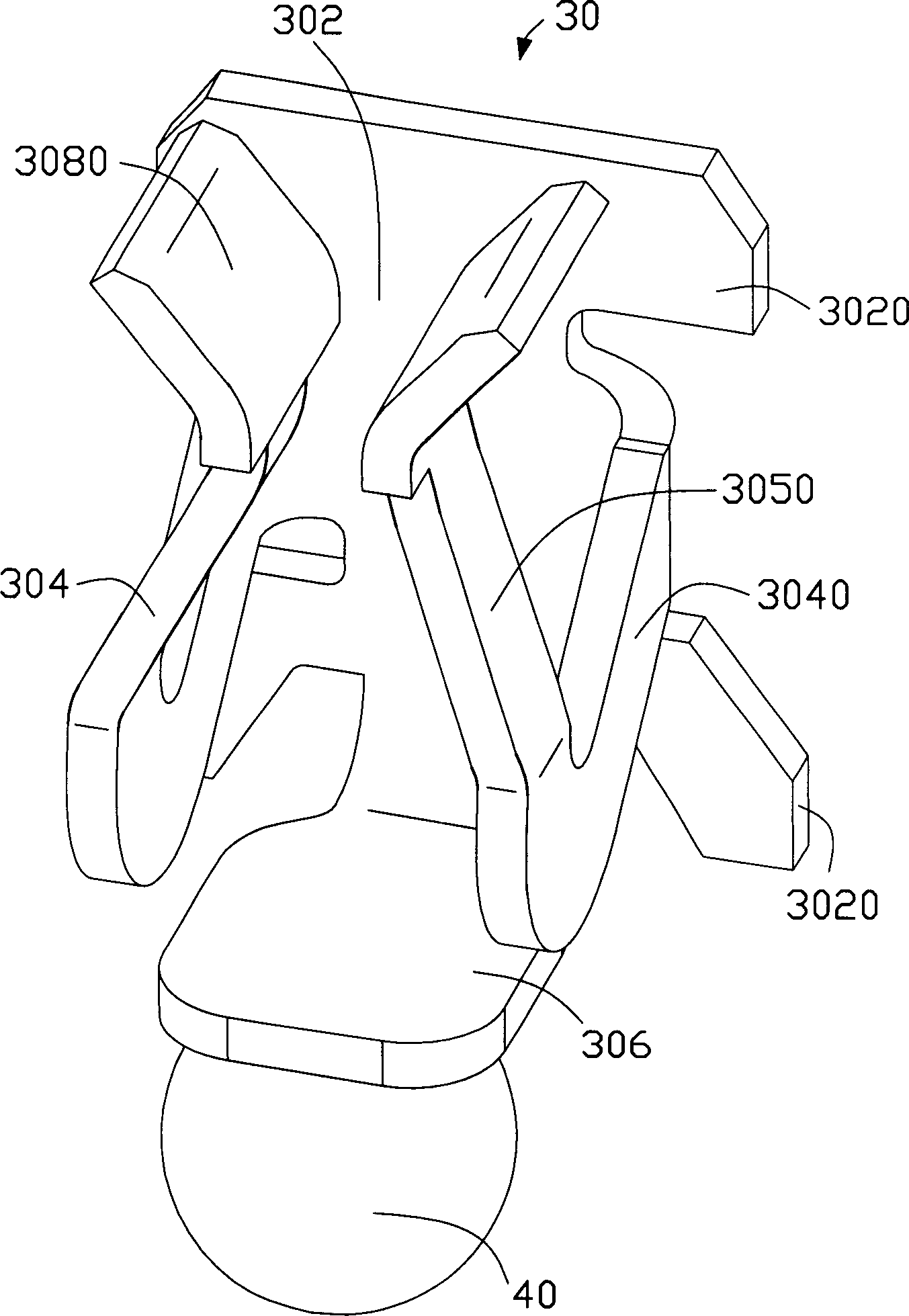

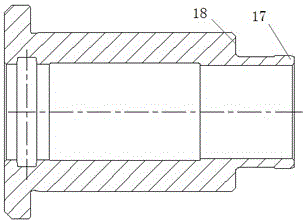

Low insertion force type socket connector

ActiveCN1877916AIncrease the extension lengthIncrease elasticityLine/current collector detailsCoupling device detailsLow insertion forceEngineering

