Method of forming fractures by means of hydrofracturing assisted by alternate spraying of high- and low-temperature fluids in deep hot dry rock

A hot dry rock, high and low temperature technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of inability to penetrate deep into the thermal reservoir, chemical stimulation and rapid reaction speed of rock mass minerals, etc. Achieve significant heat transfer efficiency, strong thermal stress, large permeation area and heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

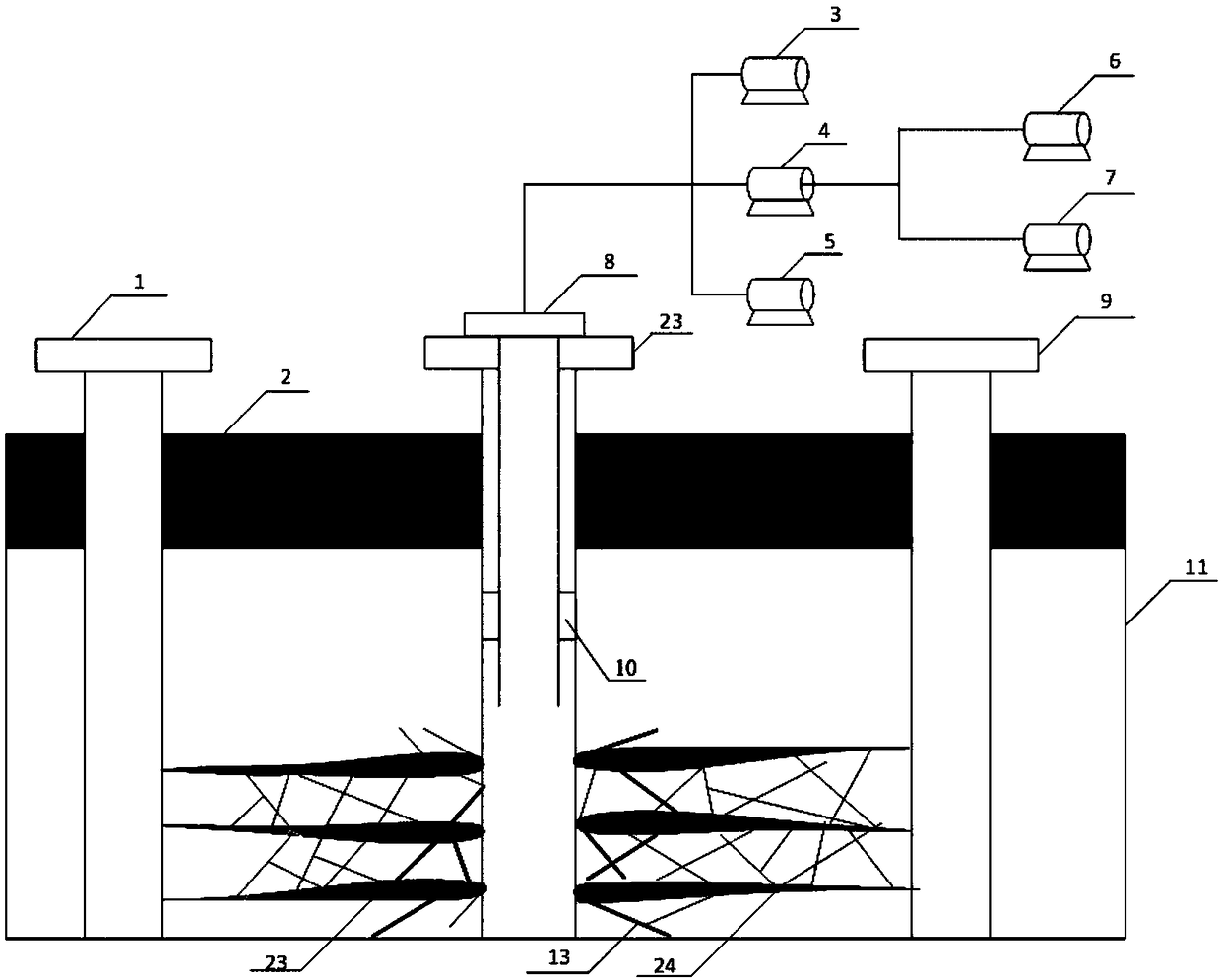

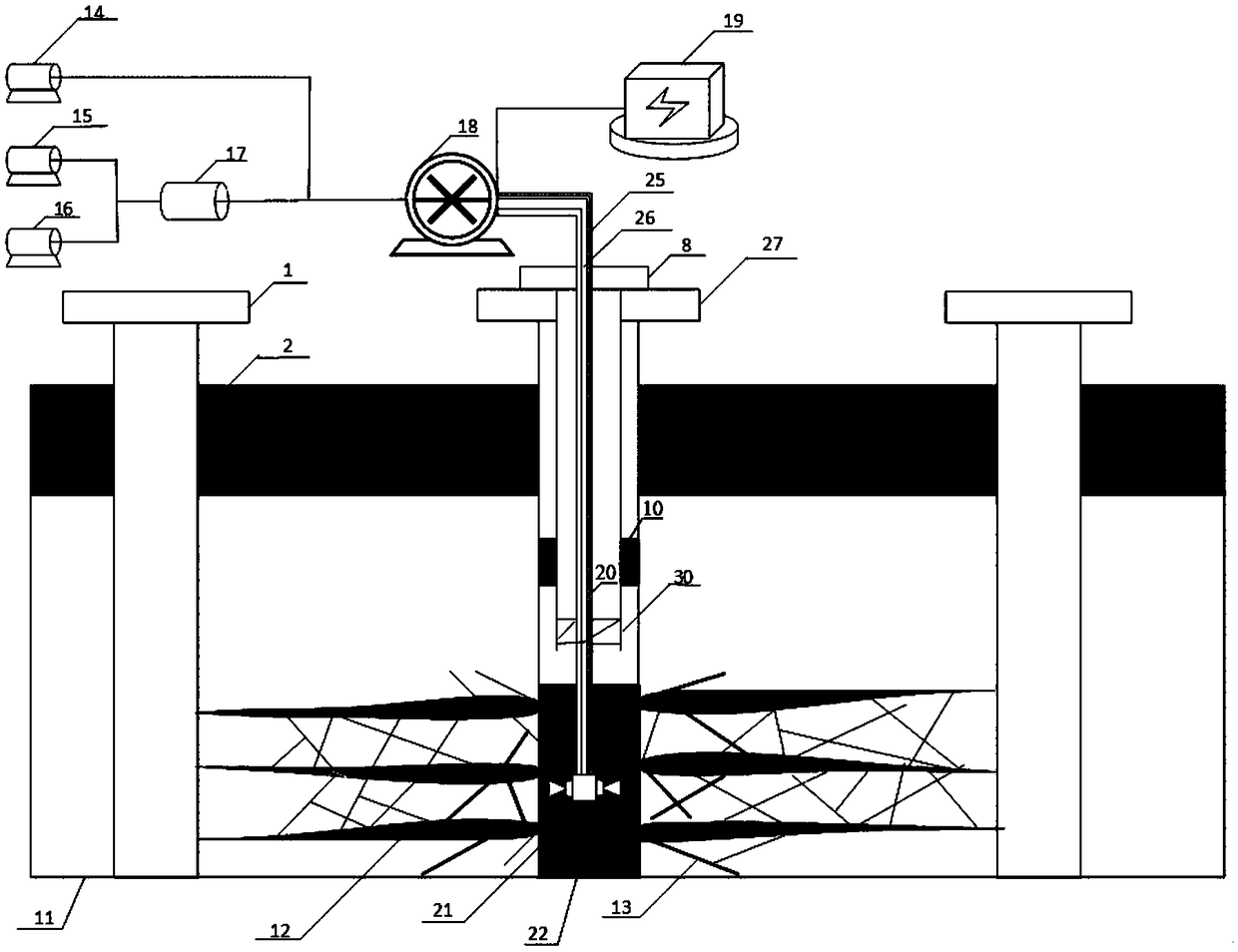

[0055] in such as figure 1 and figure 2 For the hot dry rock reservoir in the geothermal anomaly area shown, using the method provided by the present invention to assist hydraulic fracturing with alternate injection of high and low temperature fluids in deep hot dry rock, it is expected to establish a fracture network at a depth of 3000m to form a good high-efficiency heat exchange reservoir layers, the layout of injection wells and production wells is as follows figure 1 and figure 2 As shown, the distance from the injection well to the production well does not exceed 1500 meters.

