Laminar Ti/B4C composite material and preparation method thereof

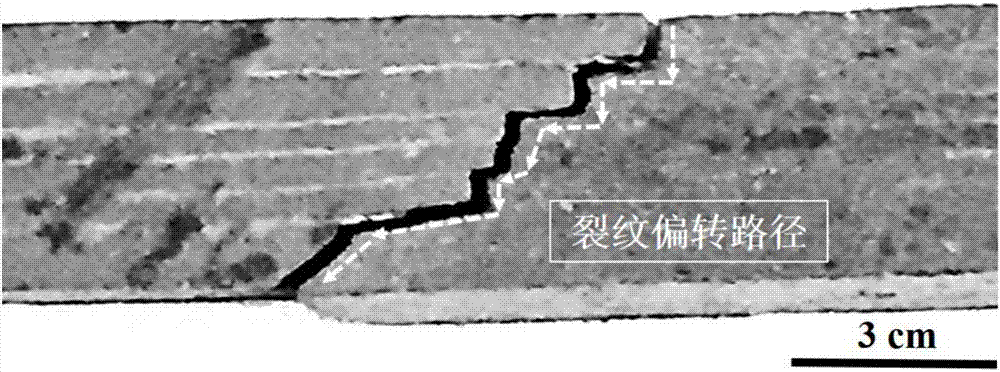

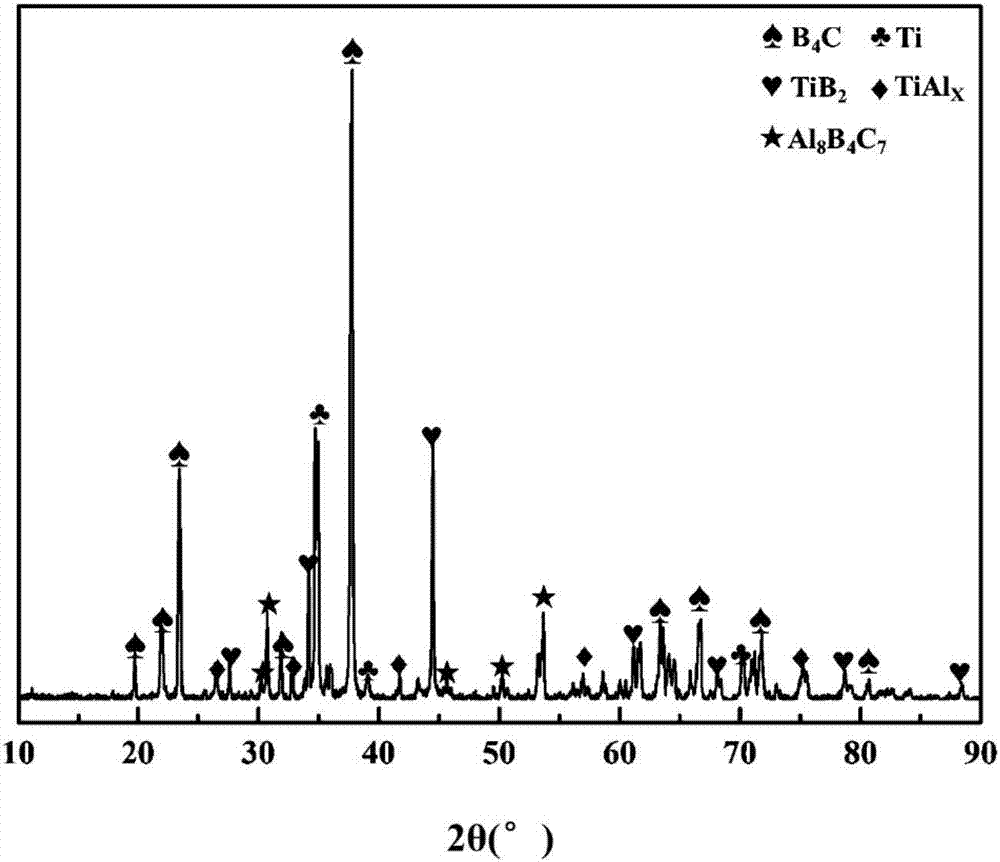

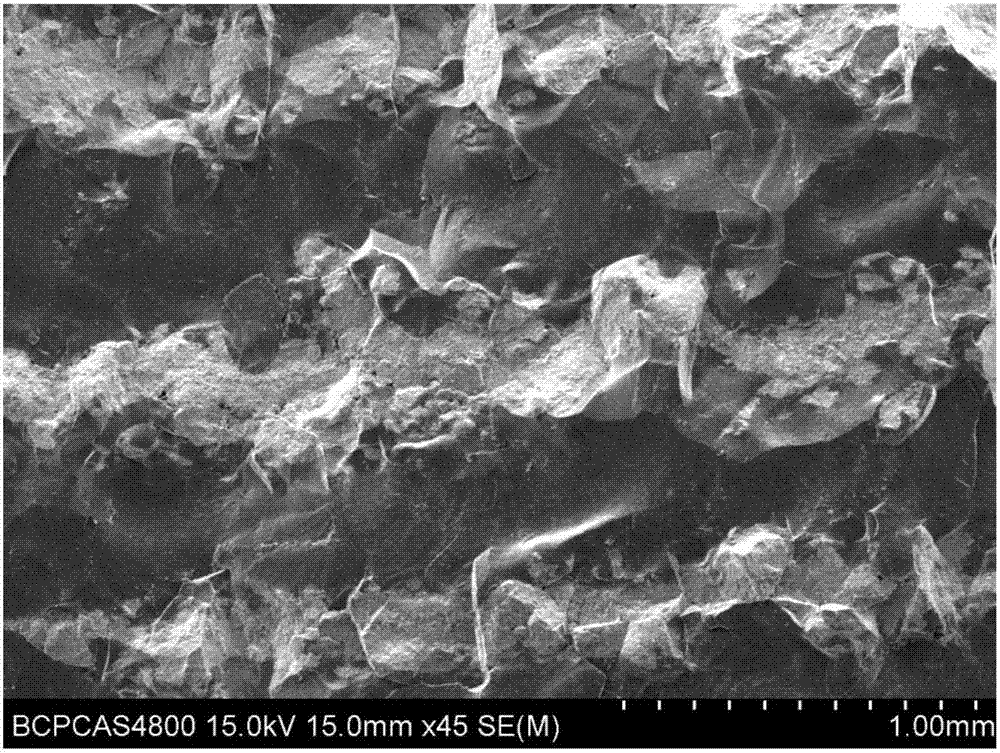

A composite material and layered technology, applied in the field of layered Ti/B4C composite material and its preparation, can solve problems such as crack deflection and influence on Ti, and achieve the effect of relatively high porosity, easy operation and good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Add 50g of titanium powder, 3g of aluminum powder, 400mL of absolute ethanol and 0.5g of polyethylene glycol (molecular weight 4000) into the ball mill jar, and then add ZrO at a ball-to-material ratio of 10:1 2 Balls, and then ball milled at a speed of 150r / min for 12 hours, and then the uniformly mixed slurry after ball milling was dried in a vacuum oven at 80°C for 8 hours to obtain Al / Ti mixed powder;

[0039](2) Using polyvinyl alcohol as the binder, under the pressure of 30MPa, Al / Ti mixed powder, B 4 The C powder was dry-pressed, and after holding the pressure for 10 minutes, a Ti flake with a thickness of 0.2 mm and Al doped and a B sheet with a thickness of 0.4 mm were obtained. 4 C flakes, Ti flakes and B 4 C flakes are stacked alternately in sequence to obtain layered Ti / B 4 C composite material green body;

[0040] (3) layered Ti / B 4 The green body of C composite material is placed in a vacuum hot-pressing sintering furnace, and the vacuum degree rea...

Embodiment 2

[0043] (1) Add 50g of titanium powder, 2g of aluminum powder, 400mL of absolute ethanol and 0.5g of polyethylene glycol (molecular weight 4000) into the ball mill jar, and then add ZrO at a ball-to-material ratio of 10:1 2 Balls, and then ball milled at a speed of 150r / min for 12 hours, and then the uniformly mixed slurry after ball milling was dried in a vacuum oven at 80°C for 8 hours to obtain Al / Ti mixed powder;

