Safety handrail

A handrail and safety technology, applied in handrails, public buildings, building structures, etc., can solve problems such as loose handrails, many specifications, and reduce costs, and achieve the effects of preventing relative rotation, ensuring stability, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

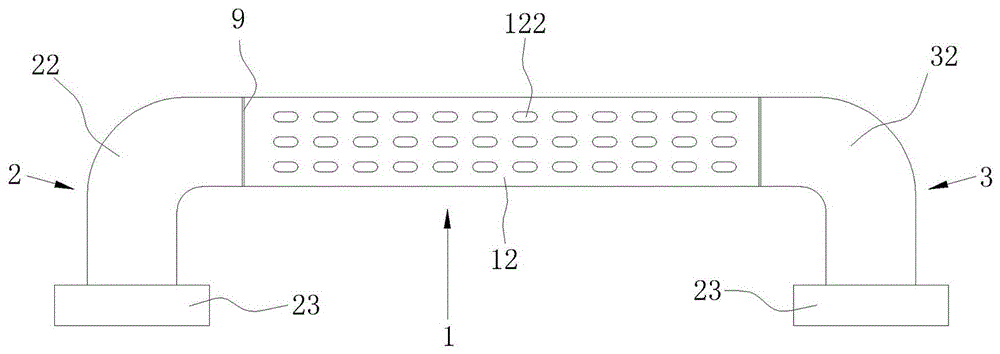

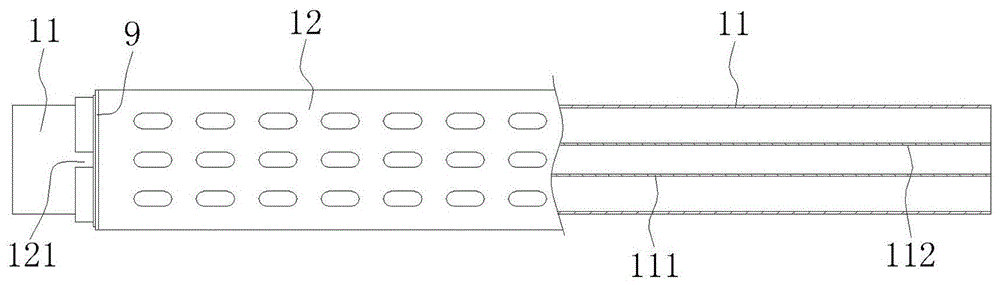

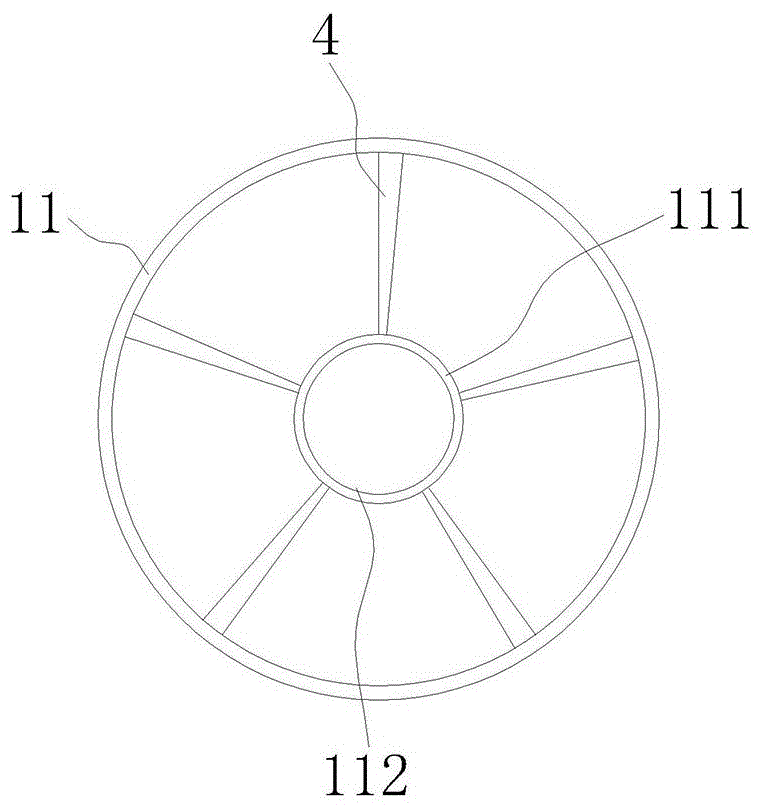

[0036] like figure 1As shown, a safety handrail includes a handrail tube 1, and the left and right ends of the handrail tube 1 are respectively fixed by a left mounting seat 2 and a right mounting seat 3. like figure 2 , image 3 As shown, the handrail tube 1 includes an inner tube 11 and a non-slip protective shell 12 covering the outer circumference of the inner tube 11. In order to achieve the purpose of anti-slip, the outer surface of the protective shell 12 can be provided with anti-skid patterns 122; There is a first connecting column 111 , a reinforcing rib 4 is connected between the outer circumference of the first connecting column 111 and the inner surface of the inner tube 11 , and the inner circumference of the first connecting column 111 has a first internal thread 112 .

[0037] Figure 4 The structure of the left mounting seat 2 is shown. The left mounting seat 2 includes a left fixing plate 21 and a left connecting pipe 22 engaged with the left end of the h...

Embodiment 2

[0043] Compared with the first embodiment, this embodiment mainly defines the matching and engaging structures of the left fixing plate 21 and the right fixing plate 31 and the protective cover 23 respectively. The matching structure of the left fixing plate 21 and the protective cover 23 is as follows: Figure 4 Shown: the left outer edge is provided with three concave notches 211, one side of the concave notches 211 is provided with a circumferentially extending extension 212, and a mounting opening 213 is left between the extension 212 and the other side , the upper end of the extension portion 212 is flush with the upper end of the recessed notch 211, and the thickness of the extension portion 212 is smaller than the thickness of the recessed notch 211. The inner side of the lower end of the protective cover 23 is provided with a protruding buckle 231 that matches the installation opening 213. The protruding buckle The size of the 231 can be entered from the installation op...

Embodiment 3

[0048] Compared with Embodiment 1, this embodiment is different in that the installation structures of the left threaded rod 222 and the right threaded rod 322 are defined. Generally speaking, taking the left threaded rod 222 as an example, such as Image 6 As shown in the figure, a relatively simple installation method between the left connecting pipe 22 and the inner pipe 11 is to set an internal thread in the fixing column 221. When installing, first screw one end of the left threaded rod 222 into the fixing column 221, and then screw the other end into the first A threaded connection is performed in the connecting column 111. The disadvantage of this installation method is that the connection of the left end of the inner pipe 11 needs to go through two threading processes, and the installation is not fast enough. , it will easily lead to the loss of parts due to the instability of the threaded connection, so it can be considered to fix the left threaded rod 222 in the fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com