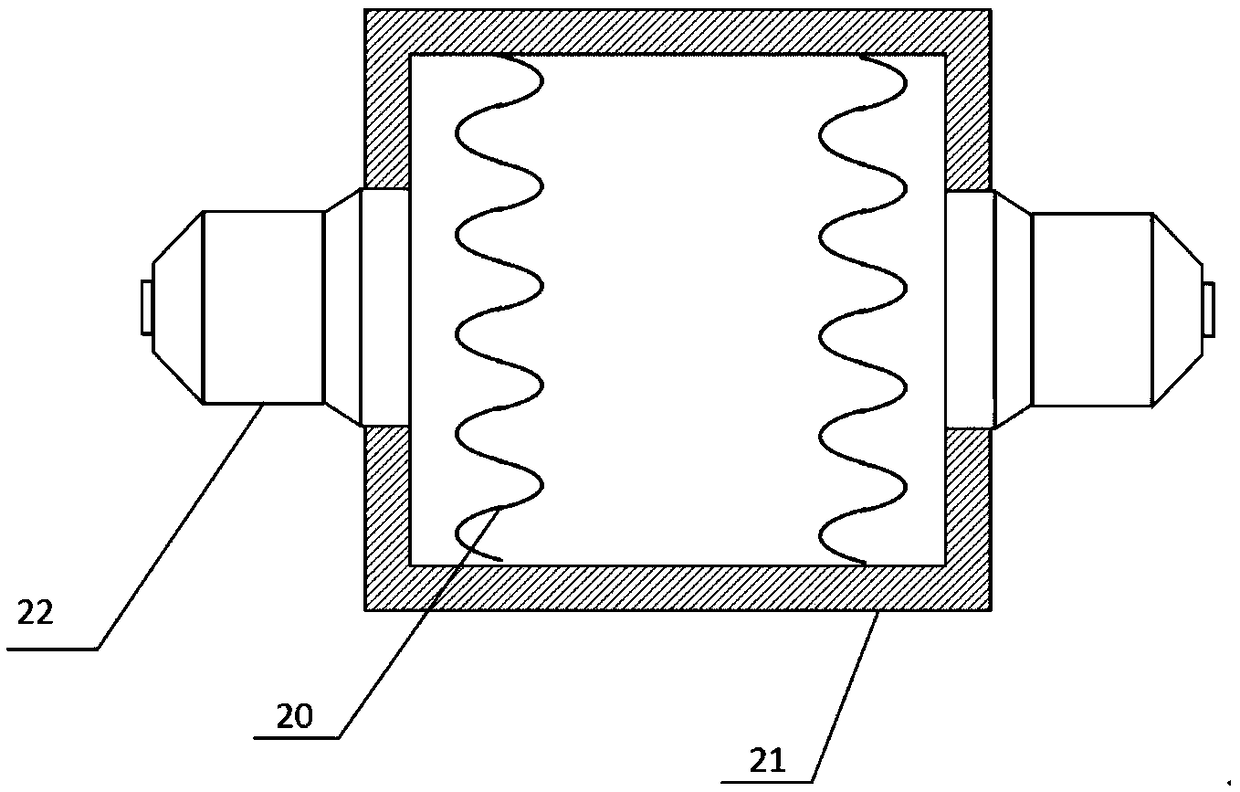

[0056] Such as figure 1 As shown, hydraulic fracturing is performed on the hot dry rock reservoir below the upper formation 2 with normal geothermal gradient. The layout of the hydraulic fracturing process device is as follows: production wells 1 and 9 are arranged and distributed on both sides of injection well 27, and the well spacing is 500 -1000 meters is appropriate; the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com