The invention discloses a low-insert force socket connector to connect chip module and print circuit board electrically, which consists of insulating bulk and several conductive terminals in the insulating bulk, wherein the support plane and assembling plane corresponding to support plane are set on the insulating bulk with several terminal containing grooves through support plane and assembling plane; the guide groove is set on and through the terminal containing groove; the conductive terminal is placed in the terminal containing groove, which contains base part, a couple of arm part from two bending extending sides of base part, contact part with smooth arc and level welding part at the bottom of base part; the smooth arc can correct deflection in the inserting course of positive chip module pin.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

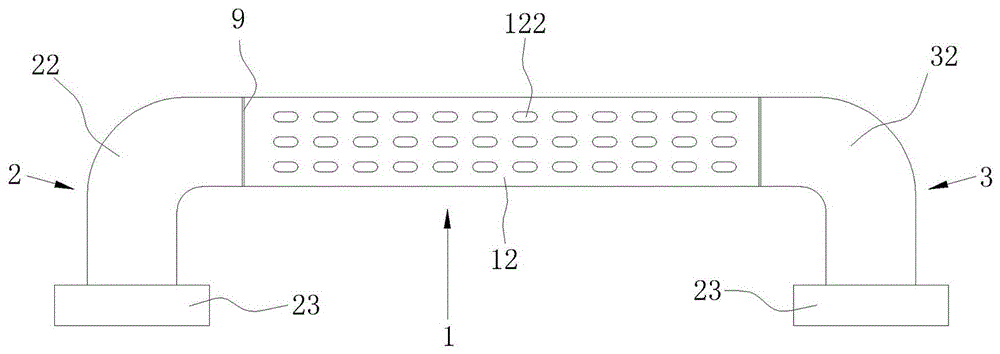

A kind of downhole hydraulic pulse fracturing seepage increasing device and method

ActiveCN104929605BReduce frequencyReduce displacementFluid removalWell/borehole valve arrangementsFluid controlPulse energy

The invention discloses a down-hole hydraulic power pulse staged fracturing permeability-increasing device and method. The device comprises a down-hole pulse fracturing device, a controllable hydraulic packer, a continuous oil pipe, a fluid control valve and a fracturing truck. The fracturing truck is connected with the controllable hydraulic packer and the down-hole pulse fracturing device through the continuous oil pipe. The controllable hydraulic packer is connected to the back end of the down-hole pulse fracturing device. The fluid control valve is arranged at the connecting opening of the continuous oil pipe. The down-hole pulse fracturing device comprises a first cylinder body, a second cylinder body, a mandrel, a sliding sleeve, a sealing ring, a spring, a nozzle and the like. Under the condition that certain construction parameters such as pumping pressure and displacement are provided for the ground fracturing truck, large-displacement low-frequency pulse fluid is generated at the shaft bottom and is injected in, and a water hammer effect is formed. The down-hole hydraulic power pulse staged fracturing permeability-increasing device is simple in structure, durable and easy to adjust, low-frequency large-displacement pulse energy can be generated, the construction technology is simple, pulse energy can be well used for breaking rocks, net-shaped complex cracks with wide extending ranges are generated, and reservoir stratum permeability is effectively improved.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

