Adjusting mechanism for brake handle

A brake handle and adjustment mechanism technology, which is applied in the mechanical field, can solve the problems of small adjustment distance of the handle, jamming, etc., and achieve the effects of stable rotation, reduced damage, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

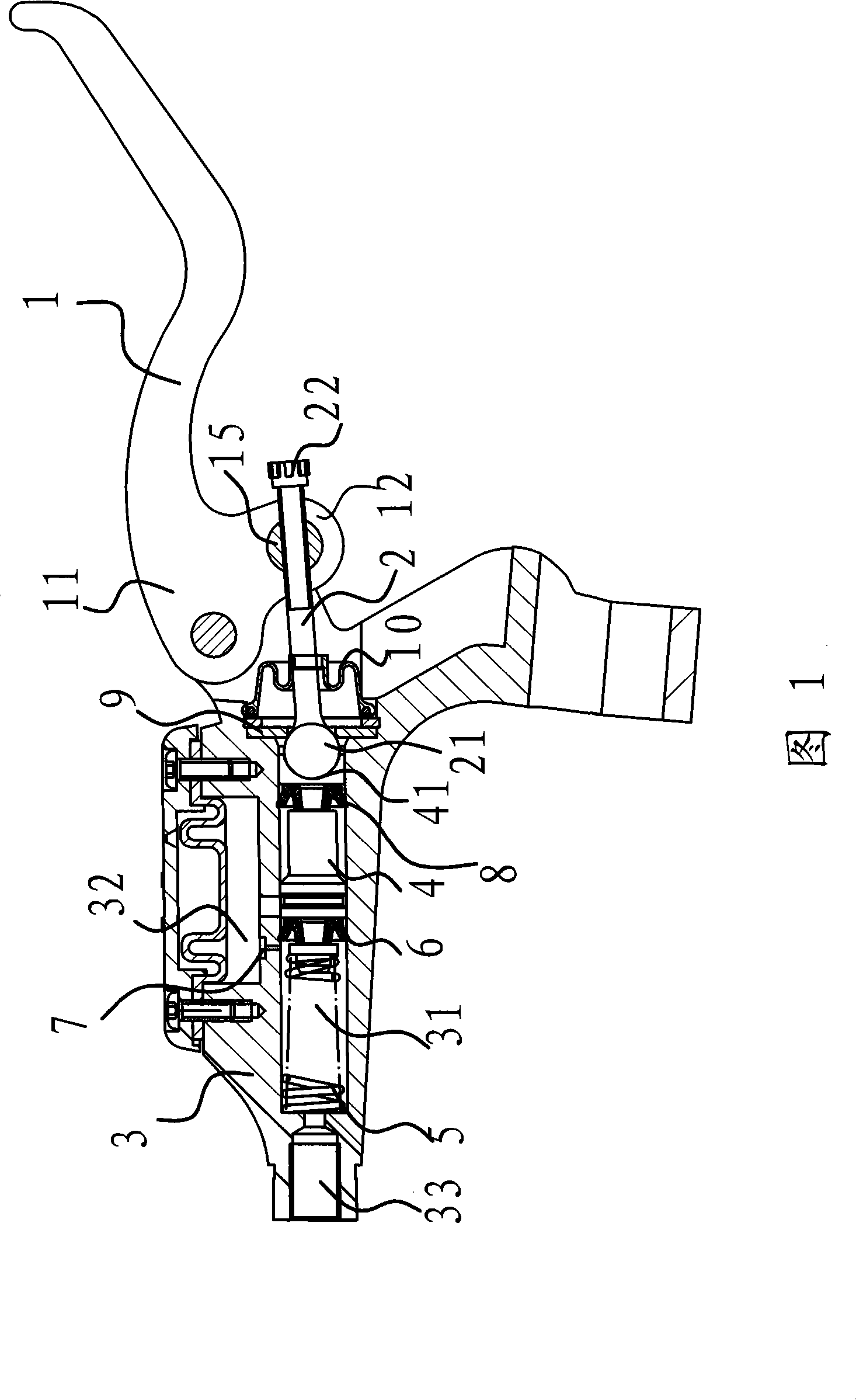

Image

Examples

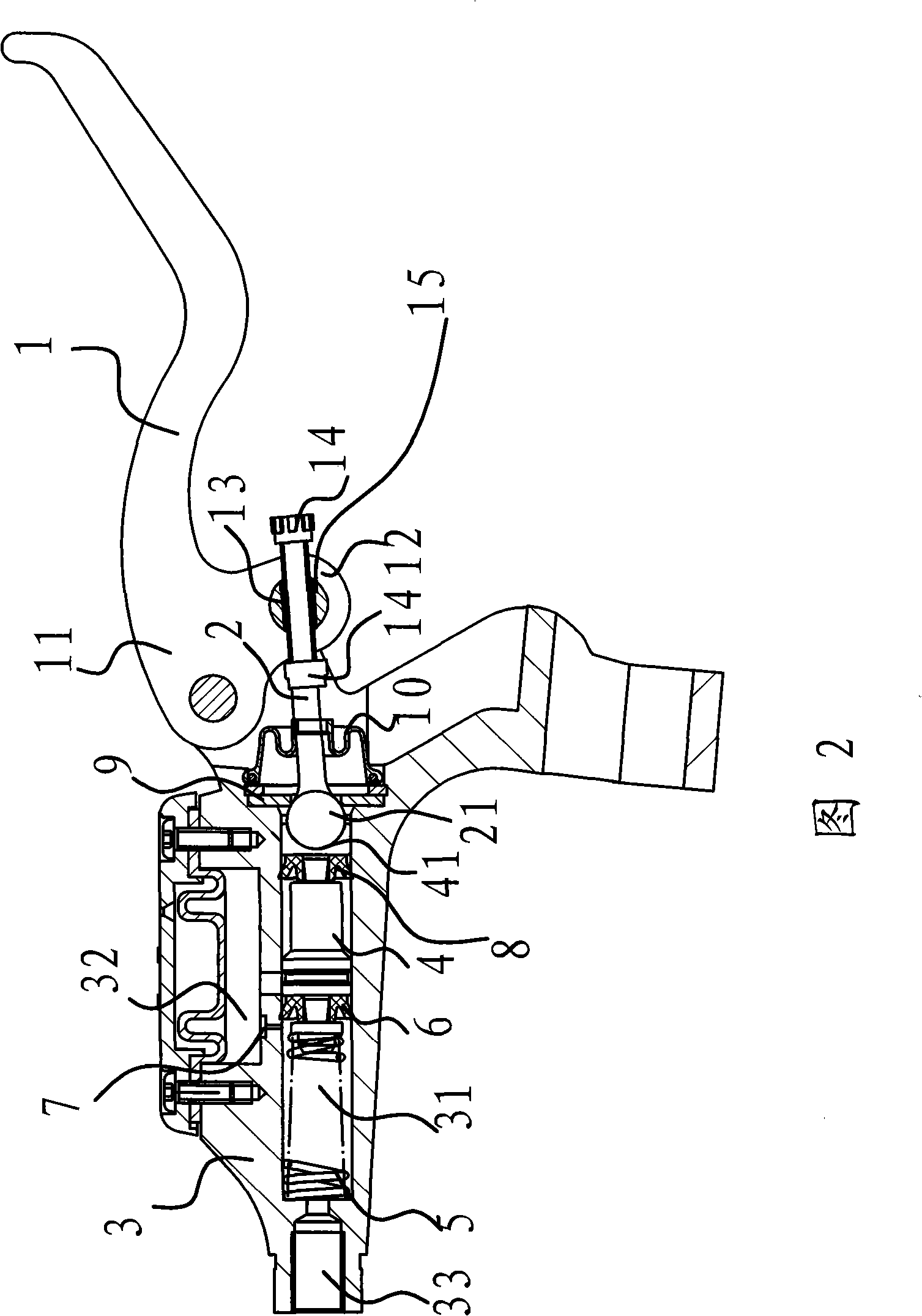

Embodiment 2

[0033] As shown in Figure 2, the content of embodiment 2 is basically the same as that of embodiment 1, the difference is that the positioning structure includes a guide hole 13 on the connecting part 12, the outer end of the connecting rod 2 passes through the guide hole 13, And can axially slide in guide hole 13, be provided with two adjustment nuts 14 on the outer end of connecting rod 2, these two adjustment nuts 14 are respectively positioned at the both sides of guide hole 13, and two adjustment nuts 14 and connecting rod 2 are connected by threads. After the outer end of the connecting rod 2 passes through the guide hole 13, its adjusting nut 14 is located on both sides of the connecting portion 12 of the brake handle 1, and the position of the brake handle 1 can be adjusted by turning the adjusting nut 14 respectively. Since the connecting rod 2 slides through the handle, when the brake handle 1 rotates, the outer end of the connecting rod 2 also slides outwards accord...

Embodiment 3

[0035] The content of embodiment 3 is basically the same as that of embodiment 1, except that the positioning structure includes an adjusting nut 13 and a worm wheel arranged on the brake handle 1, and the worm wheel is fixed on the brake handle 1 in a circumferentially rotatable manner. The above-mentioned connecting rod 2 passes through the adjusting nut 14 and can slide axially in the adjusting nut 14. The connecting rod 2 in the adjusting nut 14 is in the shape of a worm and meshes with the worm wheel. There is a spring that makes the brake handle 1 lean against the positioning structure.

[0036] When the worm wheel is turned, the connecting rod 2 moves axially in the guide hole 13 under the action of the worm wheel. When the worm wheel rotates in the forward direction, the worm wheel drives the brake handle 1 to rotate in a direction close to the pump body 3 , and vice versa, the worm wheel drives the brake handle 1 to rotate in a direction away from the pump body 3 . B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com