[0044] (2) Using polyvinyl alcohol as a binder, under a pressure of 10MPa, Al / Ti mixed powder, B 4 The C powder was dry-pressed, and after holding the pressure for 5 minutes, a Ti flake with a thickness of 0.4 mm and Al doped and a B sheet with a thickness of 0.8 mm were obtained. 4 C flakes, Ti flakes and B 4 C flakes are stacked alternately in sequence to obtain layered Ti / B 4 C composite material green body;

[0045] (3) layered Ti / B 4 The green body of C composite material is placed in a vacuum hot-pressing sintering furnace, and the vacuum degree reaches...

Embodiment 3

[0048] (1) Add 50g of titanium powder, 3g of aluminum powder, 400mL of absolute ethanol and 0.5g of polyethylene glycol (molecular weight 4000) into the ball mill jar, and then add ZrO at a ball-to-material ratio of 10:1 2 Balls, and then ball milled at a speed of 150r / min for 12 hours, and then the uniformly mixed slurry after ball milling was dried in a vacuum oven at 80°C for 8 hours to obtain Al / Ti mixed powder;

[0049] (2) Using polyvinyl alcohol as the binder, under the pressure of 20MPa, Al / Ti mixed powder, B 4 The C powder was dry-pressed, and after holding the pressure for 8 minutes, a Ti flake with a thickness of 0.4 mm and doped with Al and a B sheet with a thickness of 0.8 mm were obtained. 4 C flakes, Ti flakes and B 4 C flakes are stacked alternately in sequence to obtain layered Ti / B 4 C composite material green body;

[0050] (3) layered Ti / B 4 The green body of C composite material is placed in a vacuum hot-pressing sintering furnace, and the vacuum degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com