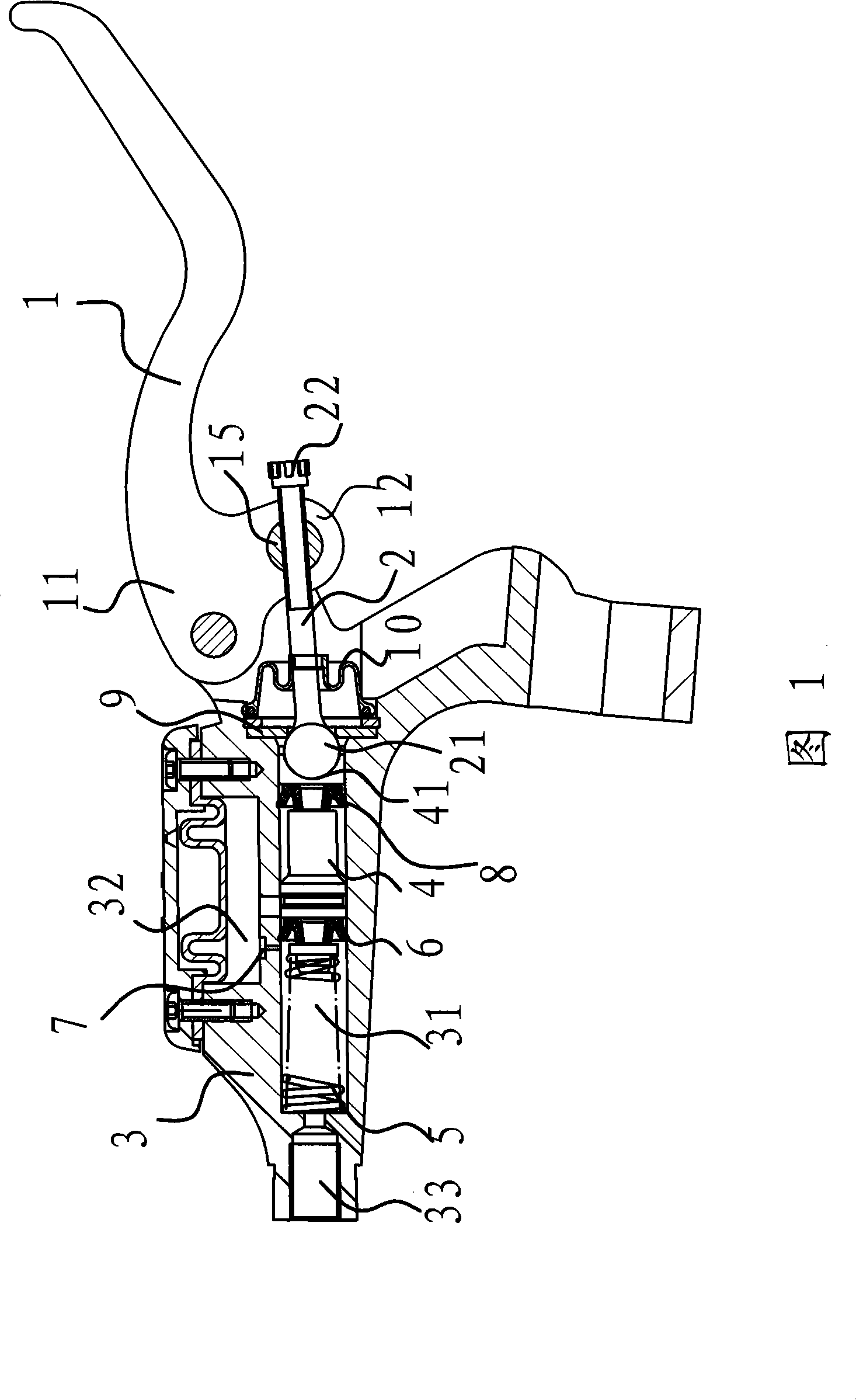

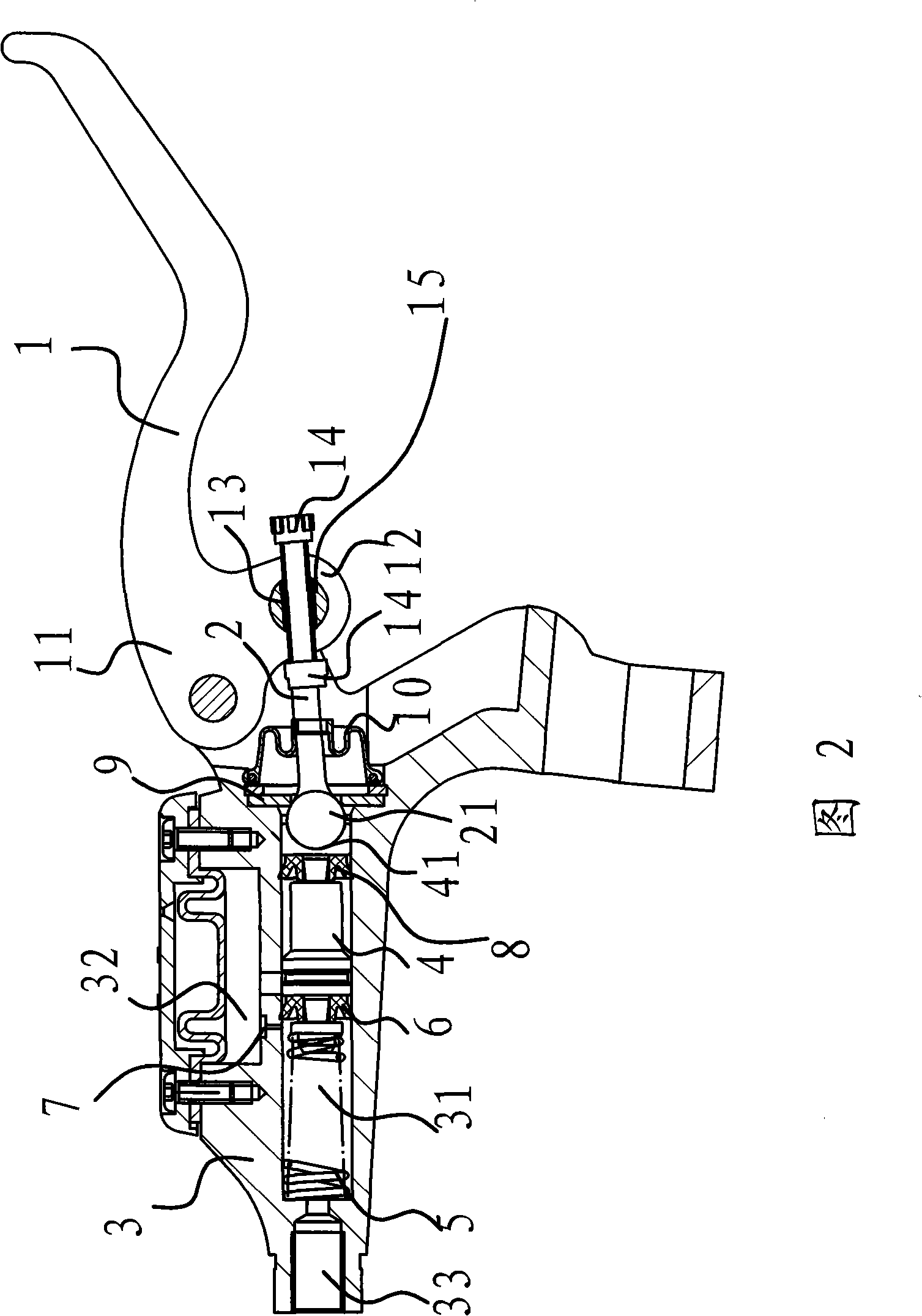

Adjusting mechanism for brake handle

InactiveCN101259867AIncrease the extension lengthLarge adjustment rangeCycle control systemsCycle brakesEngineeringMechanical engineering

The invention provides a regulating mechanism for brake handle, which belongs to the technical field of the machinery. The regulating mechanism solves the problem that the phenomenon of deadlocking occurs if the regulative distance between the rear part and front part of the handle of the regulating mechanism of the prior brake handle is too large. The regulating mechanism of the brake handle is arranged between a hydraulic brake pump and a brake handle and the hydraulic brake pump comprises a pump body and a piston arranged inside the pump body; the brake handle is hinged with the pump body and a connecting rod is arranged between the piston and the brake handle; one end of the connecting rod is connected with the external end of the piston in a rotary way and the other end of the connecting rod passes through the brake handle and can relatively move with the brake handle; a positioning structure which can regulate the position of the brake handle is arranged between the connecting rod and the brake handle. The regulating mechanism of the brake handle has simple structure, big regulative distance of the brake handle and has no effect on the idle stroke of the piston.

Owner:YUHUAN KAILING MASCH GRP CO LTD

Alternate injection of high and low temperature fluids in deep dry hot rocks to assist hydraulic fracturing to create fractures

ActiveCN108979609BObvious lithofacies structureStrong thermal stressFluid removalThermodynamicsFracturing fluid

The invention provides a method of forming fractures by means of hydrofracturing assisted by alternate spraying of high- and low-temperature fluids in deep hot dry rock. The method herein includes: setting out a well network, and performing primary hydrofracturing to form main fractures; injecting a high-temperature high-pressure fluid and low-temperature water alternately into the main fractureswithin short alternate time; forming micro fractures in the rock at the surface of the main fractures under the thermodynamic action of a great temperature difference and the impact action of a jet; allowing multilevel fracturing to enable the micro fractures to further expand and form more micro fractures under the action of a low-temperature waterborne fracturing fluid and the action of high pressure; repeating until the main fractures and the micro fractures are in mutual lap joint and communication so that a fracture cluster and / or a fracture belt is formed between injection wells and production wells; injecting a sand-carrying fluid, a proppant and a displacing fluid, and closing the wells to complete fracture forming so as to construct an efficient heat exchange reservoir. The methodenables the quantity of the fractures to be significantly increased via the thermal stress action of the temperature difference, so that a fracture network is formed; heat exchange efficiency of a heat storage space is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

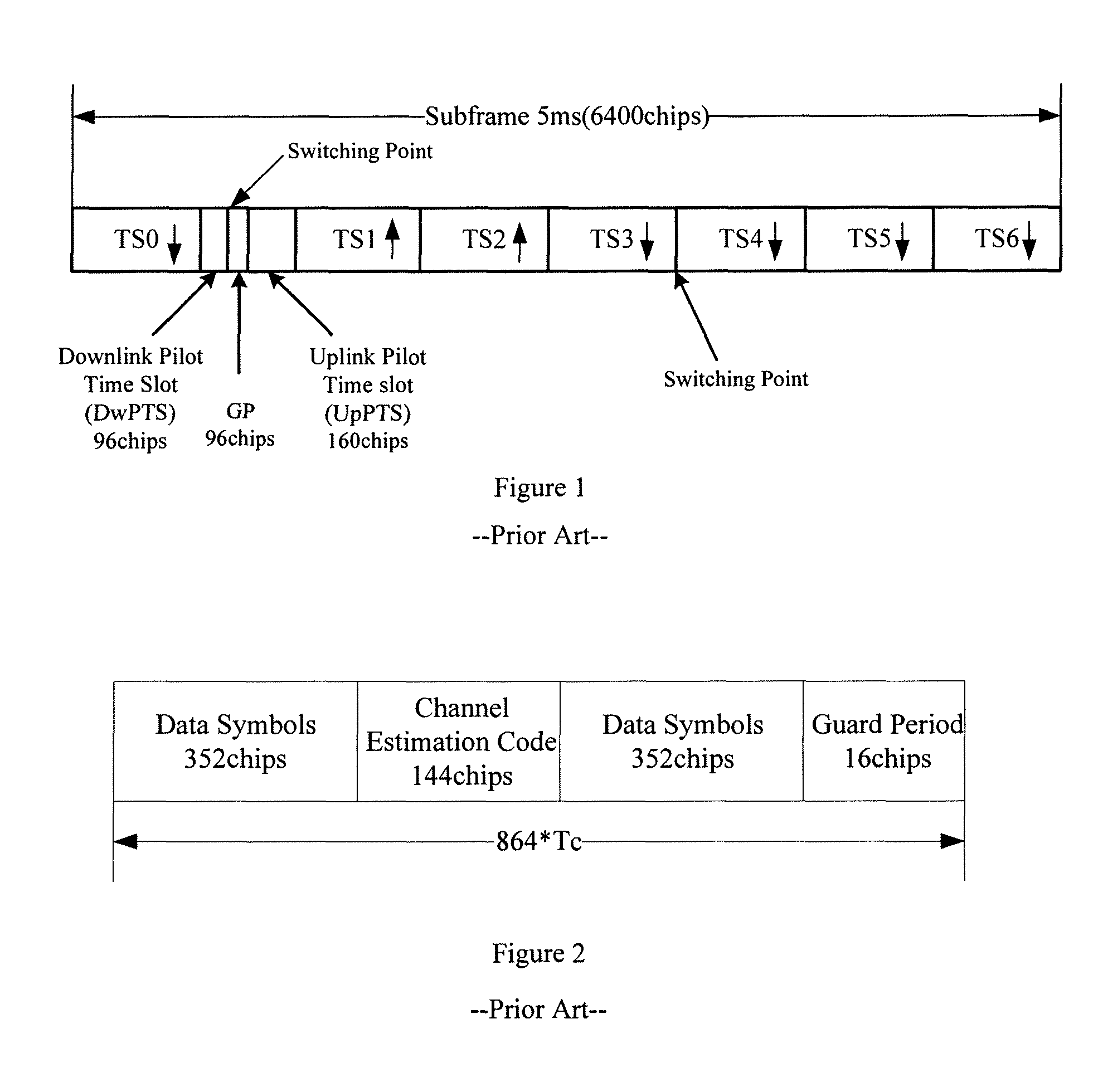

Method and system for transmitting a broadcast/multicast service

ActiveUS8064426B2Improve transmission efficiencyReduce distractionsSite diversityError preventionBroadcastingDiversity combining

The present application discloses a method and system for transmitting a Broadcast / Multicast Service (MBMS), which is used for solving the problem that macro cell coverage of the MBMS and macro diversity combining of multi-cells cannot be implemented efficiently based on a frame structure of the existing Time Division-Synchronous Code Division Multiple Access (TD-SCDMA) system in prior art. The method includes: mapping a channel estimation code and data symbols of a Broadcast / Multicast Service to a resource unit, wherein the channel estimation code is mapped in front of the data symbols in a signal frame at a time slot for all services or a time slot for the MBMS; and transmitting the resource unit. Using the present application, efficiency and performance of transmitting a MBMS are improved, and the multi-cells combining of the MBMS and deployment of the MBMS with a macro cell mechanism are implemented efficiently.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Double-eccentricity all-metal seal butterfly valve

A double-eccentricity all-metal seal butterfly valve comprises a valve body, a valve plate, a valve shaft, a disc spring type metal valve seat, an O-shaped elastic metal ring and a gland. The valve body and the valve plate are arranged in an eccentric manner, the disc spring type metal valve seat is fixed to the valve body through the gland, and the O-shaped elastic metal ring is arranged between the disc spring type metal valve seat and the valve body. The disc spring type metal valve seat is adopted in the double-eccentricity all-metal seal butterfly valve, the extending length within unit size is increased, so that elastic deformation of the valve seat during work is increased, and plastic deformation of the valve seat is reduced. Meanwhile when the valve works in the reverse direction, the O-shaped elastic metal ring can absorb part of deformation of the valve seat caused by medium pressure, so that the service life of the valve is greatly prolonged.

Owner:NINGJIN MEIHUA IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com